Design method for blade of claw rotor

A design method and rotor technology, applied in mechanical equipment, rotary piston pumps, rotary piston machines, etc., can solve problems such as unsmooth operation, reduced service life, noise and vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

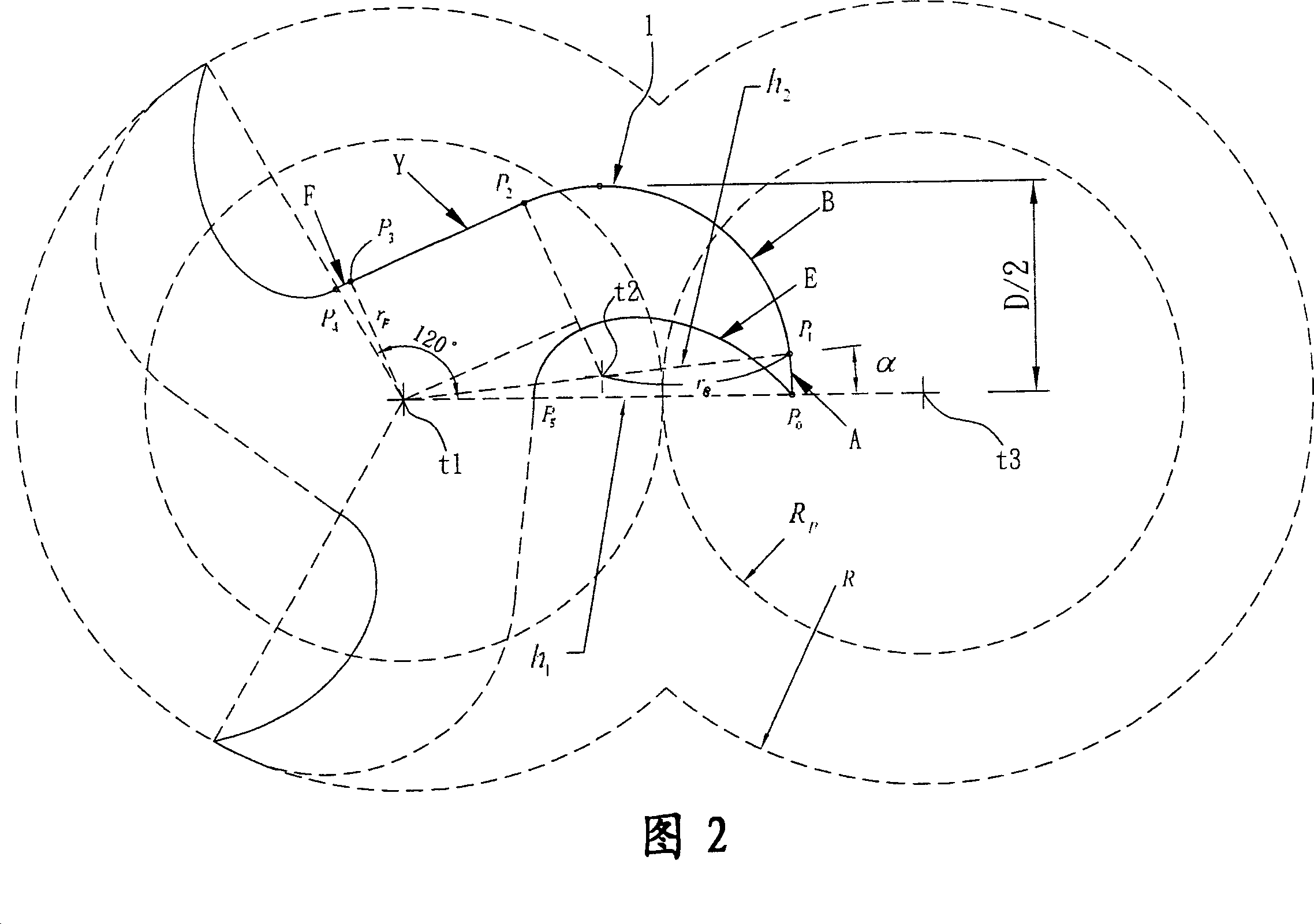

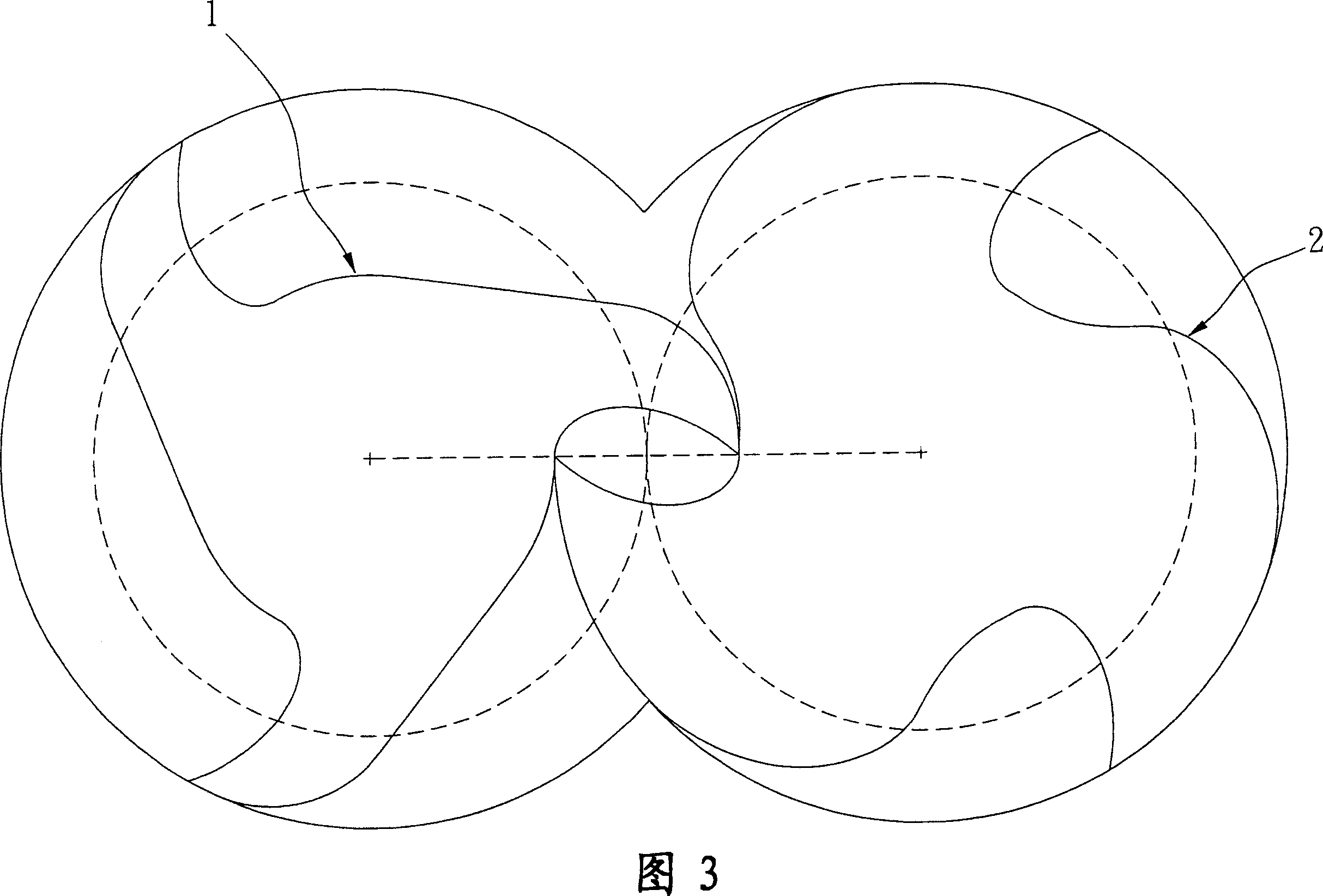

[0031] Please refer to Fig. 1 to Fig. 3, the method for obtaining the three-blade definition rotor 1 and the conjugate rotor 2 of the present invention, as shown in the figure, the three-blade shape acquisition of the definition rotor 1 includes the following steps:

[0032] 1. Specify the maximum radius of the defined rotor R = 60mm, define the rotor width D = 65mm, define the pitch circle radius Rp of the rotor and the conjugate rotor Rp = 40mm, the centers of the two pitch circles are t1 and t3 respectively, Rp is less than R, and define The ratio of the maximum rotor radius R to the pitch circle radius Rp is R=3Rp / 2.

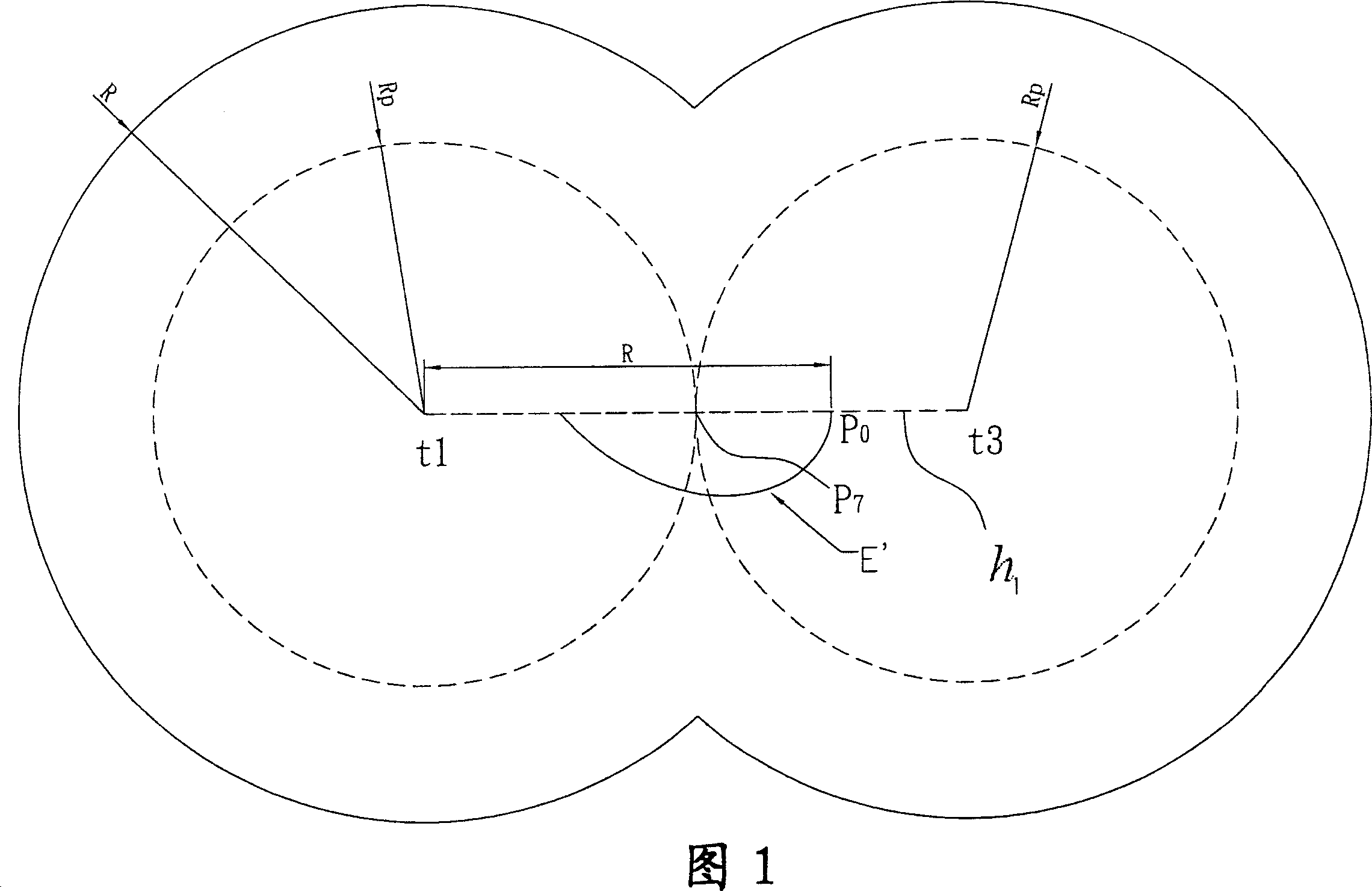

[0033] 2. Please refer to Figure 1, take the center t1 of a pitch circle as the center of the defined rotor, pass through a horizontal line h1, and obtain a first point P on the horizontal line h1 0 , this point P 0 The horizontal distance from the center of the circle t1 is R, from this point P 0 Generate a conjugate curve E' around the pitch circle cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com