Metering method and system for real time discharge volume of piston type concrete pump

A concrete pump and displacement measurement technology, which is applied in pump testing, liquid variable capacity machinery, machine/engine, etc., can solve the problems of time-consuming, frequent measurement and unrealistic, etc., and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

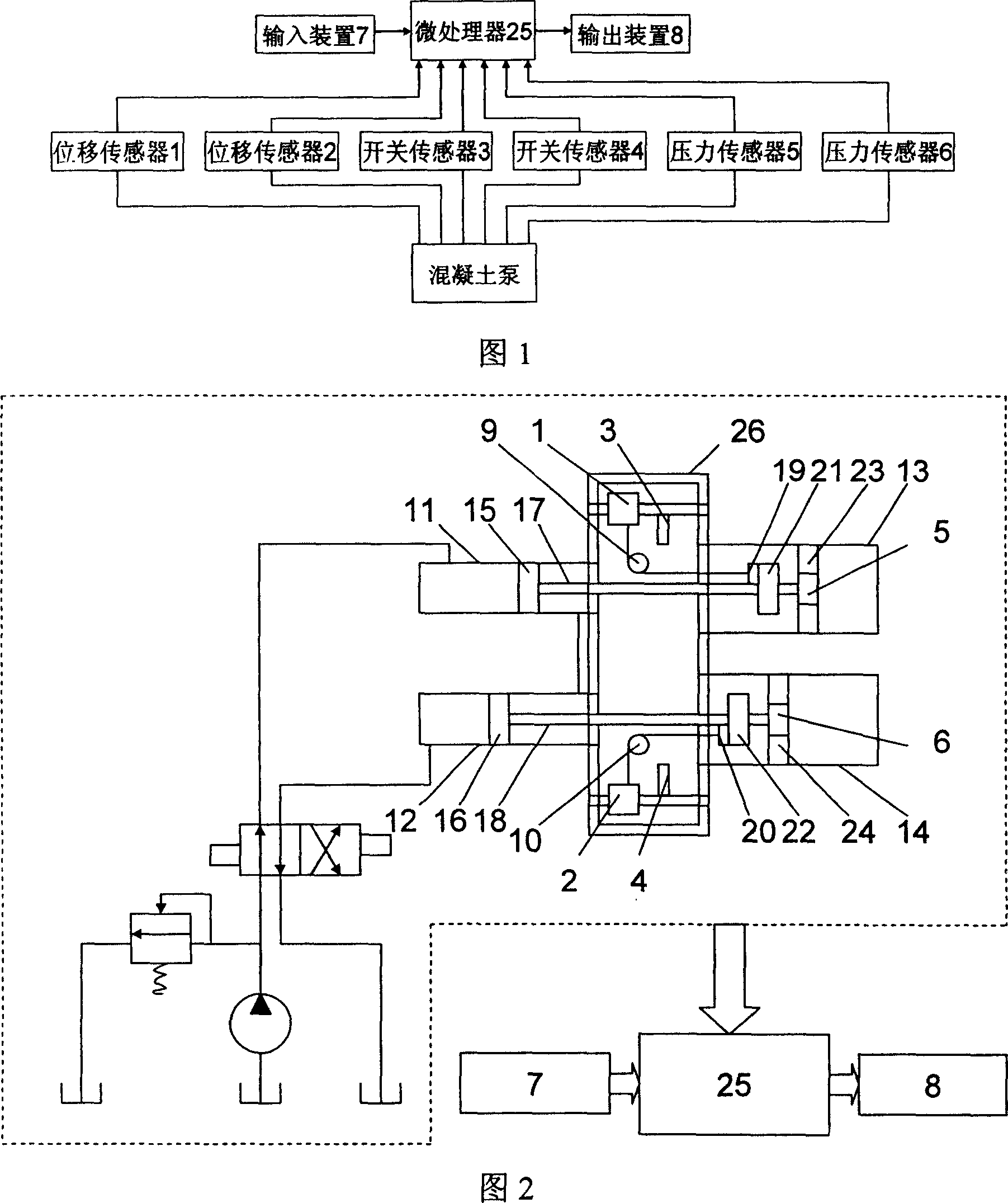

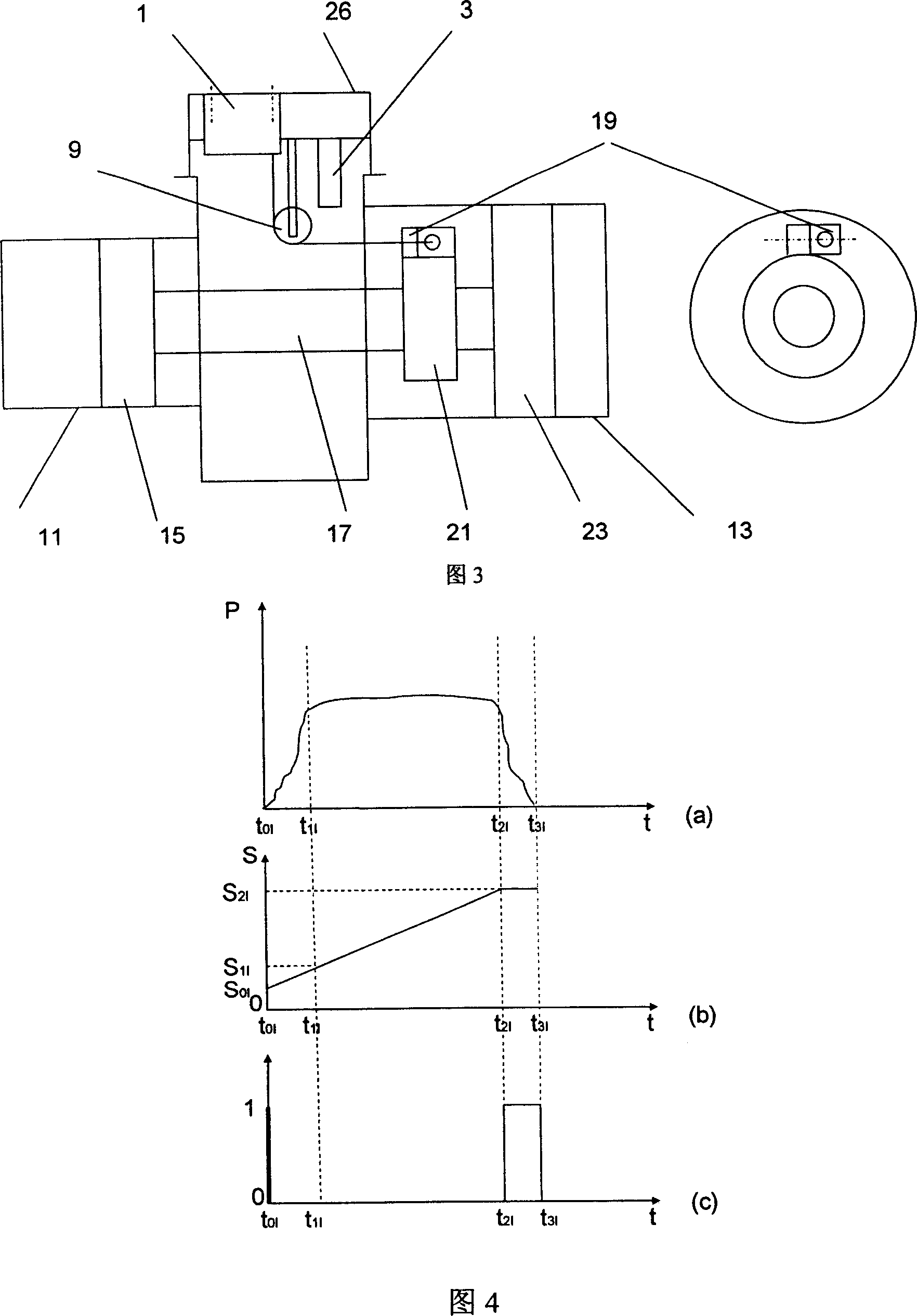

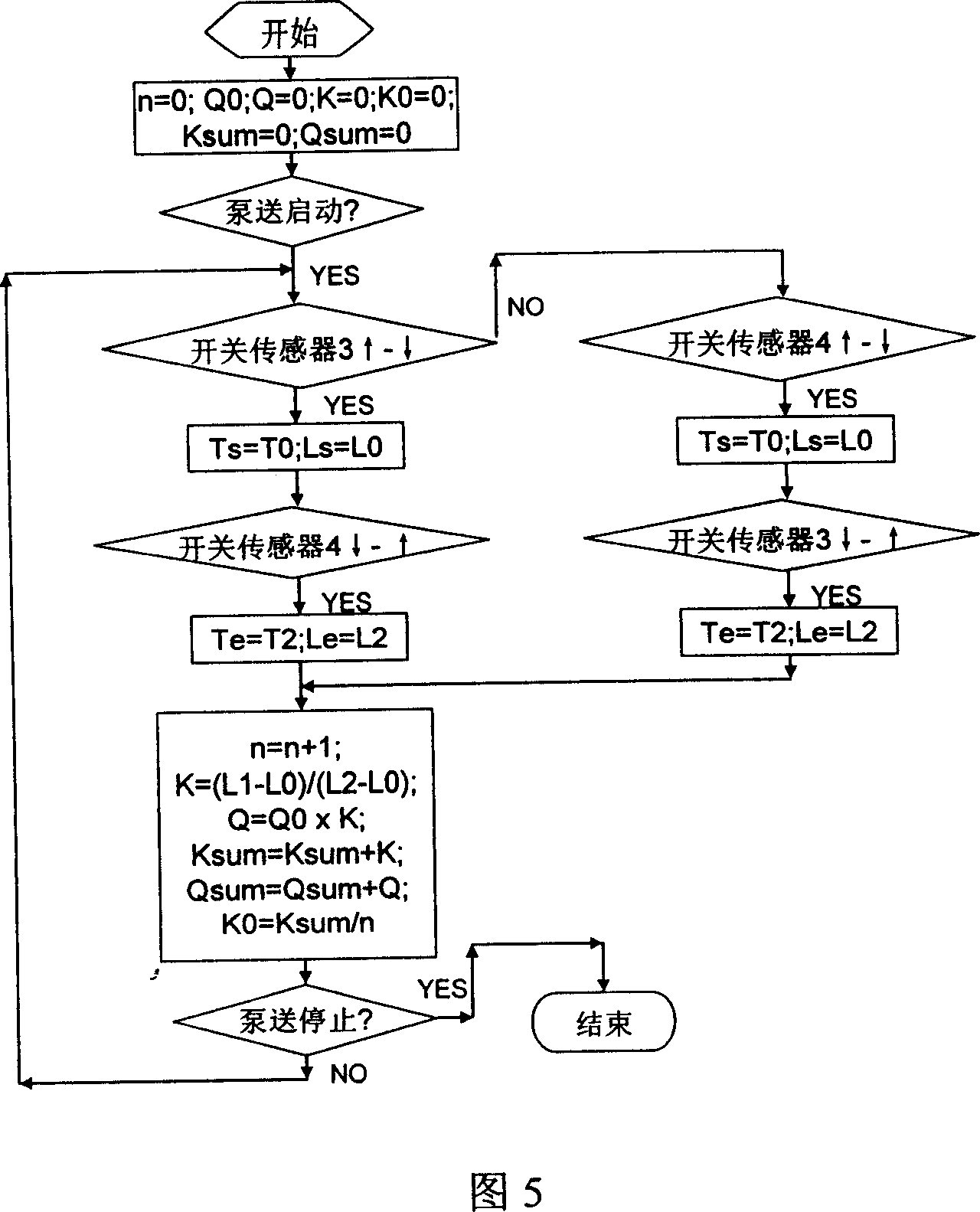

[0029] As shown in Fig. 1 and Fig. 2, the present invention comprises two drawstring type linear displacement sensors 1,2, two switch sensors 3,4, two concrete cylinder pressure sensors 5,6, input device 7, output device 8 and Microprocessor 25; two stay-rope linear displacement sensors 1,2 are mounted on the fixed support 26 of the piston concrete pump water tank, and the stay rope ends of the two displacement sensors 1 and 2 are respectively connected to the respective pulleys 9 and 10 Concrete pump piston rods 17, 18 and concrete cylinder pistons 23, 24 on the connecting flanges 21, 22; two concrete cylinder pressure sensors 5, 6 are respectively installed on the pistons 23, 24 at one end of the rodless cavity of the respective concrete cylinders 13, 14 On; two switch sensors 3,4 for determining the start time and end time of each pumping stroke are installed on the fixed bracket 26; six sensors tap the microprocessor 25, and the microprocessor 25 is also used for The input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com