A magnetic self-perpetuating relay for the over current protection

A magnetic latching relay and overcurrent protection technology, applied in the direction of electromagnetic relays, relays, detailed information of electromagnetic relays, etc., can solve problems such as relay and power supply circuit burnout, safety accidents, and electronic detection devices not being able to protect, and achieve protection The effect of circuit loops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

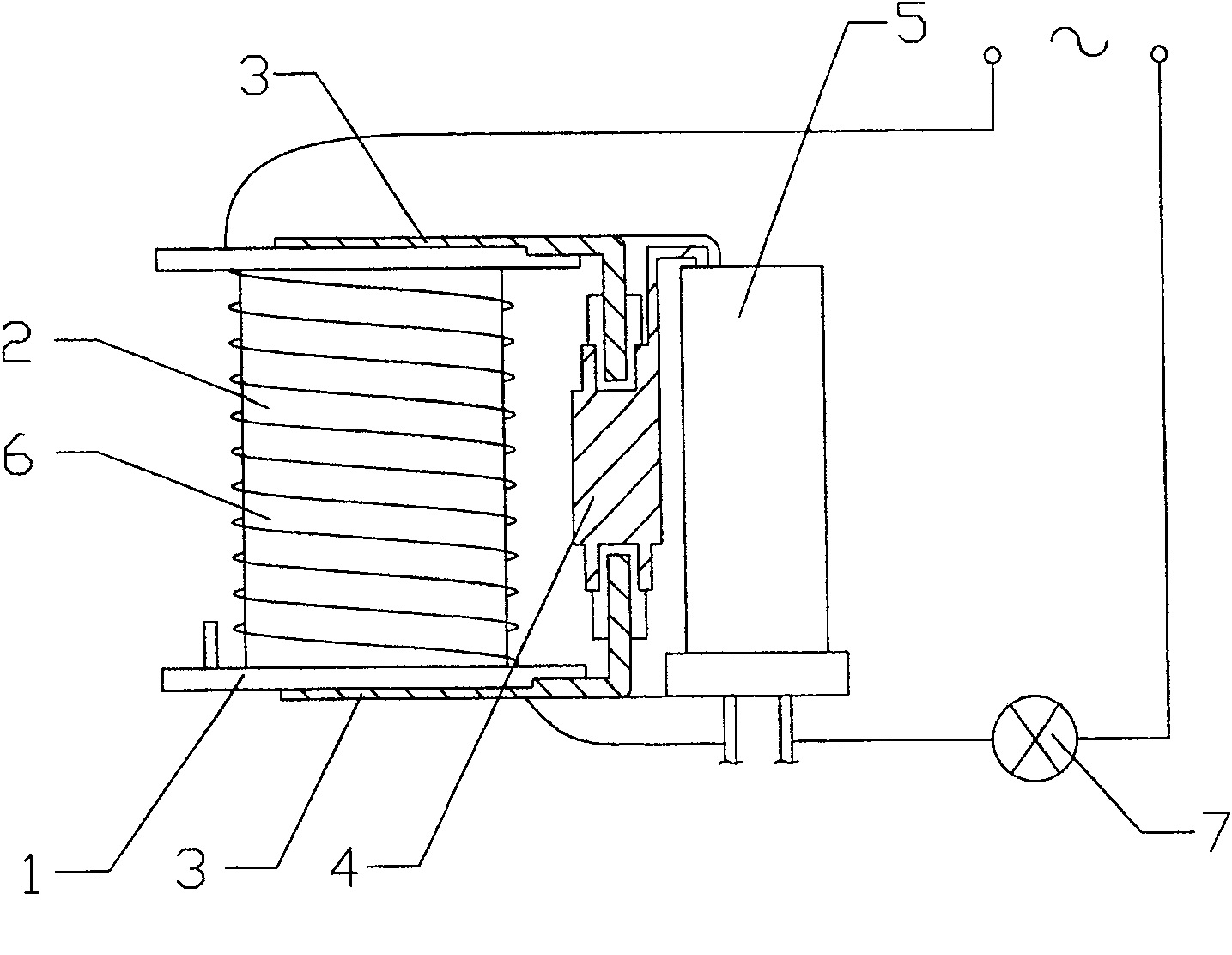

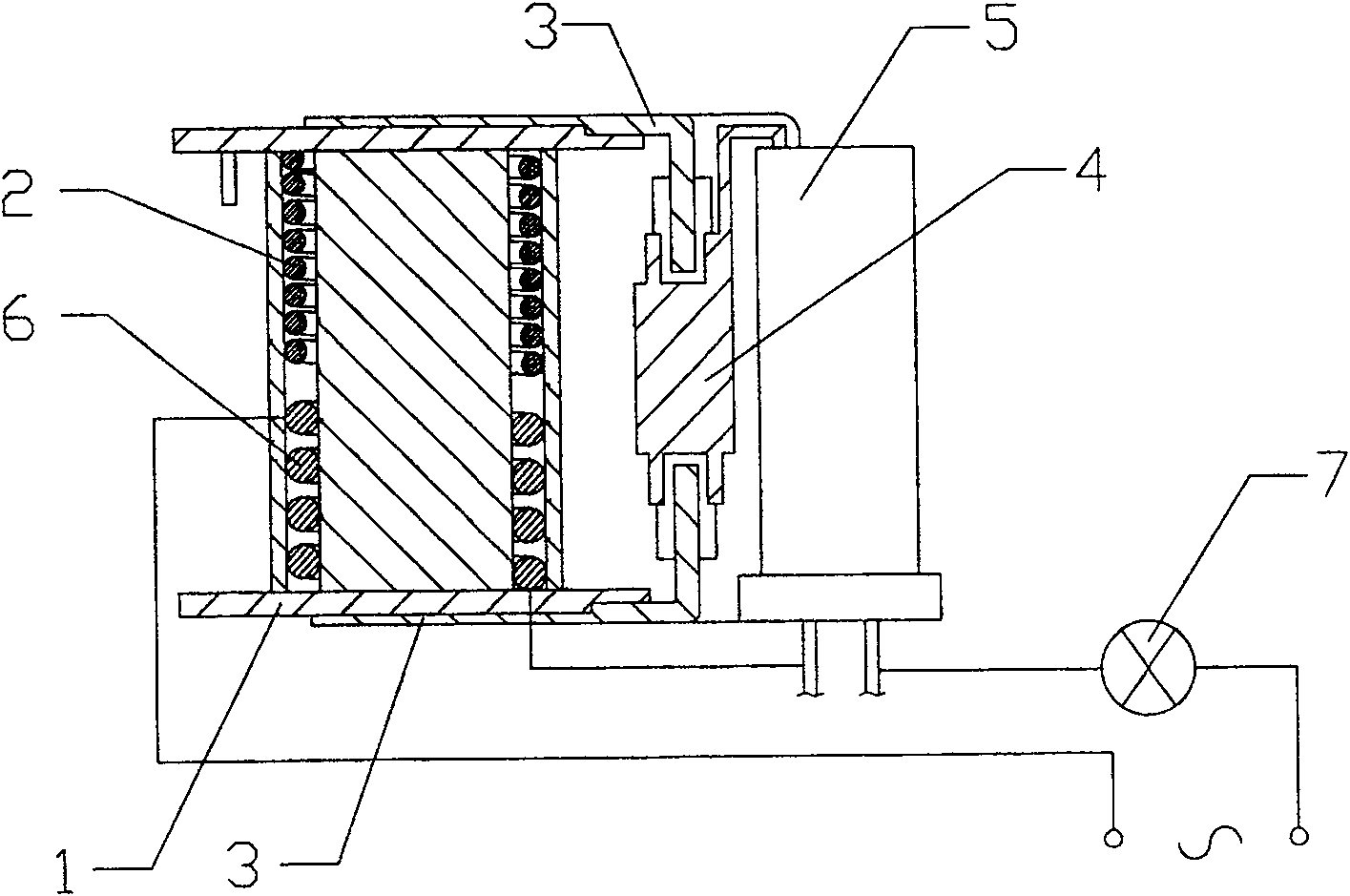

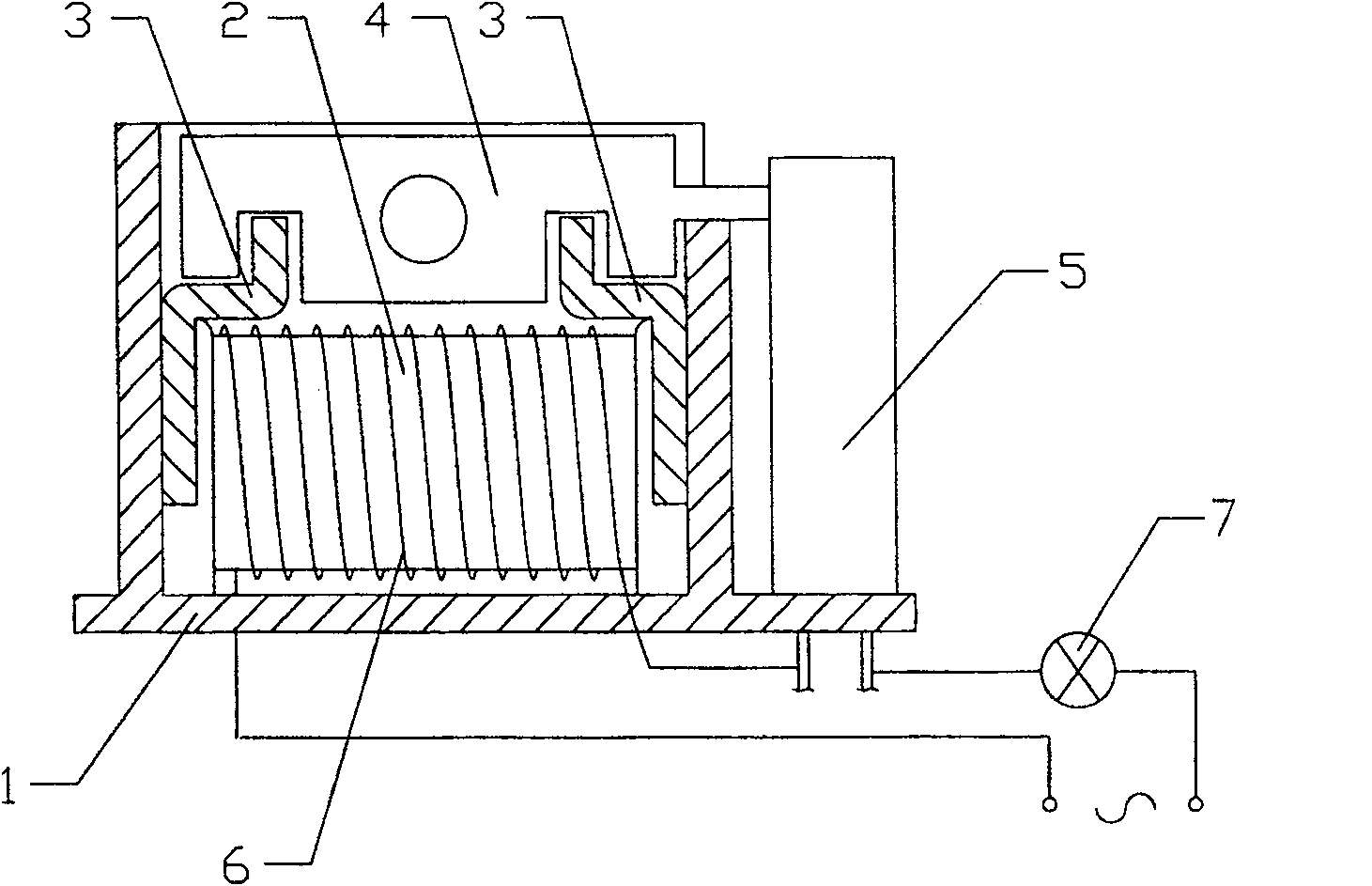

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] according to figure 1 and figure 2 As shown, the magnetic latching relay with overcurrent protection of the present invention includes a base 1 and an electromagnetic coil 2 disposed on the base 1 , and an iron core is generally provided in the middle of the electromagnetic coil 2 . A yoke 3 is provided at both ends of the base 1, and a driving arm assembly 4 is provided between the two yokes 3. The driving arm assembly 4 is movably positioned between the two yokes through a connecting piece, and generally has a magnetic Steel, wherein, the drive arm assembly 4 can be a rotary structure, such as figure 1 and figure 2 As shown, it can also be a straight mobile structure, such as image 3 and Figure 4 shown. One side of the base 1 is provided with a contact piece, which can be a double-reed structure or a multi-reed structure, and includes at least one se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com