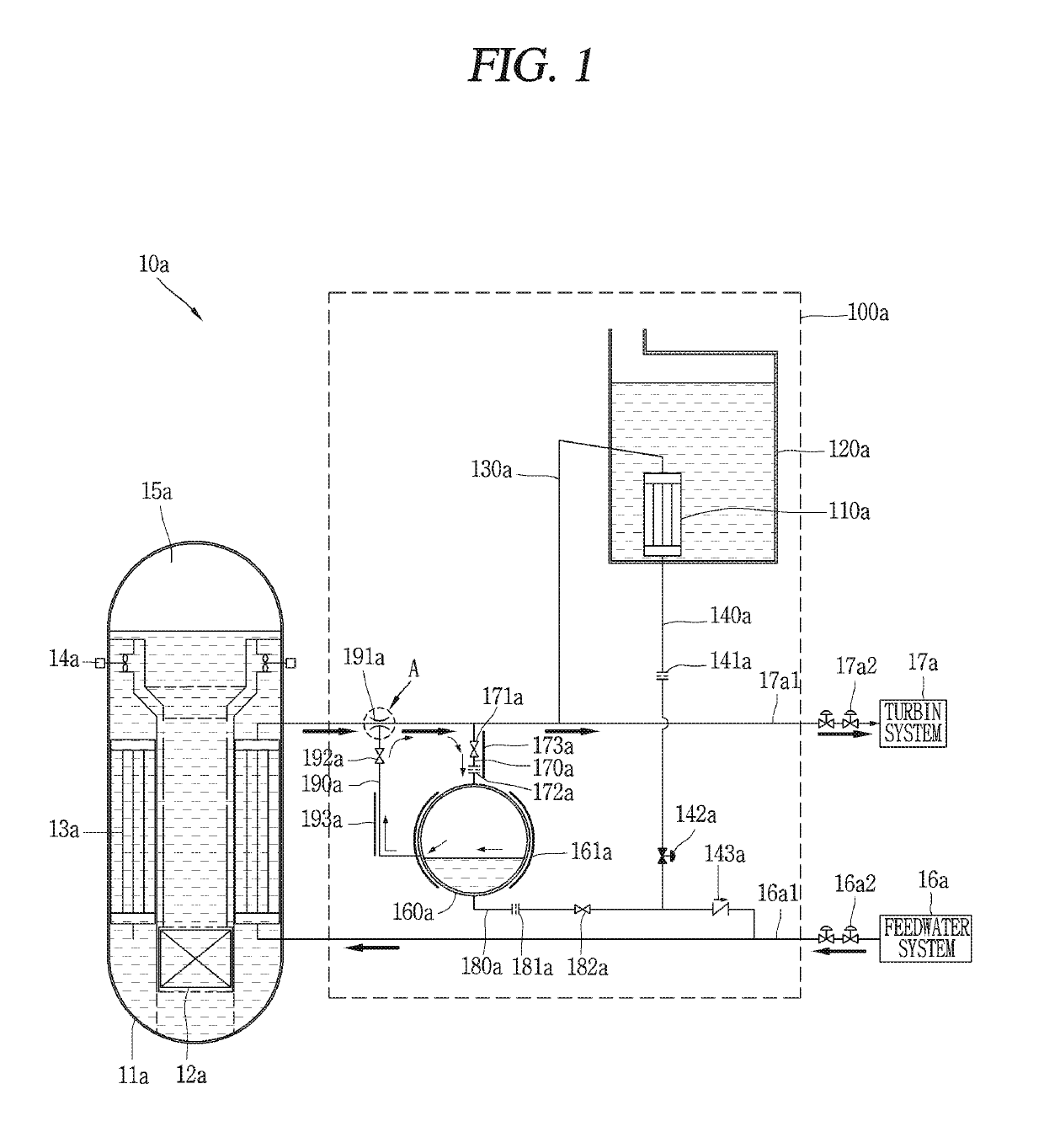

Passive heat removal system for nuclear power plant

a technology of passive residual heat removal and nuclear power plants, which is applied in the direction of nuclear reactors, greenhouse gas reduction, nuclear elements, etc., can solve the problems of difficult to achieve the target performance of the passive residual heat removal system, the flow of the passive residual heat removal system is affected during an accident, and the performance of the passive residual heat removal system is generally known to be big. , to achieve the optimal performance of the passive residual heat removal system, the effect of preventing the performance degradation of a condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

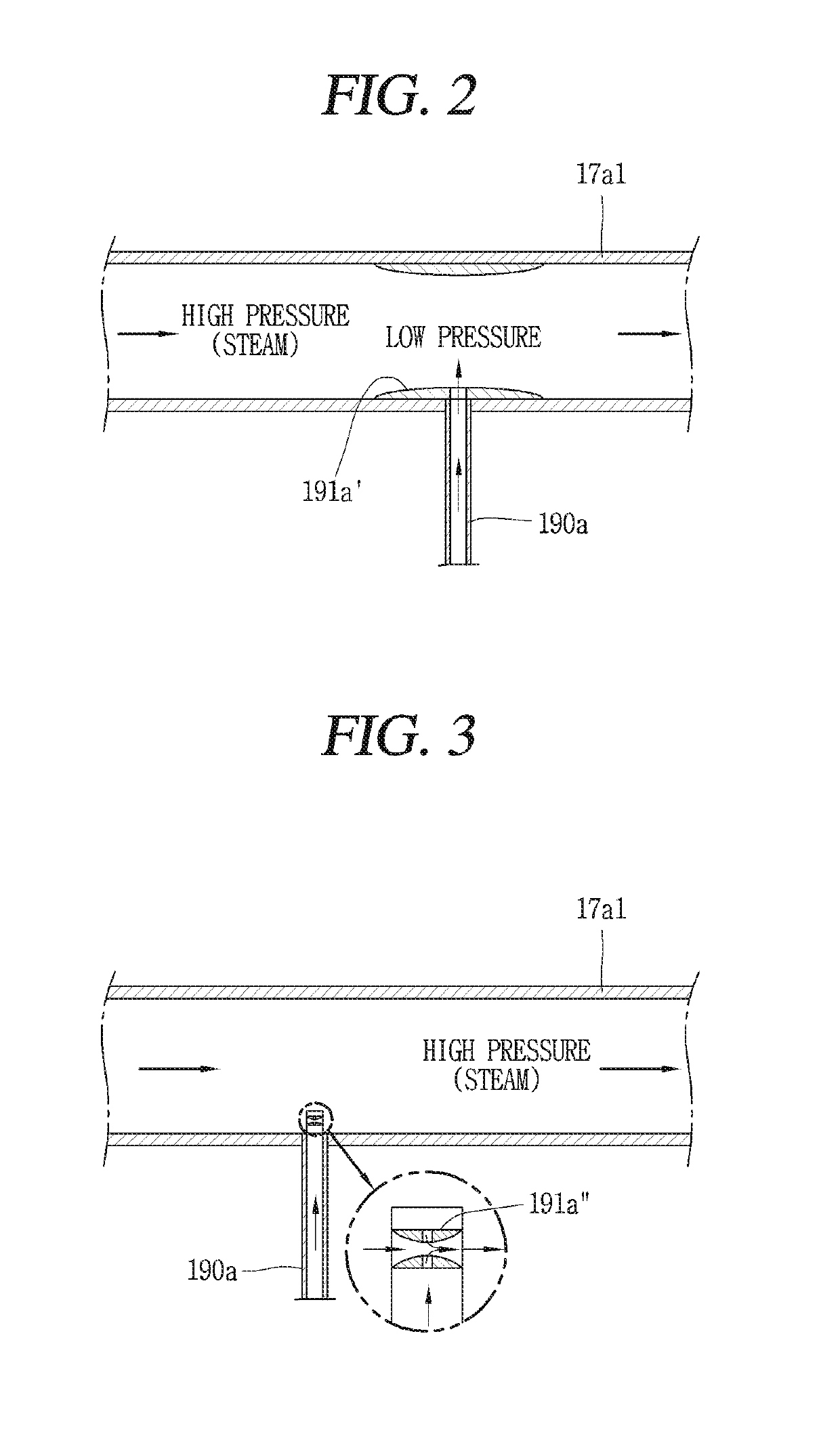

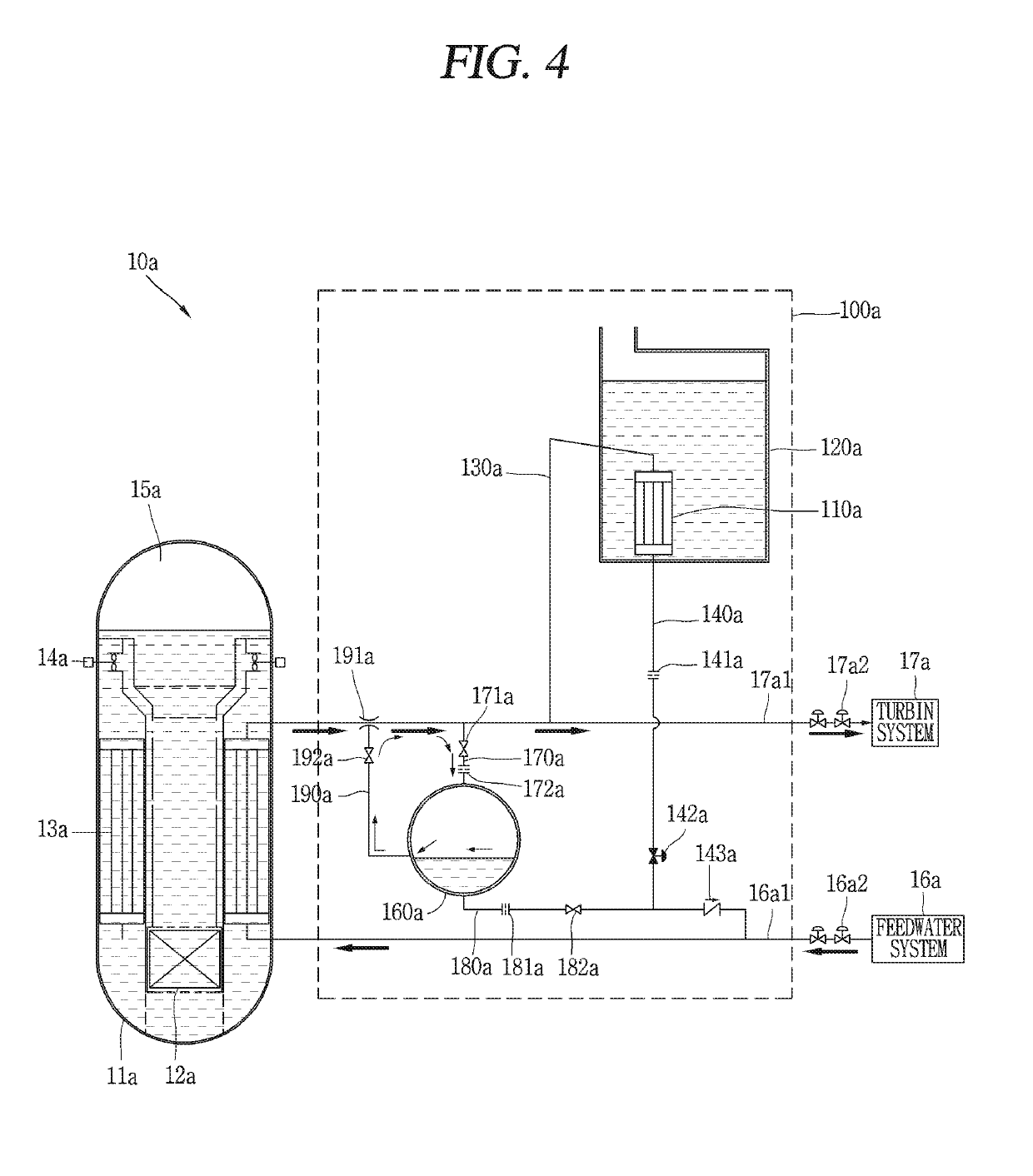

[0060]Hereinafter, a nuclear power plant including a passive residual heat removal system associated with the present disclosure will be described in more detail with reference to the accompanying drawings. Even in different embodiments according to the present disclosure, the same or similar reference numerals are designated to the same or similar configurations, and the description thereof will be substituted by the earlier description. Unless clearly used otherwise, expressions in the singular number used in the present disclosure may include a plural meaning.

[0061]In the specification, in case where it is mentioned that an element is “connected” to another element, it should be understood that an element may be directly connected to another element, but another element may exist therebetween. On the contrary, in case where it is mentioned that an element is “directly connected” to another element, it should be understood that any other element does not exist therebetween. It is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com