Twin clutch device

A dual clutch, clutch technology, applied in the direction of clutch, friction clutch, mechanical drive clutch, etc., can solve the problems of increasing the number of parts, the size of the dual clutch, increasing the number of assembly hours, etc., and achieve the effect of reliable disconnection and connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

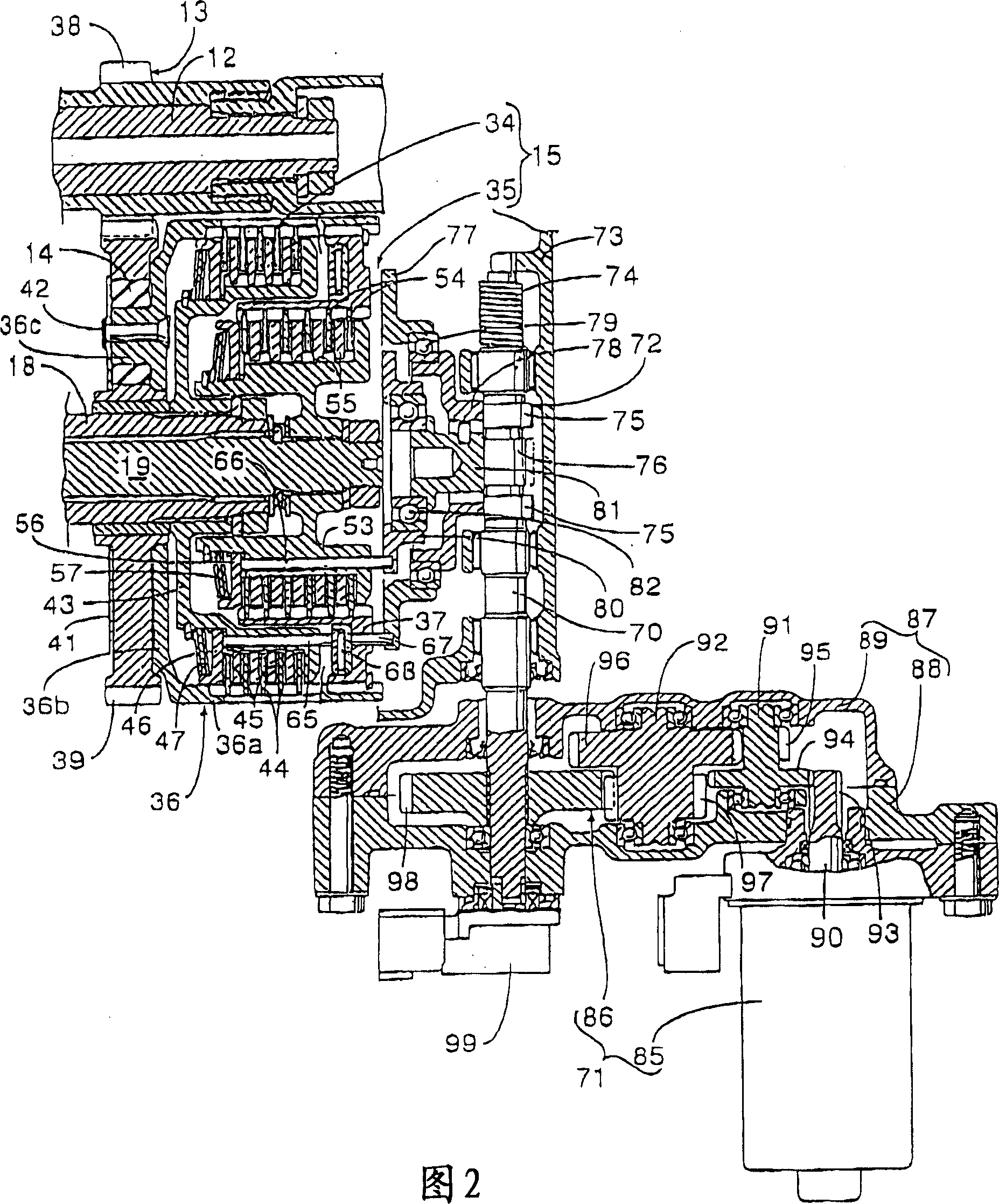

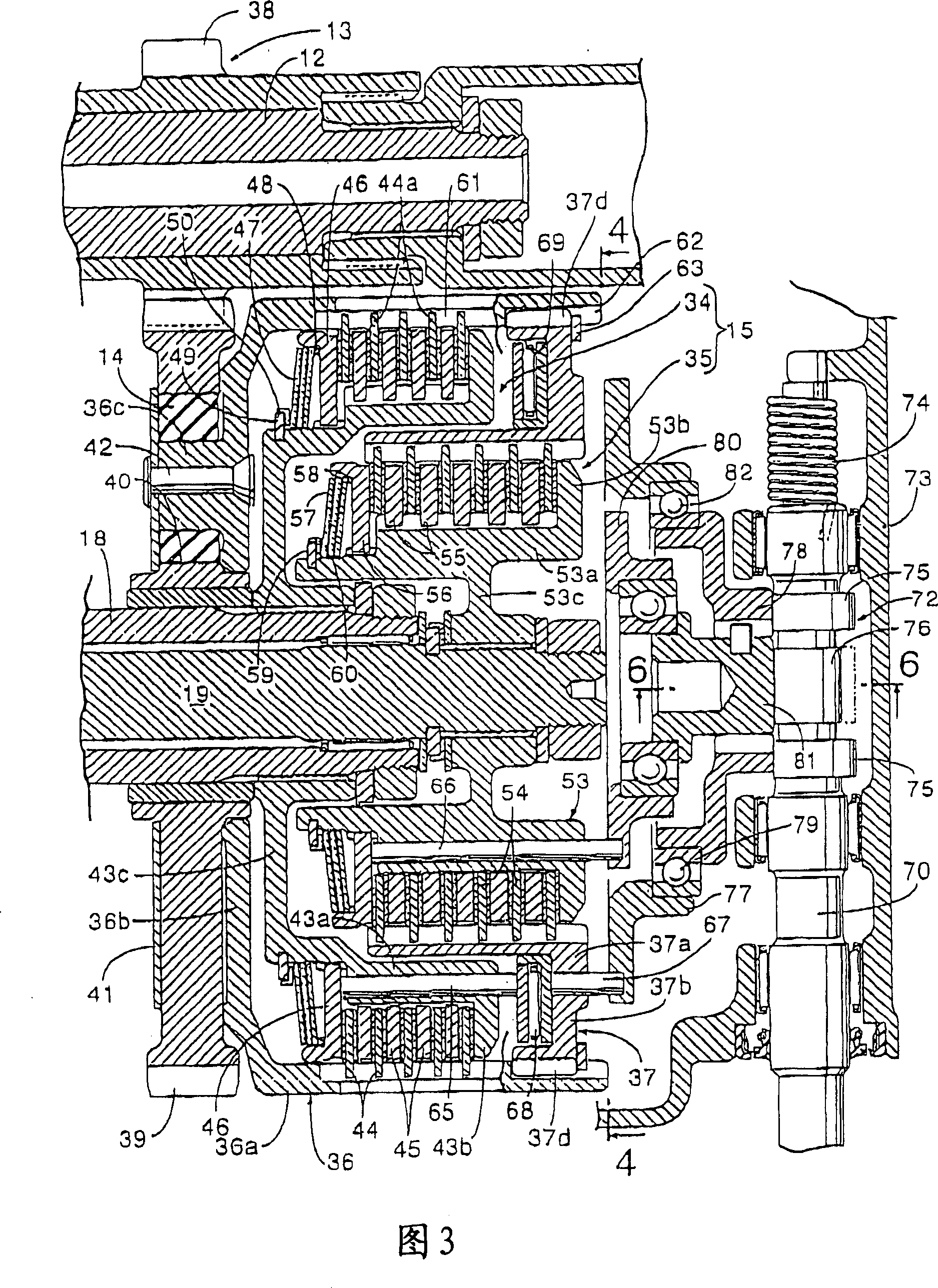

[0044] Hereinafter, an embodiment for realizing the present invention will be described based on an embodiment of the present invention shown in the drawings.

[0045] 1 to 9(b) are views showing an embodiment of the present invention.

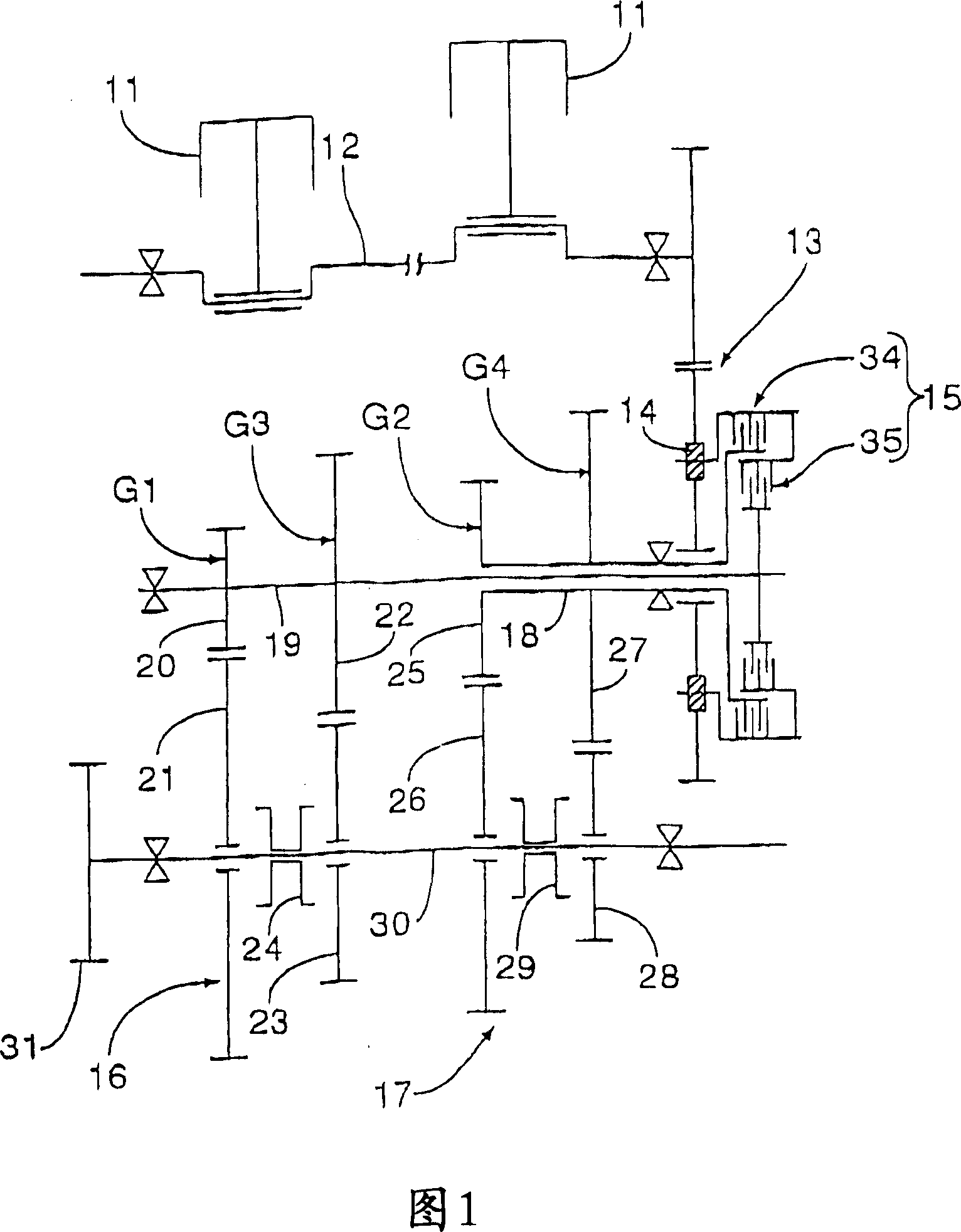

[0046] As shown in FIG. 1, a plurality of pistons 11, 11, . . . are provided, for example, for a multi-cylinder engine mounted on a motorcycle. Each piston is connected to a crankshaft 12 which is rotatably supported on a crankcase not shown in the figures. The rotational power of the crankshaft 12 is input to the dual clutch device 15 through the main gear reduction device 13 and the rubber damper 14 . On the other hand, the crankcase accommodates an odd shift gear train 16, which includes odd shift gear trains, for example, first and third shift gear trains G1, G3 that can be selectively established, and the crankshaft The housing also accommodates an even shift gear train 17 which includes even shift gear trains, for example, second and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com