Device for lifting piston compressor air inlet valve based on time control

A time control, compressor technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of high maintenance cost and huge investment, achieve low cost, low stepless adjustment, high reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

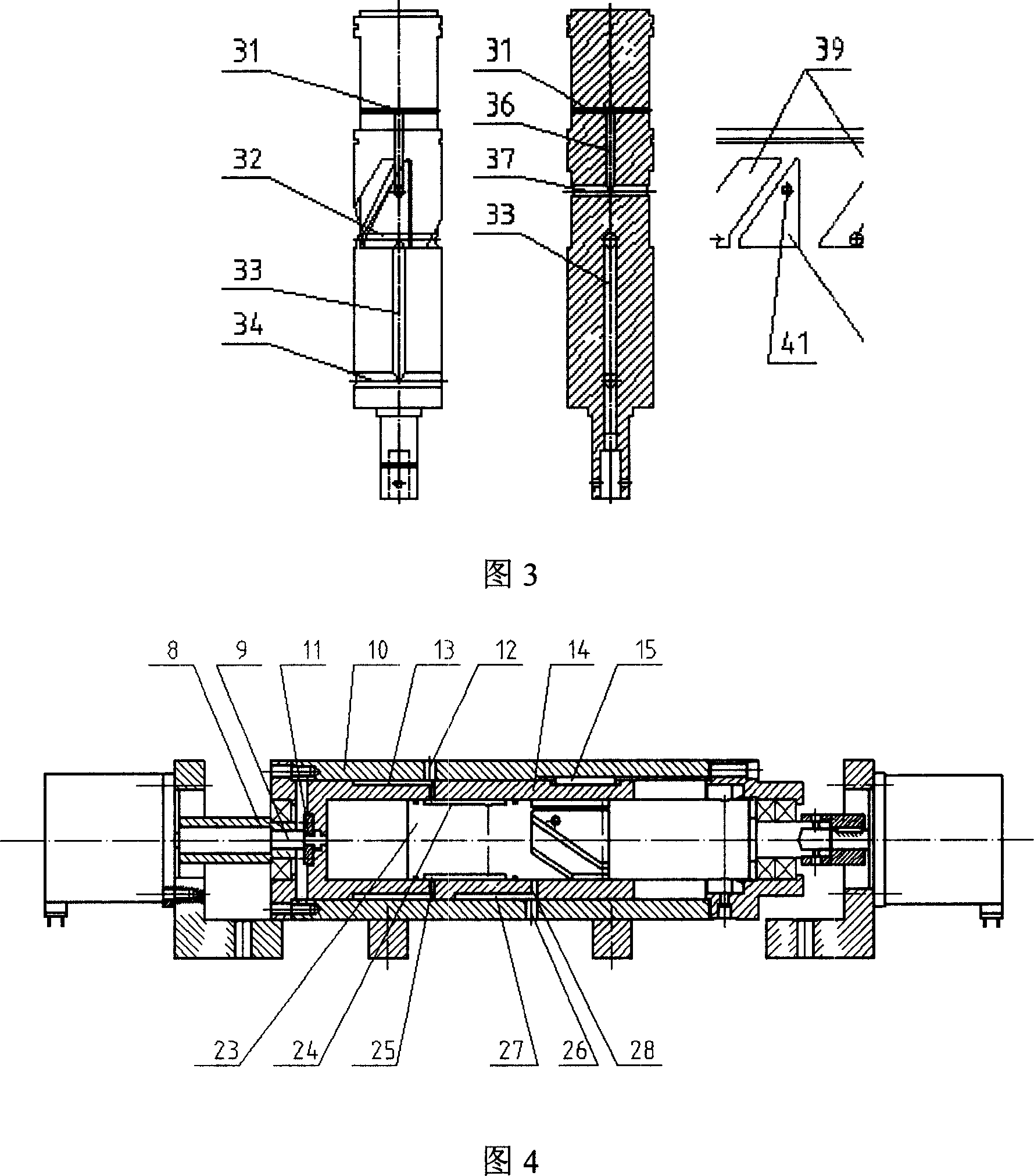

[0020] As shown in Figure 2, the present invention comprises the outer sleeve 10 that is contained on the bearing 22, inner sleeve 14, middle rotating shaft 23 and two stepper motors; The sleeve 10 forms a sliding fit; the middle part of the intermediate rotating shaft 23 has a pressure relief area 39 and an oil pressure action area 42; a guide key 15 is installed between the inner sleeve 14 and the outer sleeve 10; the stepper motor 19 passes through the connecting sleeve 18. It is connected with the intermediate rotating shaft 23 at the opening end of the inner sleeve. The stepping motor is installed on the support 35. The right end of the intermediate shaft 23 is supported by the bearing 17 and the end cover 16. Another stepping motor 7 is connected to the inner sleeve through the screw rod 9. The other end of the sleeve is connected, the stepper mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com