Broken line repair method of TFT substrate

a technology of tft substrate and broken line, which is applied in the field of display technology, can solve the problems of poor quality of liquid crystal display with broken lines, waste of liquid crystal display, and the inability to reduce the line ratio to be 0 , to achieve the effect of reducing the risk of broken lines, promoting the adhesion result and uniformity of metal growing film, and raising the success ratio of broken line on the substra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]For better explaining the technical solution and the effect of the present invention, the present invention will be further described in detail with the accompanying drawings and the specific embodiments.

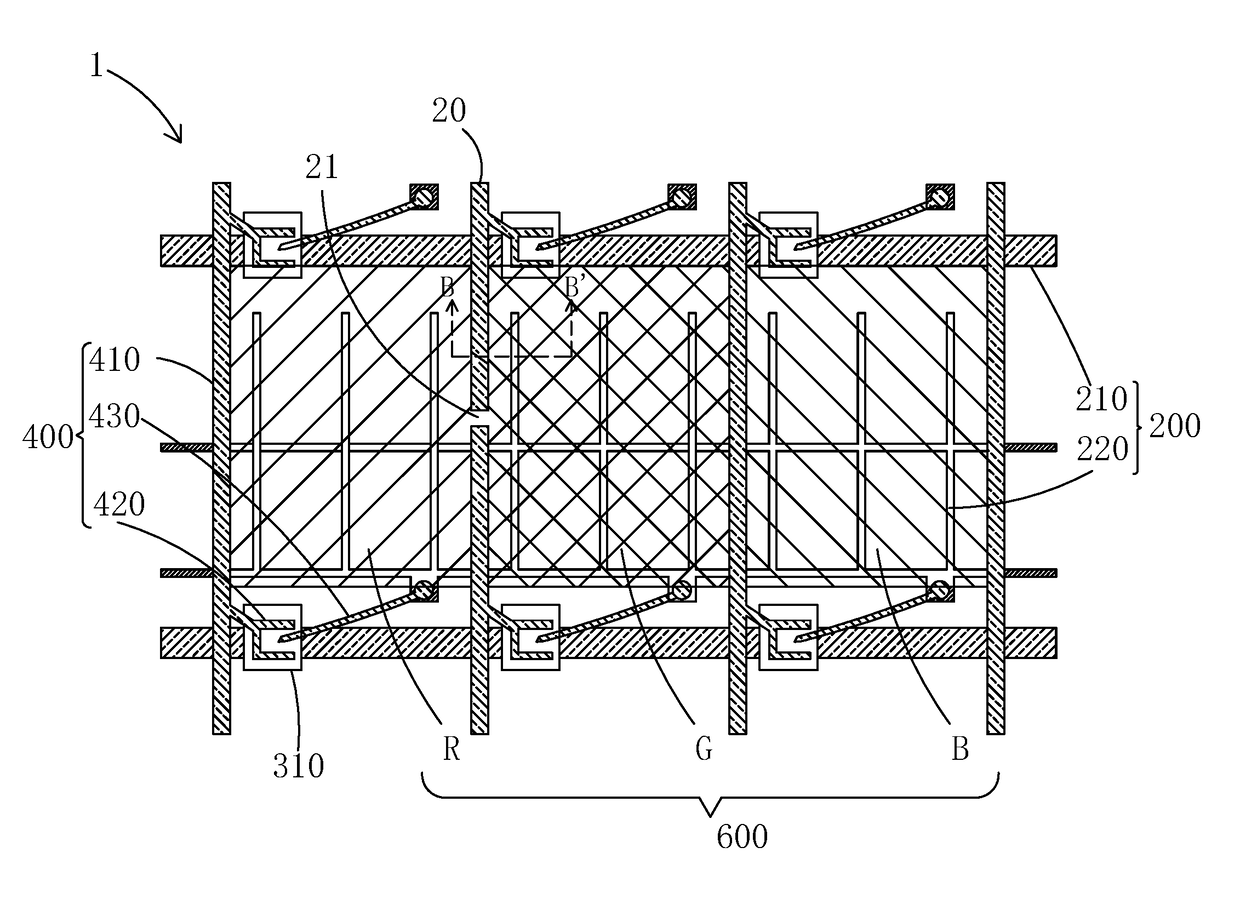

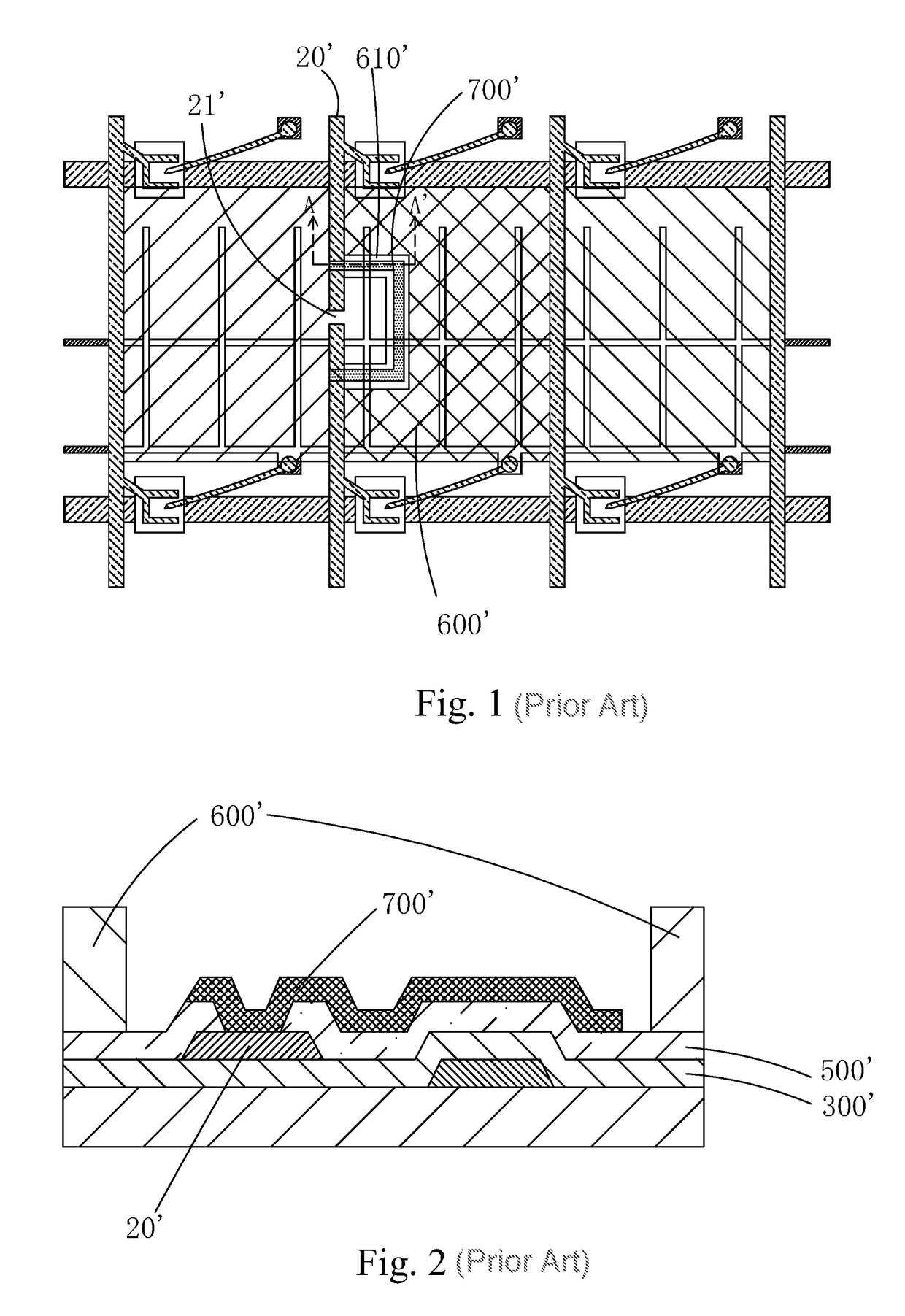

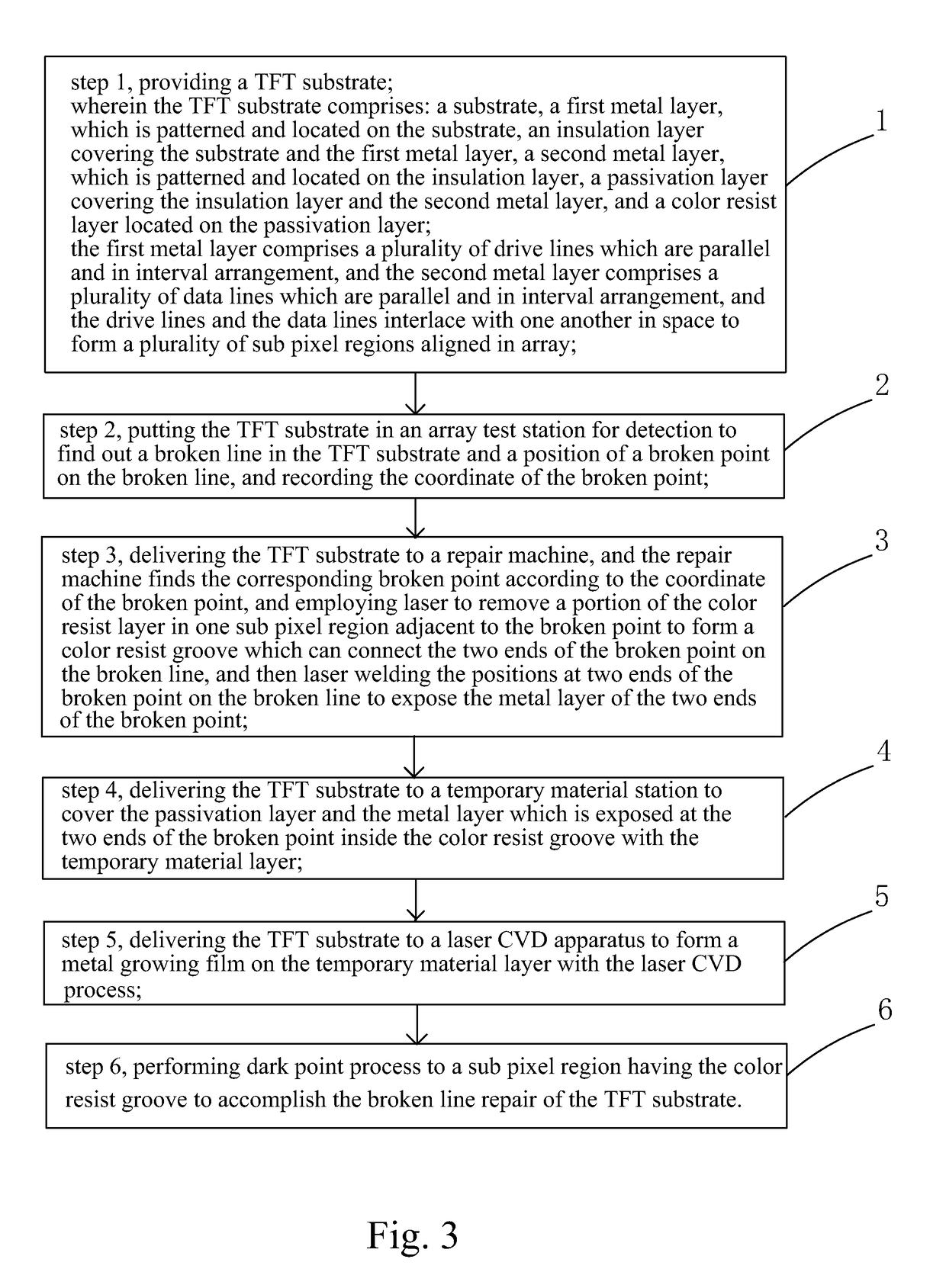

[0054]Please refer to FIG. 14 combining FIG. 3, the present invention provides a broken line repair method of a TFT substrate. When the method is applied to repair the broken line in the display region of the TFT substrate, the method comprises steps of:

[0055]step 1, referring to FIG. 4 and FIG. 5, providing a TFT substrate 1 in which a broken line is to be repaired.

[0056]Specifically, the TFT substrate 1 comprises: a substrate 100, a first metal layer 200, which is patterned and located on the substrate 100, a gate insulation layer 300 covering the substrate 100 and the first metal layer 200, a second metal layer 400, which is patterned and located on the gate insulation layer 300, a passivation layer 500 covering the gate insulation layer 300 and the second metal layer 400, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| colors | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

| structure diagram | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com