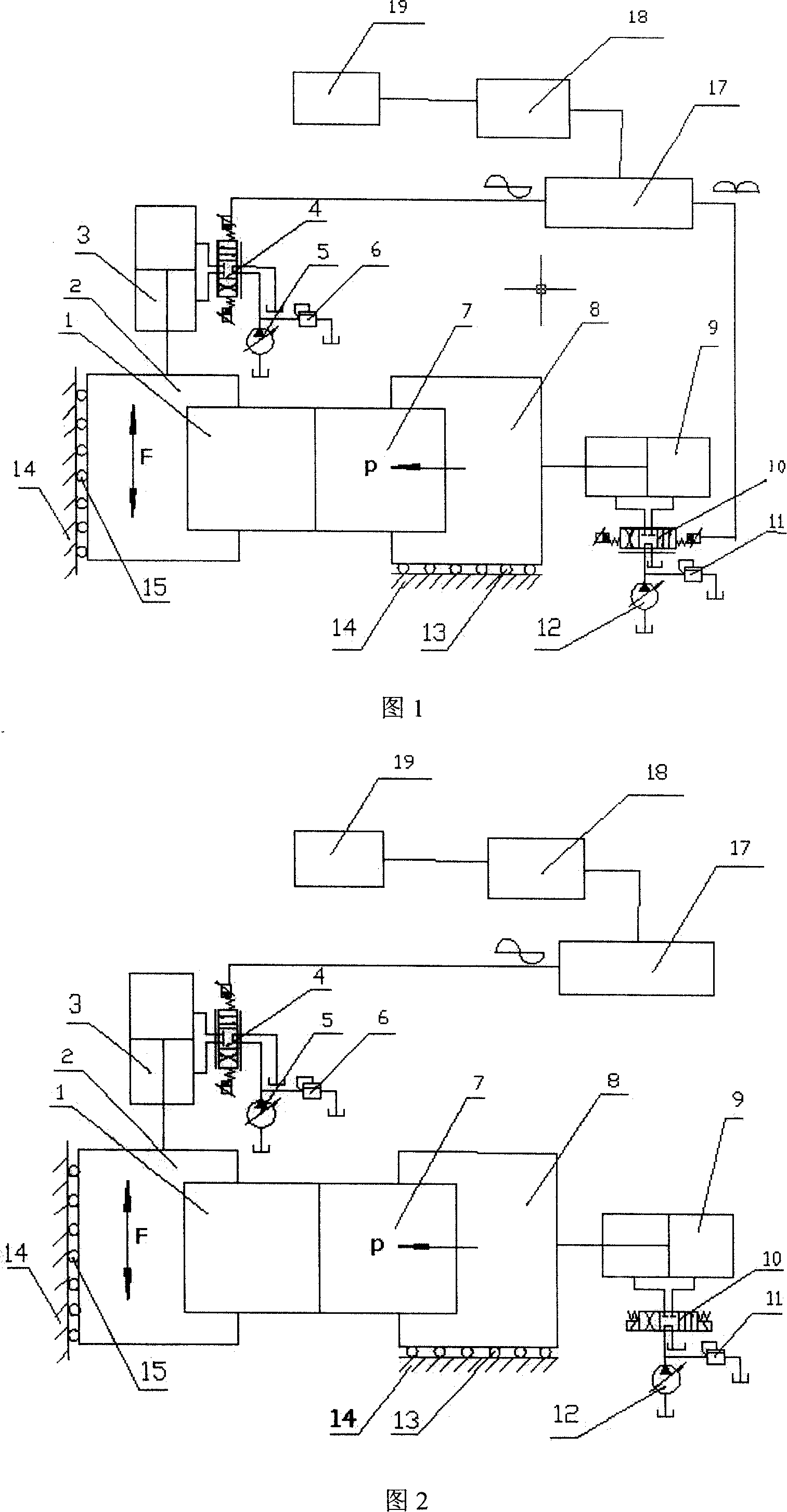

Friction pressure loading unit of linear friction welding machine and loading method thereof

A friction pressure, linear friction technology, applied in fluid pressure actuation devices, mechanical equipment, welding equipment, etc., can solve the problems of large driving force, unfavorable energy saving and consumption reduction, and achieve the effect of reducing driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to reduce the vibration driving force, the present invention proposes a friction force pulsating loading method, so that the friction pressure P changes periodically during the linear friction welding process: when the workpiece 1 at the vibration end moves to the neutral position, the inertial force is the smallest, and the friction The pressure is the largest; when the vibration end workpiece 1 moves to the two limit positions, the inertial force is the largest, and the frictional pressure is the smallest at this time. The frictional pressure P has the same frequency of change as the inertial force, but the phase is different by π / 2. The superposition of the maximum inertia force and the maximum friction force is avoided, thus reducing the maximum driving force required for vibration. Therefore, when the required vibration frequency and amplitude are the same, the power required by the vibration system is reduced; when the system drive system power is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com