Micro-LED chip and manufacturing method thereof, and display panel

a micro-led chip and manufacturing method technology, applied in the field of display technology, can solve the problems of low drive efficiency and increase power consumption, and achieve the effects of improving the high power consumption problem of driving tfts, increasing the voltage, and reducing the power consumption of driving thin film transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]Embodiments of the present invention are described in detail below with reference to the accompanying drawings. The directional terms in the present disclosure, such as “upper”, “lower”, “front”, “rear”, “left”, “right”, “inside”, “outside”, and “lateral”, are merely illustrative with reference to the accompanying drawings, and are not intended to limit the protection scope of the present application. In the drawings, the same reference numerals in the drawings denote the same elements.

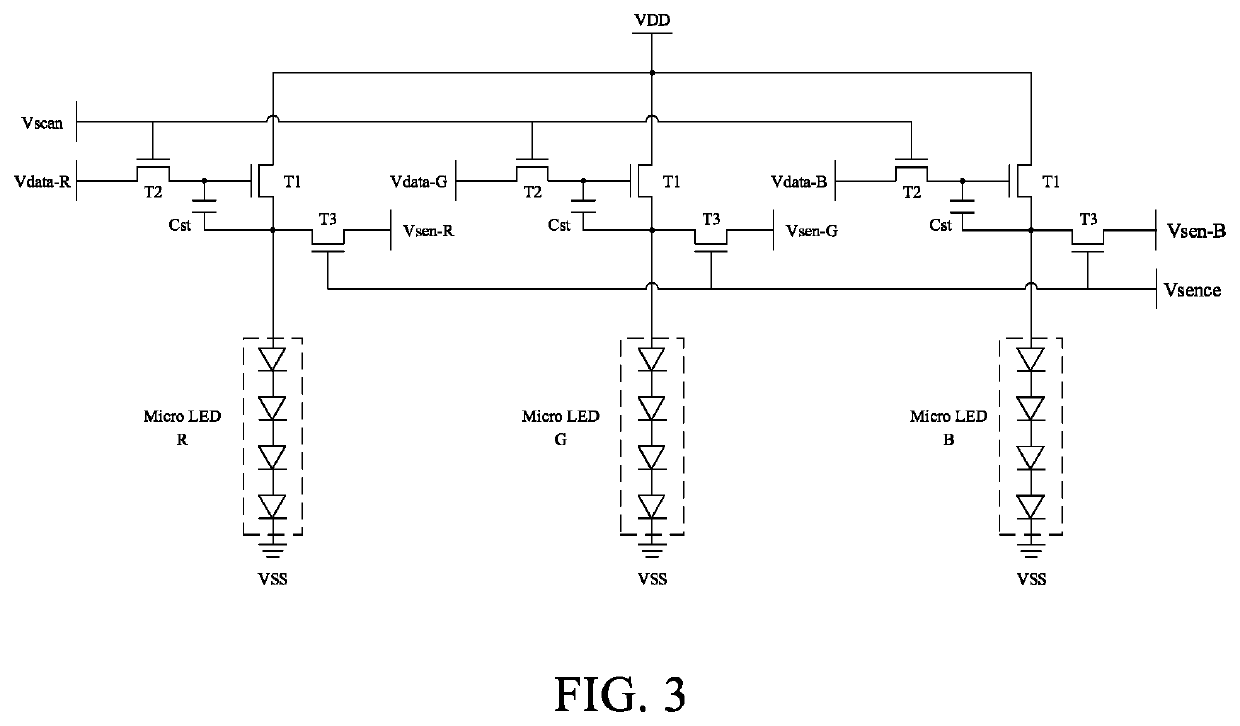

[0050]In view of a high power consumption problem of driving thin film transistors (TFTs) in conventional micro-LED displays, the present invention provides a micro-LED chip to solve this problem.

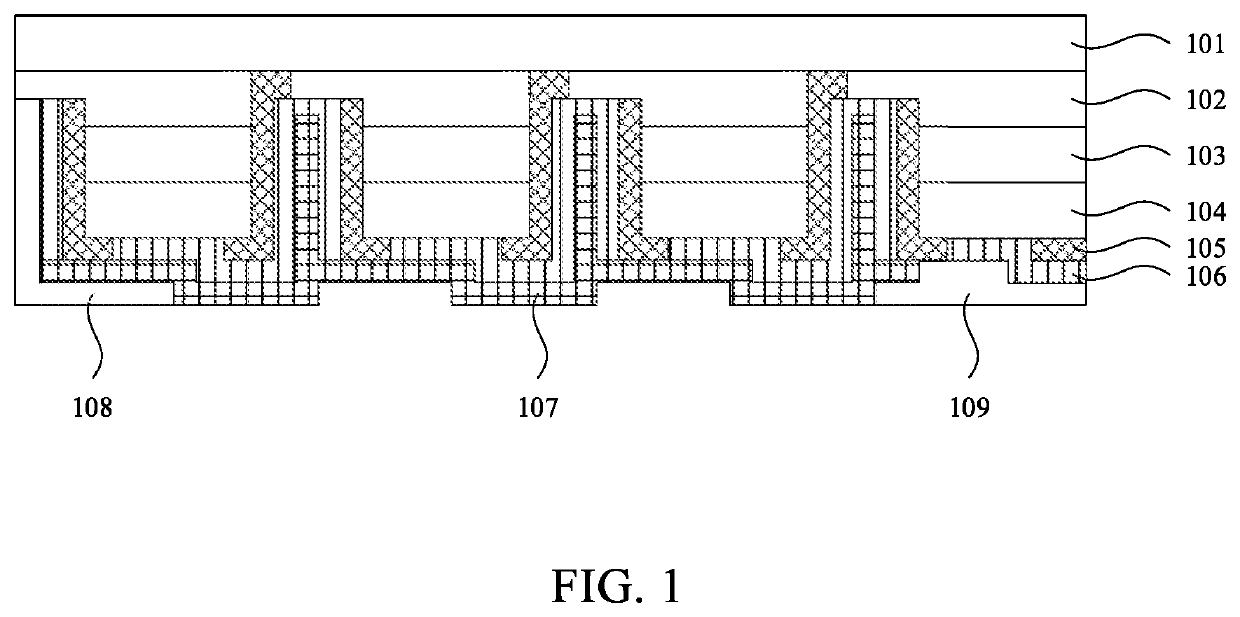

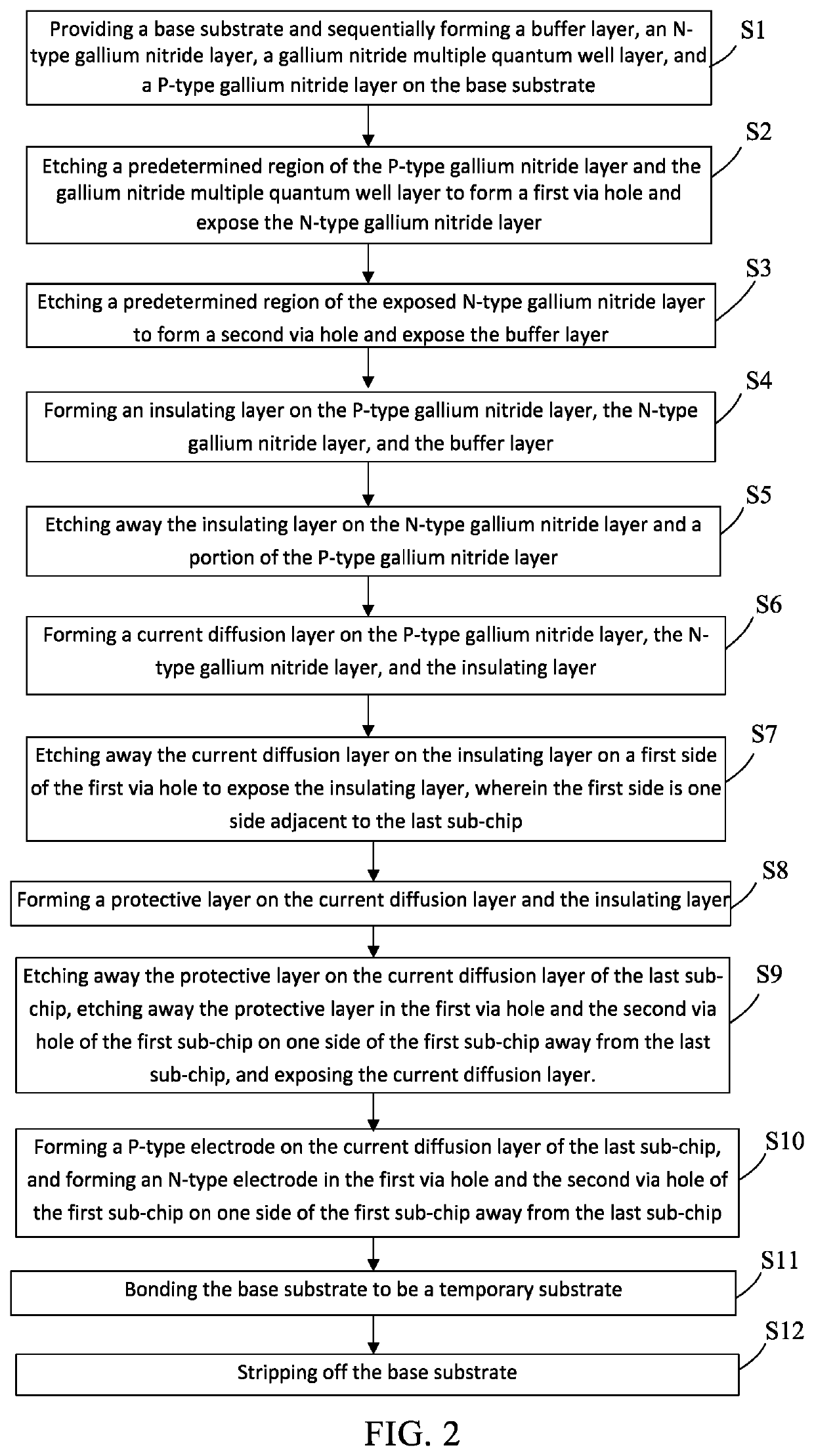

[0051]In one embodiment, as shown FIG. 1, the present application provides a micro LED chip comprises the following sequentially stacked on each other from top to bottom:

[0052]A buffer layer 101: In an embodiment, the buffer layer 101 is an intrinsic gallium nitride layer with a thick thickness greater ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current diffusion | aaaaa | aaaaa |

| semiconductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com