Expanding wall anchor and use for fixing a component to a support material

a technology for supporting materials and expansion walls, which is applied in the direction of fastening means, dowels, mechanical equipment, etc., can solve the problems of product performance decline, product performance drop, and product failure to meet the earlier type testing certification conditions, etc., to reduce the holding performance of wall anchors, improve operation, and improve the effect of performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0057]The description that follows contains a comparative example to illustrate the foregoing.

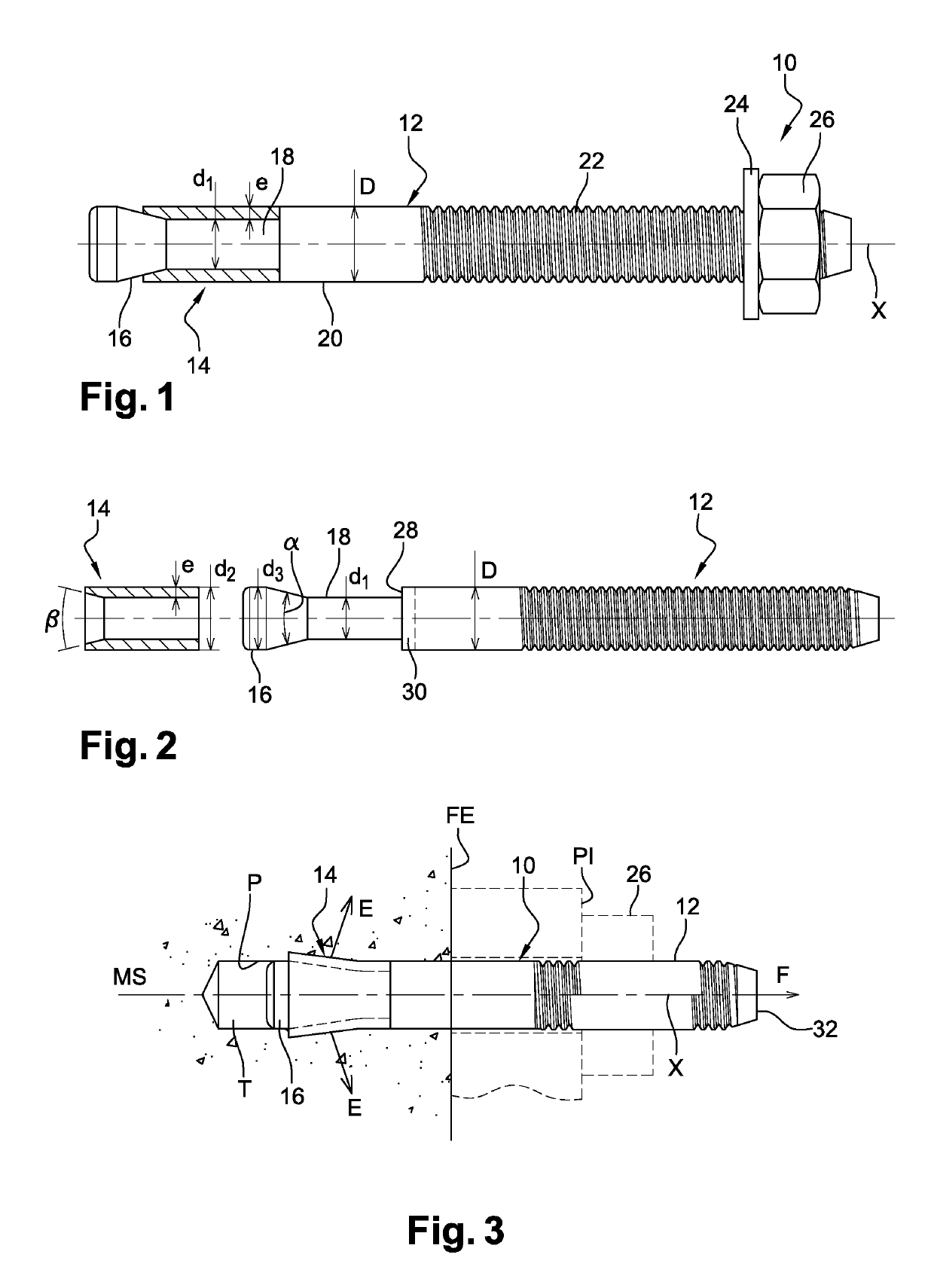

[0058]We have compared a product according to the invention (product A) that meets all of the requirements stipulated for cracked concrete and seismic loadings against a product of the prior art that meets only the requirements stipulated for cracked concrete without seismic loadings (product B) and against a third product designed exclusively for non-cracked concrete (product C). The three wall anchors compared have the same nominal diameter, in this instance 12 mm (M12), and were set at identical anchoring depths into concretes of identical strengths. The various components of these wall anchors are made of comparable steels commonly used by those skilled in the art. The only appreciable differences are their ratio e / d1 and their angle α as defined above. The reference wall anchor is the wall anchor according to the invention (product A) which works under all the conditions and for which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com