Pliable loudspeaker and its making method

A loudspeaker and manufacturing method technology, which is applied in the direction of electrostatic transducer speakers, sensors, electret electrostatic transducers, etc., can solve the problems of energy consumption, high price, unfavorable mass production, etc., so as to avoid high cost and expand application Scope, the effect that is conducive to mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

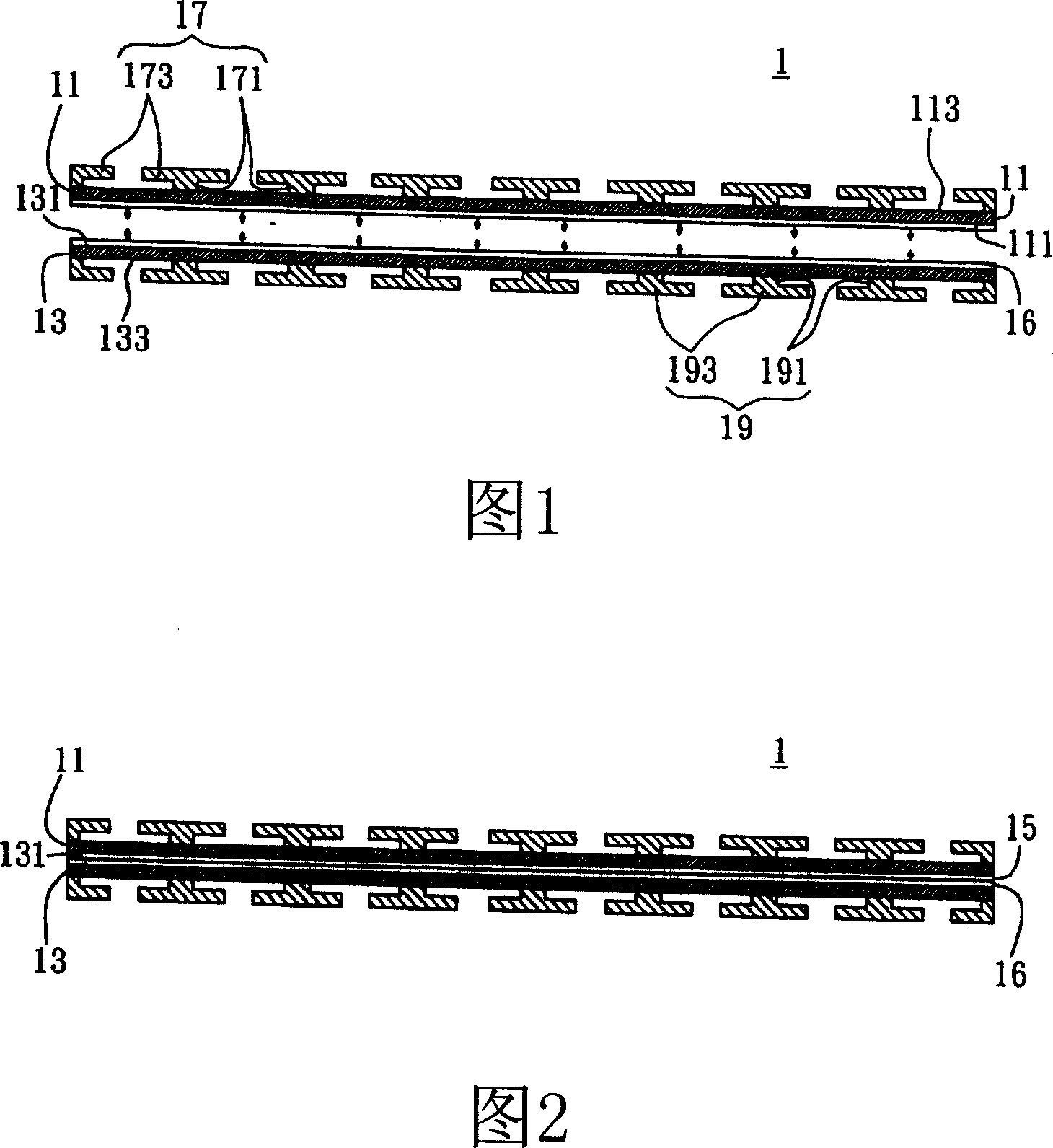

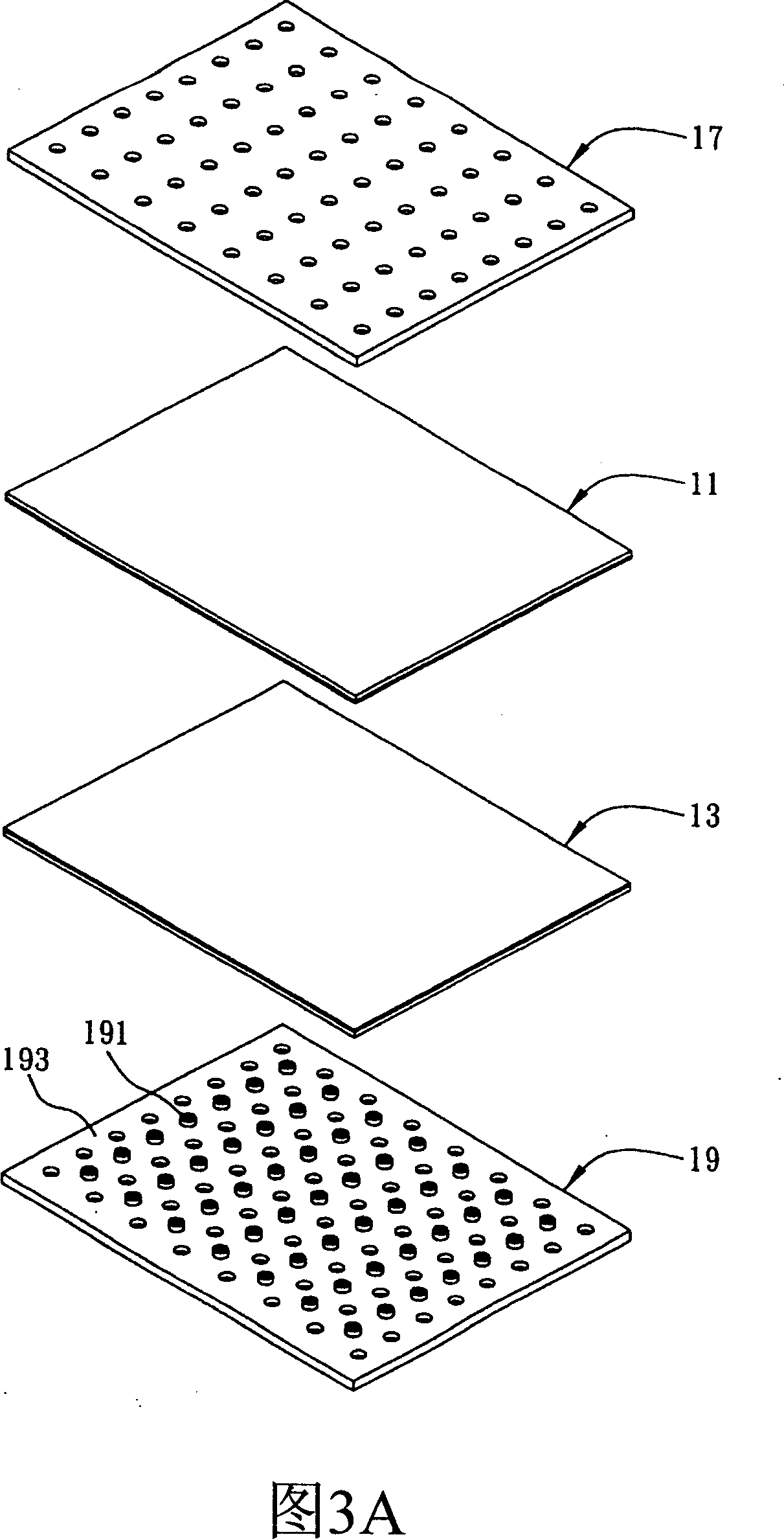

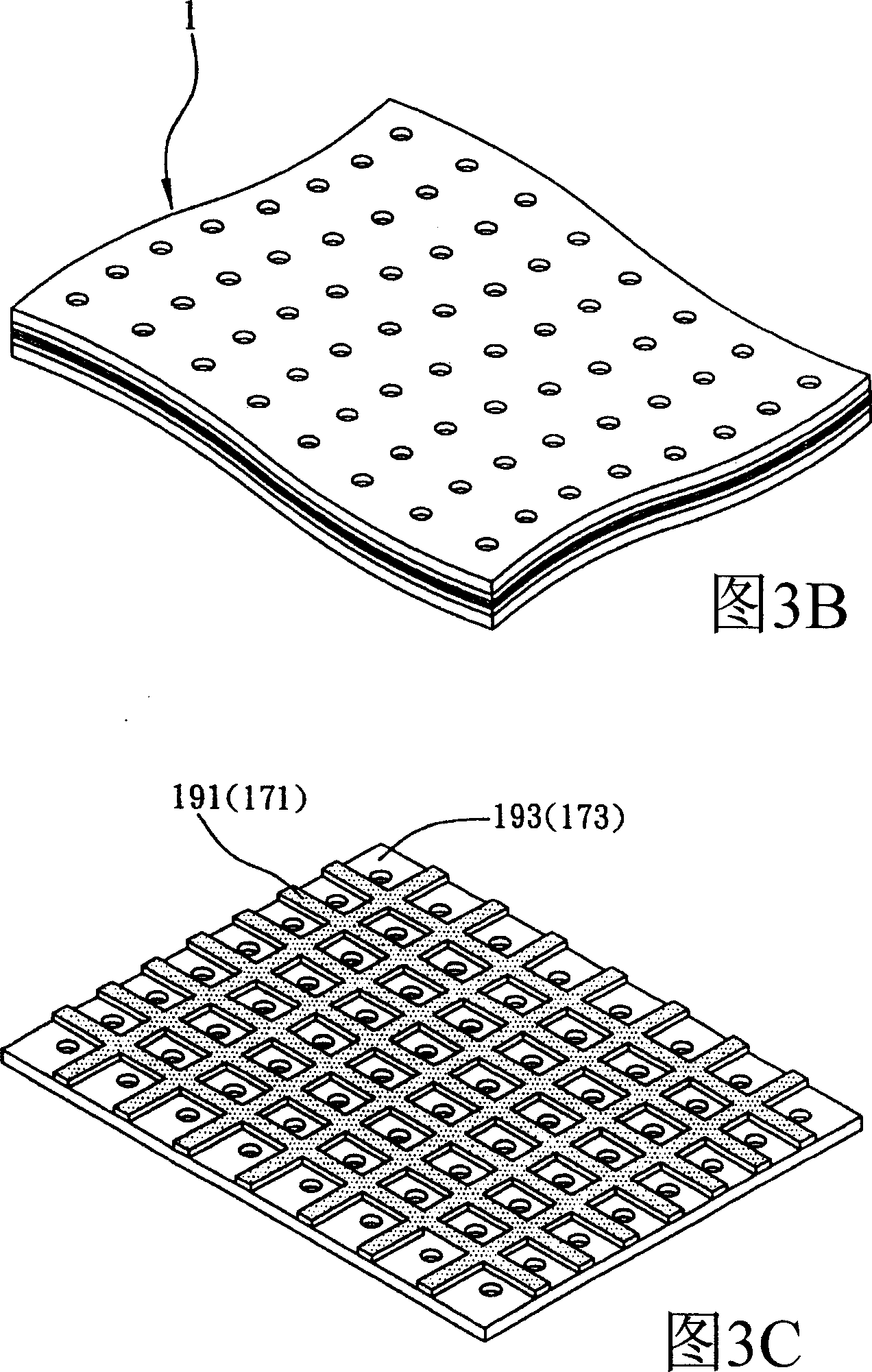

[0072] 1 to 6 are drawings of the first embodiment of the flexible loudspeaker and its manufacturing method according to the present invention.

[0073] Referring to FIG. 1 , a schematic exploded view of the flexible speaker of the present invention is shown. The flexible speaker 1 shown in the figure includes a first diaphragm 11 , a second diaphragm 13 , a first electrode 15 , a second electrode 16 , and The first flexible driving member 17 and the second flexible driving member 19 .

[0074] As shown in FIG. 1 , the first diaphragm 11 and the second diaphragm 13 have first surfaces 111 , 131 and second surfaces 113 , 133 , respectively. In this embodiment, the first vibrating film 11 and the second vibrating film 13 can be selected as electret piezoelectric vibrators, such as electret piezoelectric vibrators that can retain static charges for a long time after the dielectric material is electrized. diaphragm, and the first diaphragm 11 and the second diaphragm 13 can be di...

no. 2 example

[0095] FIG. 7 is a drawing of a second embodiment of a flexible speaker and a manufacturing method thereof according to the present invention. Wherein, the same or similar components as in the foregoing embodiments are represented by the same or similar component symbols, and the detailed description is omitted to make the description of the present case more clear and easy to understand.

[0096] The biggest difference between the second embodiment and the first embodiment is that the first flexible driving member and the second flexible driving member in the first embodiment can be composed of, for example, a flexible conductive perforated plate and a spacer. In the example, the first flexible driving member and the second flexible driving member can be, for example, conductive metal sheets. At the same time, as shown in FIG. 7 , in the manufacturing process of this embodiment, an electrode is formed on the first surface of one of the first and second diaphragms in step S2 ′...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com