Patents

Literature

32results about How to "Highly problematic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

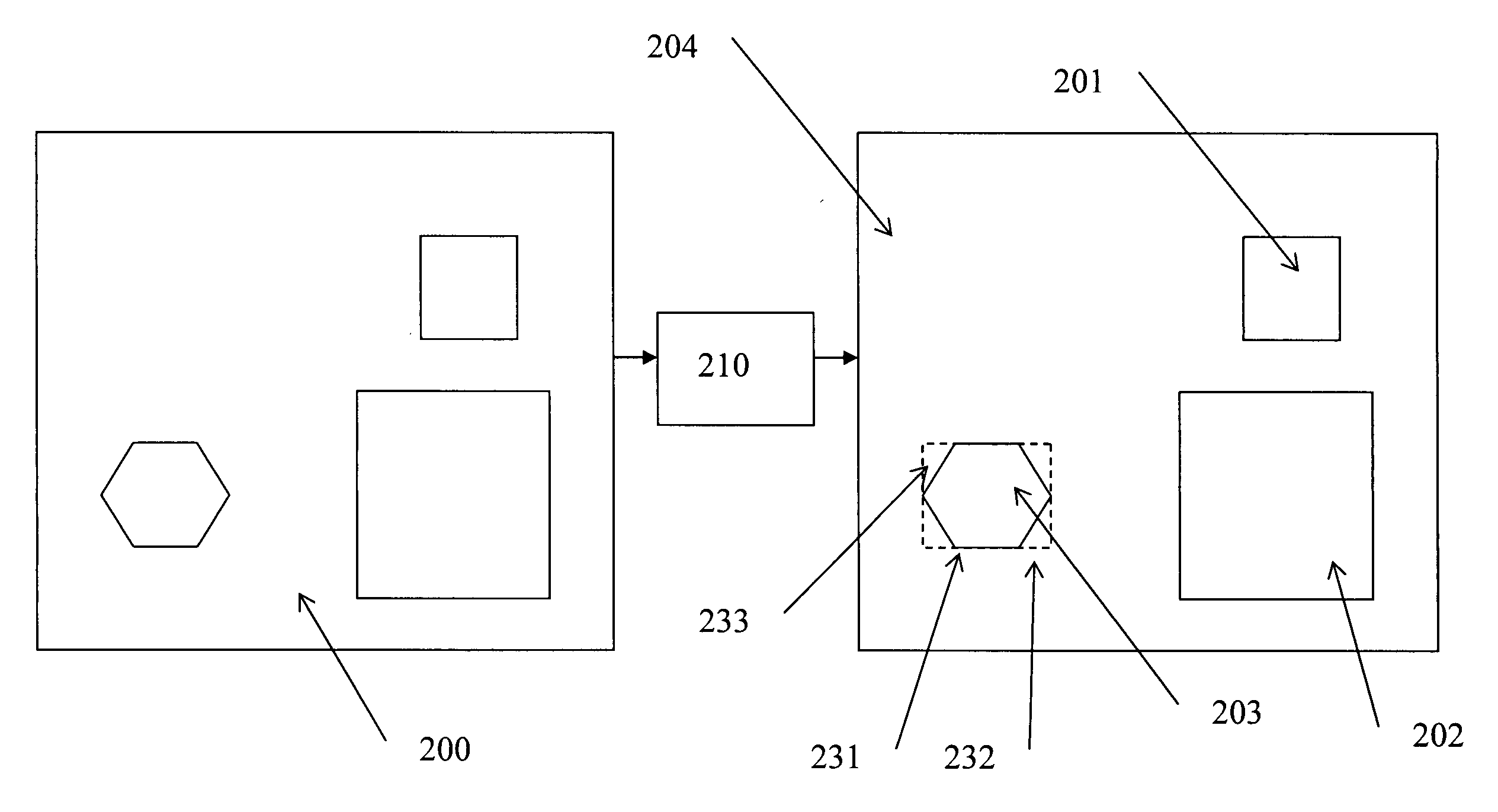

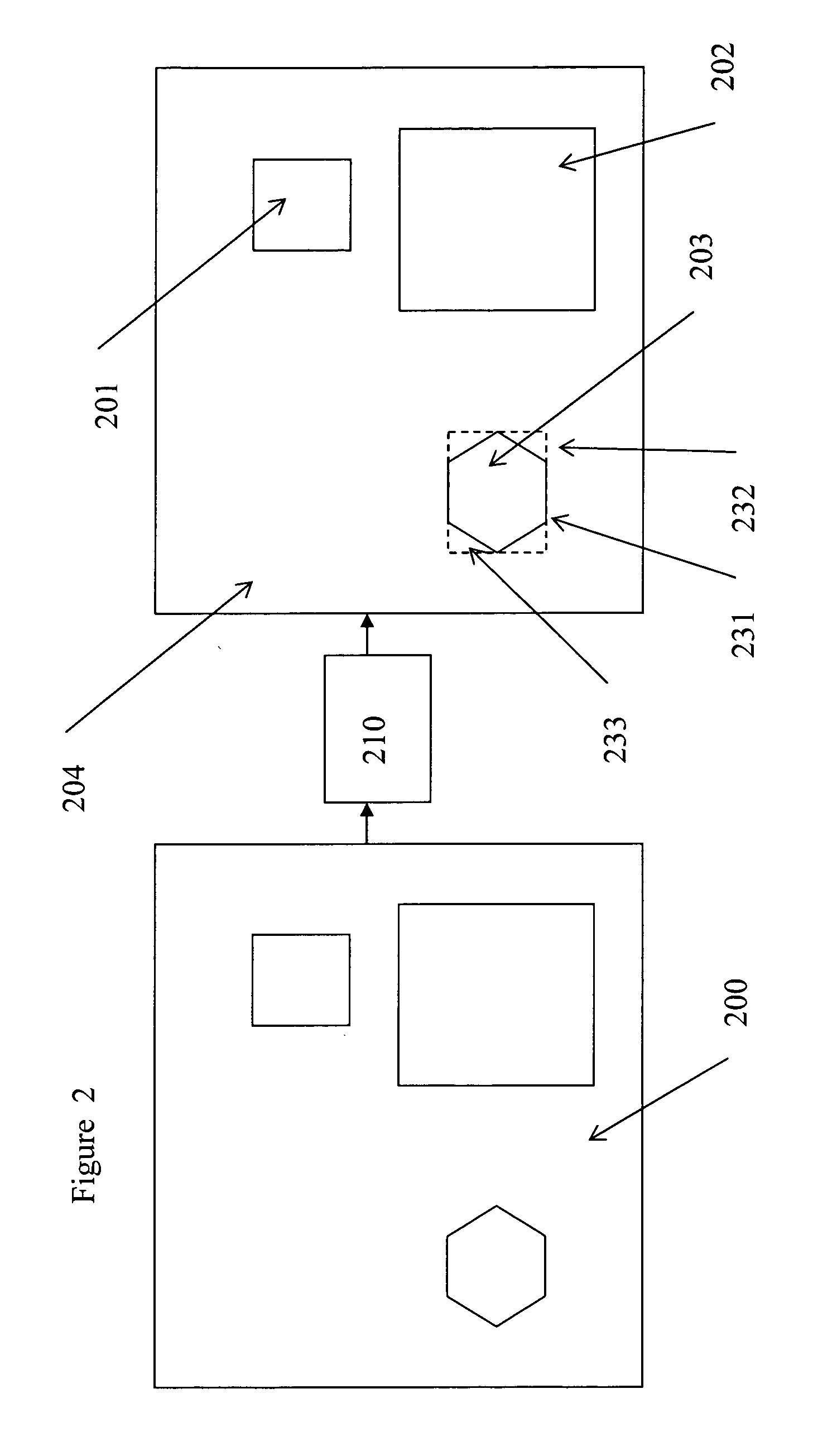

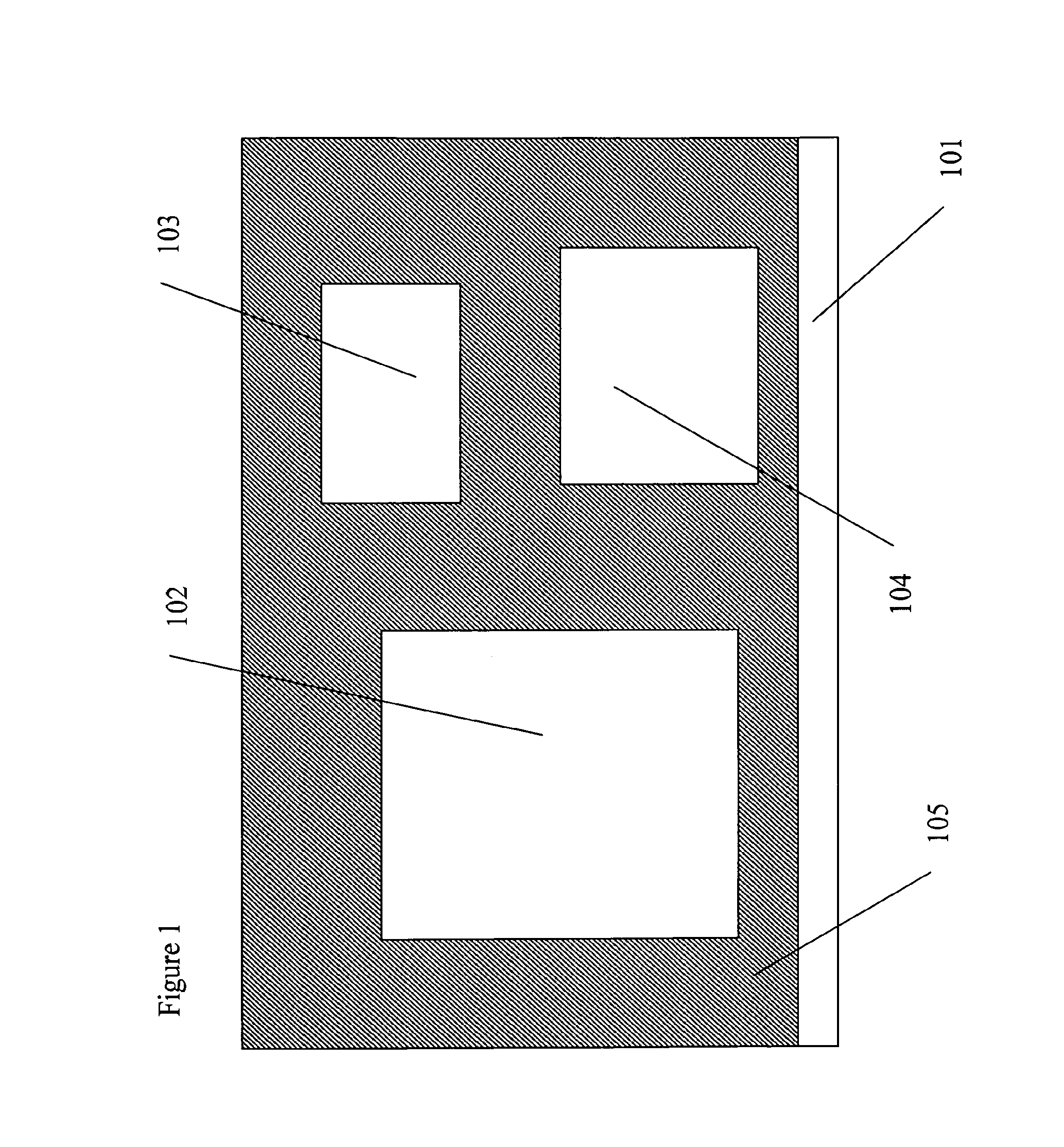

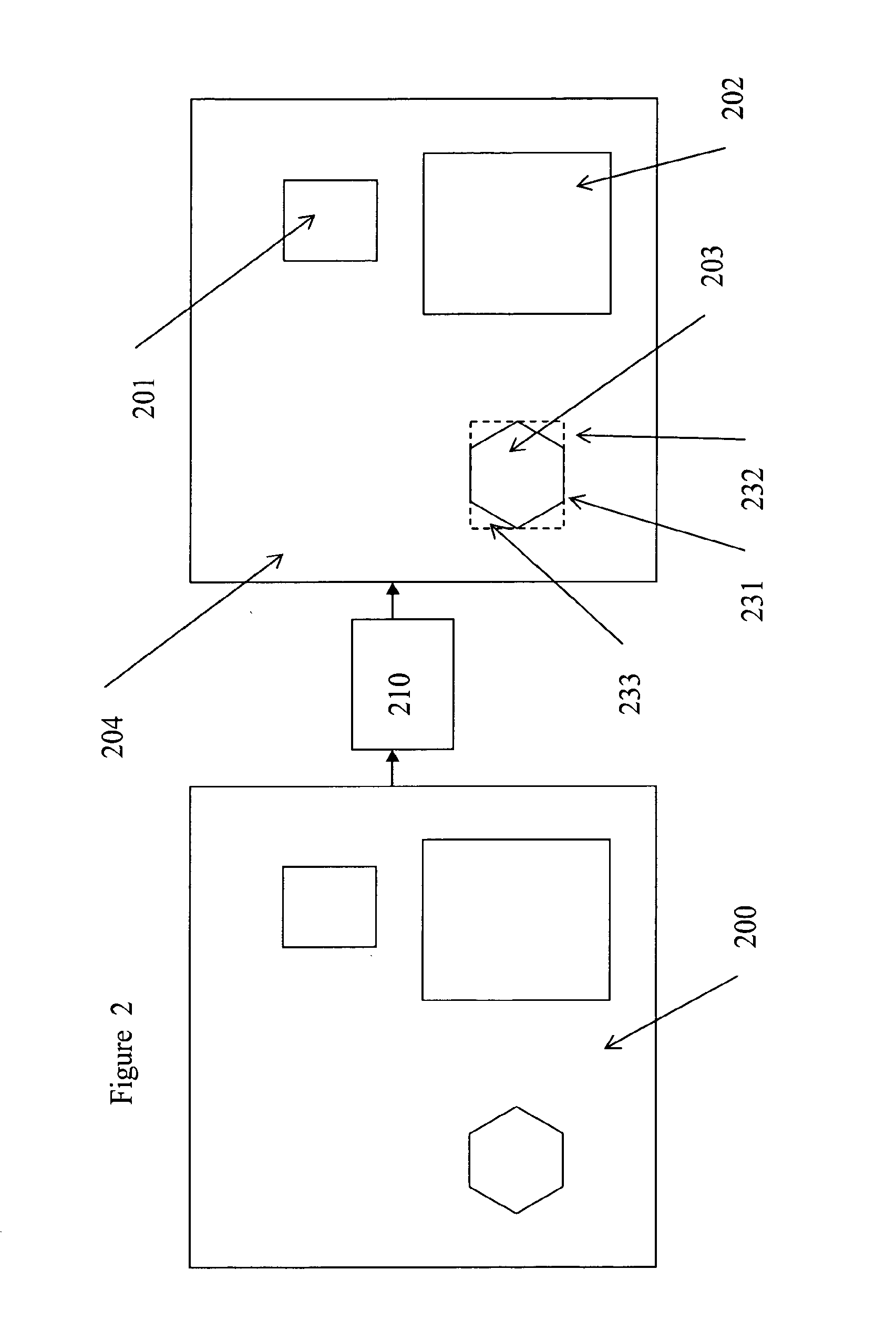

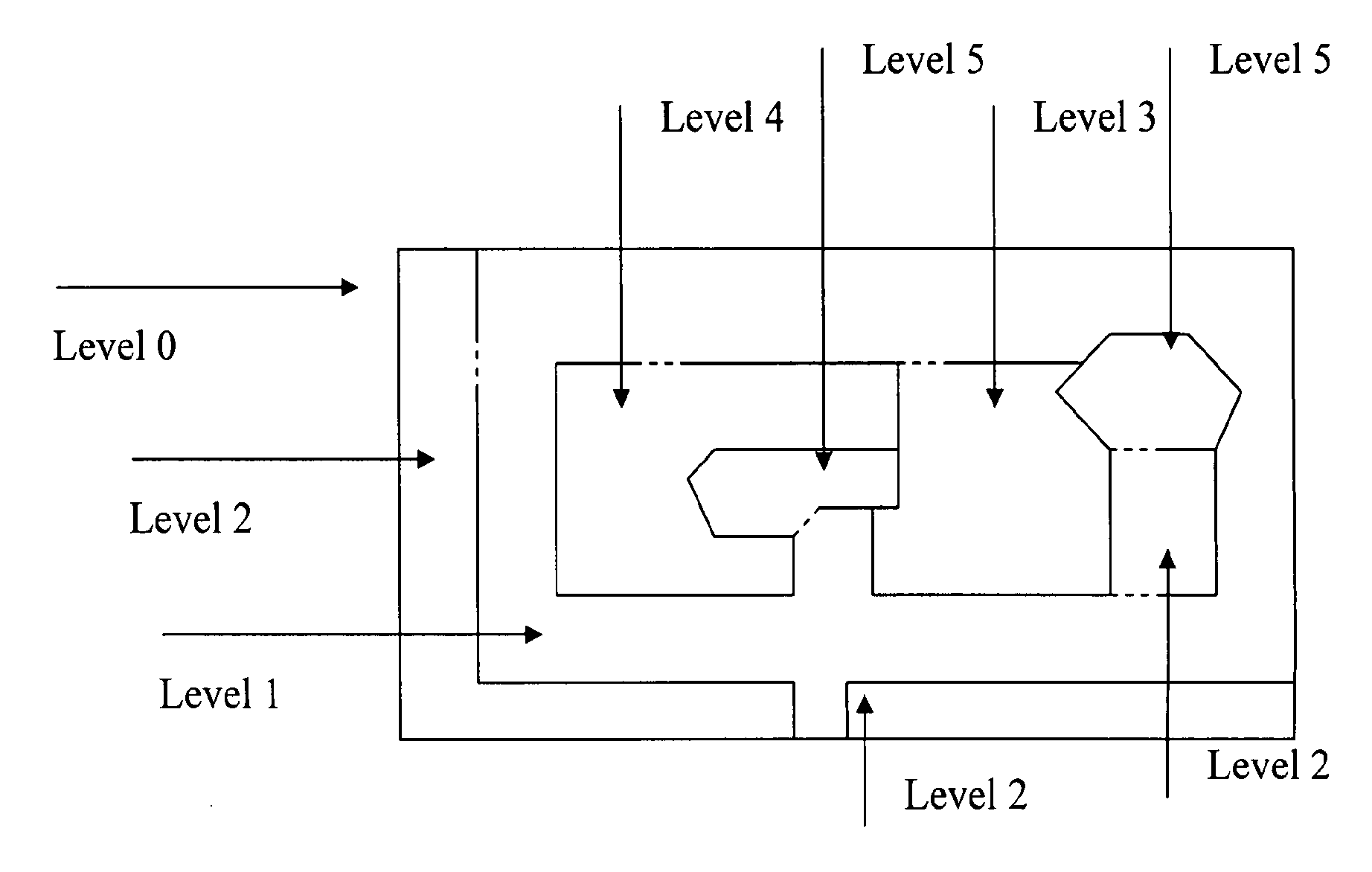

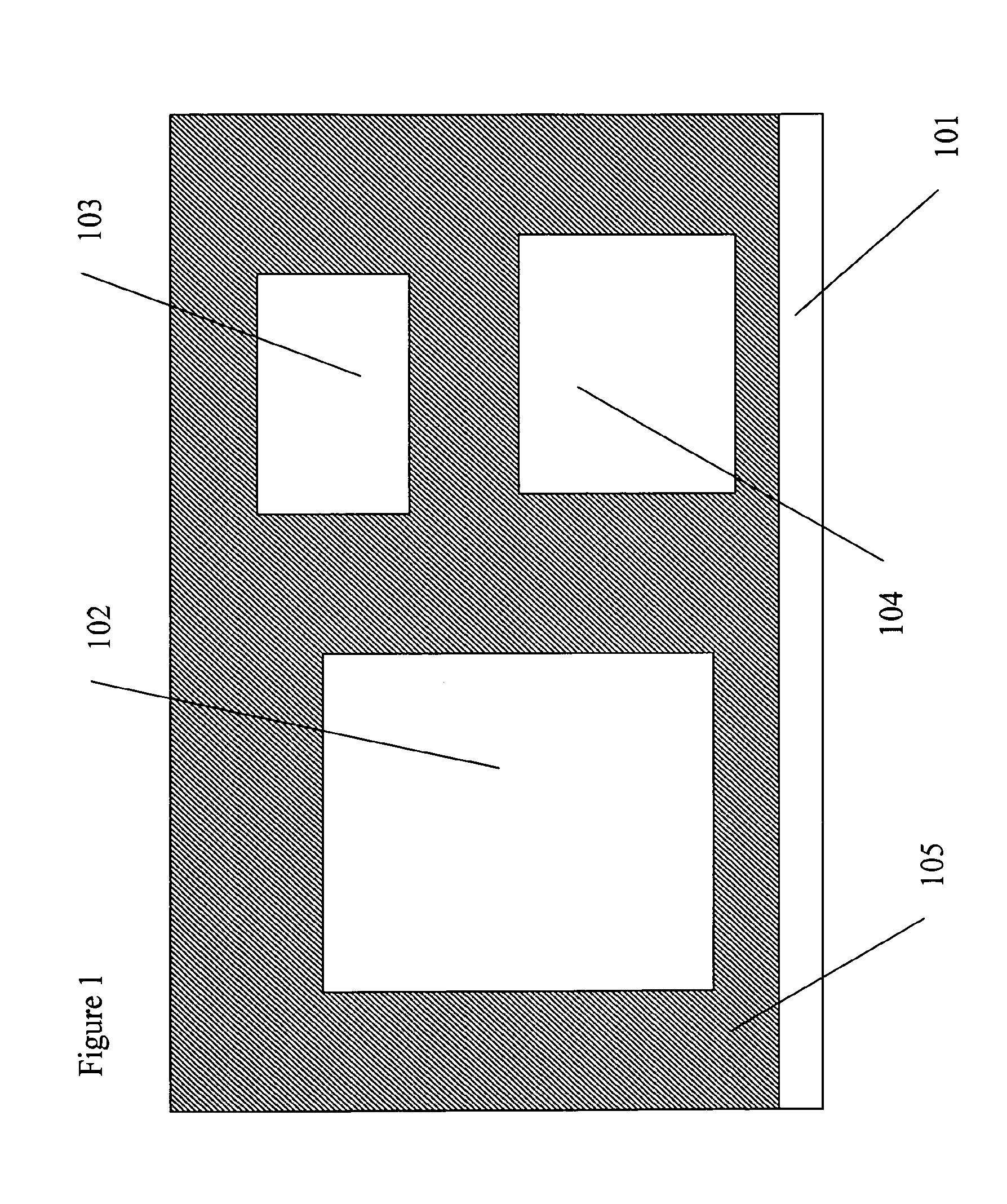

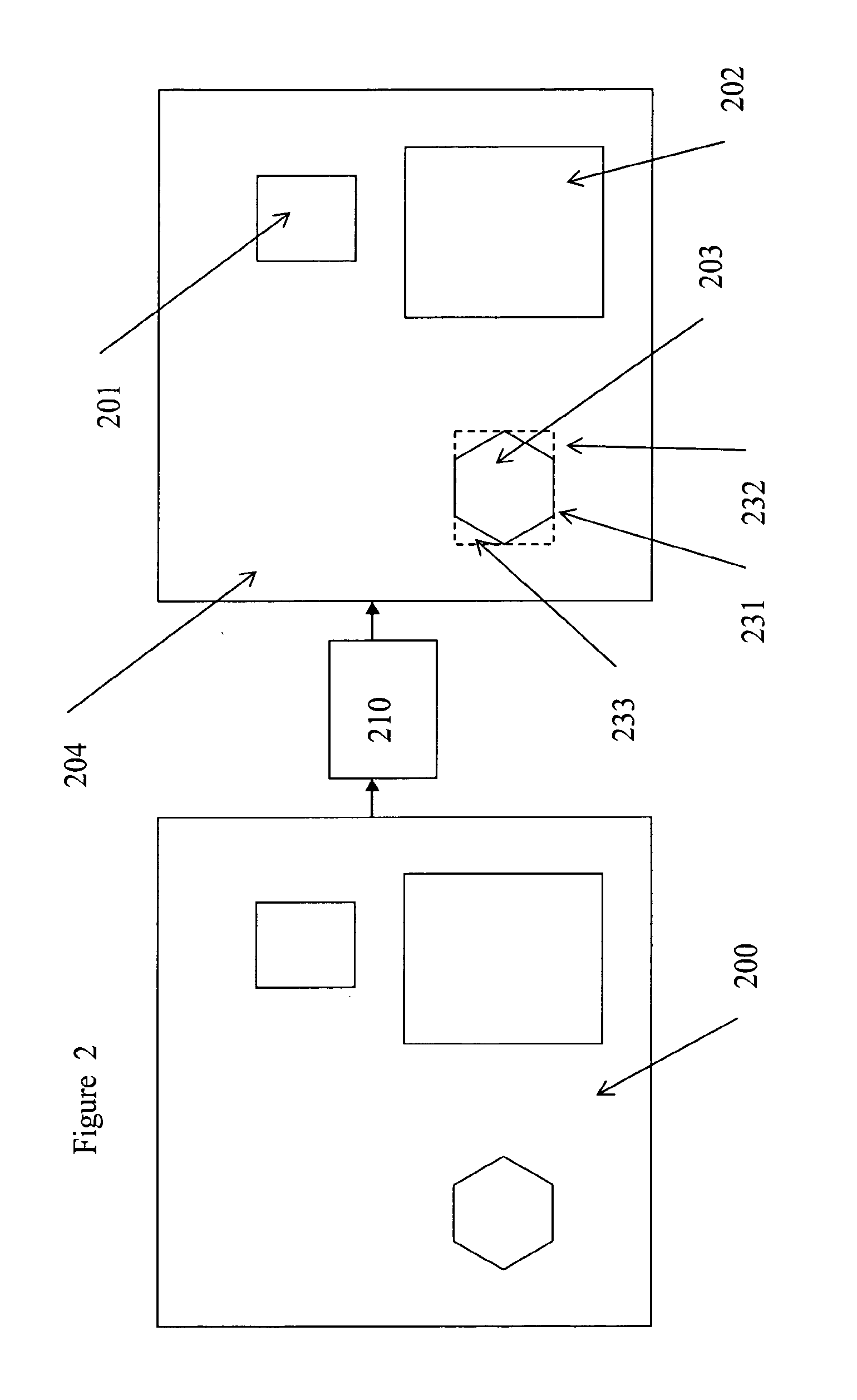

Method and device for image and video transmission over low-bandwidth and high-latency transmission channels

InactiveUS20070183493A1Increase the compression ratioLow priorityPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningVideo transmissionEncoding algorithm

The present invention provides a method for transmission of a images and / or video over bandwidth limited transmission channels having varying available bandwidth, which method comprises the use of a classification algorithm for decomposing the images and / or video to be transmitted into multiple spatial areas, each area having a specific image type; detecting the image type of each of those areas separately selecting for each of those areas an image and / or video encoding algorithm having a compression ratio. The classification algorithm prioritizes each of the areas, the classification algorithm increasing the compression ratio of the image and / or video encoding algorithm dedicated to spatial areas having lower priority in case of decreasing bandwidth.

Owner:BARCO NV

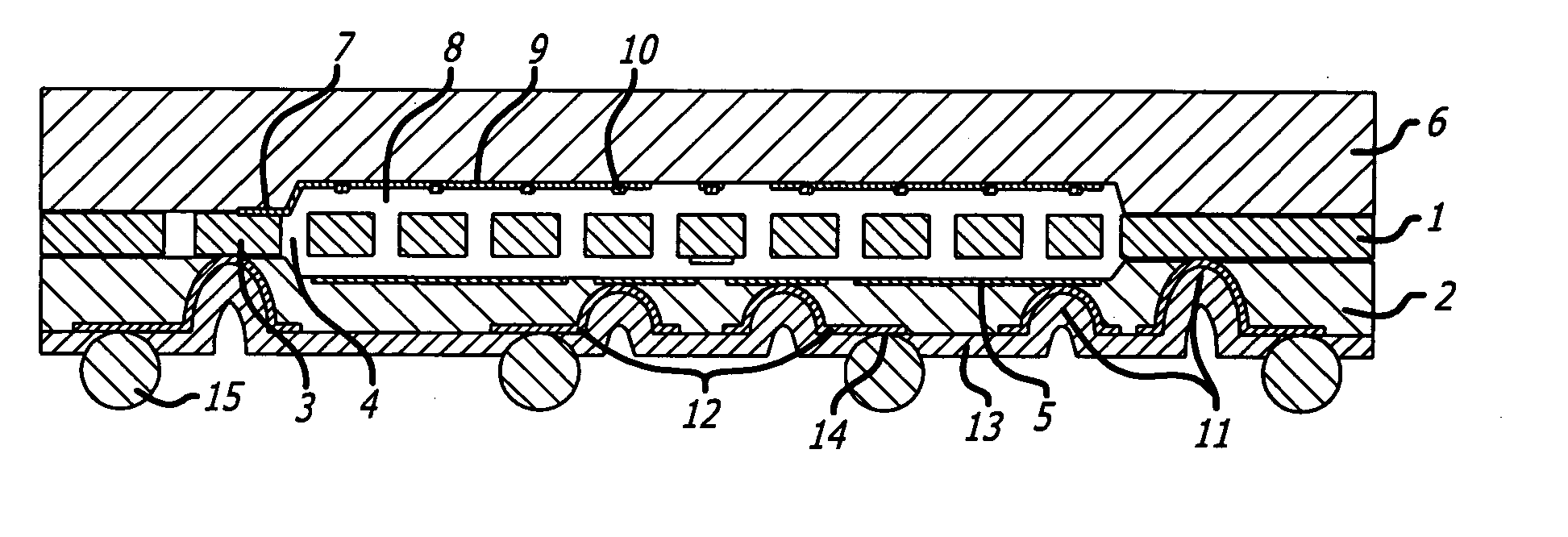

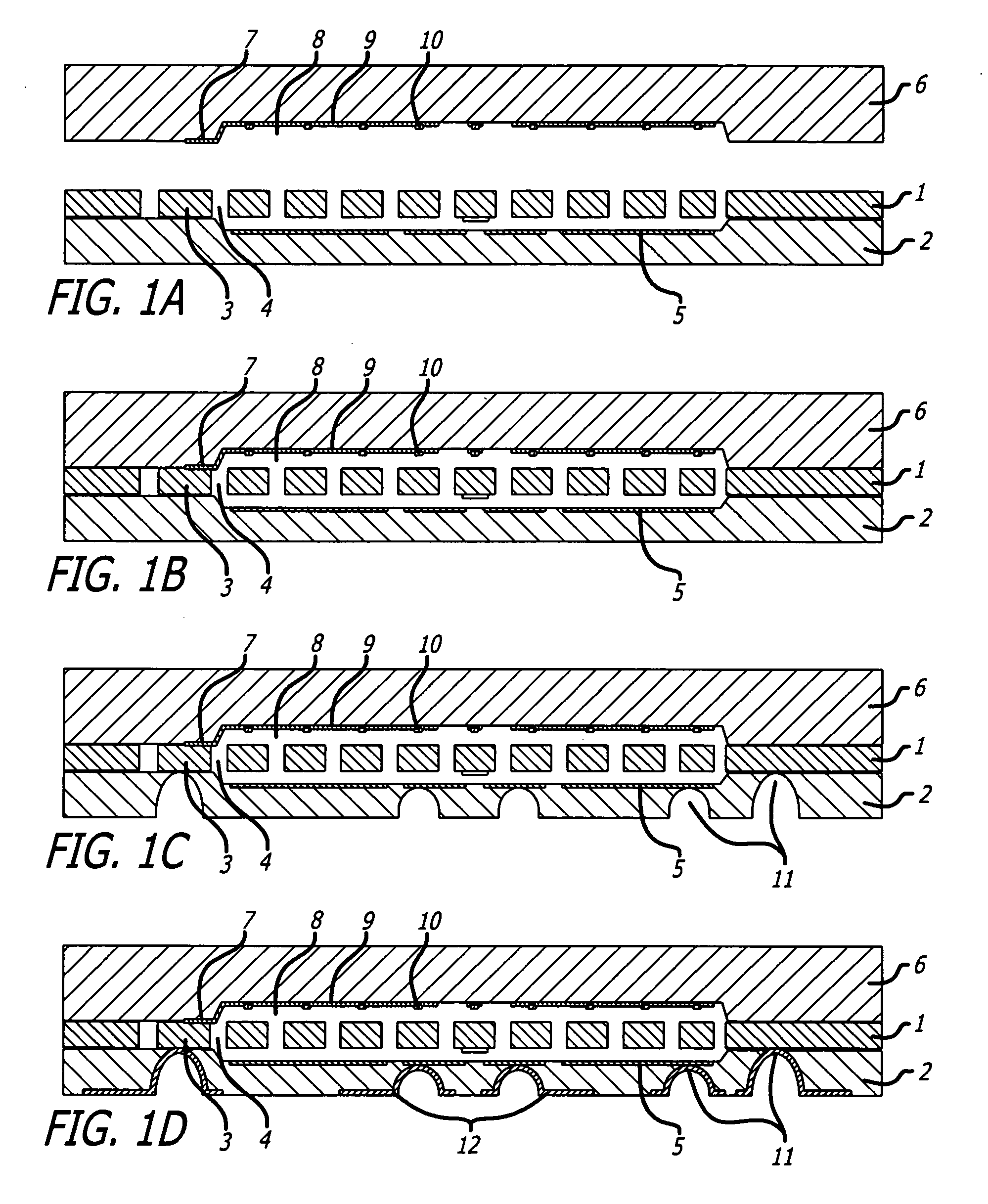

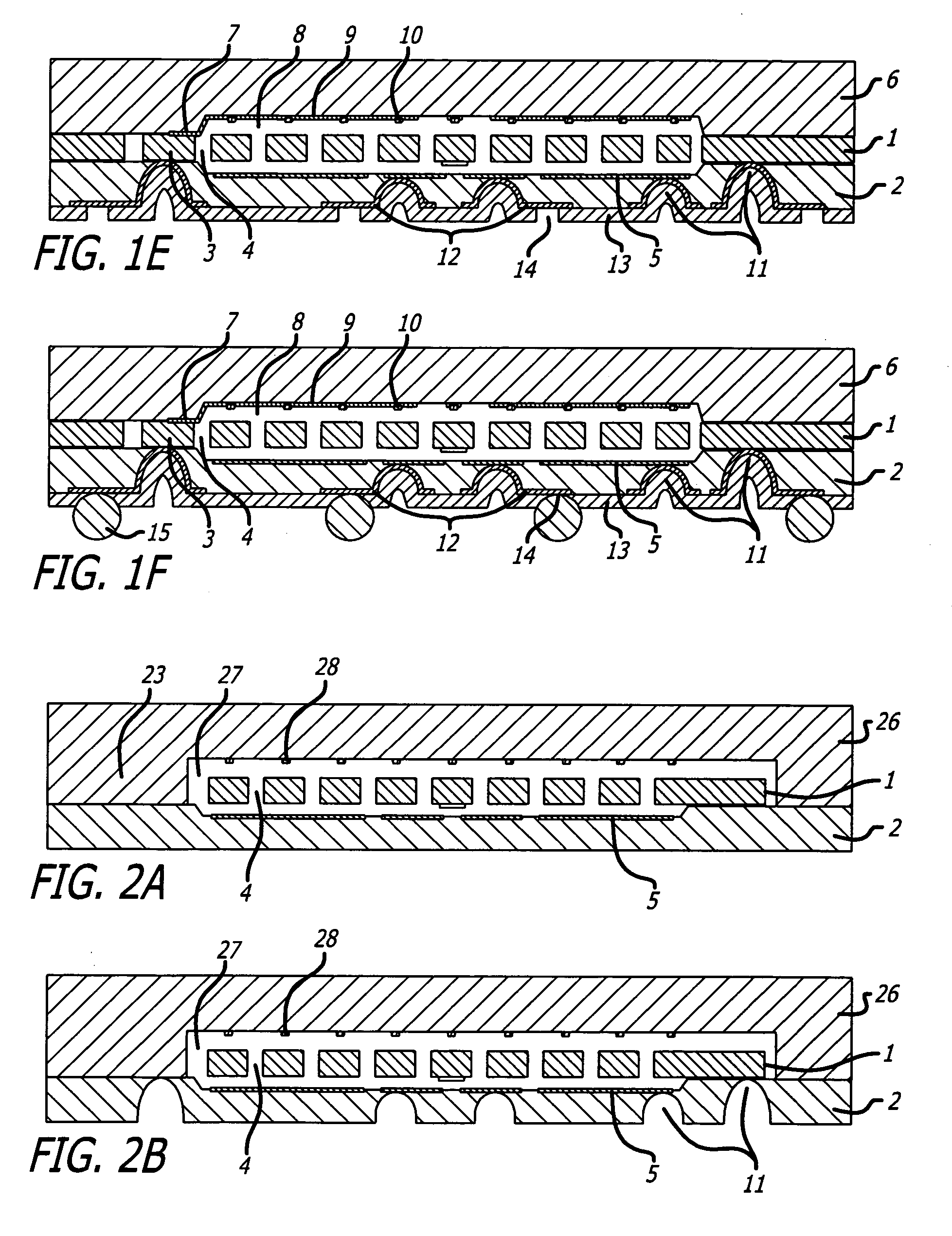

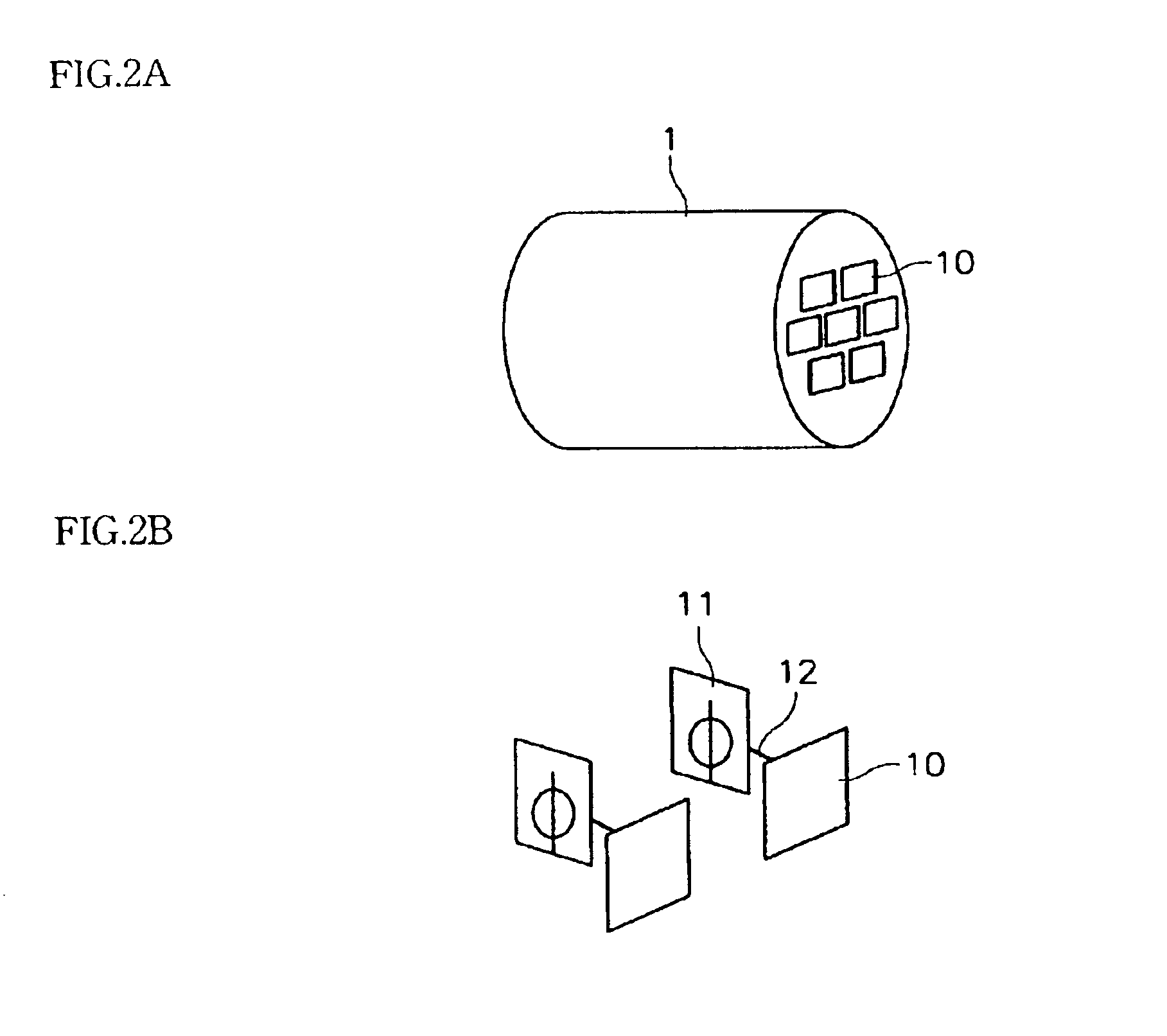

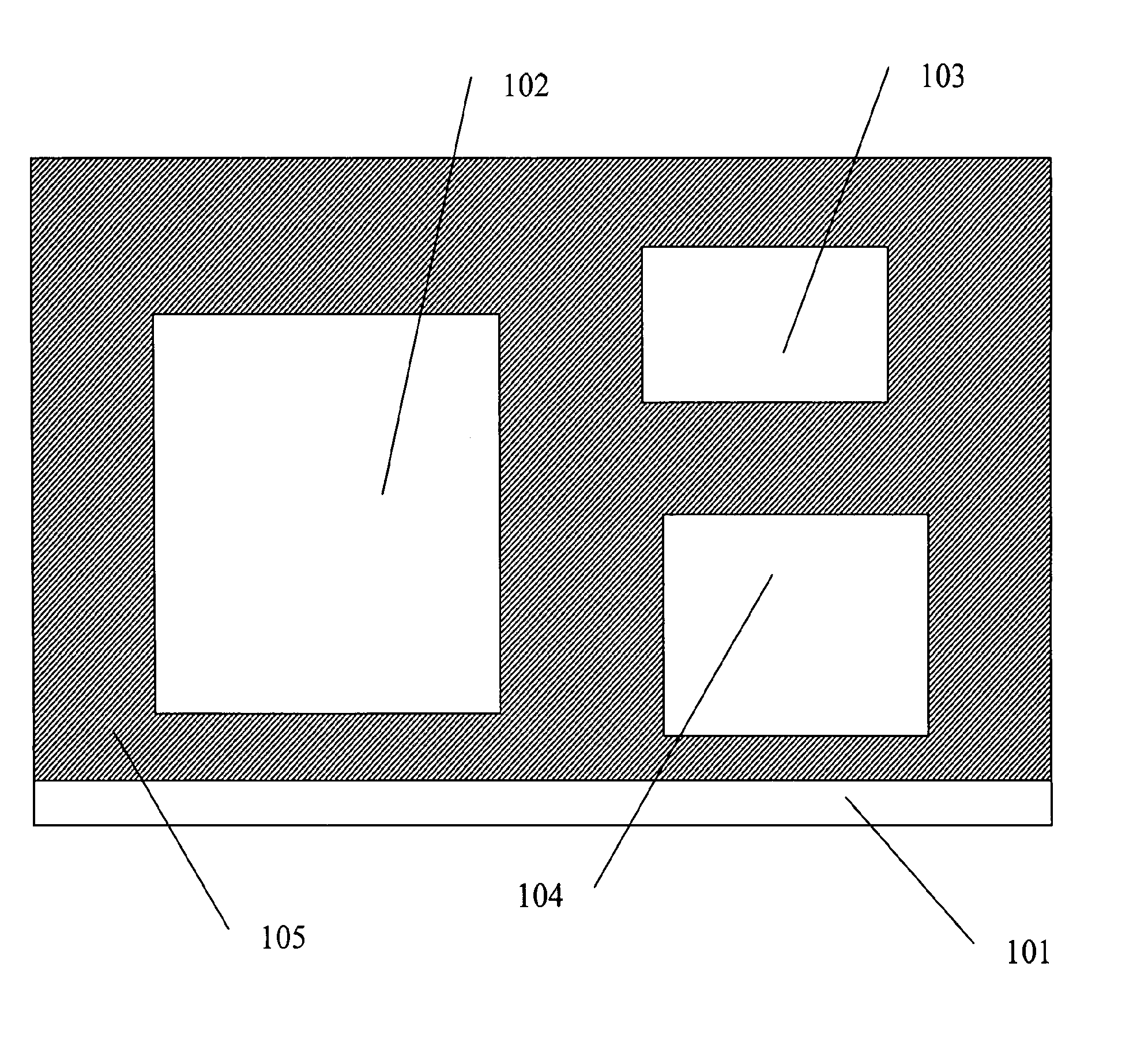

Wafer level packaging process

ActiveUS20070099395A1Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesThinningWafer-level packaging

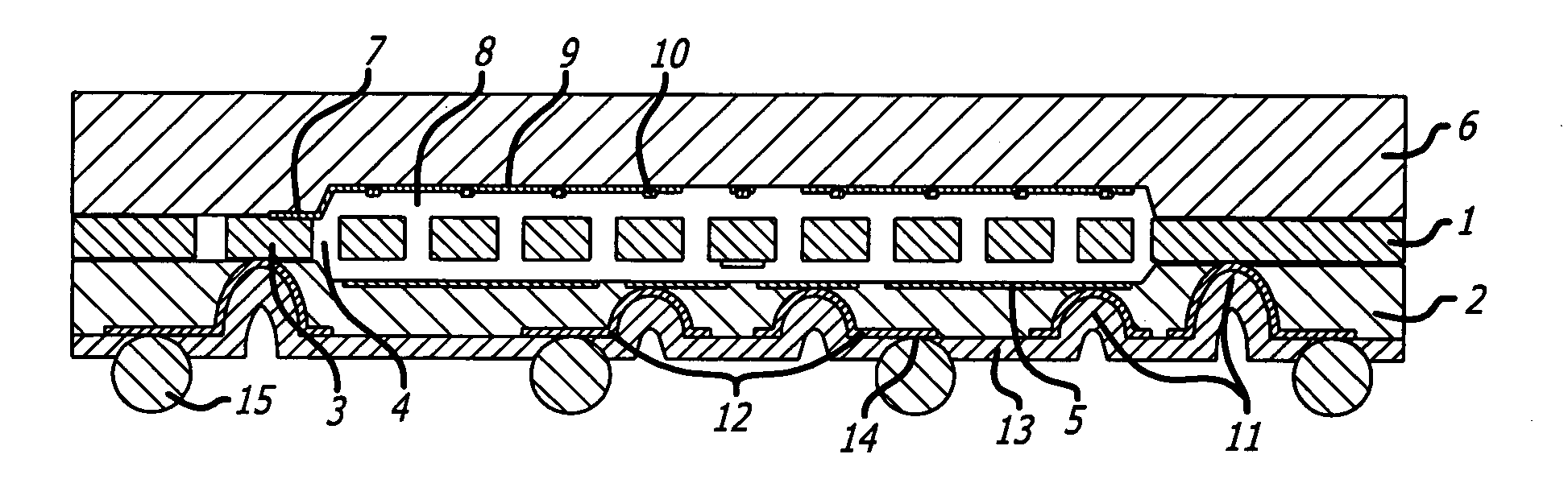

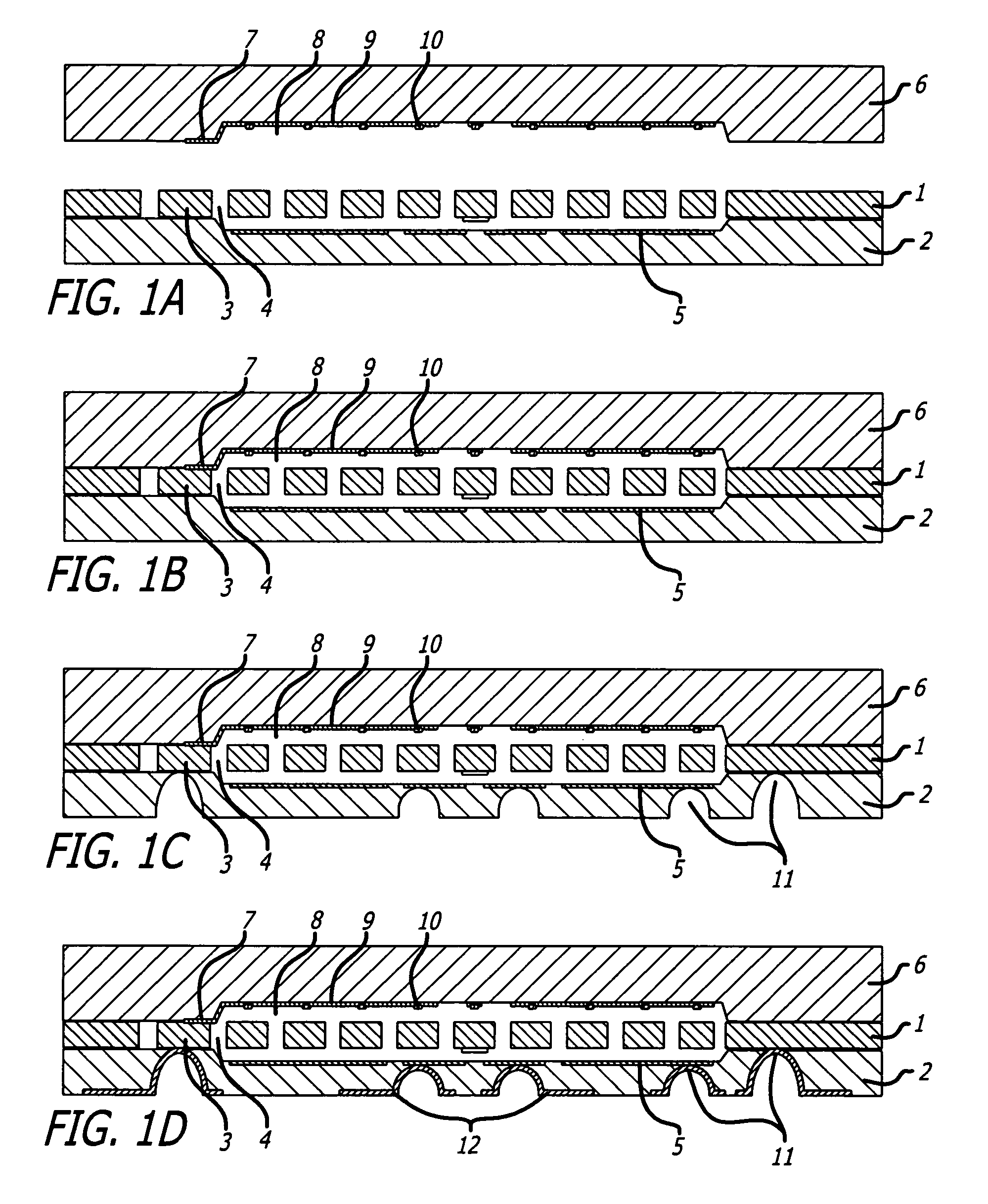

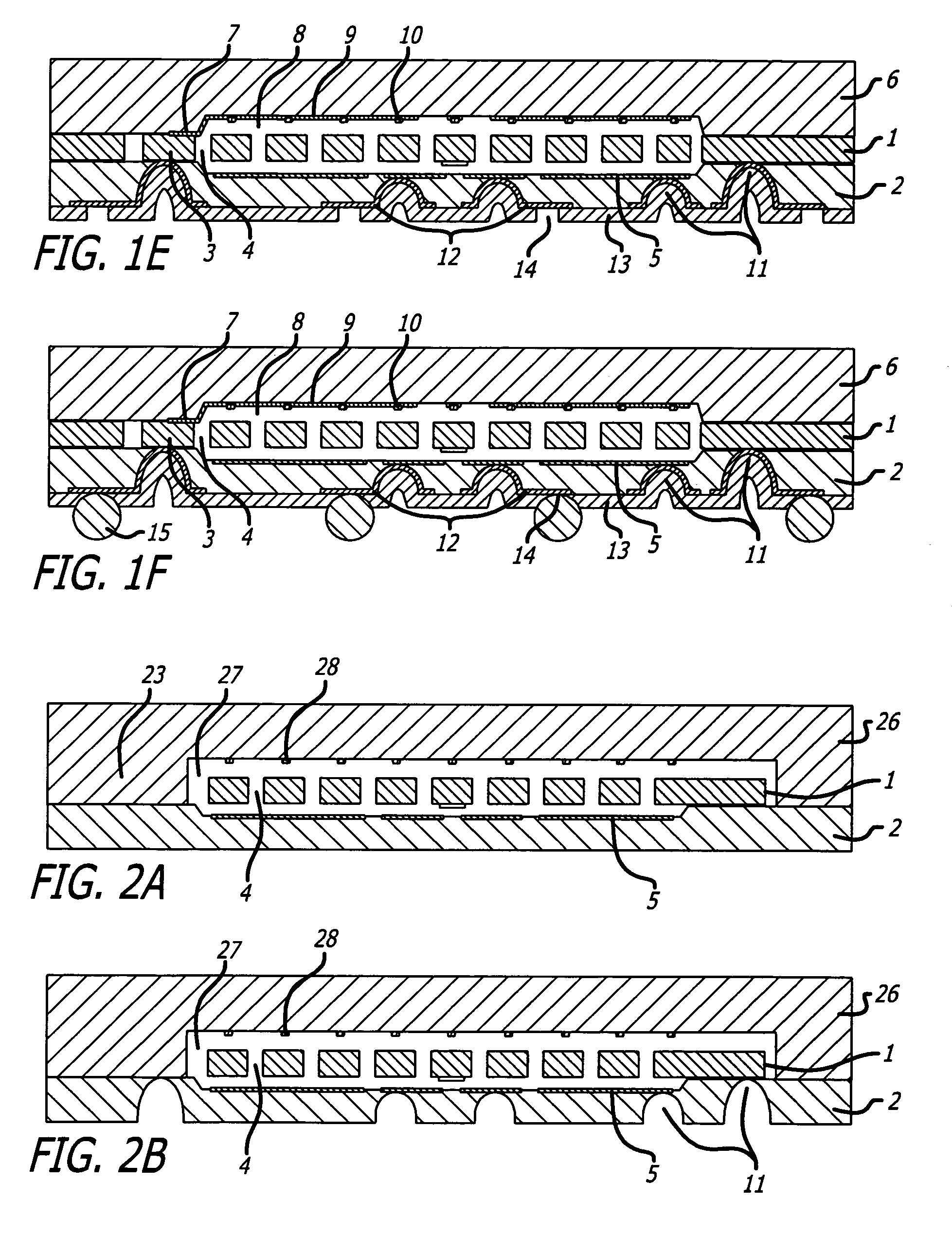

Wafer level packaging process for packaging MEMS or other devices. In some embodiments, a MEMS wafer with normal thickness is firstly bonded to a cap wafer of normal thickness, followed by a thinning on the backside of the MEMS wafer. After this, the bonded wafer stack and the capping of the hermetically packaged MEMS devices are still rigid enough to do further processing. On this basis, through vias on the thinned substrate can be easily formed and stopped on the regions to be led out (e.g., metal pads / electrodes, highly doped silicon, etc.). Vias can be partially filled as this is the final surface of process. Even thick metal coated / patterned vias have much more space to relax possible thermal stress, as long as the vias are not completely filled with hard metal(s). Various embodiments are disclosed.

Owner:MAXIM INTEGRATED PROD INC

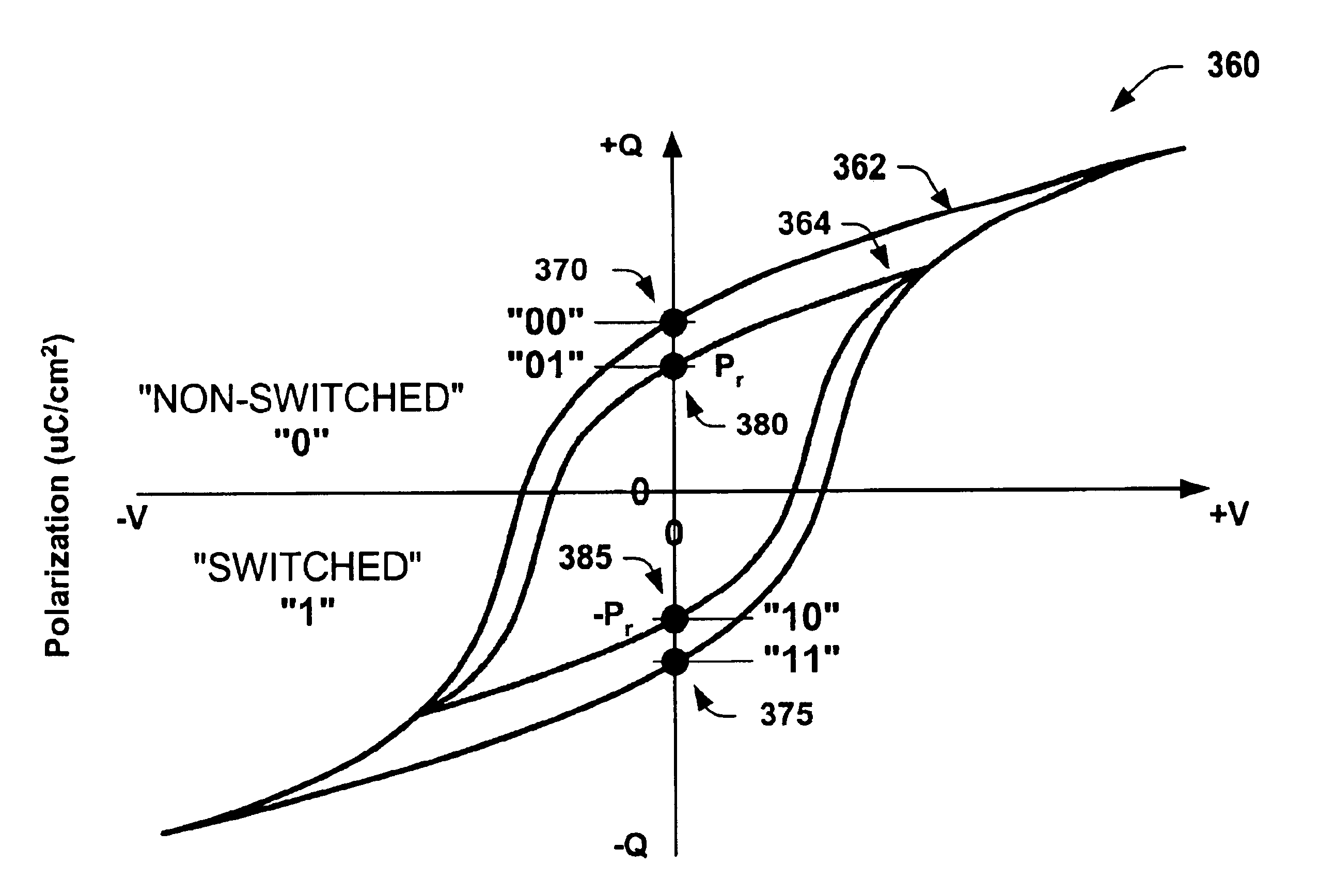

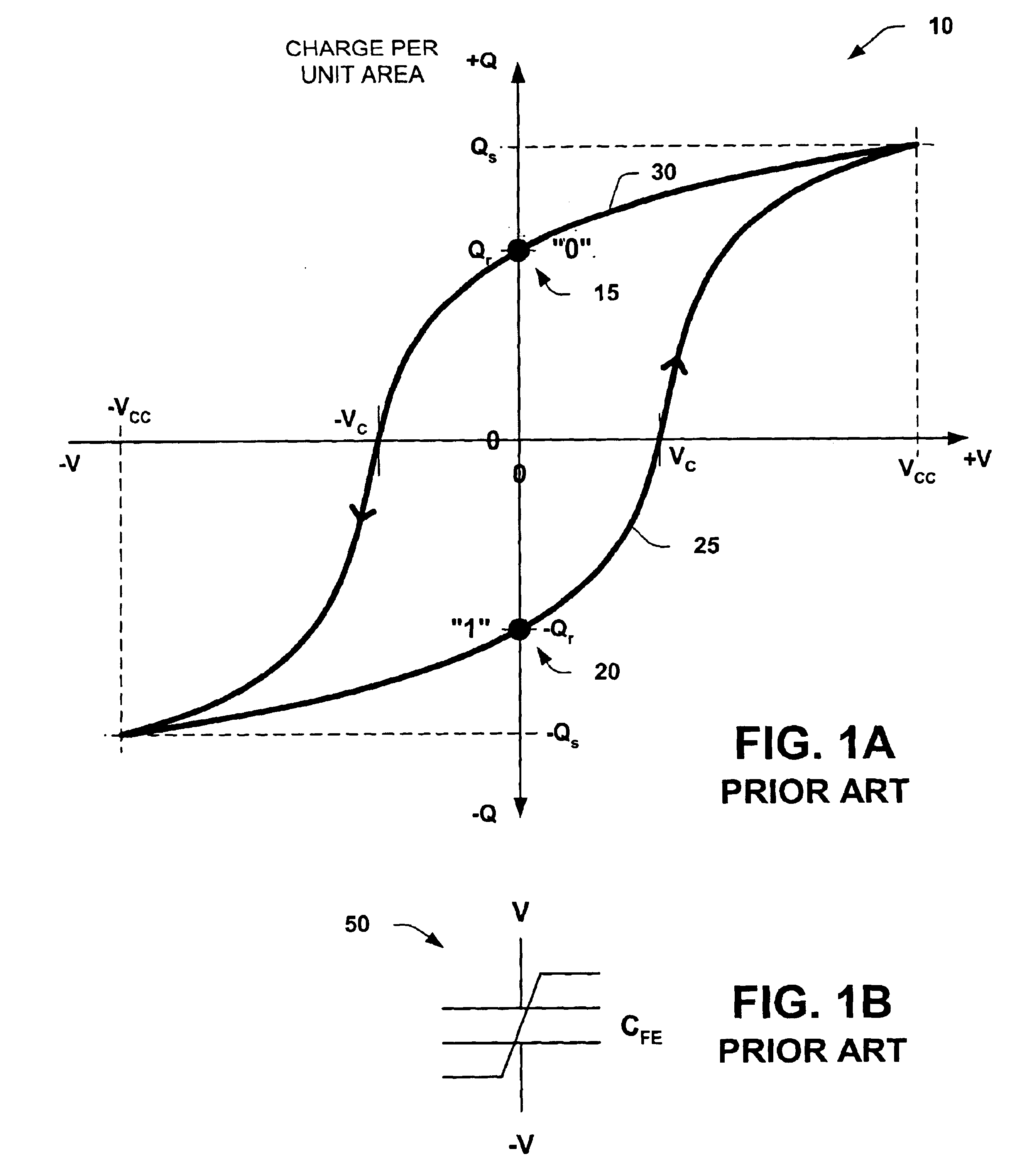

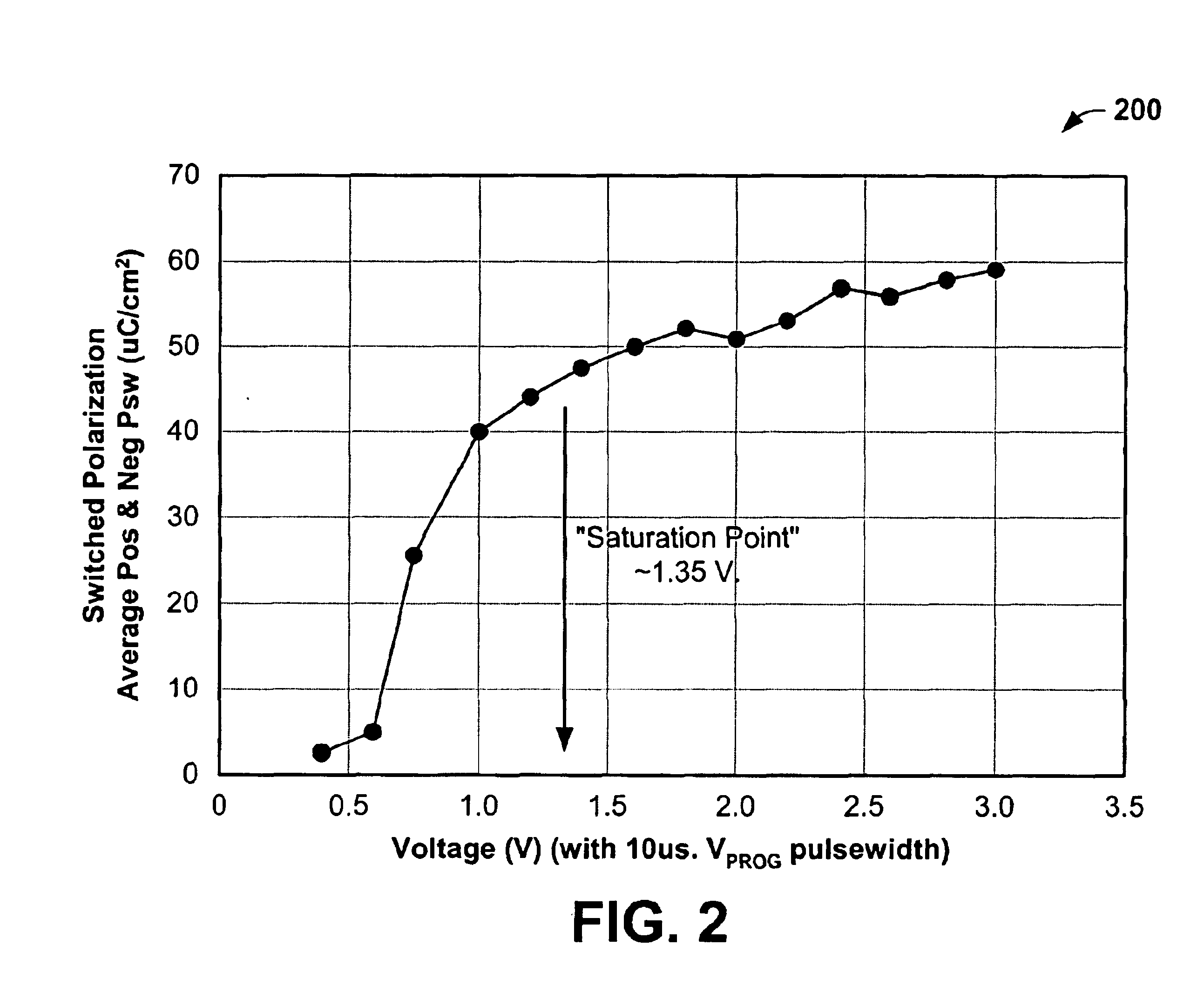

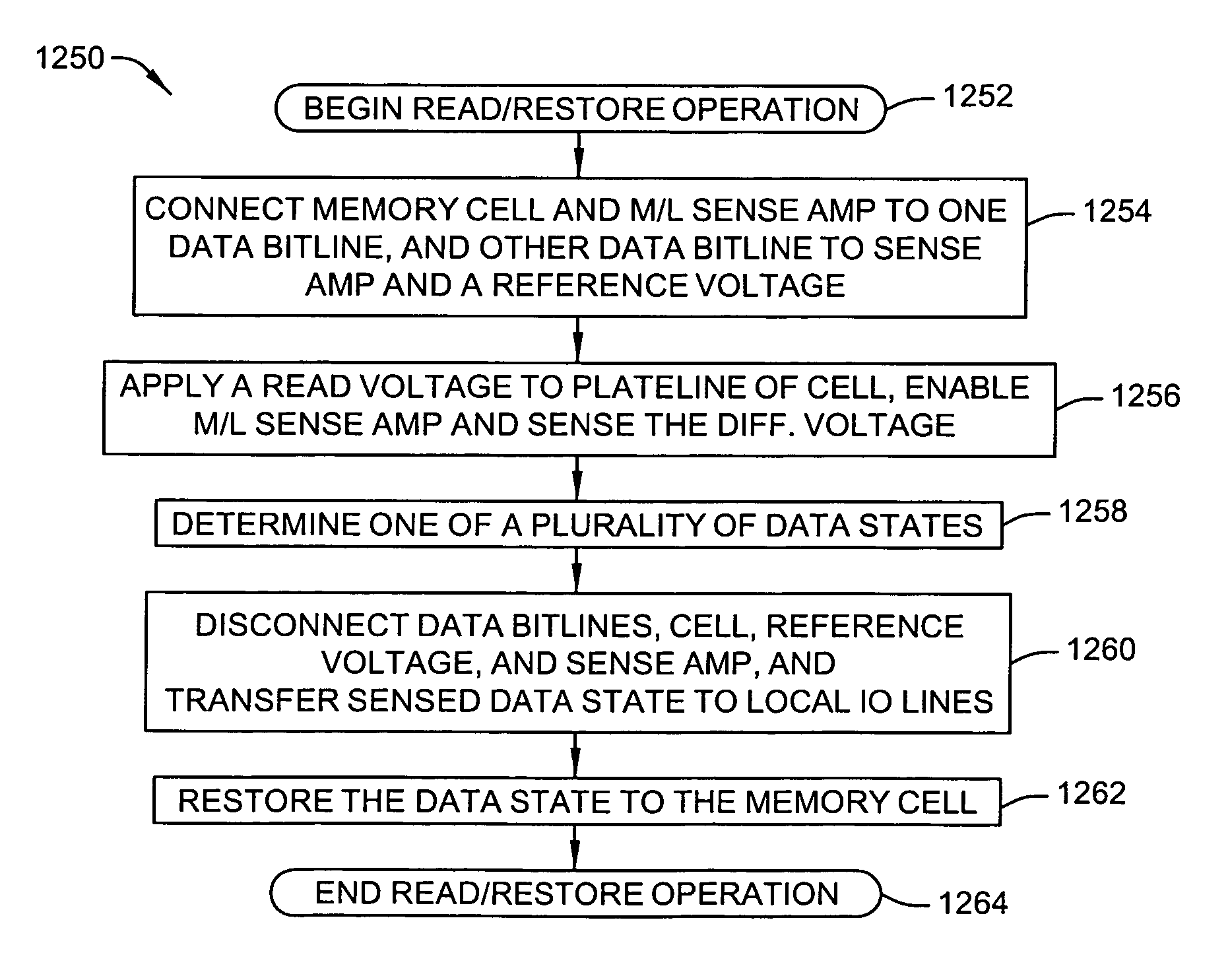

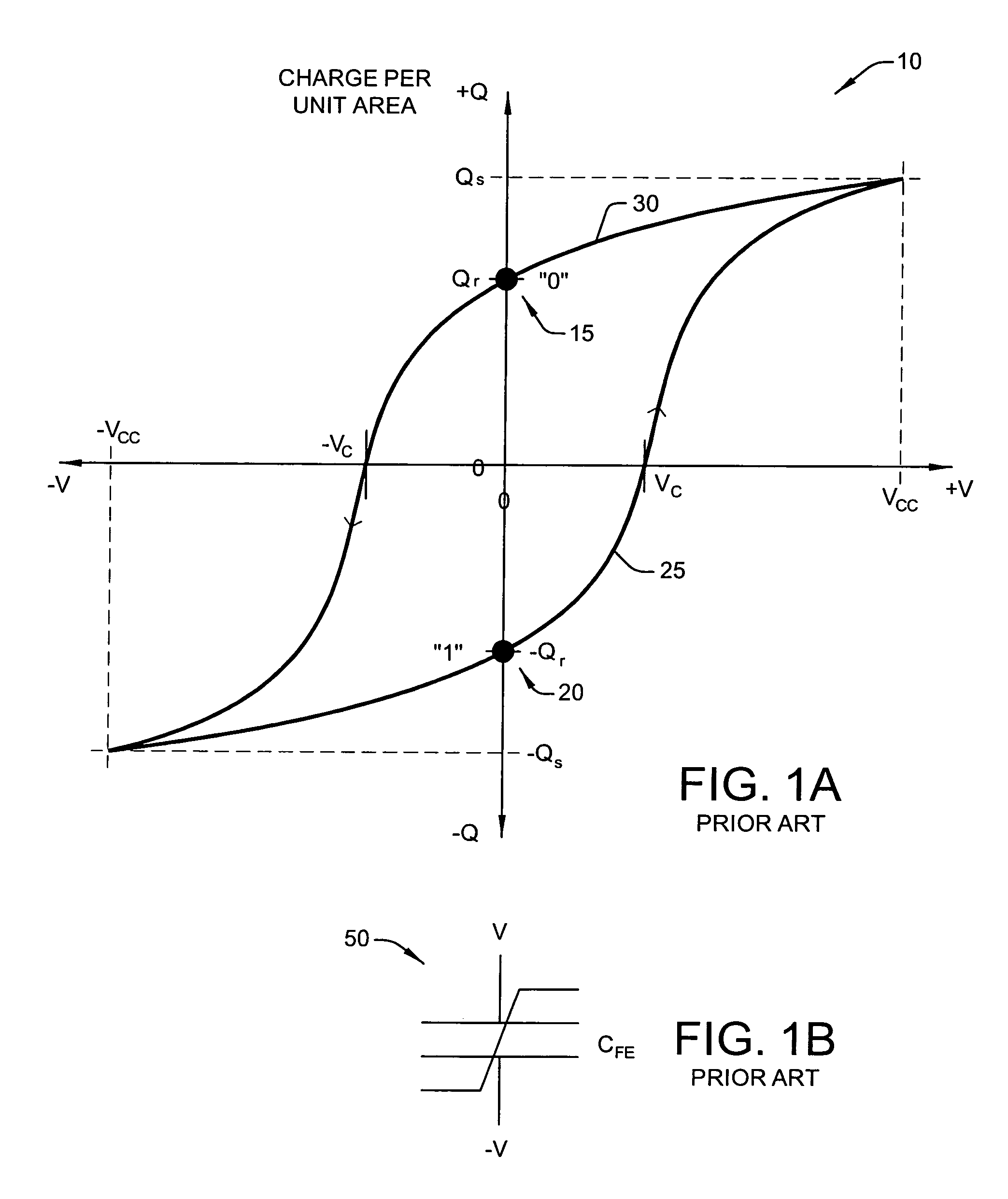

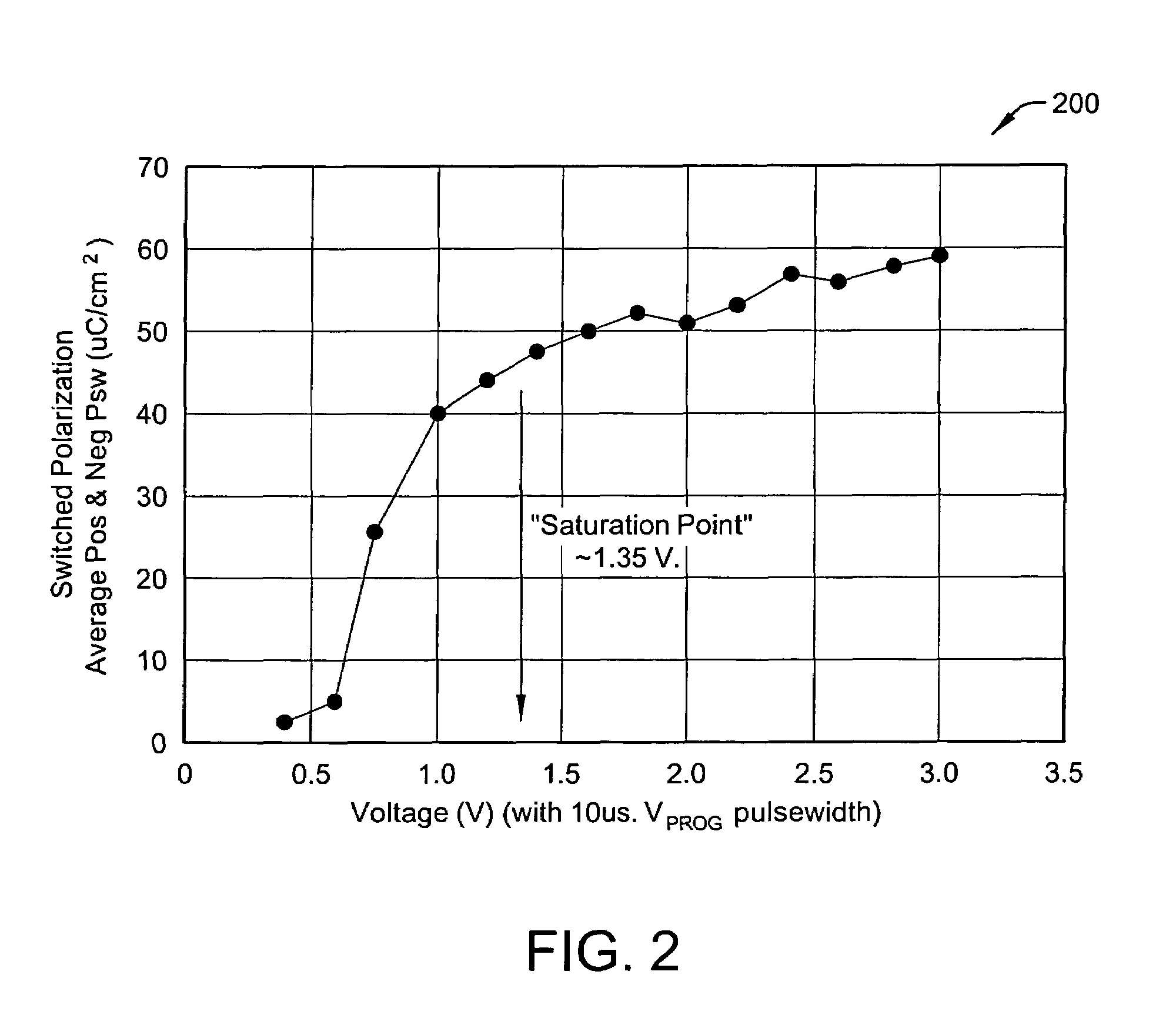

Ferroelectric memory with wide operating voltage and multi-bit storage per cell

InactiveUS6856534B2Avoid lossReduce the effective areaSolid-state devicesSemiconductor/solid-state device manufacturingSingle polarizationComputer hardware

Apparatus and methods are described for a multi-level FeRAM memory device. Using write and read circuits associated with the memory device, multiple data states may be written to and read from the ferroelectric memory device which are associated with a single polarization direction, thereby allowing for a single cell to contain more than one bit of data.

Owner:TEXAS INSTR INC

Wafer level packaging process

ActiveUS7393758B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesHard metalWafer stacking

Owner:MAXIM INTEGRATED PROD INC

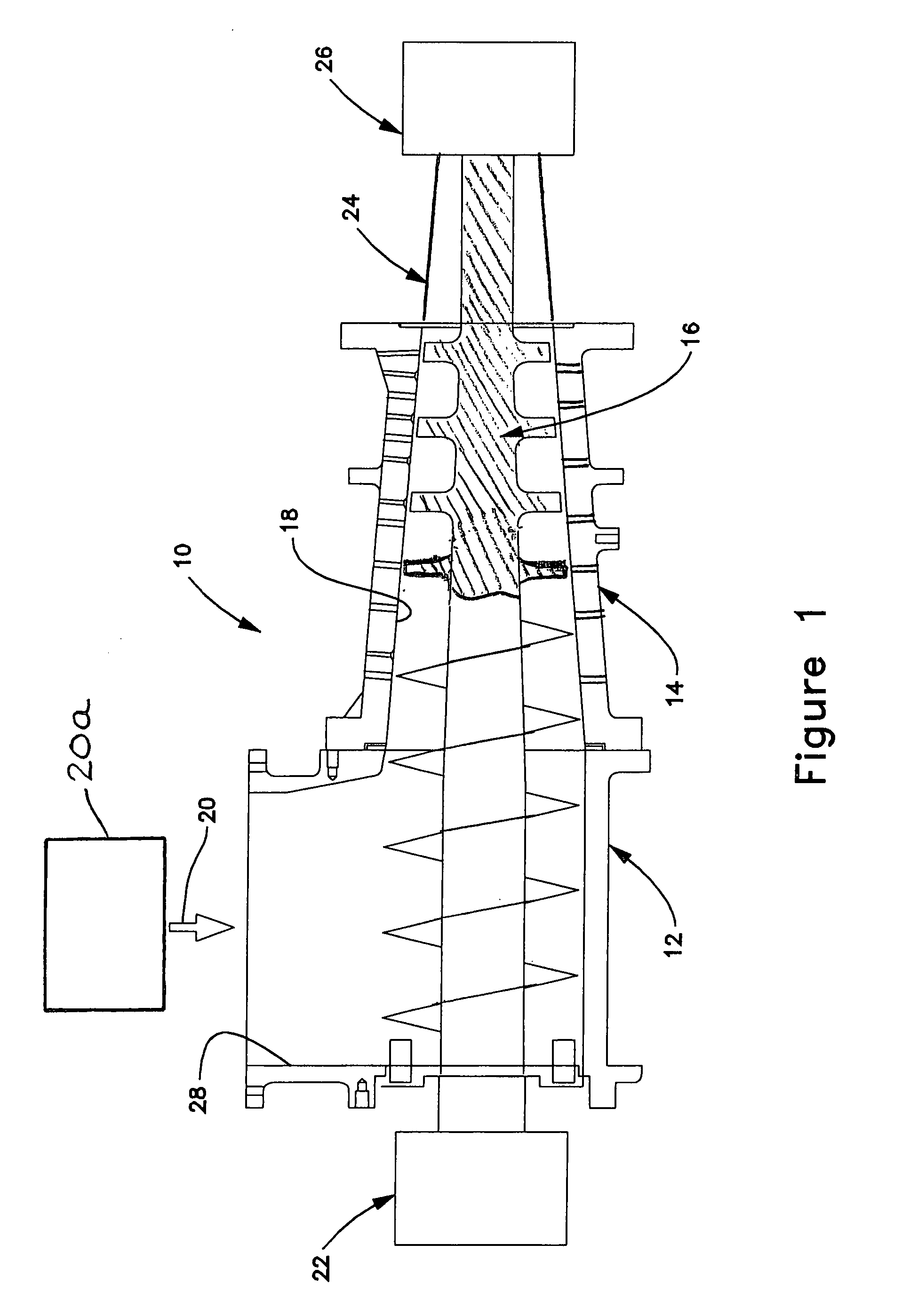

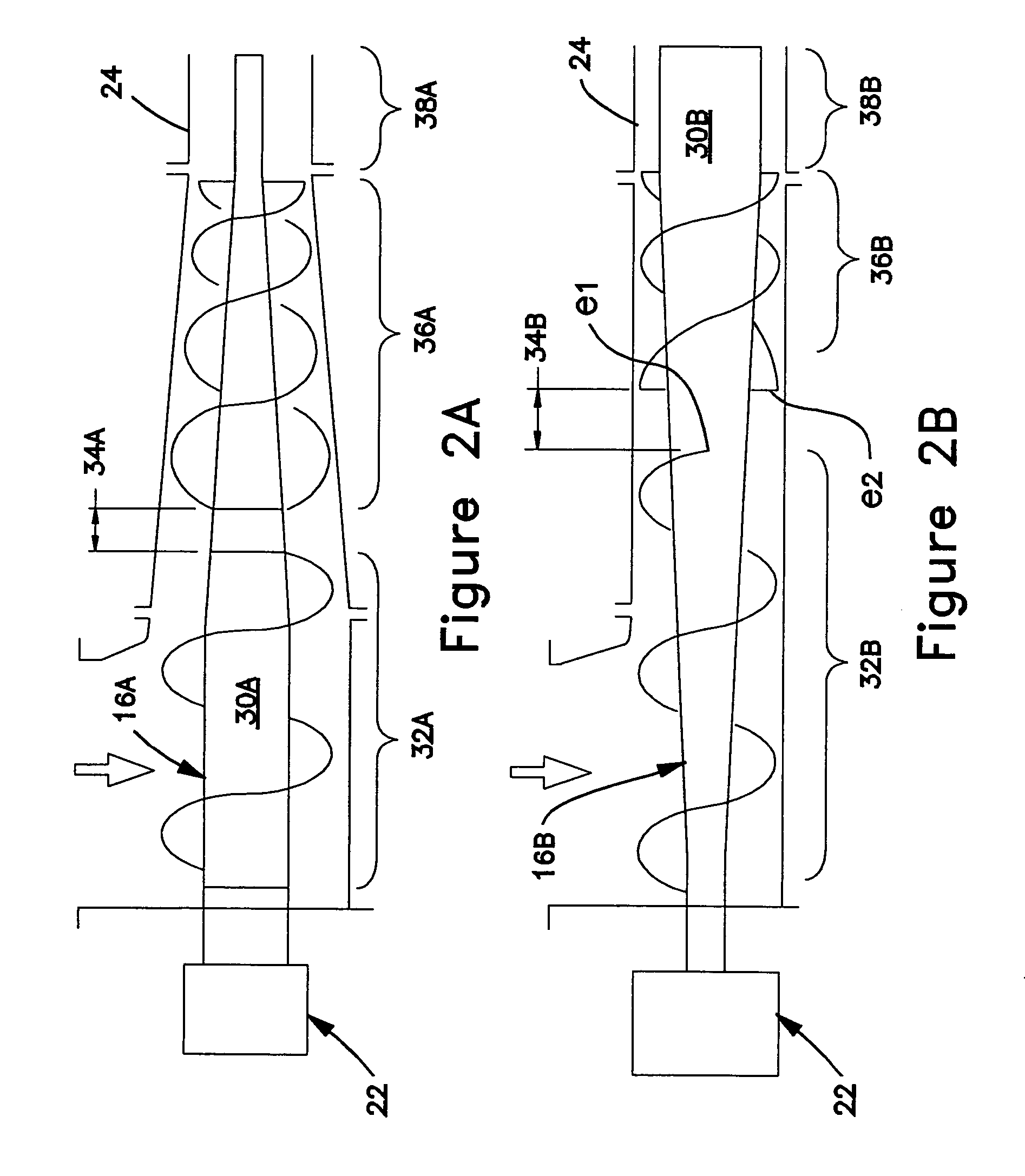

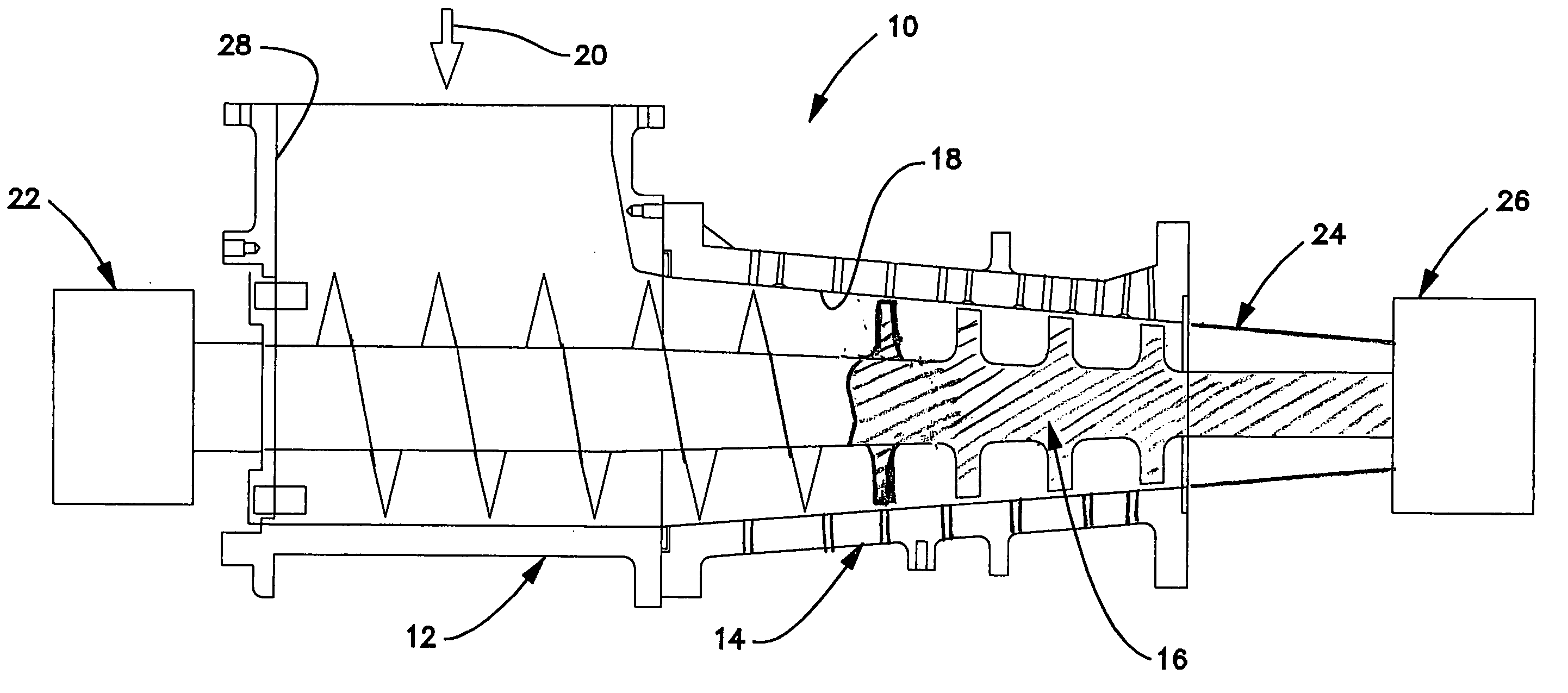

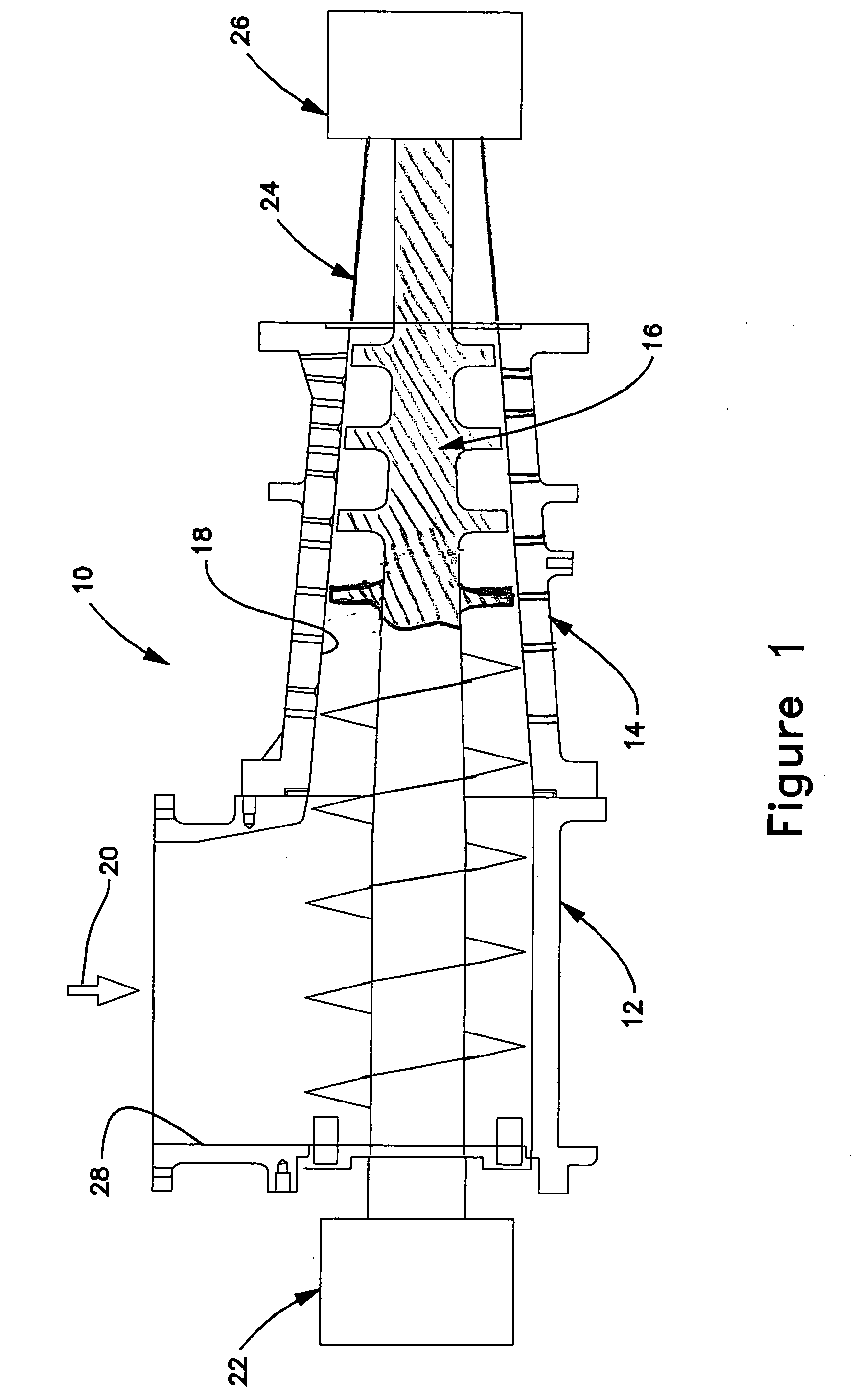

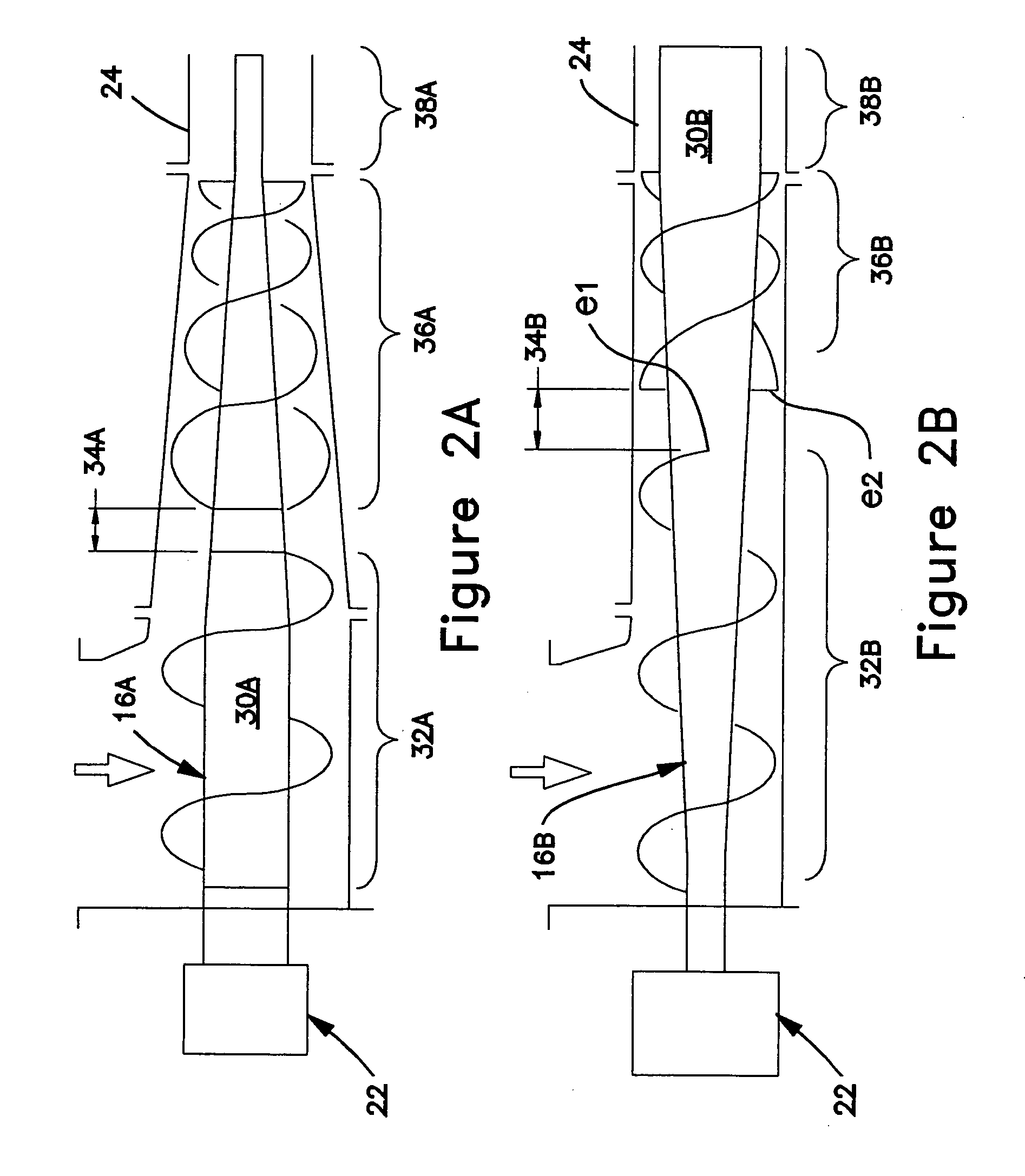

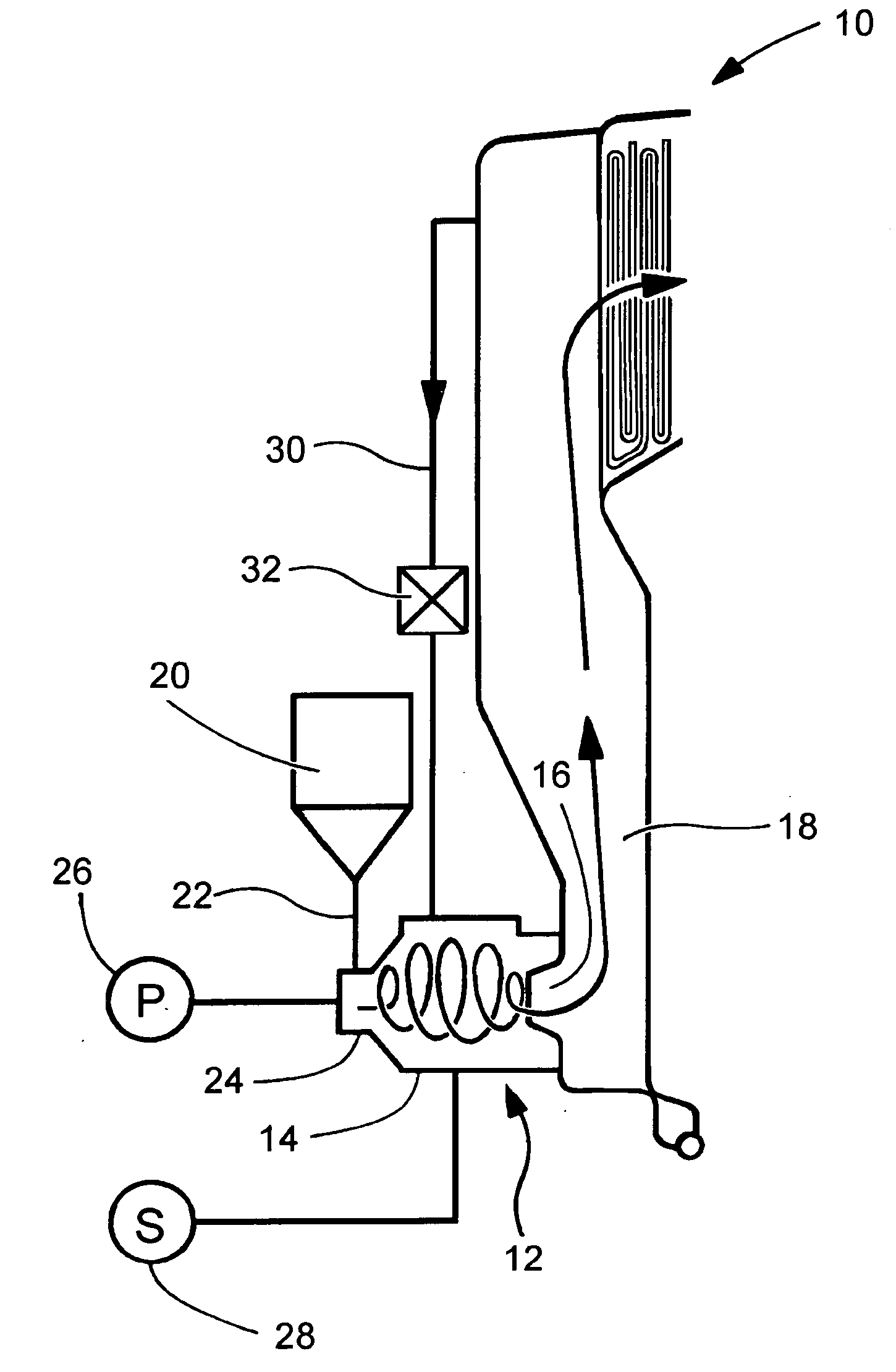

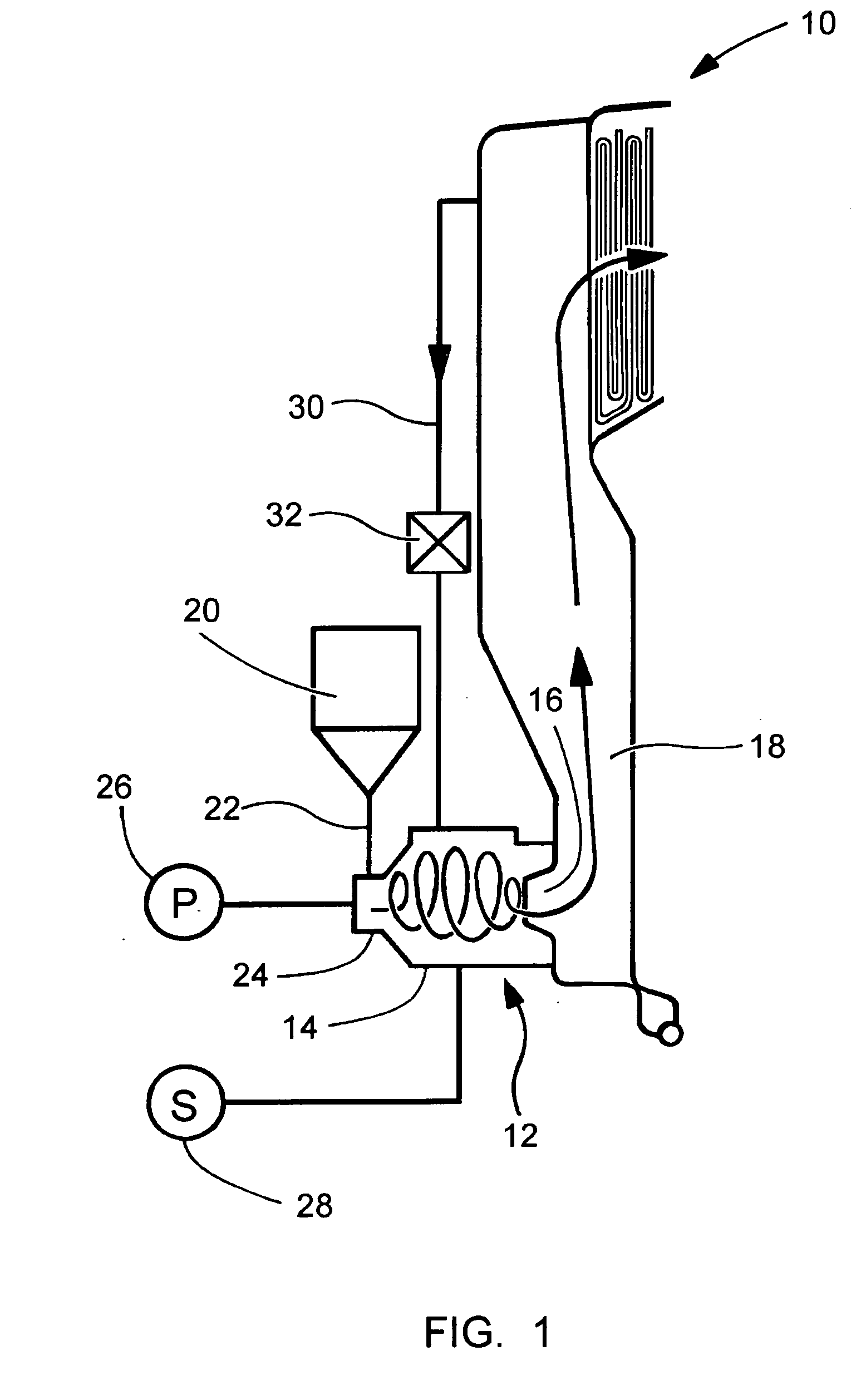

Compression screw with combination single and double flights

ActiveUS7357074B2Improve efficiencyEfficiently transitionSedimentation settling tanksRotary pressEngineeringScrew thread

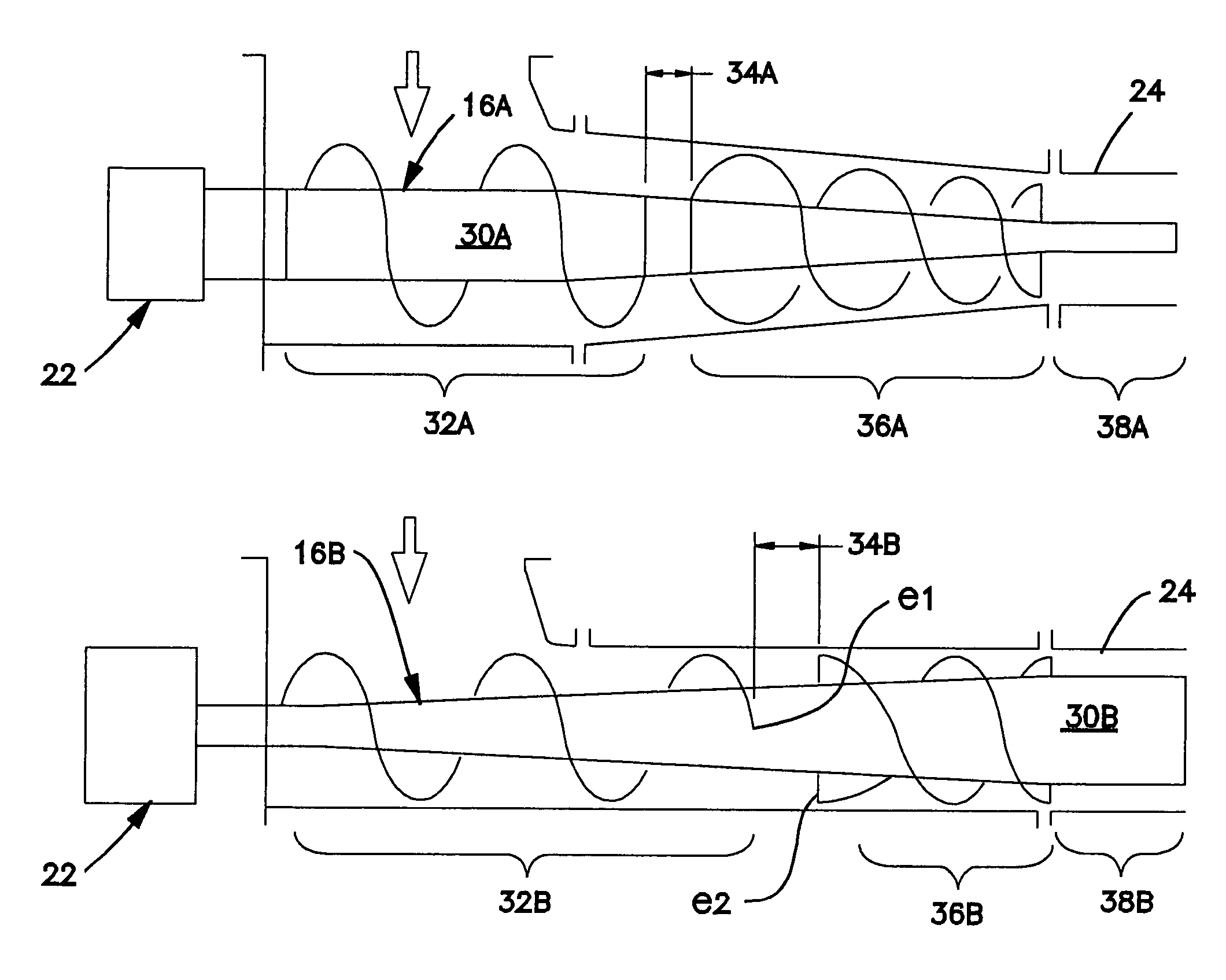

A screw for a compression dewatering device comprising an elongated shaft having axially spaced apart first and second ends, a conveying section at the first end of the shaft, having a single helical screw flight rigidly projecting from the shaft, a flightless transition section axially adjacent the conveying section, and a dewatering section axially adjacent the transition section, having a double helical screw flight rigidly projecting from the shaft. Another embodiment is a compression screw with similar characteristics having a perforated tubular dewatering wall intermediate the ends, followed by an imperforate spool wall at the discharge end. A gravity feed device is operatively associated with the inlet end of the screw shaft for depositing bulk solids material through the feed opening onto the conveying screw, and a drive system is operatively connected to the inlet end of the screw for rotating the screw in the housing.

Owner:ANDRITZ INC

Ferroelectric memory with wide operating voltage and multi-bit storage per cell

InactiveUS7304881B2Refreshed periodicallyReduce the effective areaSolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareSingle polarization

Apparatus and methods are described for a multi-level FeRAM memory device. Using write and read circuits associated with the memory device, multiple data states may be written to and read from the ferroelectric memory device which are associated with a single polarization direction, thereby allowing for a single cell to contain more than one bit of data.

Owner:TEXAS INSTR INC

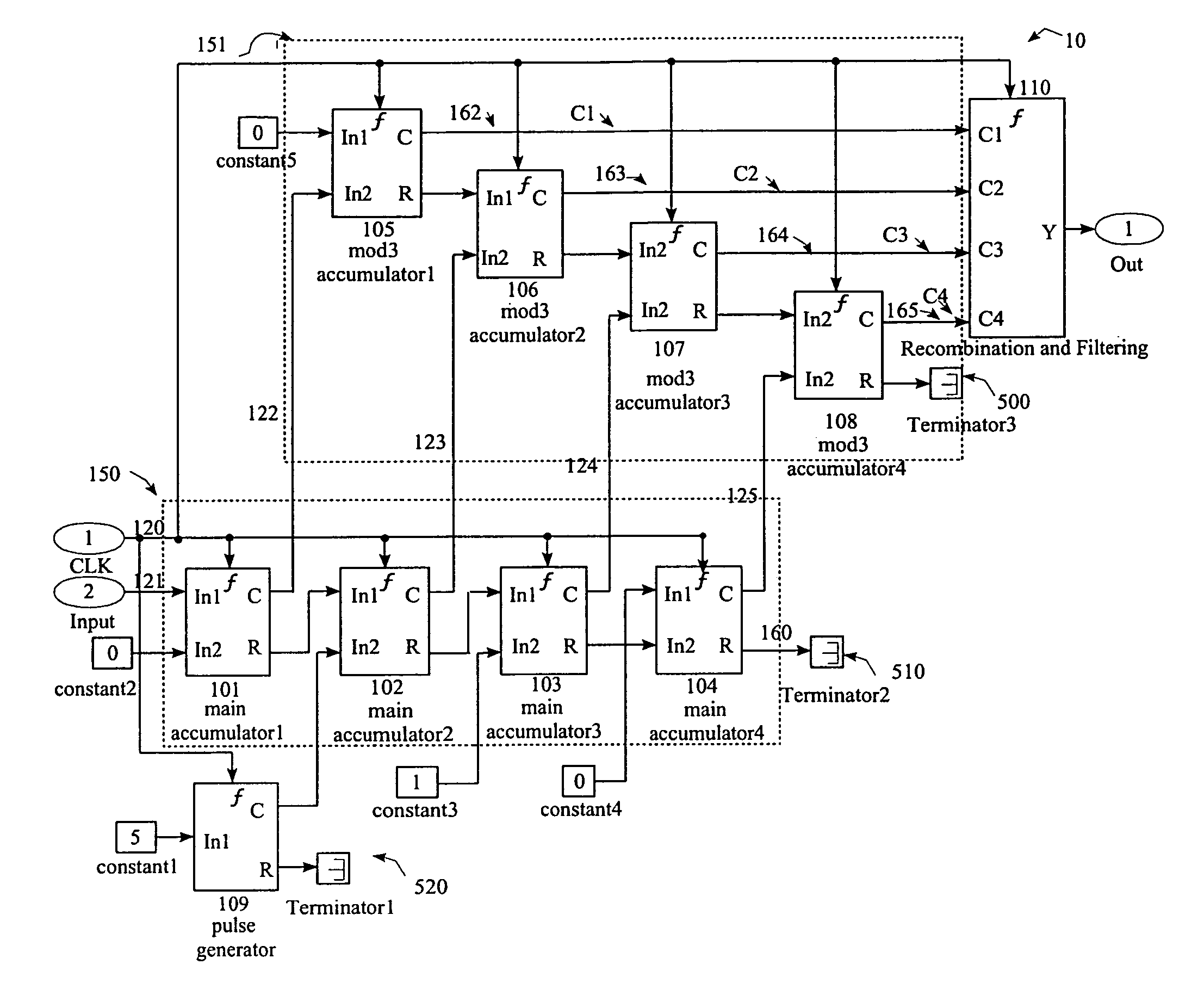

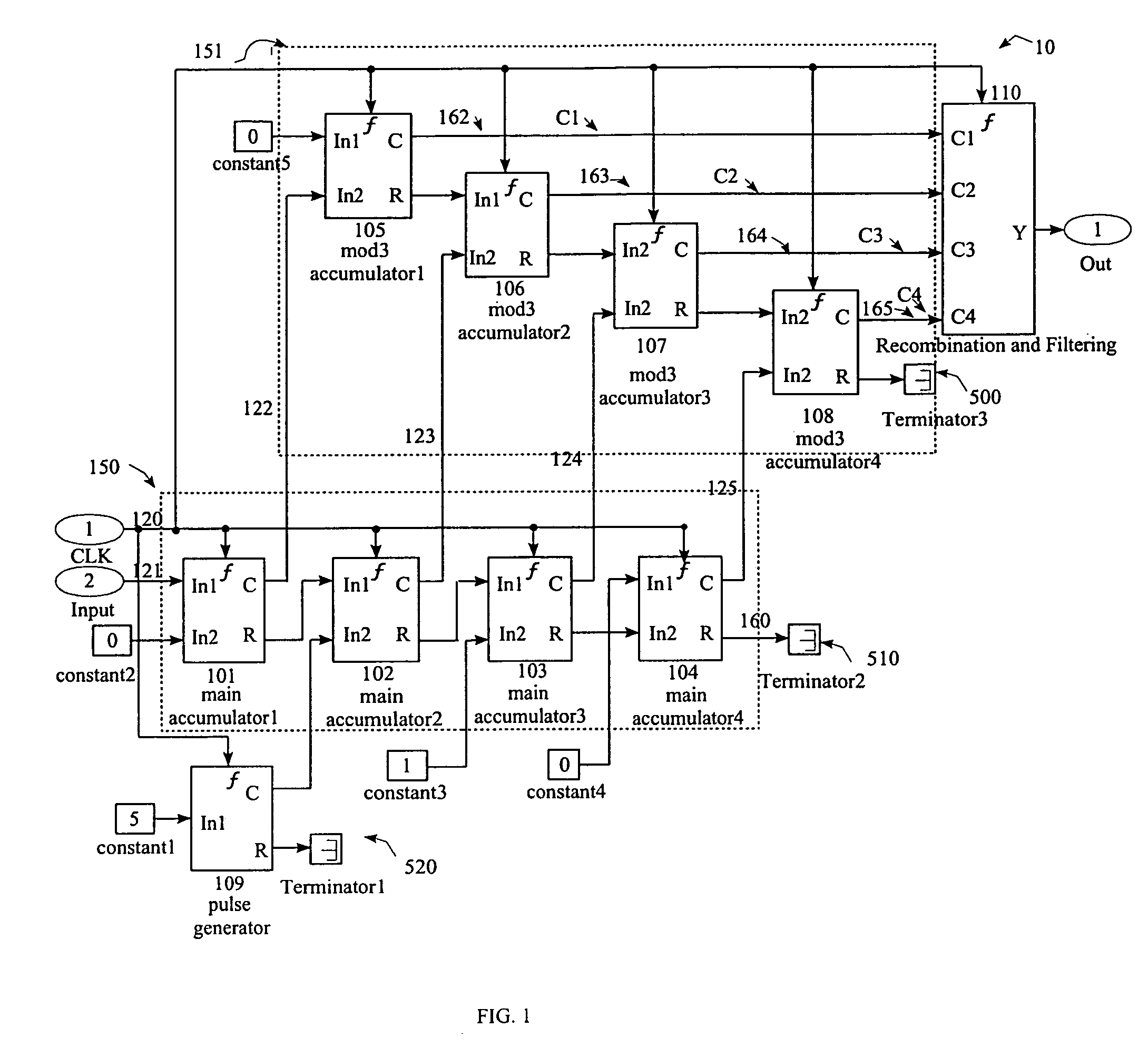

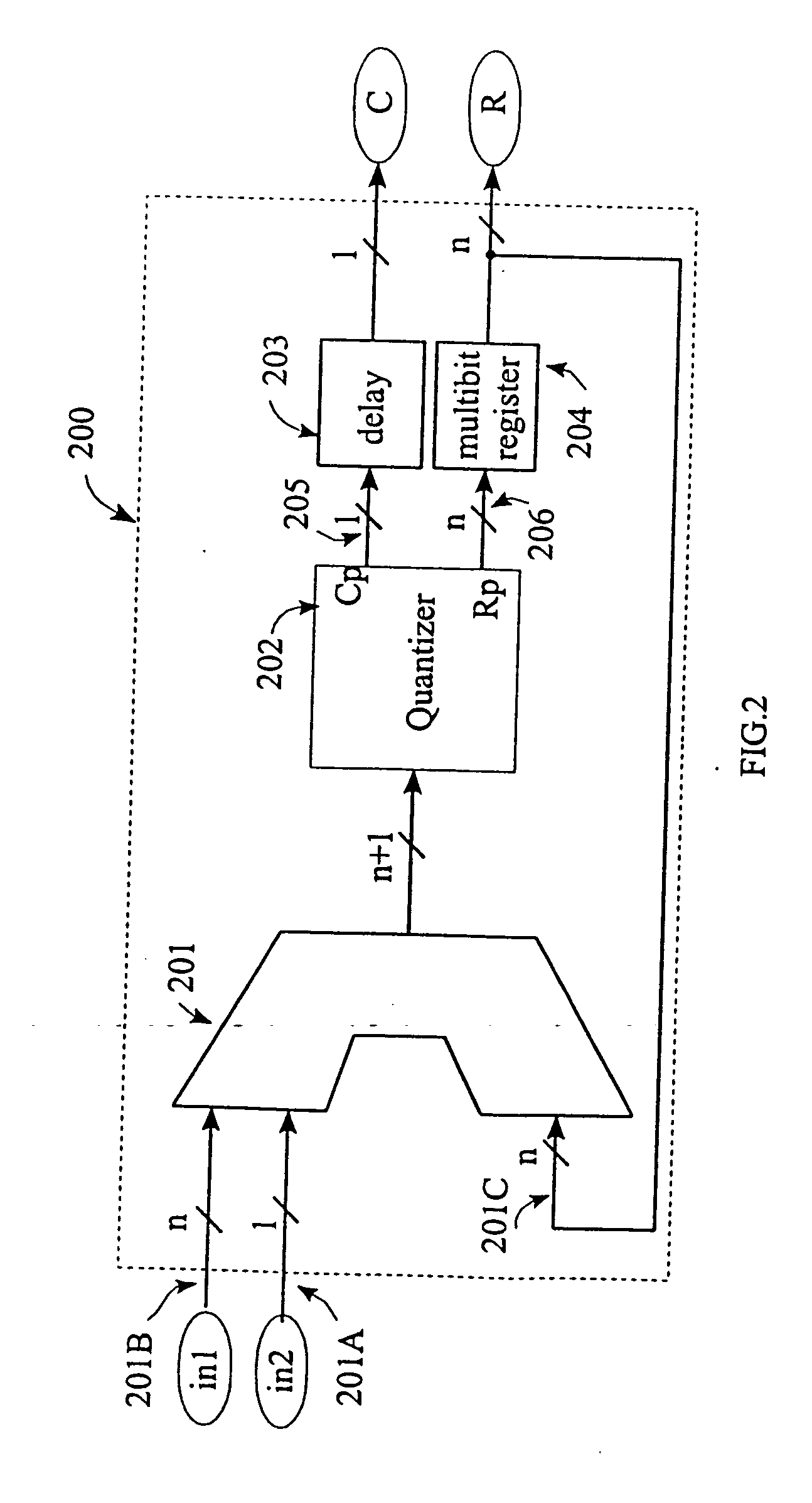

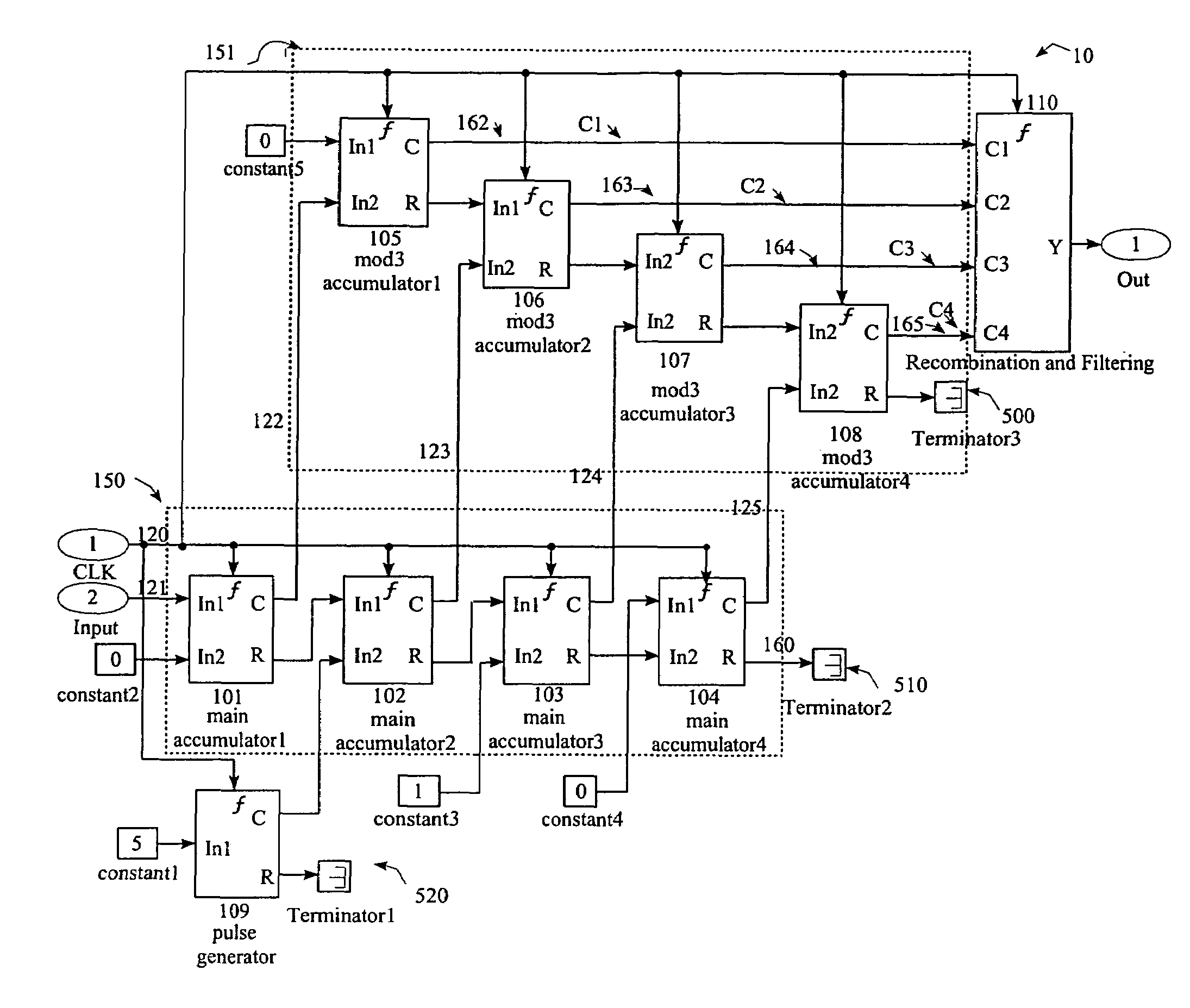

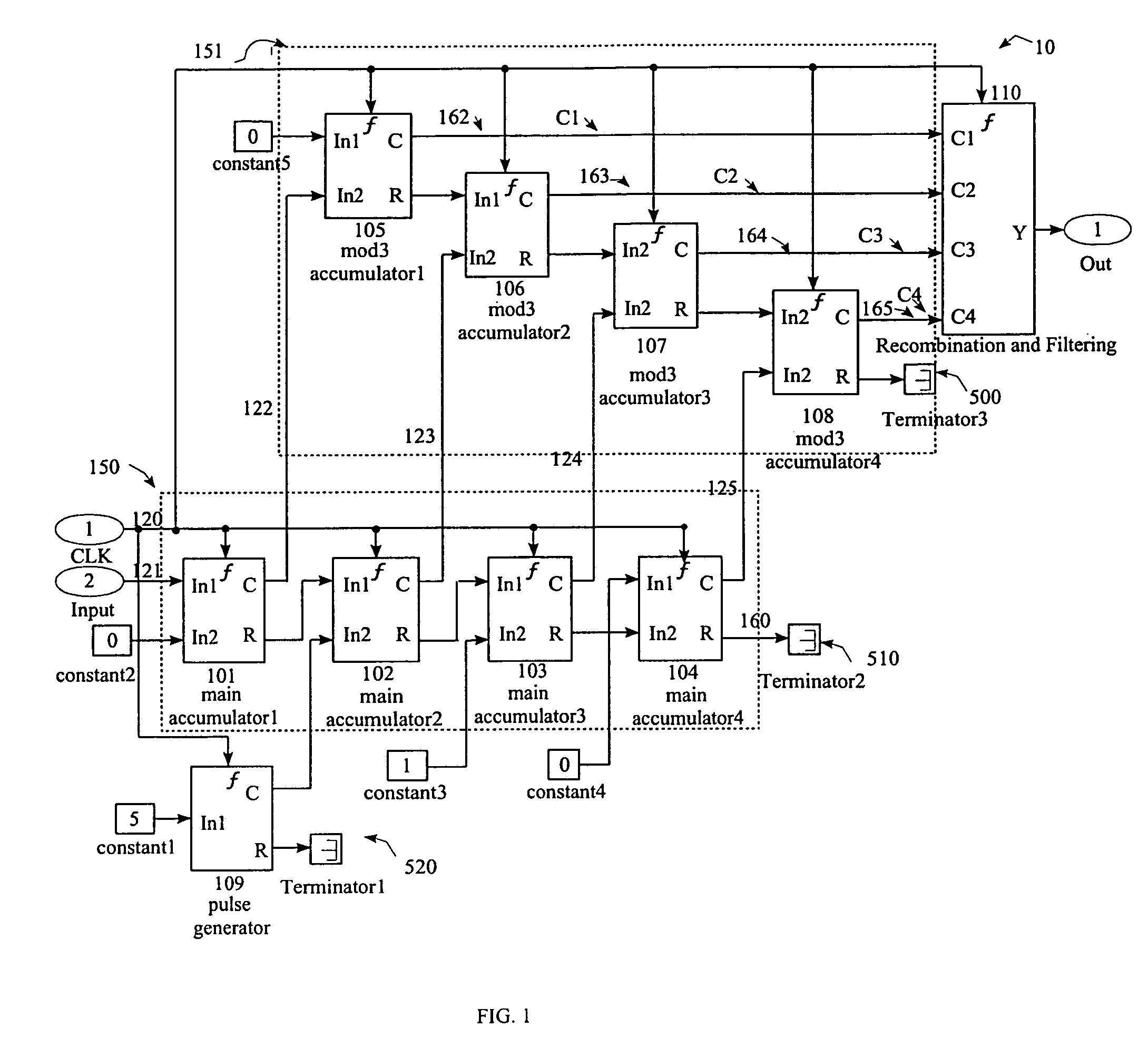

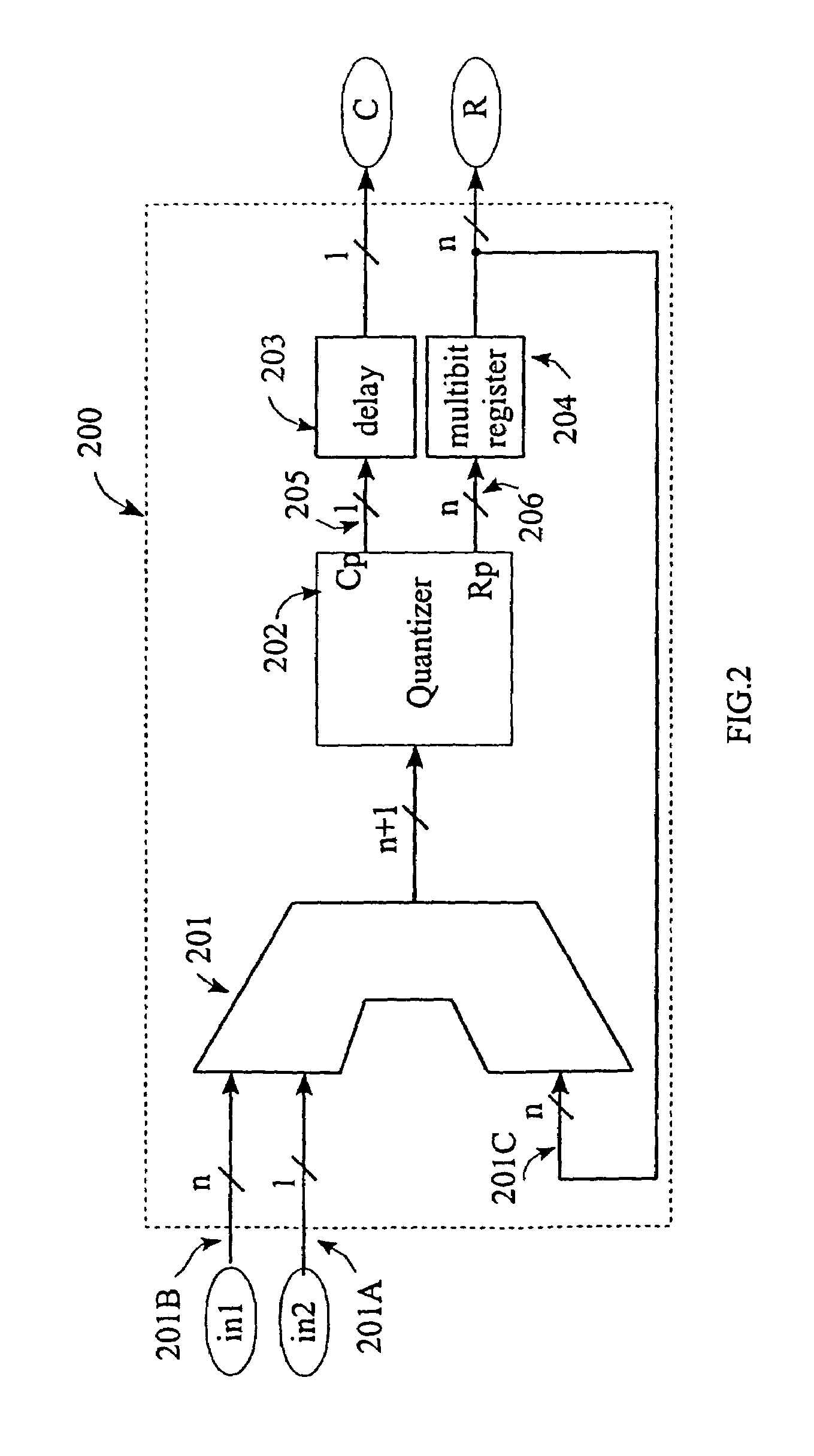

Multiple stage delta sigma modulators

InactiveUS20070018871A1Highly problematicElectric signal transmission systemsPulse automatic controlImage resolutionFrequency synthesizer

A delta sigma modulator which employs a plurality of accumulators with non-power-of-2 modulus. The accumulators may consist of a primary non-power-of-2 modulus accumulator and a secondary non-power-of-2 modulus accumulator. The number of bits in the primary accumulators affects the frequency resolution of the resultant delta sigma fractional N frequency synthesizer and can be the minimum number of bits required by the resolution specification. The secondary accumulator integrates the carry outputs of its corresponding primary accumulators. This integration results in attenuating the dc content of the modulator output by a factor equal to the modulus of the secondary accumulators and may require compensation in the recombination block.

Owner:KABEN WIRELESS SILICON

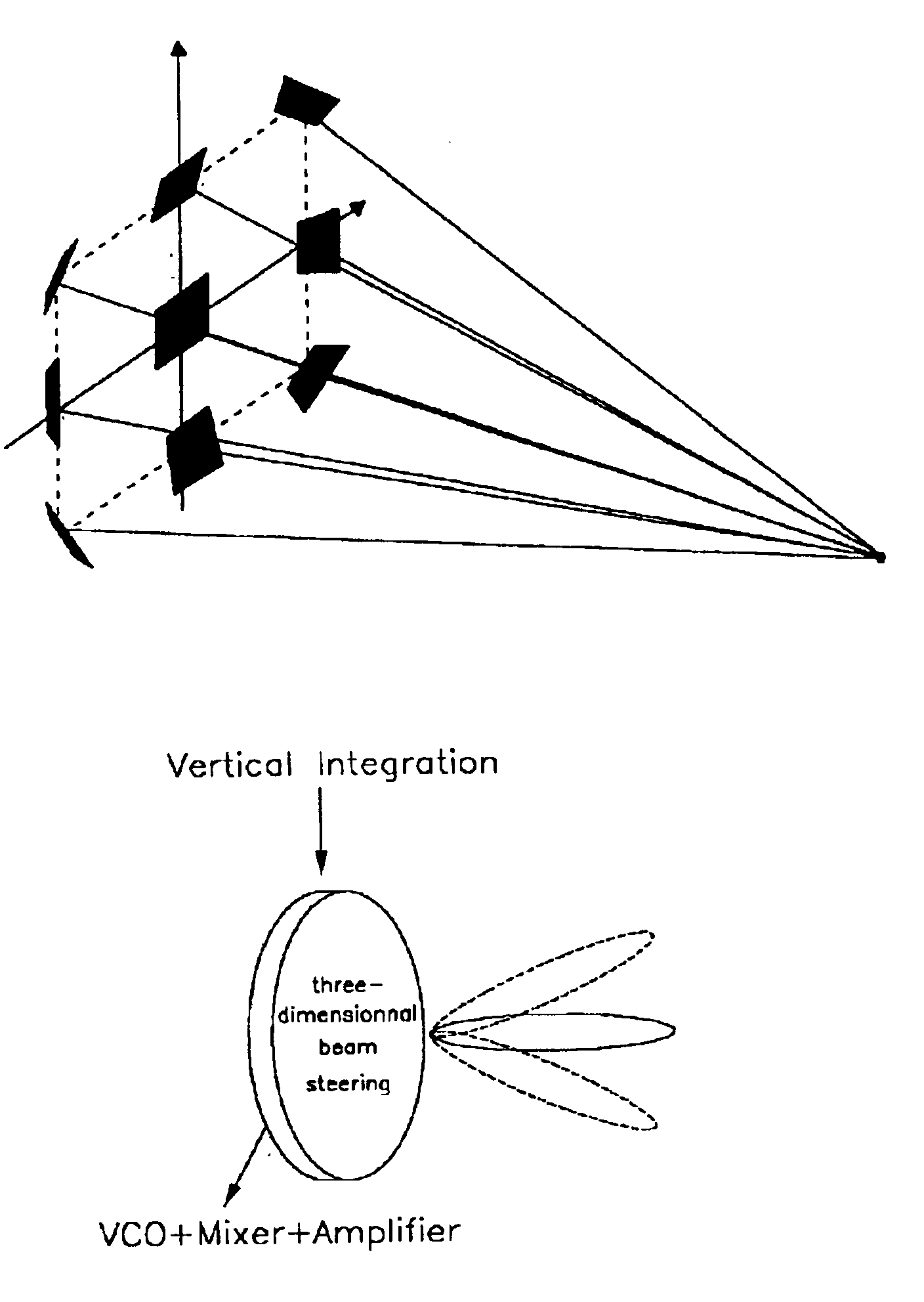

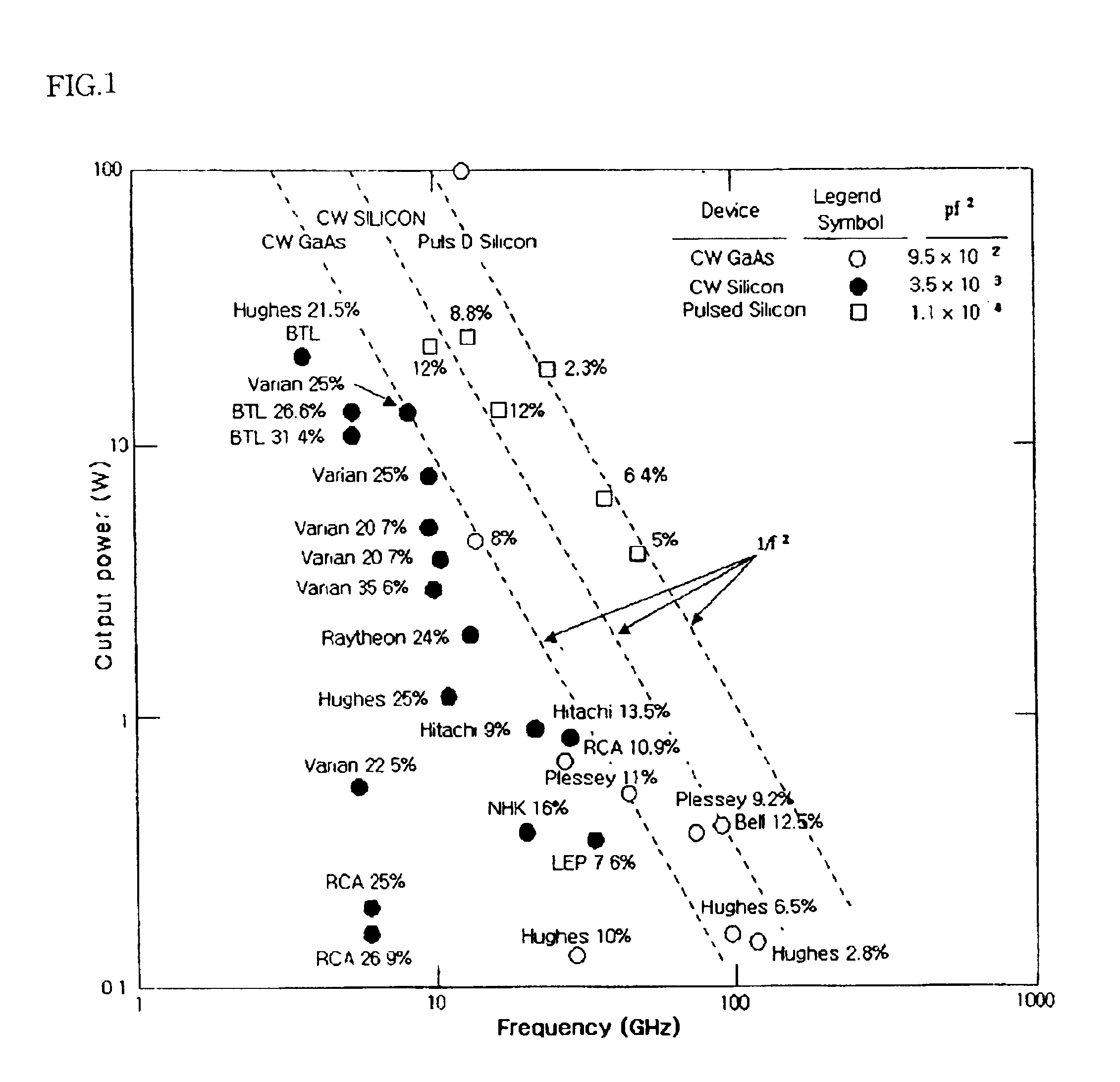

3-dimensional beam steering system

InactiveUS6873289B2Increase receiving powerReception problemSimultaneous aerial operationsRadiating elements structural formsElectricityLight beam

The present invention relates to a beam steering system. The system includes an array of a plurality of antenna elements, each antenna element being electrically and mechanically controlled for steering a beam in a specific direction, and a millimeter wave subsystem quasi-optically integrated with a 3-dimensional beam steering device and an MMIC-type active circuit. The antenna element is controlled in real time by an electrical driving method so as to be moved in 2-dimensional space. That is, in the 3-dimensional system of the present invention, the beam is electrically controlled by a phase shifter, and each antenna element is physically moved by a mechanical driving mechanism. The 3-dimensional beam steering antenna and the associated devices are monolithically integrated on a substrate using MEMS technology, and the active circuit elements such as a mixer, a power amplifier (PA), a low noise amplifier (LNA), a VCO, etc. are integrated in an MMIC active array. The 3-dimensional beam steering device and the active MMIC circuit are integrated into one system by being interconnected using the quasi-optical technique. According to the present invention, shortcomings of the millimeter wave in that the SNR is low due to the low device output and high transmission loss in the free space can be overcome using the new RF transmission technique of 3-dimensional beam steering, and by introducing a micro antenna structure which is electrically and mechanically controlled such that wideband RF communication and 3-dimensional imaging is allowed in a Pico cell environment.

Owner:SEOUL NATIONAL UNIVERSITY

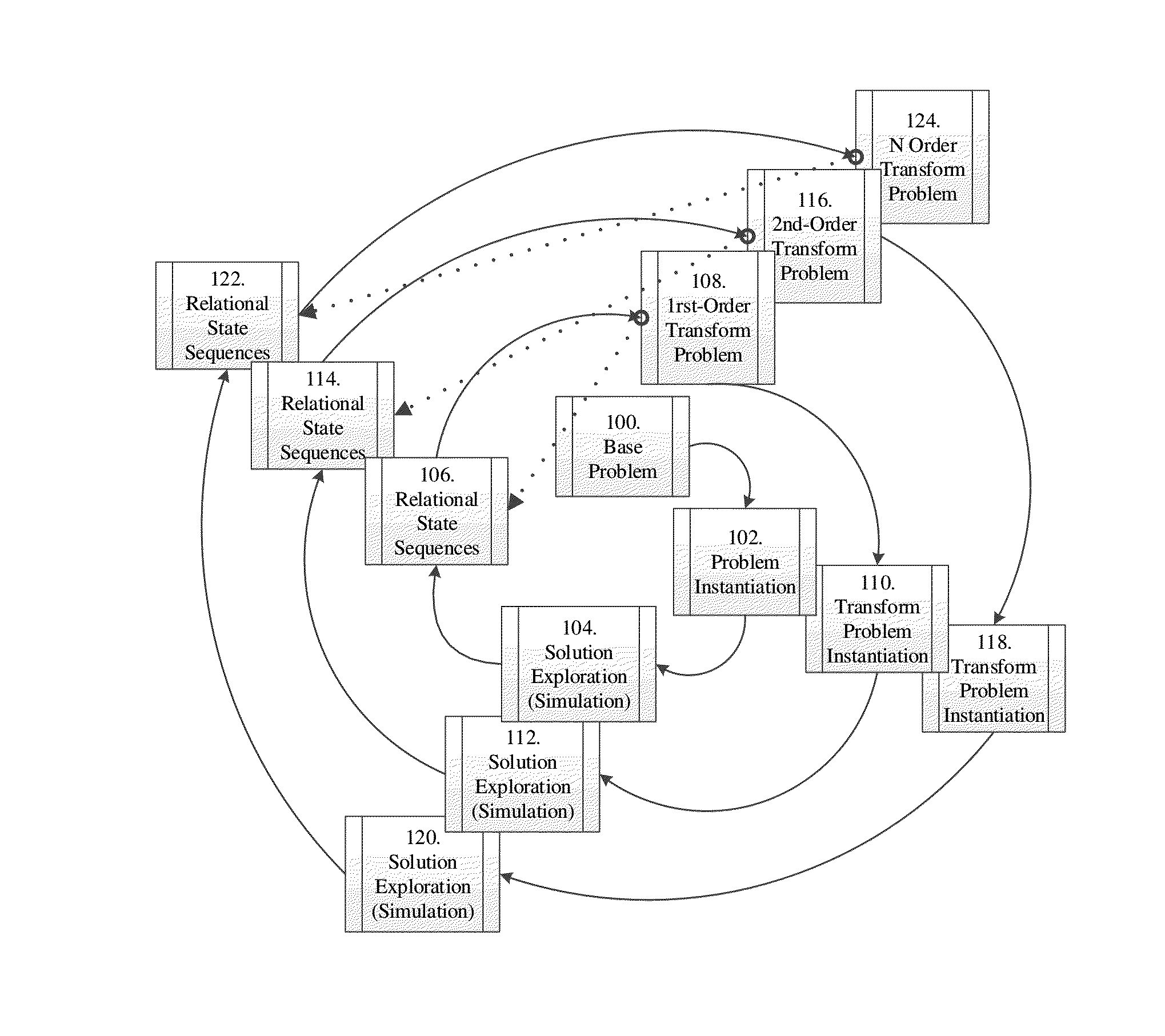

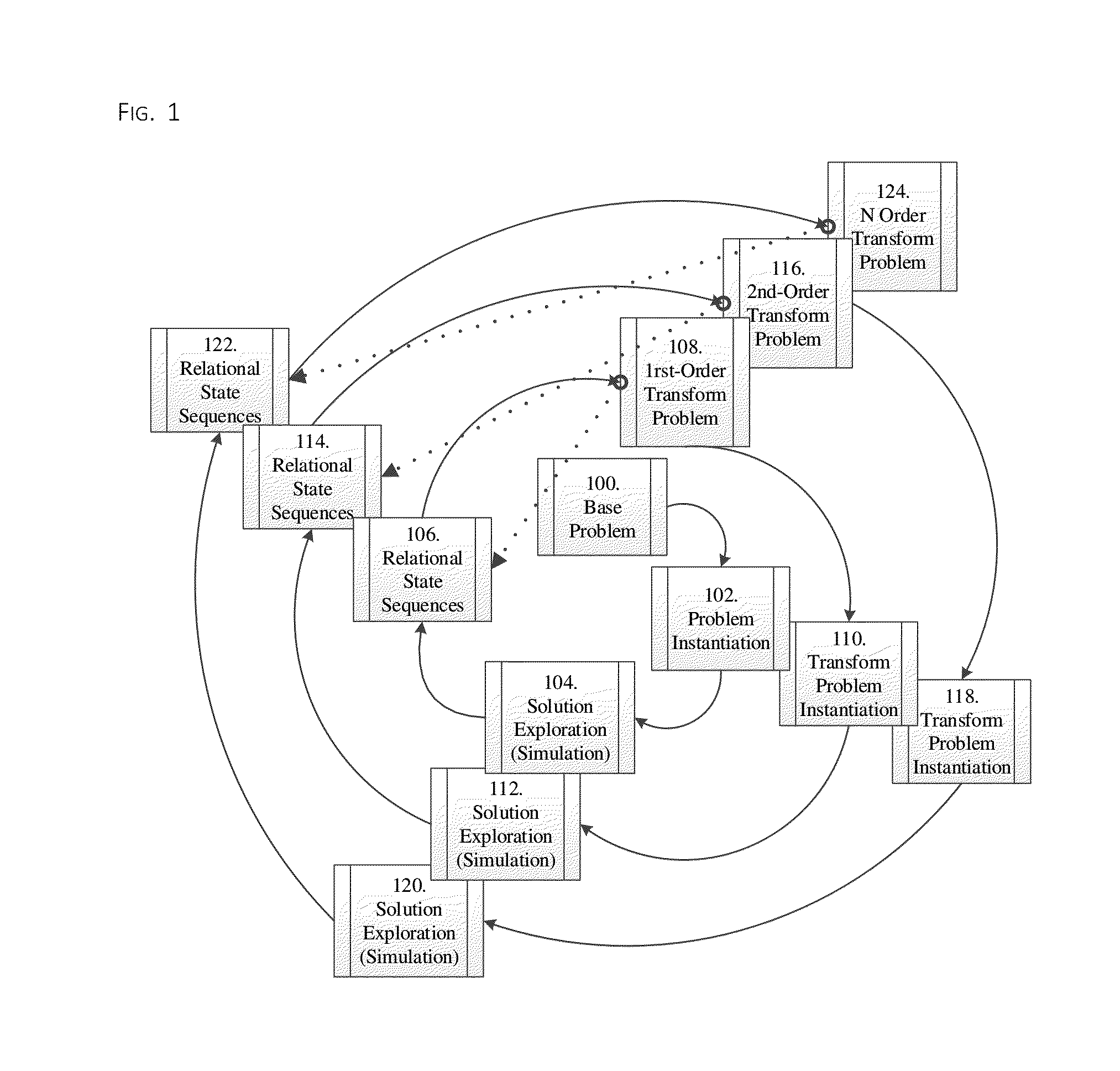

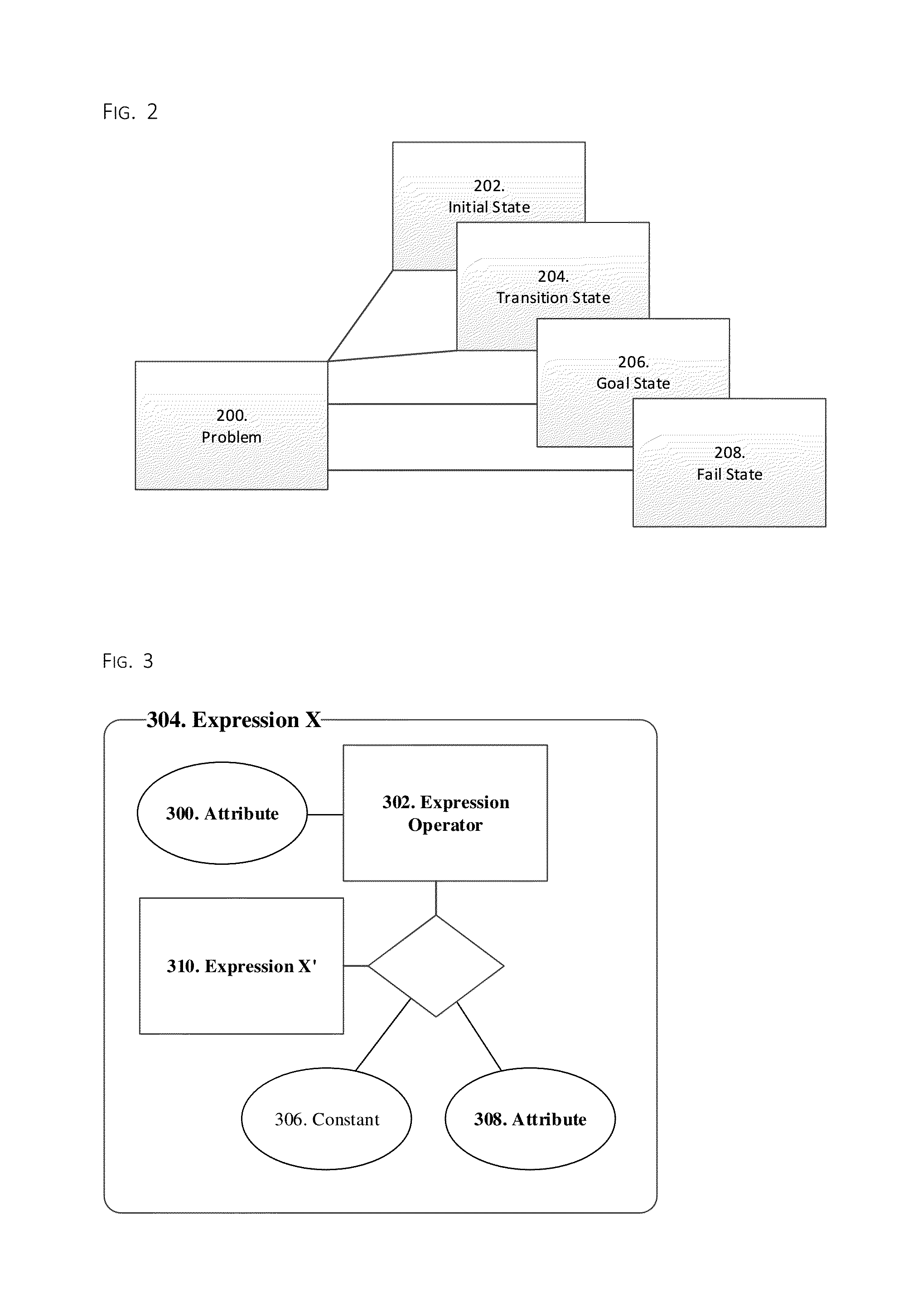

Method and System for Universal Problem Resolution with Continuous Improvement

PendingUS20160217371A1Improve ability of to solveSatisfies needForecastingDatabase modelsState dependentProblem resolution

A universal problem resolution method and system implementing continuous improvement for problem solving that utilizes simulative processing of relational data sets associated with initial states, allowed transition states, and goal states for a problem. The framework autonomously generates and solves higher order problems to find sequences of operations necessary to transform state sequences derived from the lower-order transformation simulations recursively. The solutions yield increasingly higher-order abstractions that converge to generalization such that the unwinding of the higher order sequences back down to the original problem yields the exact sequence of steps for unsolved instances of the problem in linear time without the need for re-simulation. Cooperating agents analyze solution path determinations for problems including those concerning their own optimization. This spawns state transition rules generalizable to higher layers of abstraction resulting in new knowledge enabling self-optimization.

Owner:LEITHISER ROBERT

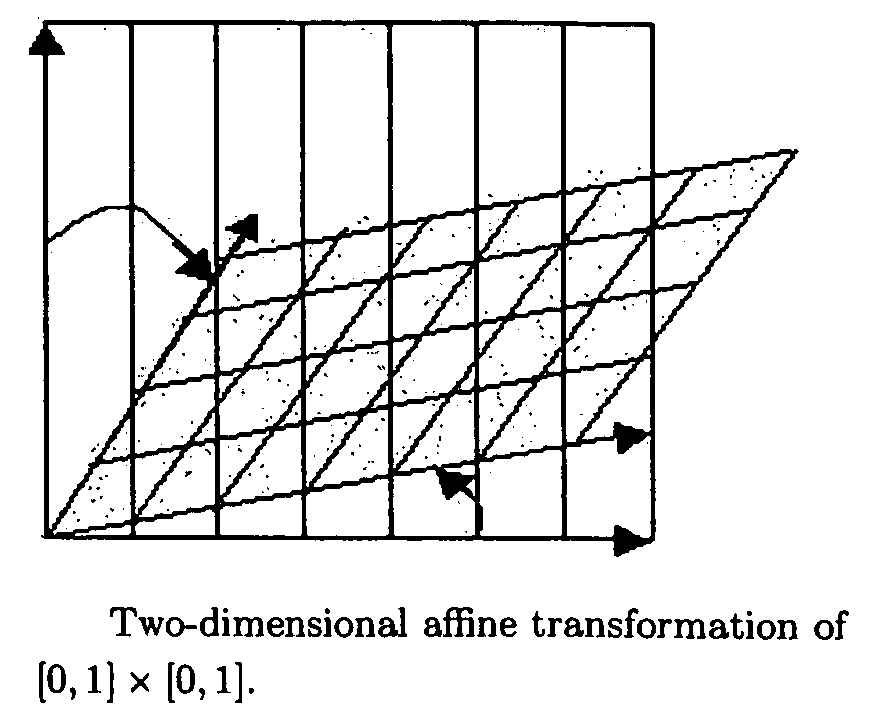

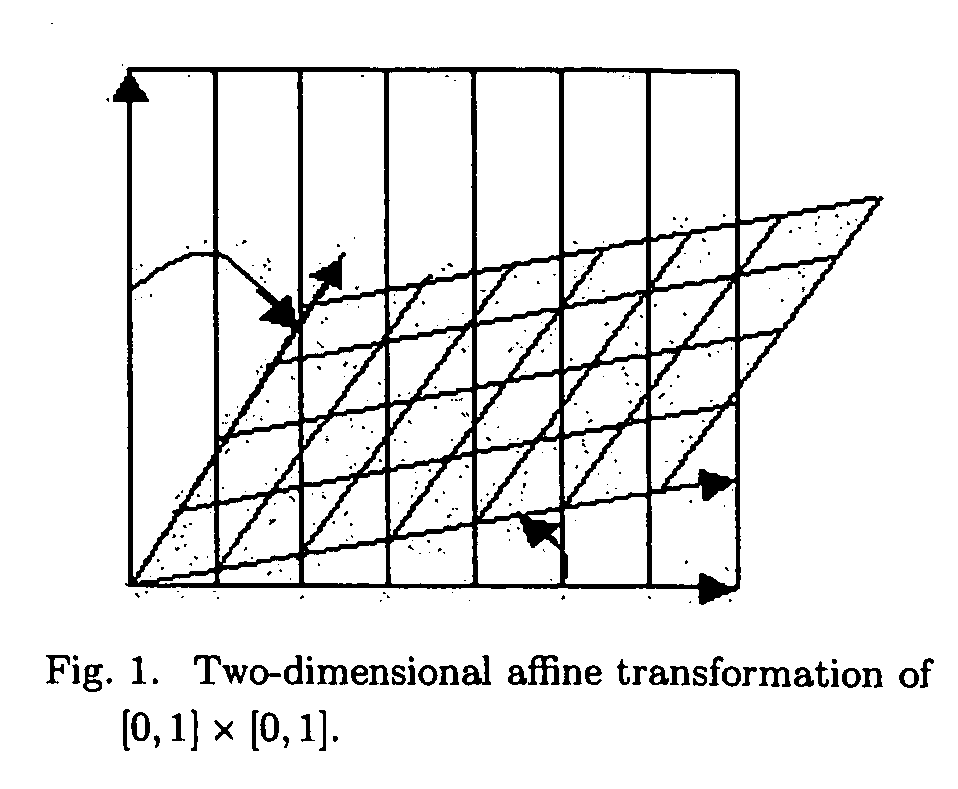

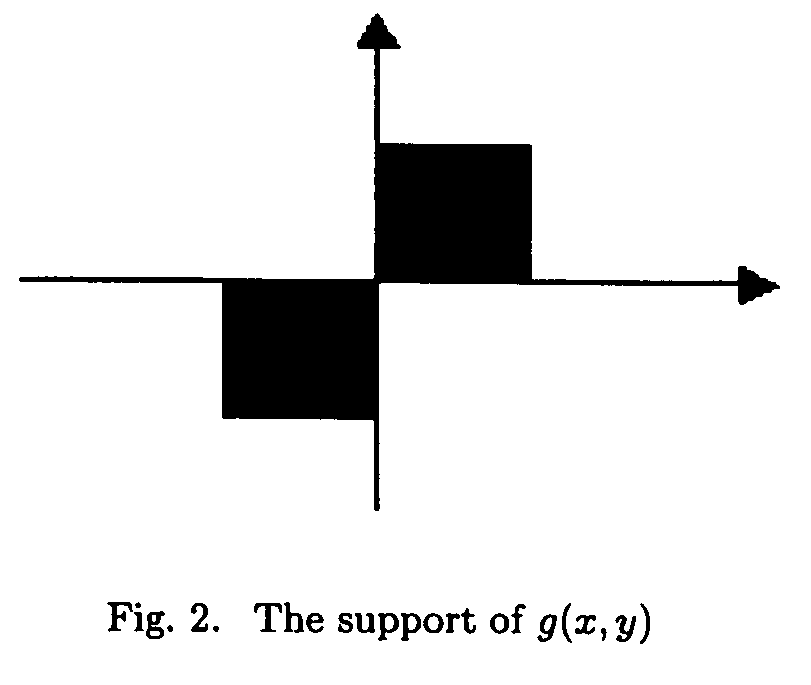

Parametric estimation of multi-dimensional homeomorphic transformations

ActiveUS20050105804A1Accurate yet computationally very simple solutionHighly problematicCharacter and pattern recognitionPattern recognitionObject registration

In object registration and recognition based on a set of known templates, the tremendous set of possible transformations that may relate the template and an observed signature makes any detection and recognition problem ill-defined unless this variability is taken into account. The present invention estimates the deformation that transforms some pre-chosen representation of an object (template) into the current observation. The method employs a set of non-linear operators to replace a high dimensional problem by an equivalent linear problem, expressed in terms of the unknown parameters of the transformation model. The solution is applicable to any homeomorphic transformation regardless of its magnitude. In the special case where the transformation is affine the solution is shown to be exact.

Owner:PERSPECTIVE IMAGING SOLUTIONS

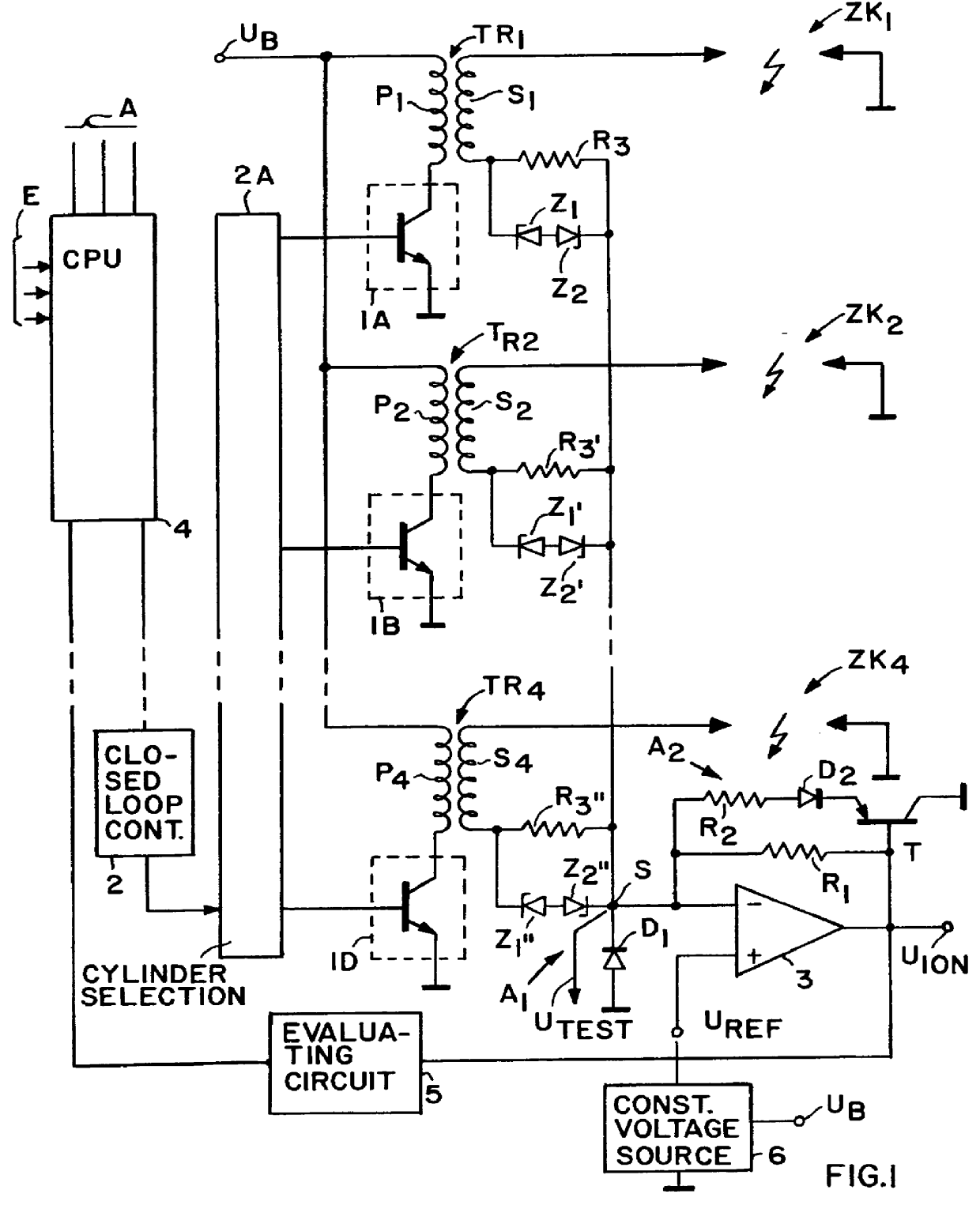

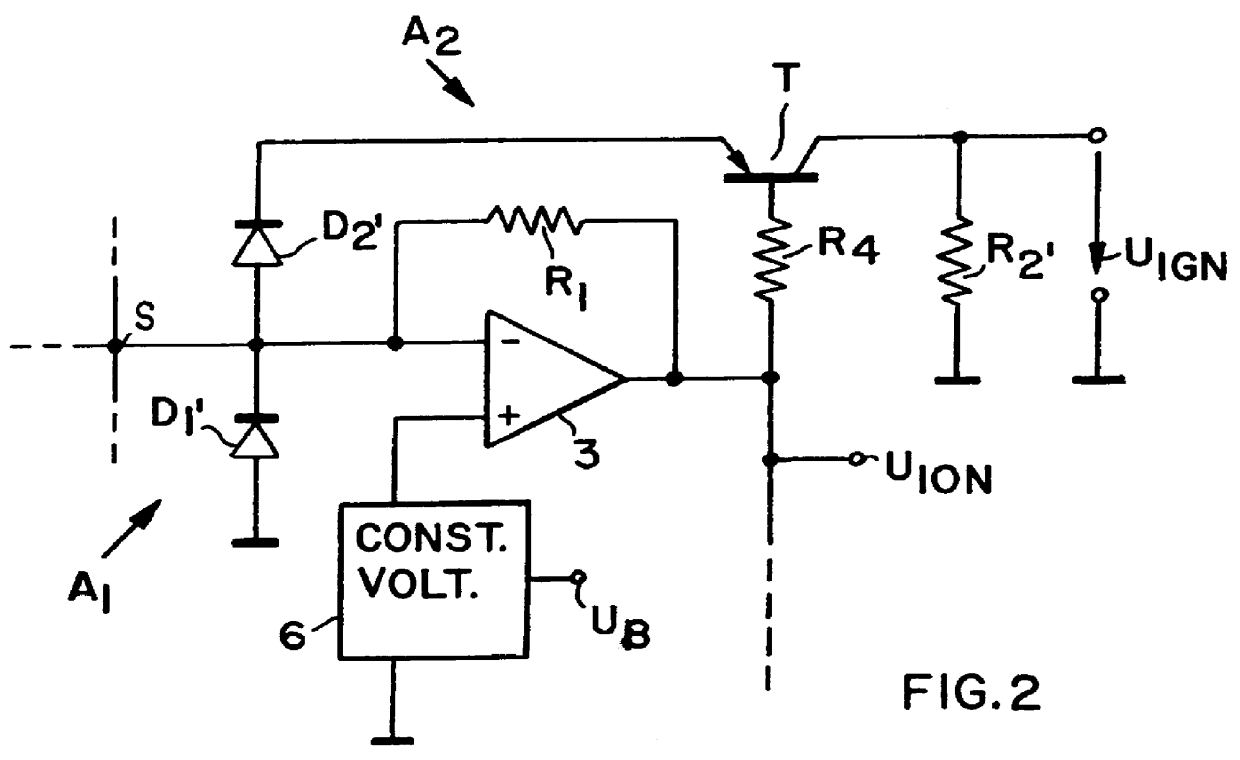

Circuit arrangement for measuring an ion current in a combustion chamber of an internal combustion engine

InactiveUS6043660AHighly accurate measurementShortens decay periodMachines/enginesInstallations with induction energy storageCombustion chamberPower flow

A circuit arrangement measures an ion current generated in the combustion chamber of an internal combustion engine during an iron current flow phase following an ignition phase. A voltage drop across a feedback resistor (R1) connected in parallel to an inverting amplifier is measured since the voltage drop is proportional to the ion current resistance. The amplifier is connected with its inverting input to a low voltage end of a secondary winding of an ignition transformer or coil. The high voltage end of the secondary winding is connected through a spark gap of a spark plug to ground, whereby the spark plug functions as an ion current sensor during the ion current flow phase. Negative voltage peaks flowing during an ignition phase and the ignition current flowing during the ignition phase are diverted through respective first and second circuit branches. The first branch has a first semiconductor diode (D1) grounding the low voltage end of the secondary winding for discharging the negative high voltage peaks while blocking the ignition current. The other diverting branch has a second semiconductor (D2) connected in parallel to the inverting amplifier.

Owner:VOLKSWAGEN AG +1

Compression screw with combination single and double flights

ActiveUS20060196370A1Highly problematicHigh CRSedimentation settling tanksMoving filtering element filtersPropellerEngineering

A screw for a compression dewatering device comprising an elongated shaft having axially spaced apart first and second ends, a conveying section at the first end of the shaft, having a single helical screw flight rigidly projecting from the shaft, a flightless transition section axially adjacent the conveying section, and a dewatering section axially adjacent the transition section, having a double helical screw flight rigidly projecting from the shaft. Another embodiment is a compression screw having a perforated tubular dewatering wall intermediate the ends, followed by an imperforate spool wall at the discharge end. The screw includes a central shaft, a conveying section extending axially from the inlet end of the shaft, having a single helical screw flight rigidly projecting from the shaft, a flightless plug section extending axially from the discharge end of the shaft, within the spool wall, and a dewatering section adjacent the plug section, having a double helical screw flight rigidly projecting from the shaft. A flightless transition section is situated between the conveying section and the dewatering section. A gravity feed device is operatively associated with the inlet end for depositing bulk solids material through the feed opening onto the conveying screw, and a drive system is operatively connected to the inlet end of the screw for rotating the screw in the housing.

Owner:ANDRITZ INC

Cyclone furnace for oxygen fired boilers with flue gas recirculation

InactiveUS20060201405A1Reduce emissionReduce nitrogen oxide emissionsPulverulent fuel combustion burnersCombustion chambersFlueProcess engineering

A cyclone furnace and method uses a cyclone burner having a cyclone barrel with a re-entrant throat connected to a main furnace for passing combustion products including flue gas that is rich in carbon dioxide. Crushed coal and oxygen are supplied the cyclone burner and at least some of the flue gas from the main furnace is recirculated to the cyclone barrel.

Owner:THE BABCOCK & WILCOX CO

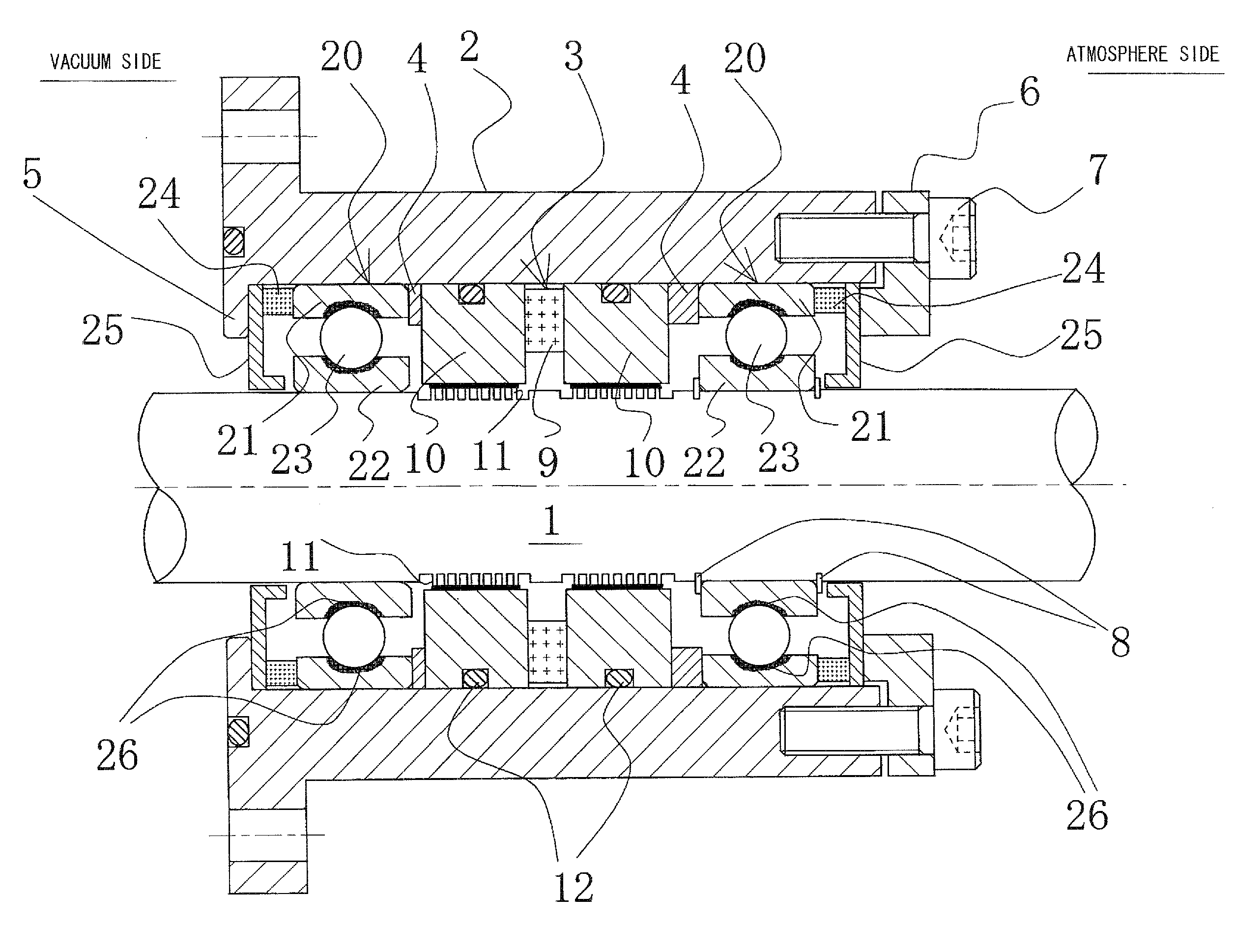

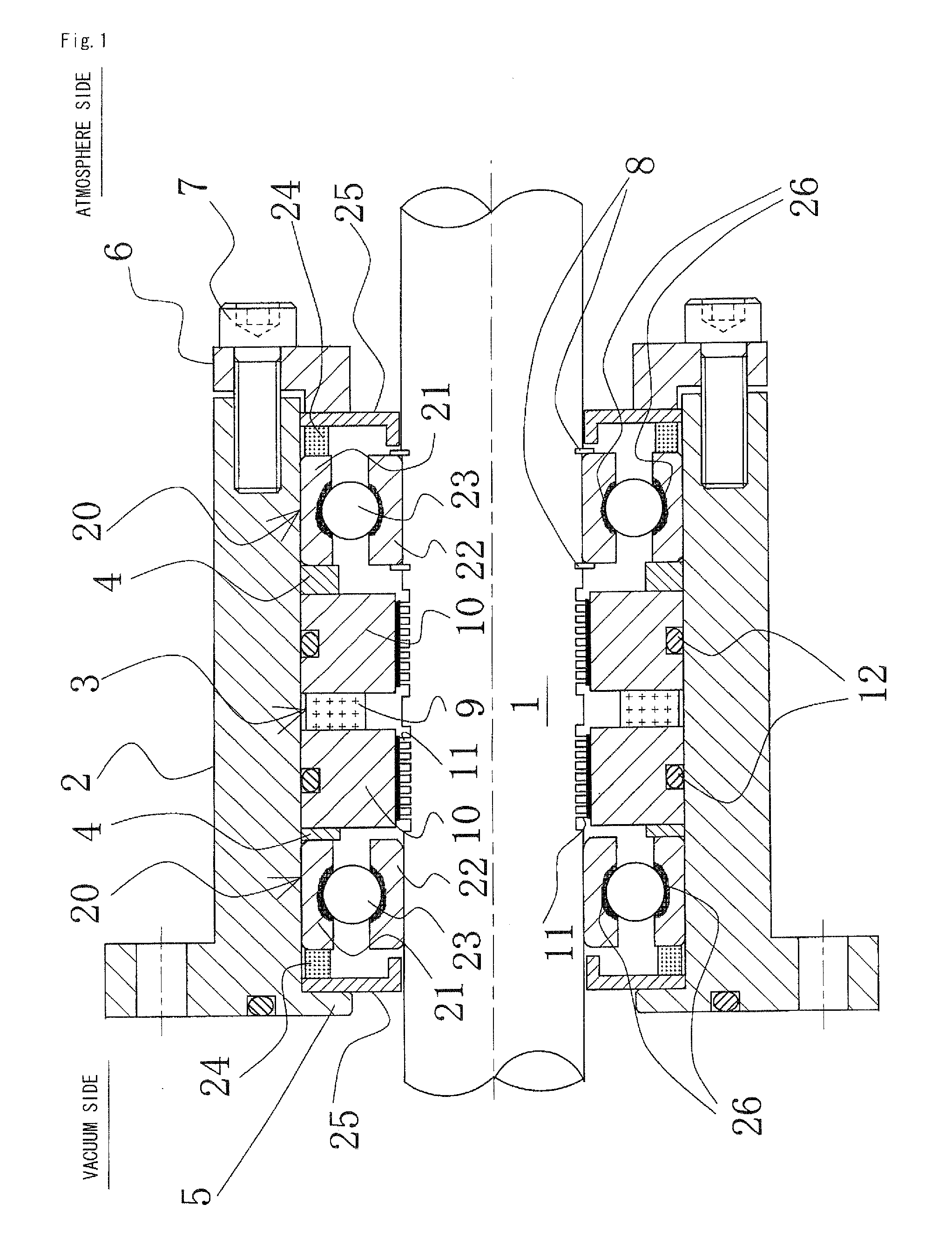

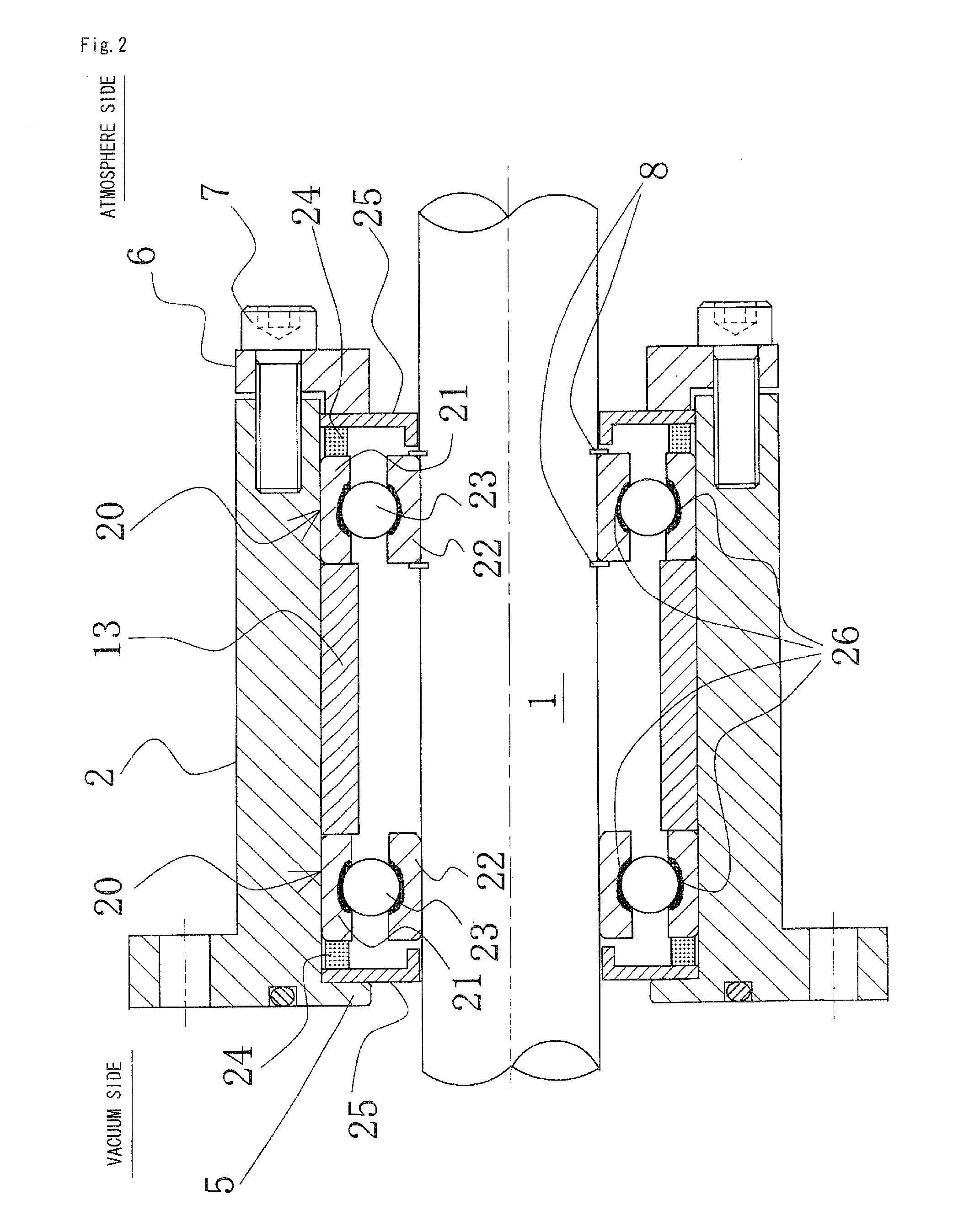

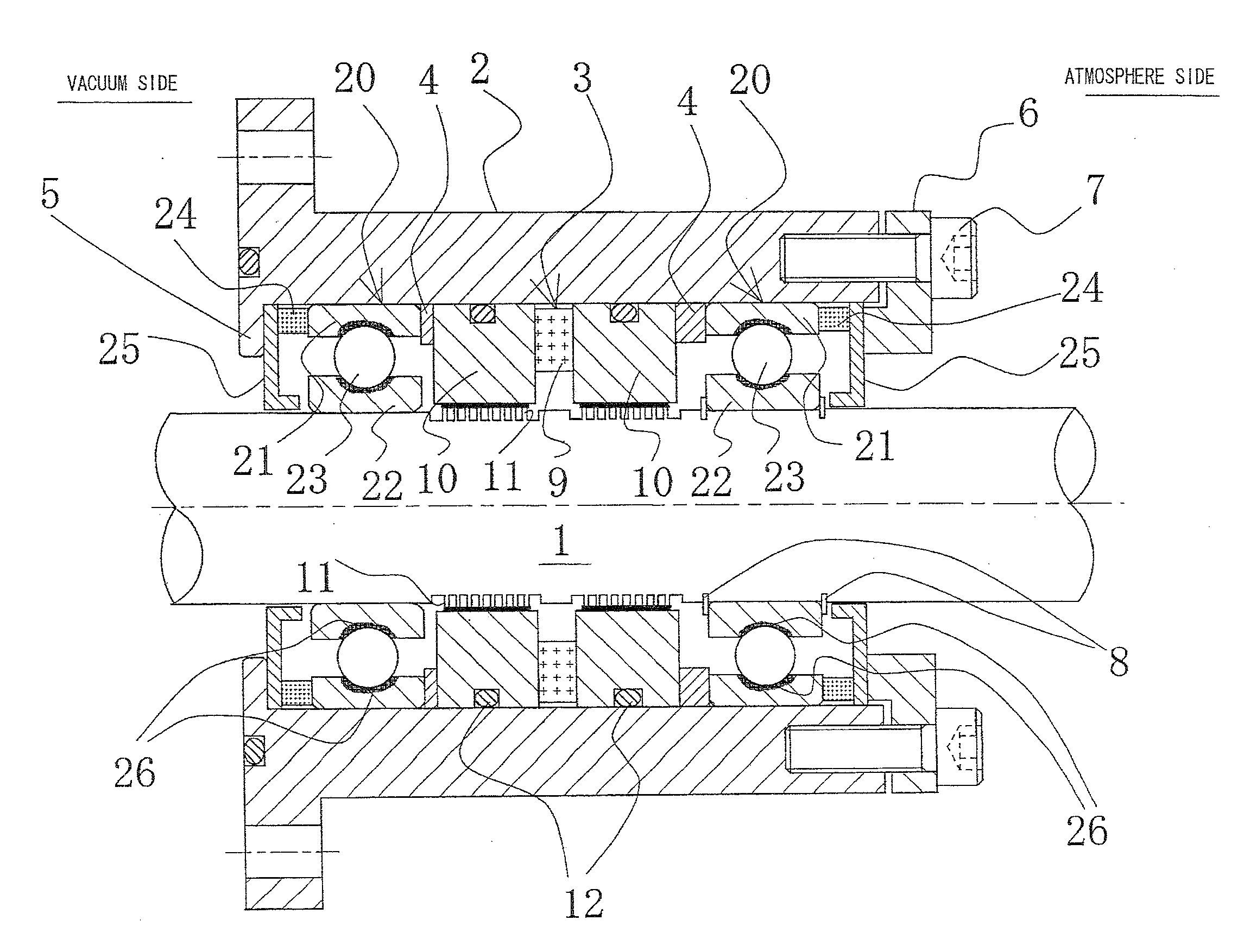

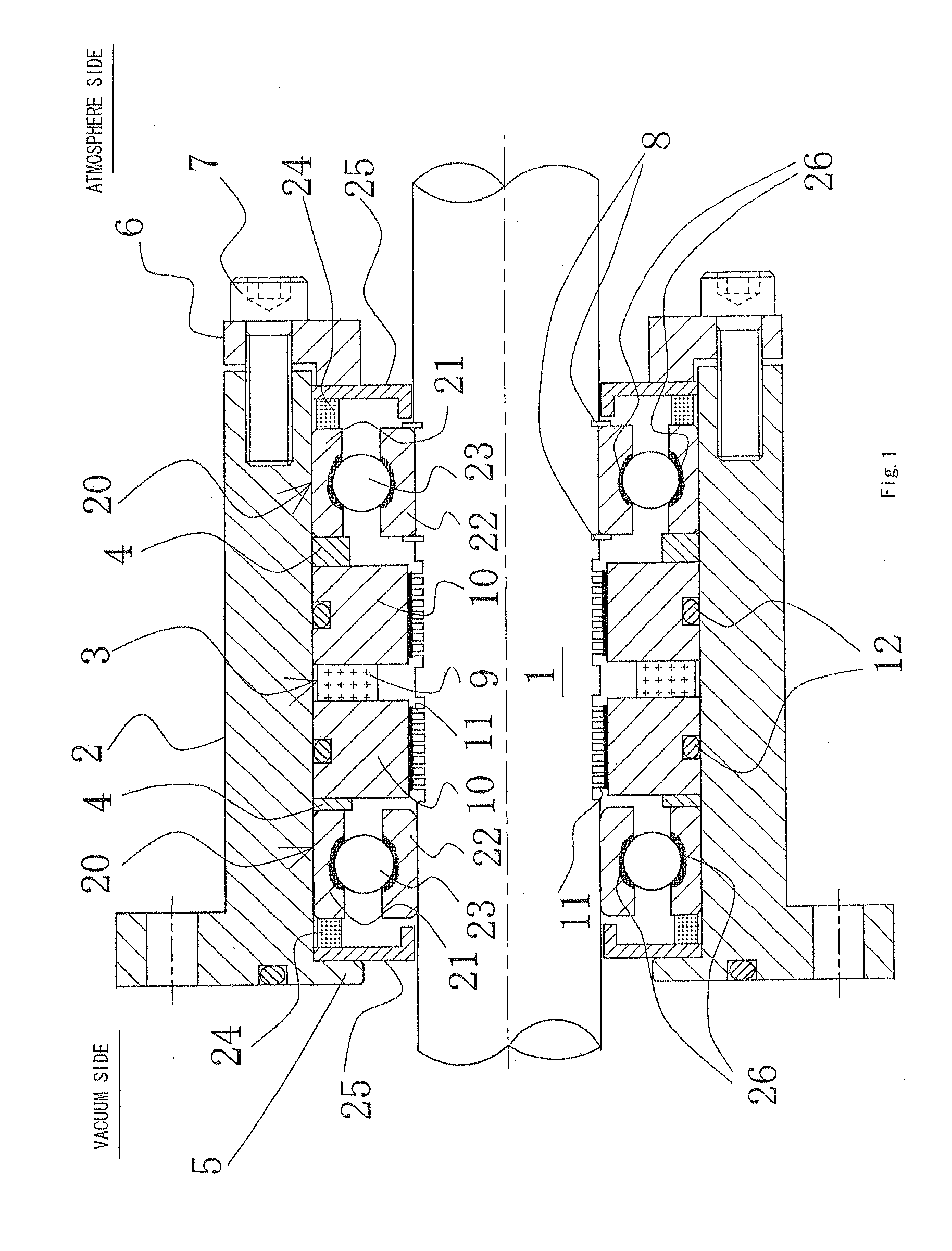

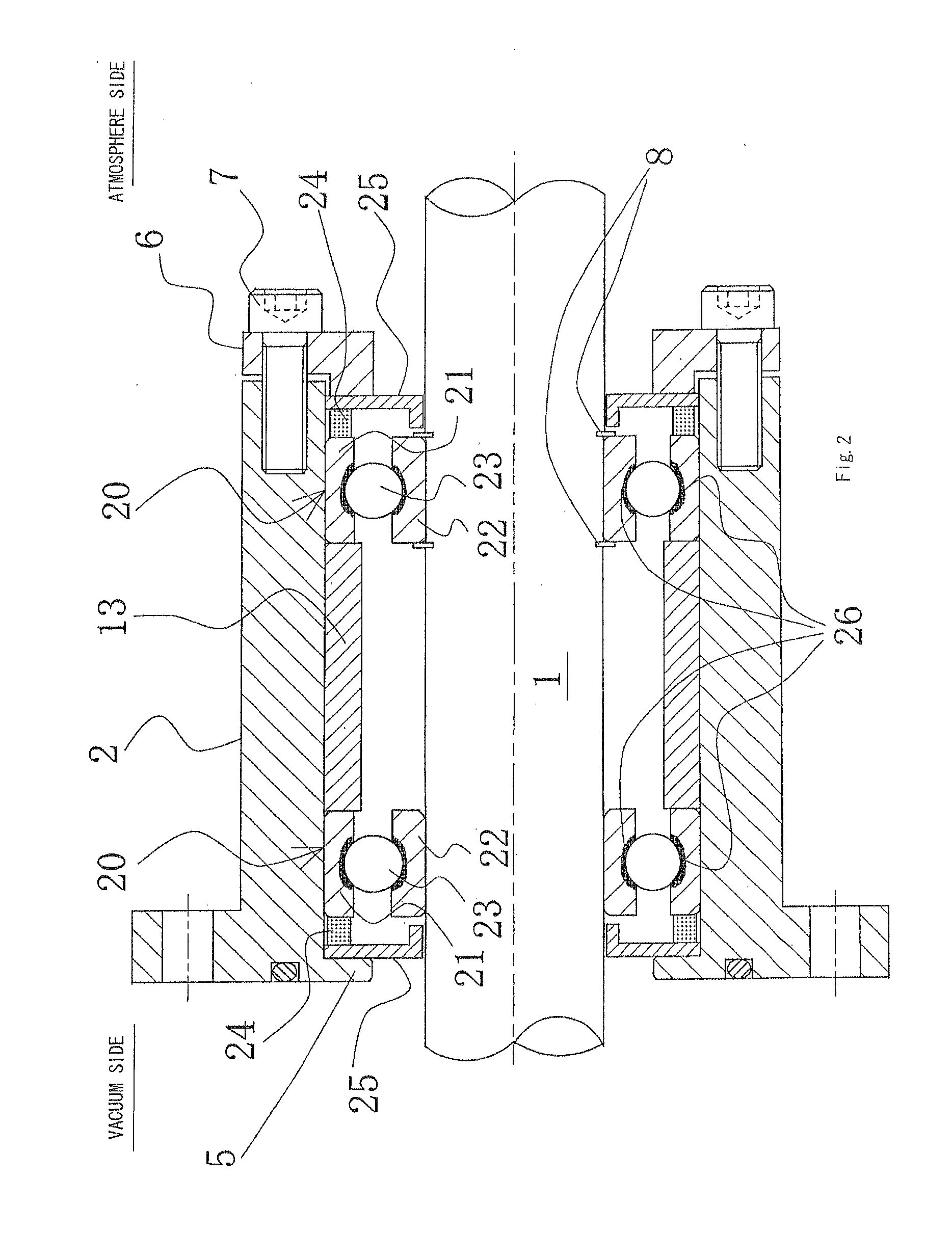

Rolling bearing

ActiveUS20120314984A1Highly problematicForm sufficiently and easilyEngine sealsShaftsLubricationMagnet

A rolling bearing used in a power transmission device for transmitting power such as turning force, includes a magnet for holding in a lubrication portion of the rolling bearing. A lubricating magnetic fluid for lubricating the lubrication portion is provided on at least one side of an outer race of the rolling bearing, and an annular yoke made of a magnetic material loosely fitted to a rotating shaft is provided on the opposite side of said magnet relative to said outer race.

Owner:EAGLE INDS

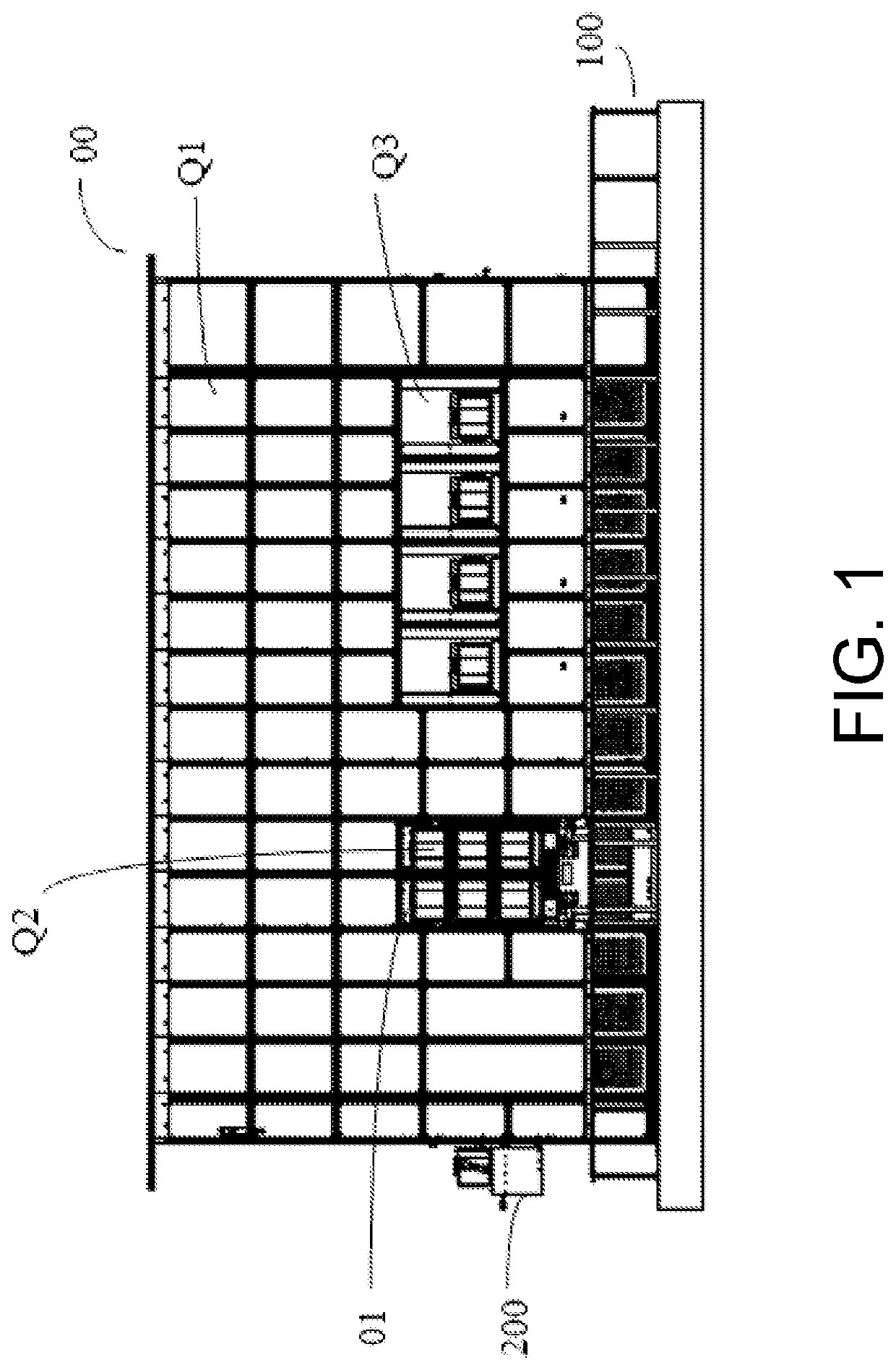

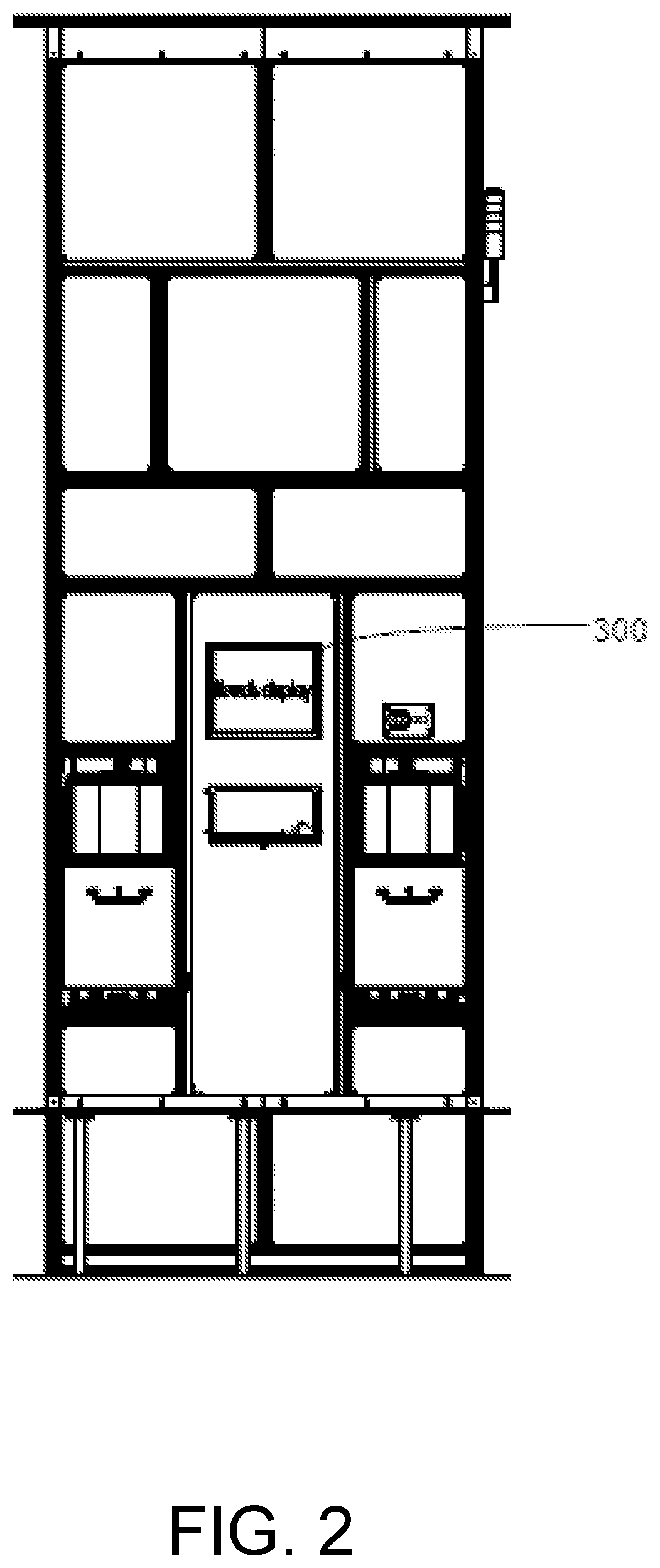

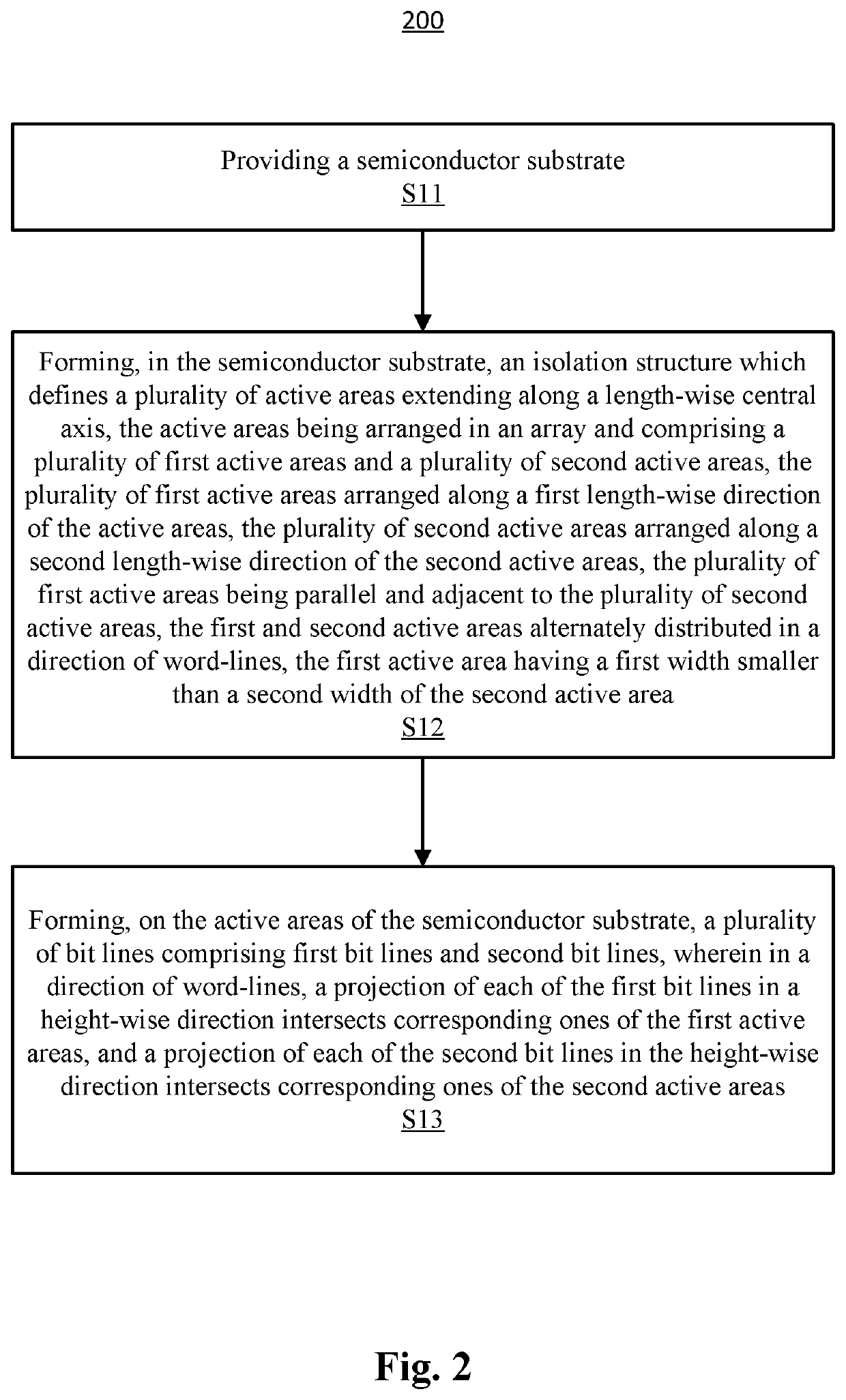

Material transportation system, transportation method and storage apparatus

ActiveUS20200115159A1Increase flexibilityReduce design costSemiconductor/solid-state device manufacturingStorage devicesProcess engineeringDelivery system

The present invention provides a material transportation system, a material transportation method and a material storage apparatus. The material storage apparatus is provided with a movable storage rack, wherein the movable storage rack is configured for carrying a plurality of material boxes and can be separated from the material storage apparatus; and an automatic transportation apparatus can move freely along any route in any direction, wherein the automatic transportation apparatus is configured for carrying the movable storage rack. Moreover, the movable storage rack is sent to be in front of the material storage apparatus or transported from the material storage apparatus to a target storage position. The present invention simultaneously transports a plurality of material boxes between the material storage apparatuses and between the material storage apparatus and the processing equipment. By adopting the automatic transportation apparatus, the single-box track overhead traveling crane and the overhead track in the traditional OHT system are canceled, so that the problems that the traditional OHT system is high in design complexity, highly difficult and limited in later adjustment, and limited in the practical application can be overcome.

Owner:SHANGHAI FORTREND TECH CO LTD

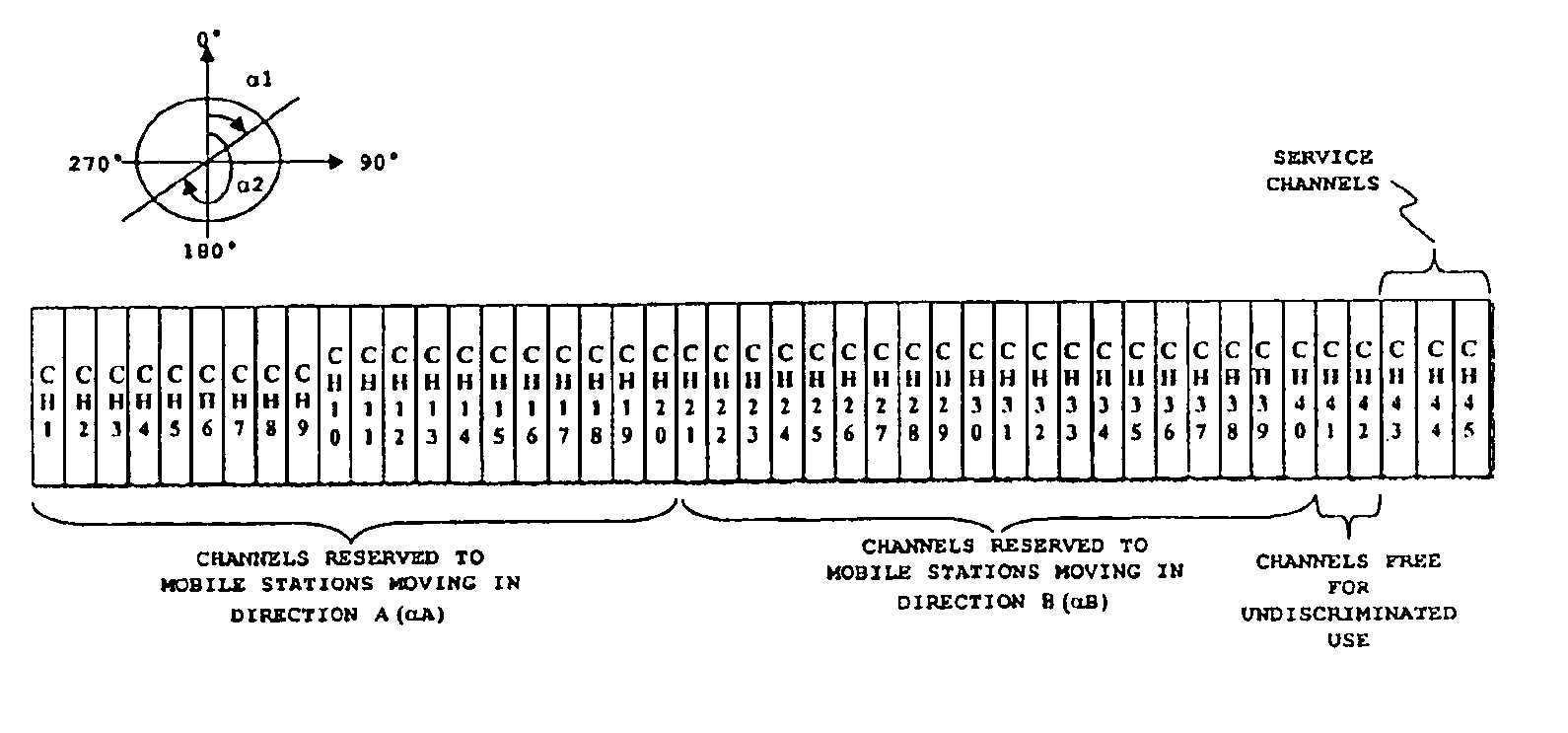

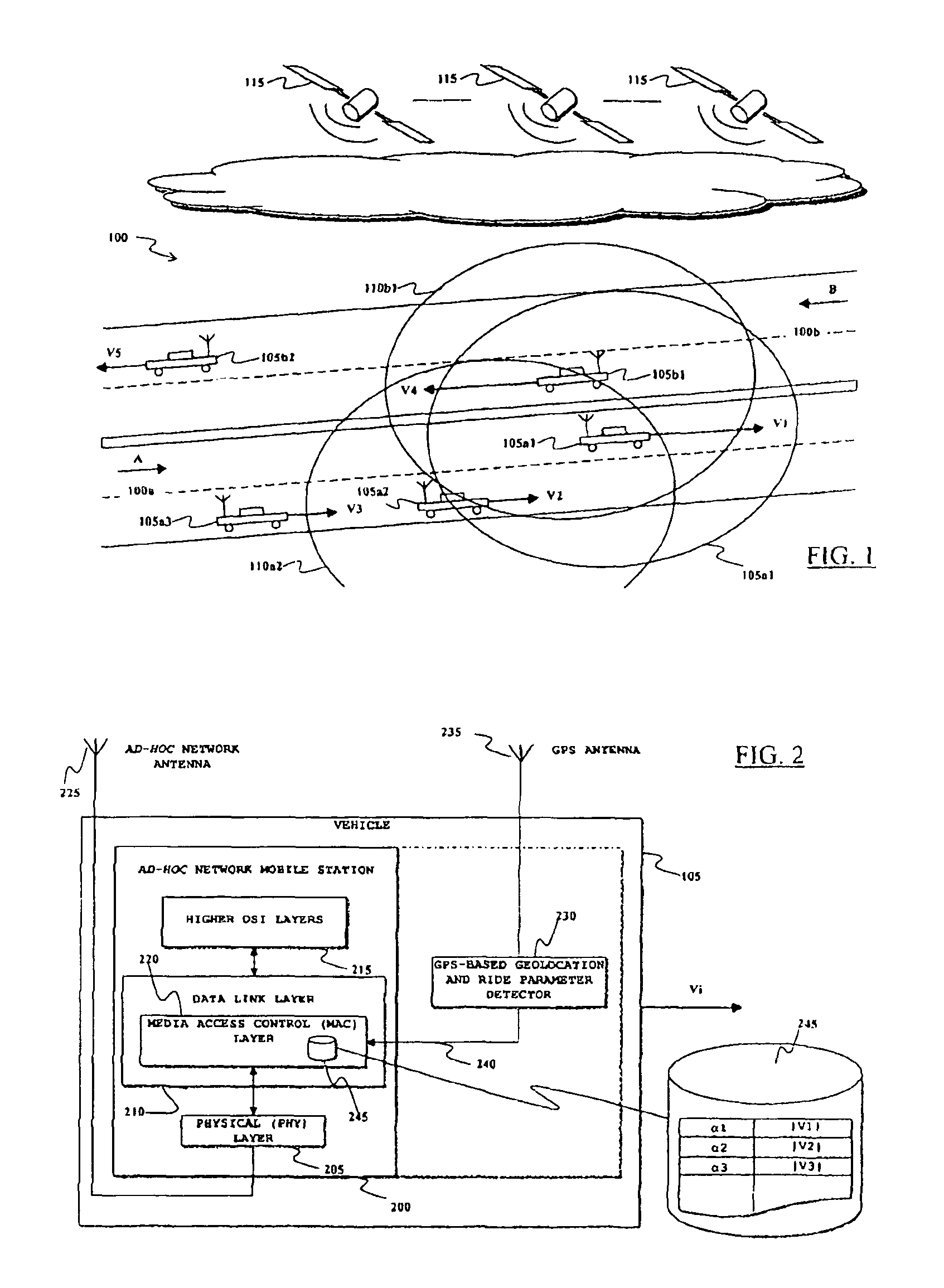

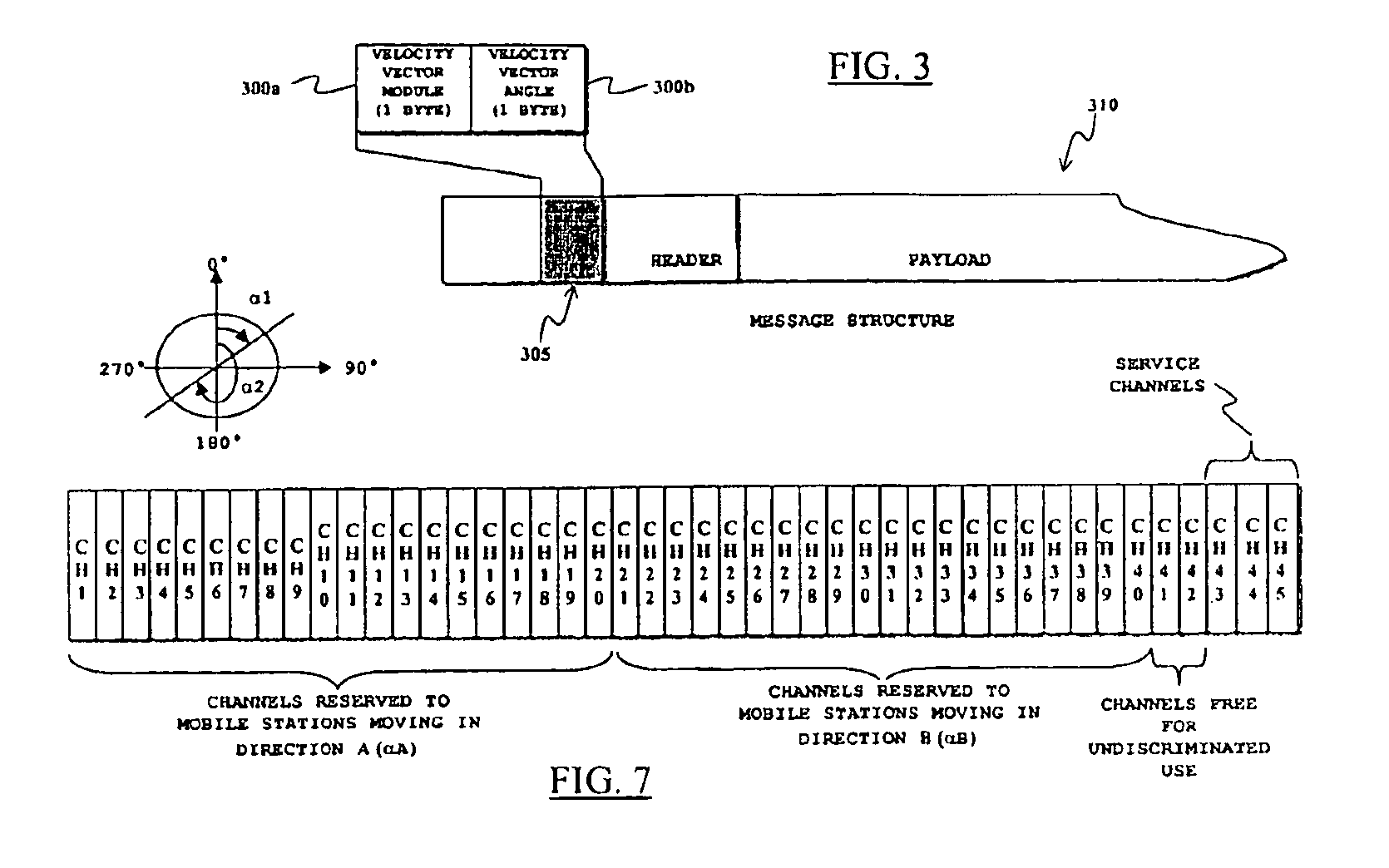

Controlling access to a shared communication medium of a mobile ad-hoc network

InactiveUS7965678B2Increase the probability of collisionReduce decreaseNetwork traffic/resource managementNetwork topologiesMobile deviceCommunications media

Owner:FOND SILVIO TRONCHETTI PROVERA

Rolling bearing

ActiveUS20140044386A1Easy to manufactureHighly problematicShaftsBall bearingsRotational axisRolling-element bearing

A rolling bearing used in a power transmission device for transmitting power such as turning force, characterized in that a magnet for holding in a lubrication portion of the rolling bearing a lubricating magnetic fluid for lubricating the lubrication portion is provided on at least one side of an outer race of the rolling bearing, and an annular yoke made of a magnetic material loosely fitted to a rotating shaft is provided on the opposite side of said magnet relative to said outer race, and a cross-sectional profile of the yoke has an I-shape.

Owner:EAGLE INDS

Multiple stage delta sigma modulators

InactiveUS7324030B2Highly problematicElectric signal transmission systemsPulse automatic controlImage resolutionFrequency synthesizer

A delta sigma modulator which employs a plurality of accumulators with non-power-of-2 modulus. The accumulators may consist of a primary non-power-of-2 modulus accumulator and a secondary non-power-of-2 modulus accumulator. The number of bits in the primary accumulators affects the frequency resolution of the resultant delta sigma fractional N frequency synthesizer and can be the minimum number of bits required by the resolution specification. The secondary accumulator integrates the carry outputs of its corresponding primary accumulators. This integration results in attenuating the dc content of the modulator output by a factor equal to the modulus of the secondary accumulators and may require compensation in the recombination block.

Owner:KABEN WIRELESS SILICON

Method and device for image and video transmission over low-bandwidth and high-latency transmission channels

ActiveUS20140304332A1Highly problematicReduce quality problemsParticular environment based servicesComputer security arrangementsVideo transmissionVideo encoding

Owner:BARCO NV

Method and device for image and video transmission over low-bandwidth and high-latency transmission channels

InactiveUS20160021533A1Highly problematicReduce quality problemsUnauthorised/fraudulent call preventionEavesdropping prevention circuitsVideo encodingVideo transmission

Owner:BARCO NV

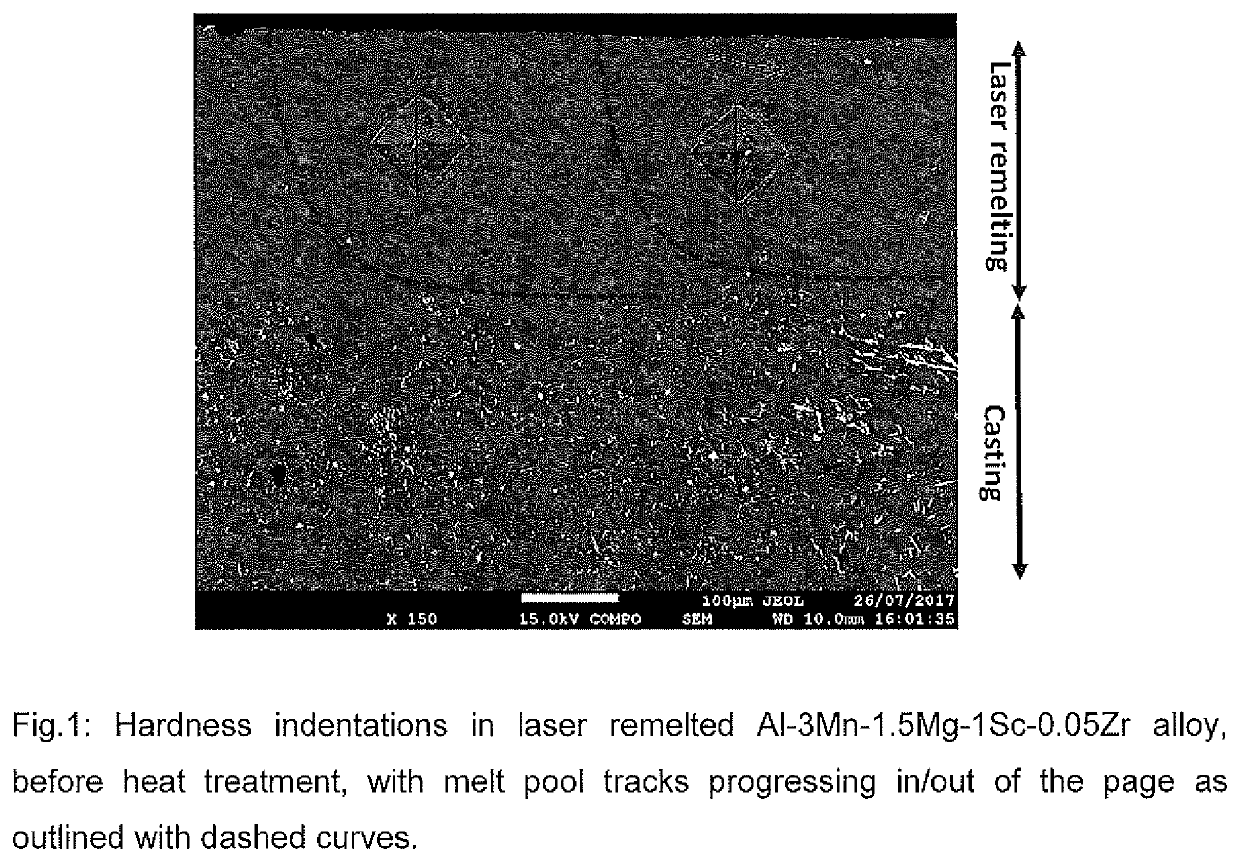

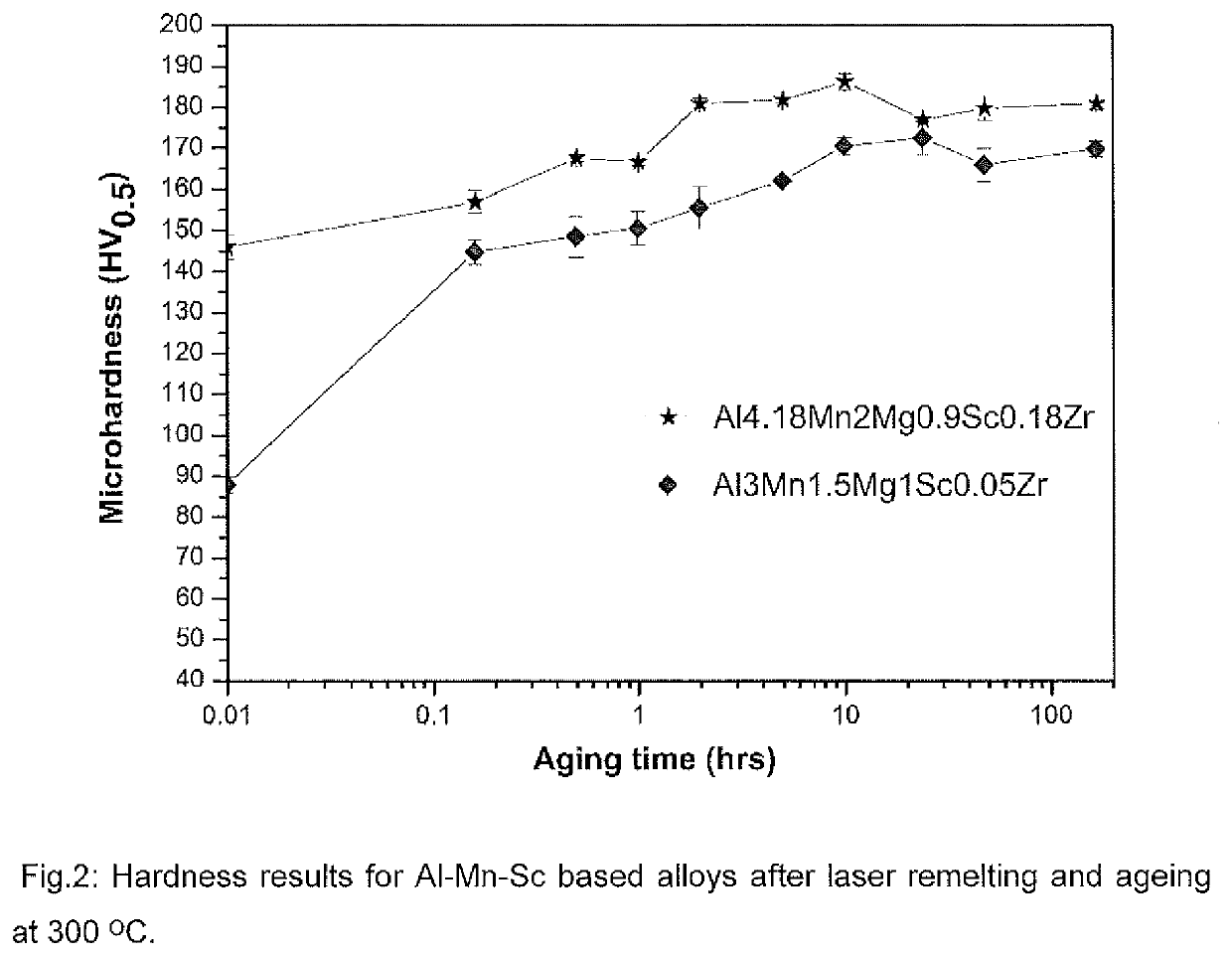

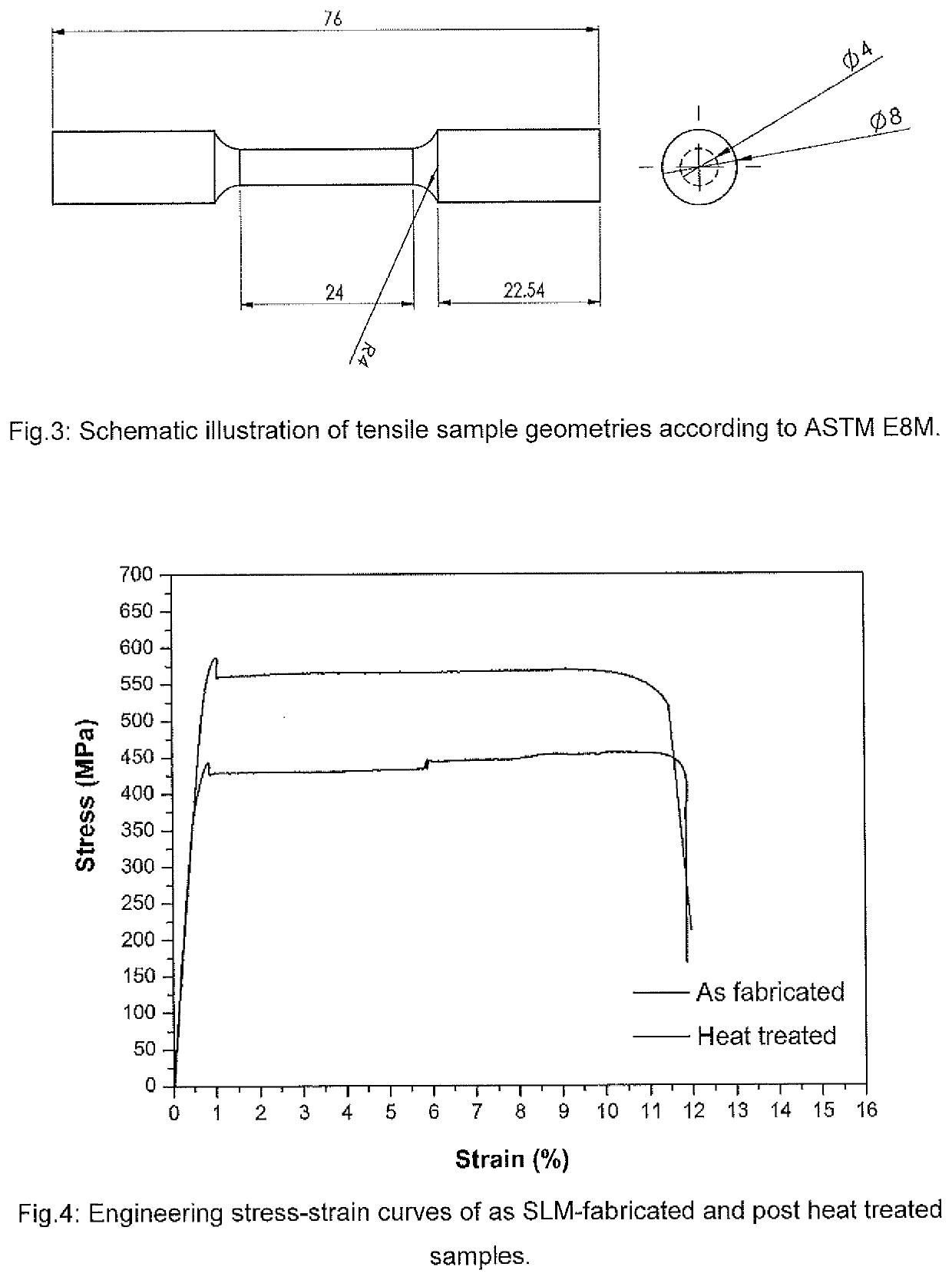

High strength aluminium alloy for rapid solidification manufacturing processes

PendingUS20200362440A1Efficient releaseImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySiluminManganese

An aluminium based alloy, and a method for production of components by additive manufacturing (AM) or other rapid solidification process with the alloy, is based on the alloy having a composition with from 2.01 wt % to 15.0 wt % manganese, from 0.3 wt % to 2.0 wt % scandium, with a balance apart from minor alloy elements and incidental impurities of aluminium.

Owner:MONASH UNIV

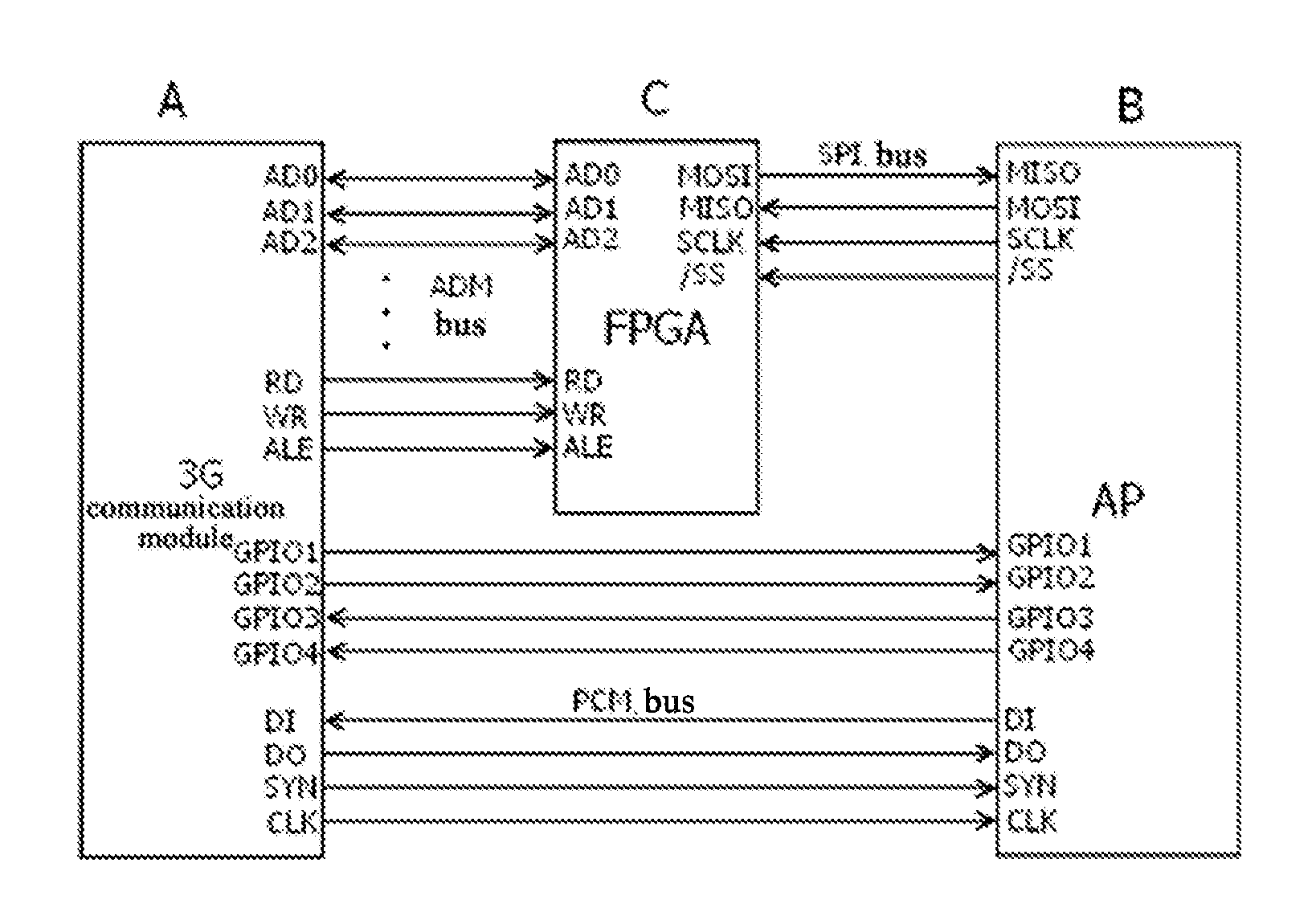

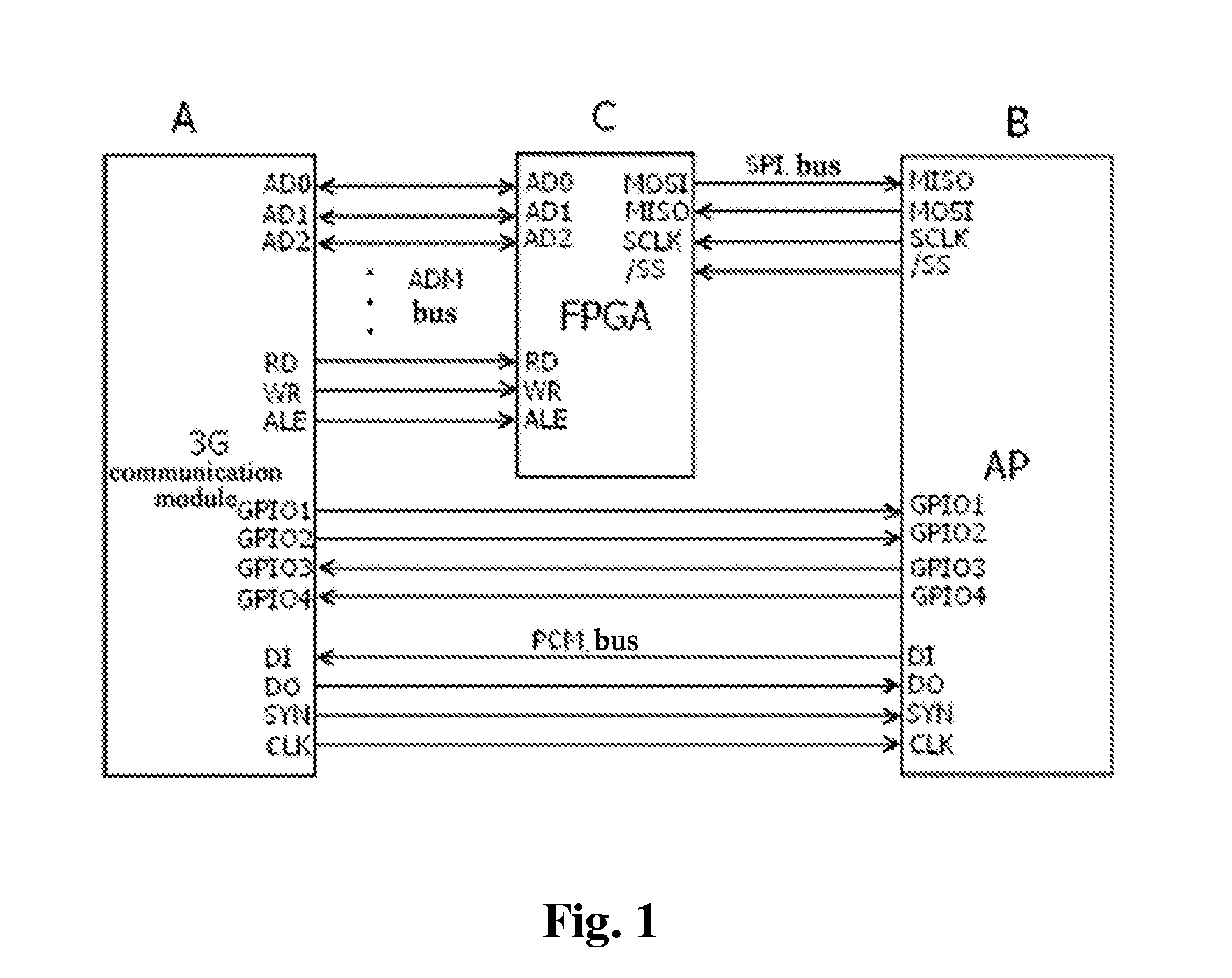

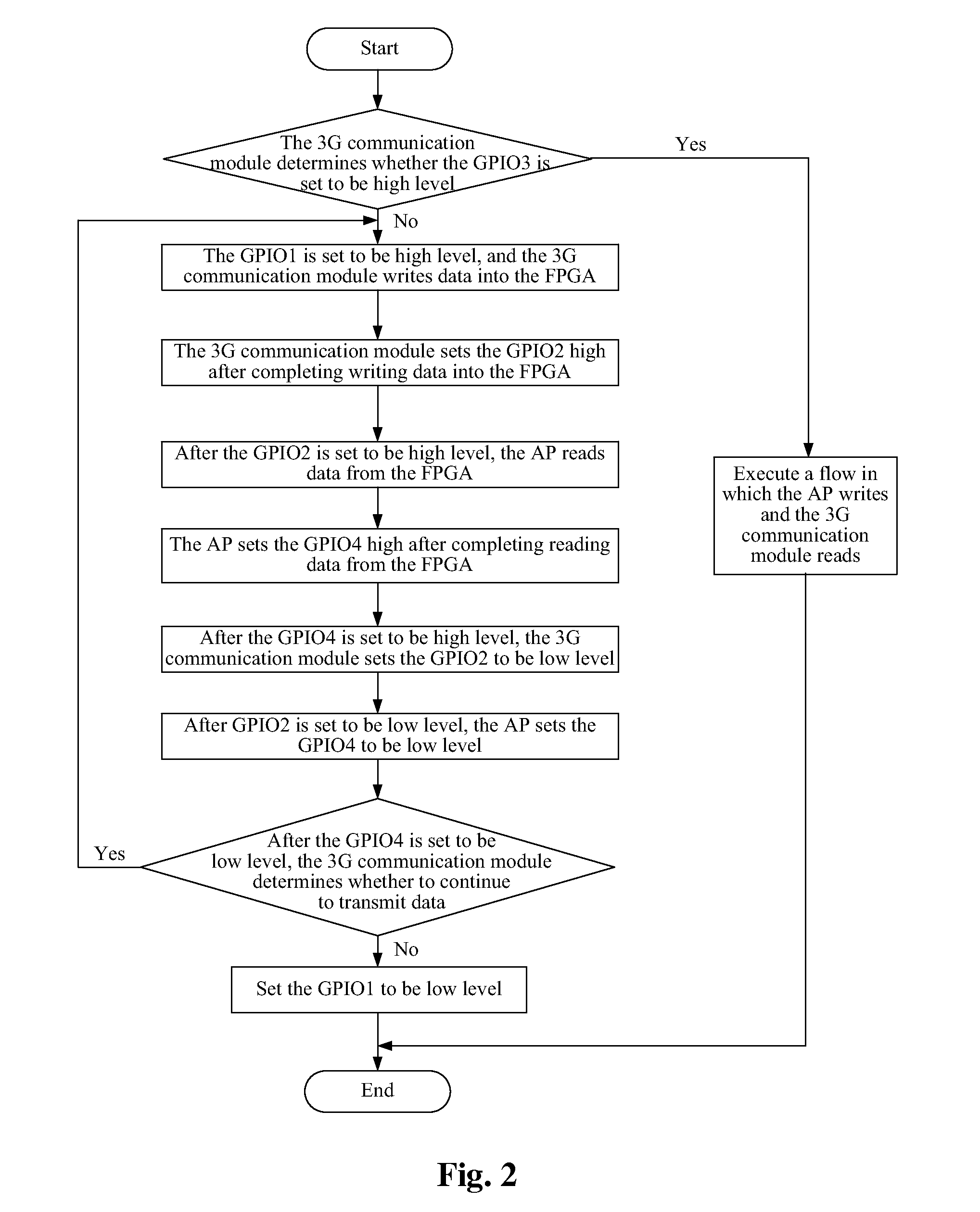

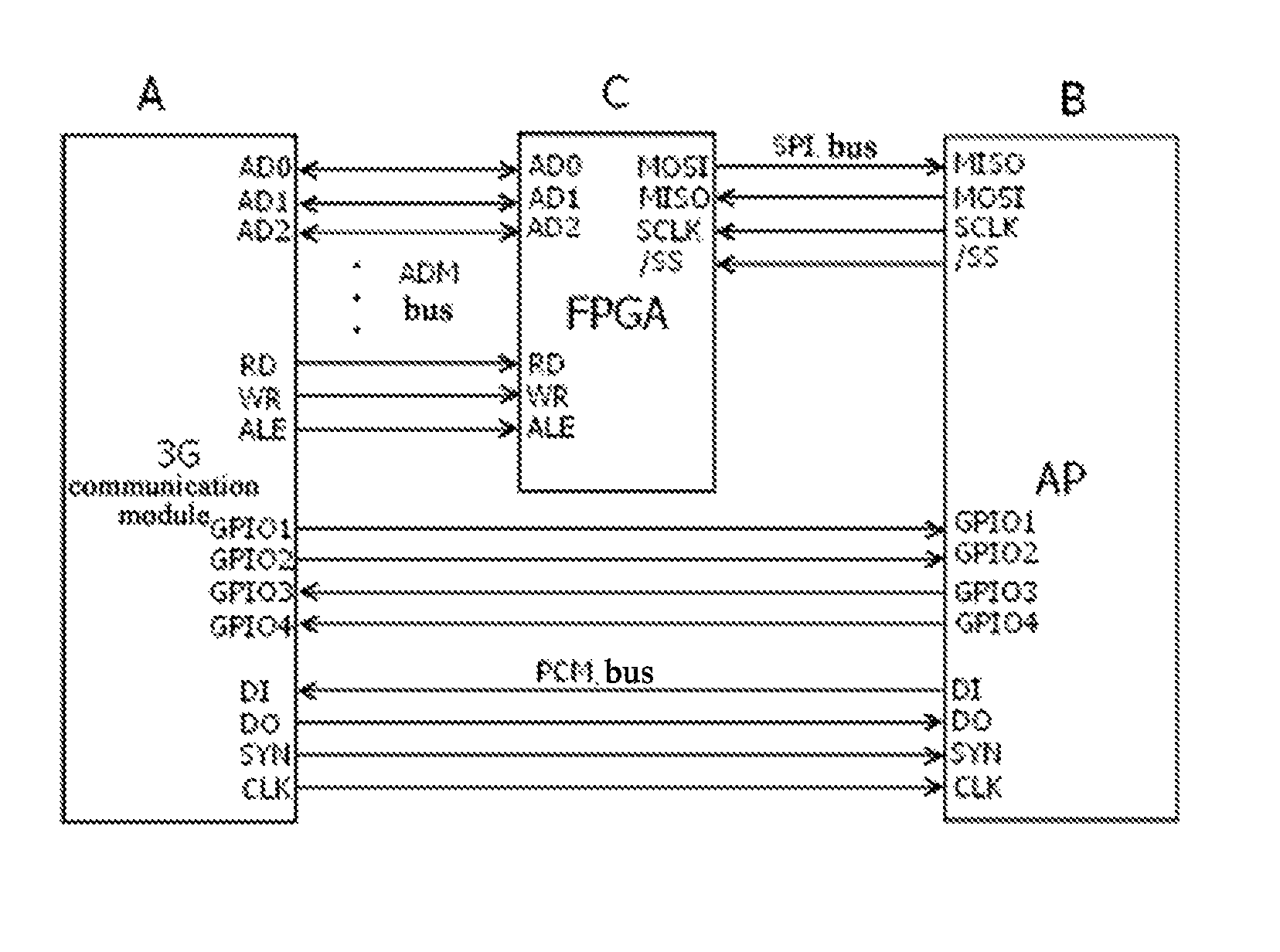

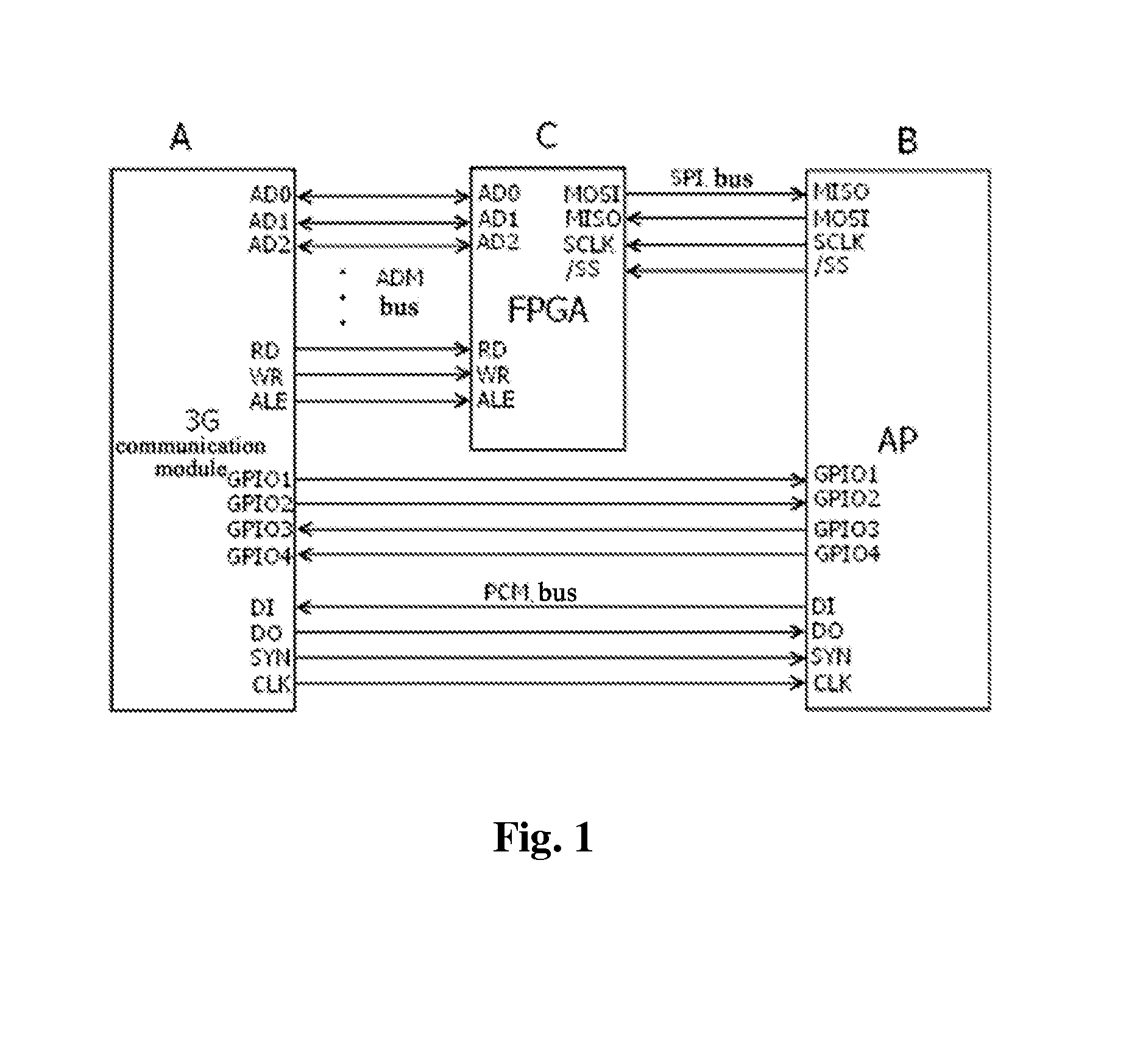

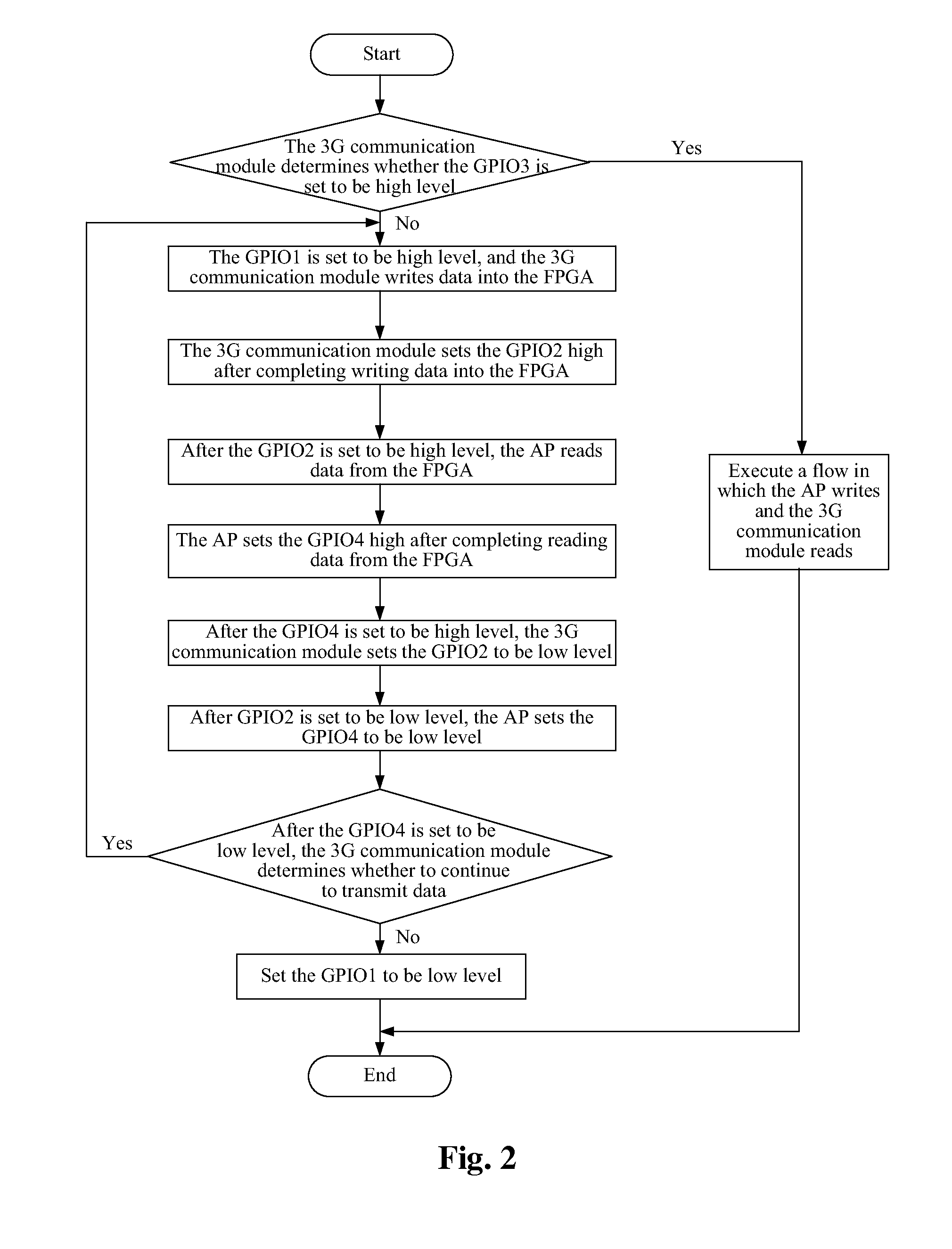

Device and Method for Enhancing Flexibility of Interface Between 3G Communication Module and Application Processor

InactiveUS20130036245A1Overall design flexibilityImprove versatilityElectric digital data processingWireless communicationThird generationBus interface

Owner:ZTE CORP

Cosmetic Preservative System

PendingUS20210212912A1Improve antibacterial propertiesMild for skin toleranceCosmetic preparationsToilet preparationsSodium acetatePropanoic acid

According to the present invention there is provided a cosmetic composition comprising a cosmetically acceptable carrier and a preservative system, wherein the preservative system comprises: (i) an antimicrobial agent; (ii) a chelating agent comprising ethylenediamine tetraacetic acid (EDTA) or a derivative thereof; and (iii) an antimicrobial booster agent selected from the group consisting of ethylhexylglycerin, caprylyl glycol, hydroxy acetophenone, caprylhydroxamic acid, phenethyl alcohol, p-anisic acid, glyceryl caprylate, levulinic acid, sodium levulinate, propanediol, hexanediol, pentylene glycol, capryloyl glycine, methylpropanediol, phenylpropanol, sodium anisate, and combinations thereof, wherein the antimicrobial agent is present in an amount of from about 0.001% to about 1% by weight of the composition.

Owner:THE BOOTS CO PLC

Device and method for enhancing flexibility of interface between 3G communication module and application processor

InactiveUS8751719B2Increase flexibilityOverall design flexibilitySubstation equipmentRadio transmissionThird generationComputer module

This invention provides a device and method for enhancing flexibility of interface between 3G communication module and application processor. The device comprises the 3G communication module, the AP and an interface transfer module connected between them, wherein the interface transfer module is configured to perform bus transfer. A bus interface of the 3G communication module adapted to voice service data and a bus interface of the AP adapted to voice service data are directly connected. The bus transfer in the present invention is: the interface transfer module converts the bus data format of the non-voice service data adapted to the 3G communication module or the AP into the bus data format of the non-voice service data adapted to the AP or the 3G communication module. With this invention, the 3G communication module can be connected with various APs conveniently, and the generality of the 3G communication module is improved.

Owner:ZTE CORP

Material transportation system, transportation method and storage apparatus

ActiveUS11299347B2Increase flexibilityReduce design costDigital data processing detailsSemiconductor/solid-state device manufacturingProcess engineeringDelivery system

The present invention provides a material transportation system, a material transportation method and a material storage apparatus. The material storage apparatus is provided with a movable storage rack, wherein the movable storage rack is configured for carrying a plurality of material boxes and can be separated from the material storage apparatus; and an automatic transportation apparatus can move freely along any route in any direction, wherein the automatic transportation apparatus is configured for carrying the movable storage rack. Moreover, the movable storage rack is sent to be in front of the material storage apparatus or transported from the material storage apparatus to a target storage position. The present invention simultaneously transports a plurality of material boxes between the material storage apparatuses and between the material storage apparatus and the processing equipment.

Owner:SHANGHAI FORTREND TECH CO LTD

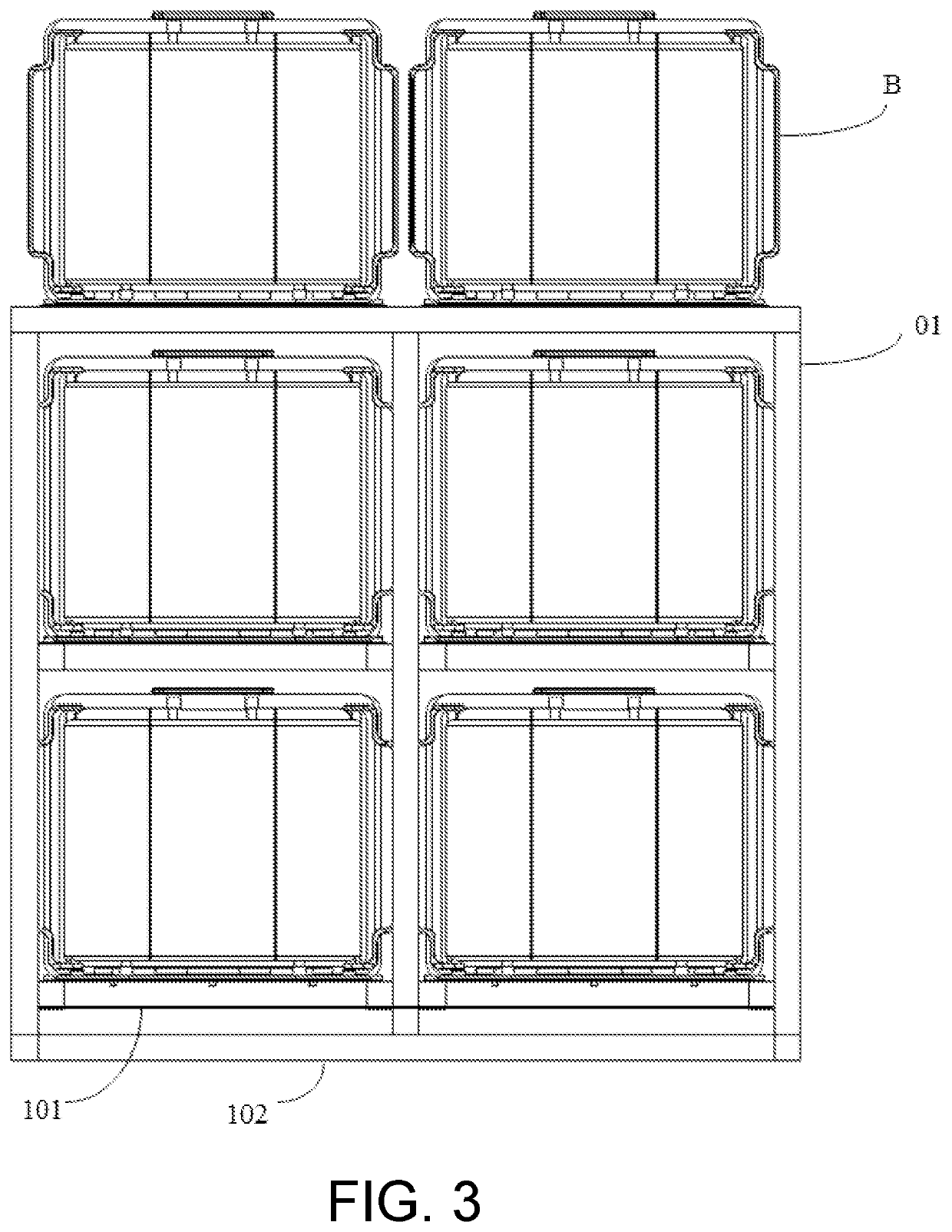

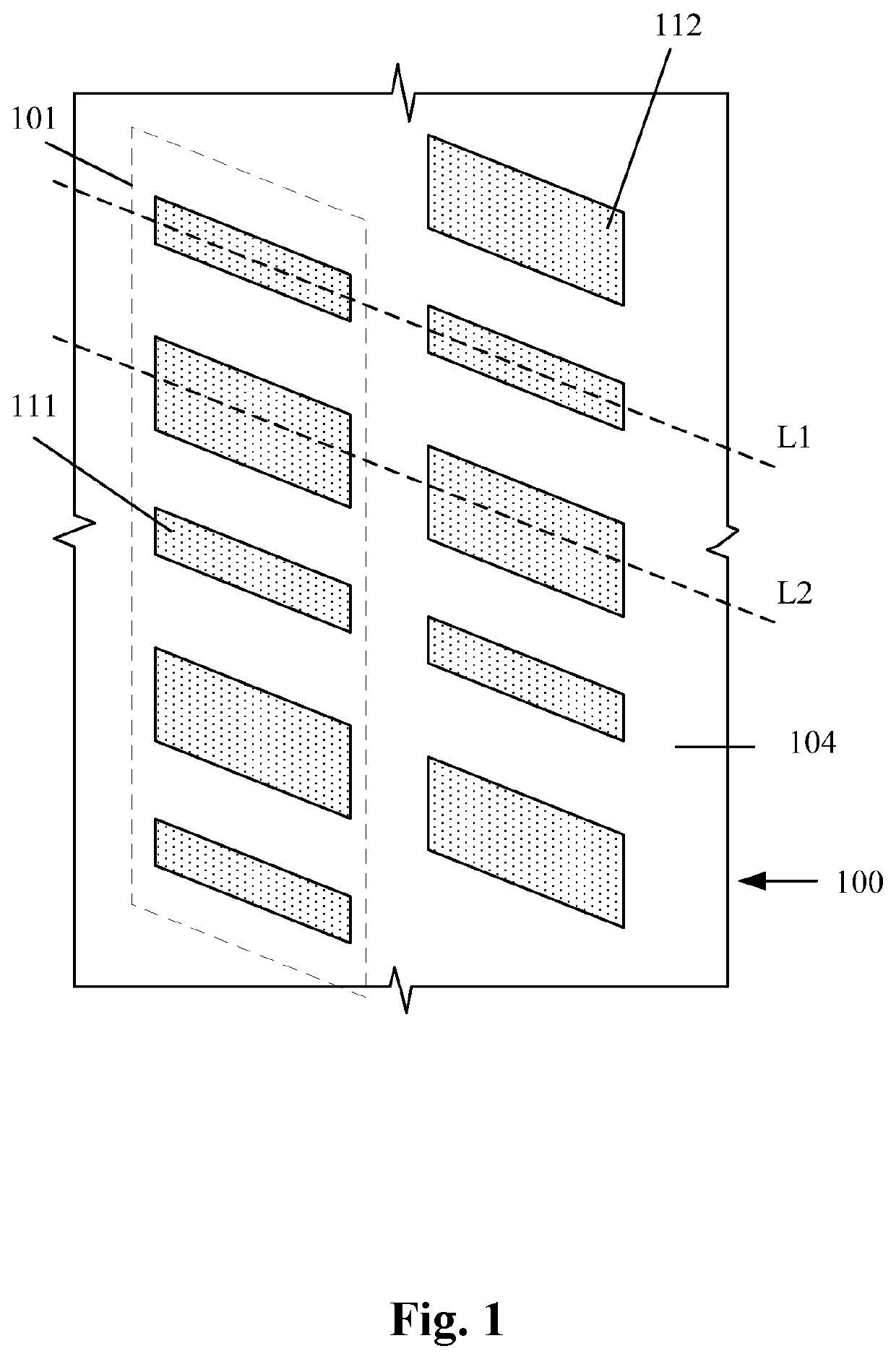

Dynamic random access memory array, semiconductor layout structure and fabrication method thereof

ActiveUS20200279594A1Fabrication difficultyIncrease the turn-on voltageTransistorSemiconductor/solid-state device detailsEngineeringComputer science

A semiconductor layout structure for a dynamic random access memory (DRAM) array, comprising an isolation structure and a plurality of active areas situated in a semiconductor substrate, each of the active areas extending along a length-wise central axis. The isolation structure is situated among the active areas. The active areas are arranged in an array and comprise a plurality of first active areas and a plurality of second active areas. The first active areas are arranged along a first length-wise direction of the active areas. The second active areas are arranged along a second length-wise direction of the active areas. The first active areas are parallel and adjacent to the second active areas, and the first and second active areas are alternately distributed in a direction of word-lines. The first active area having a first width smaller than a second width of the second active area.

Owner:CHANGXIN MEMORY TECH INC

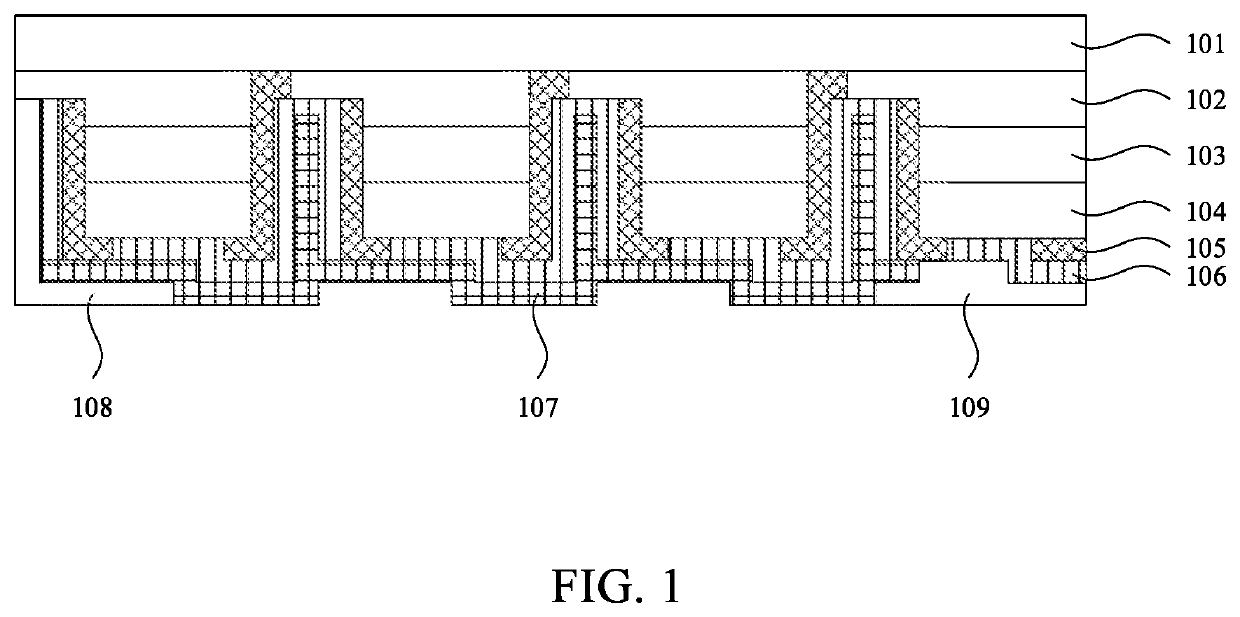

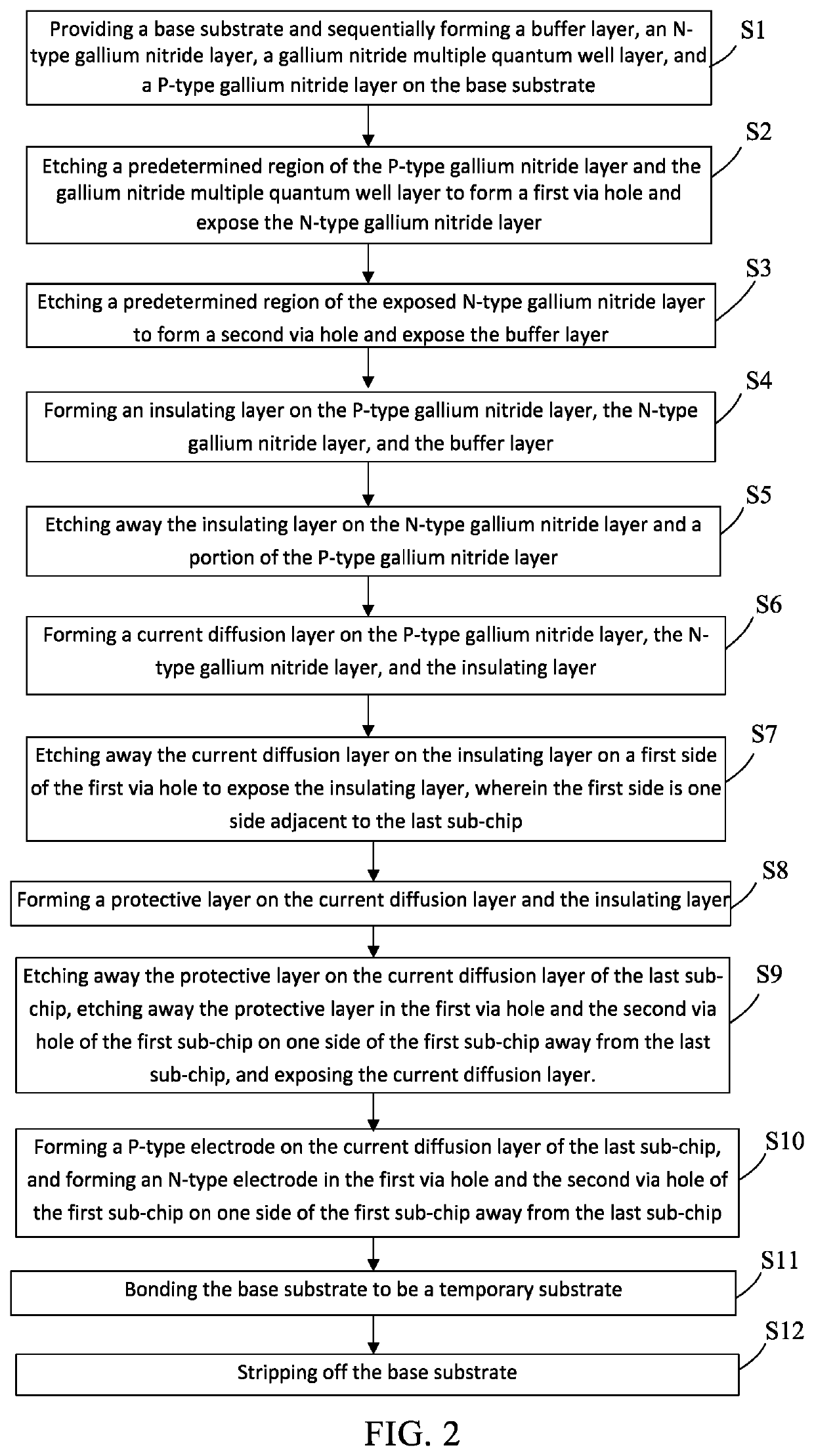

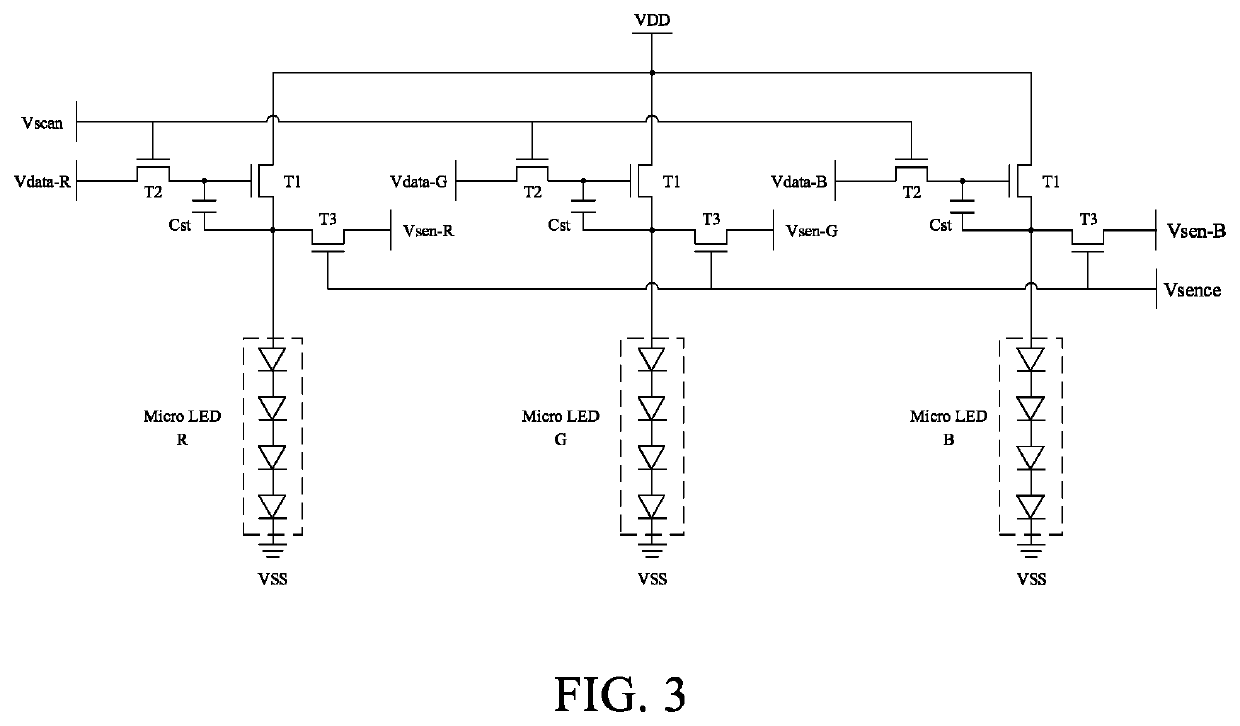

Micro-LED chip and manufacturing method thereof, and display panel

ActiveUS11316069B2High voltageReduce power consumptionSolid-state devicesSemiconductor devicesLED displayDisplay device

The present invention provides a micro-LED chip, a manufacturing method of the micro-LED chip, and a display panel. The micro-LED chip includes a plurality of sub-chips connected in series. The first sub-chip and the last sub-chip are connected to a first electrode and a second electrode, respectively. Accordingly, a voltage across the micro-LED chip is increased, power consumption of a driving thin film transistor (TFT) is reduced, and a high power consumption problem of driving TFTs in conventional micro-LED displays is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

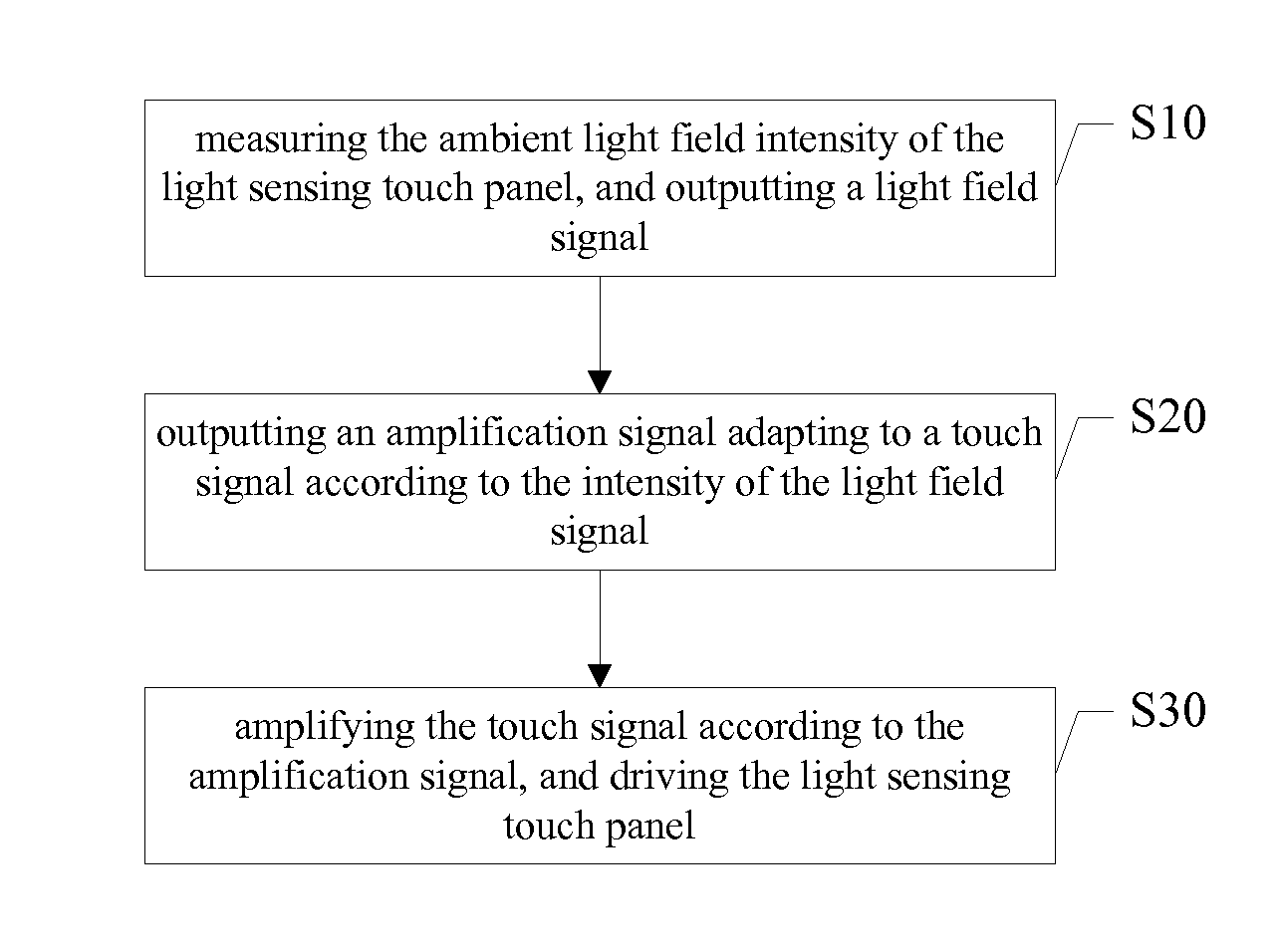

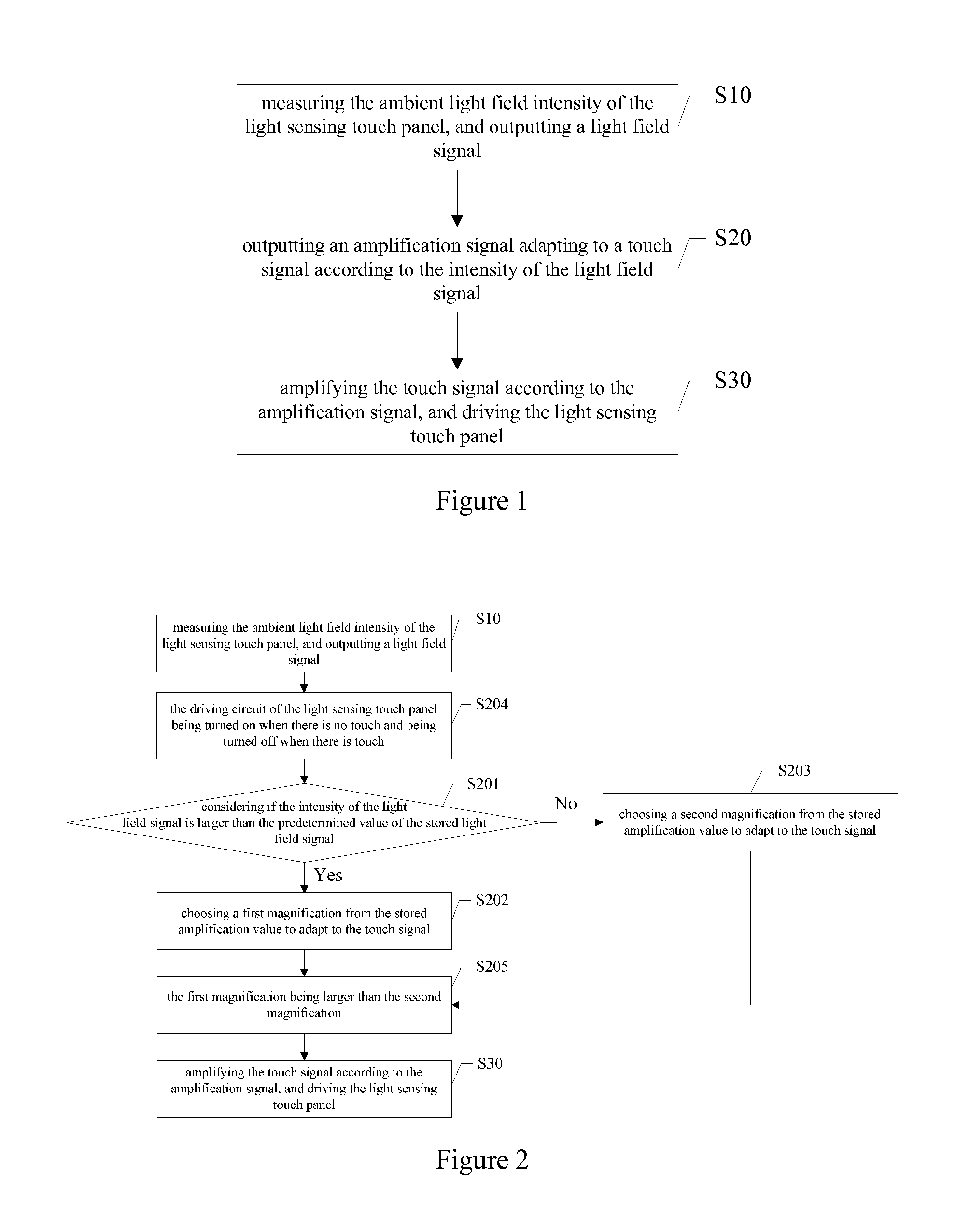

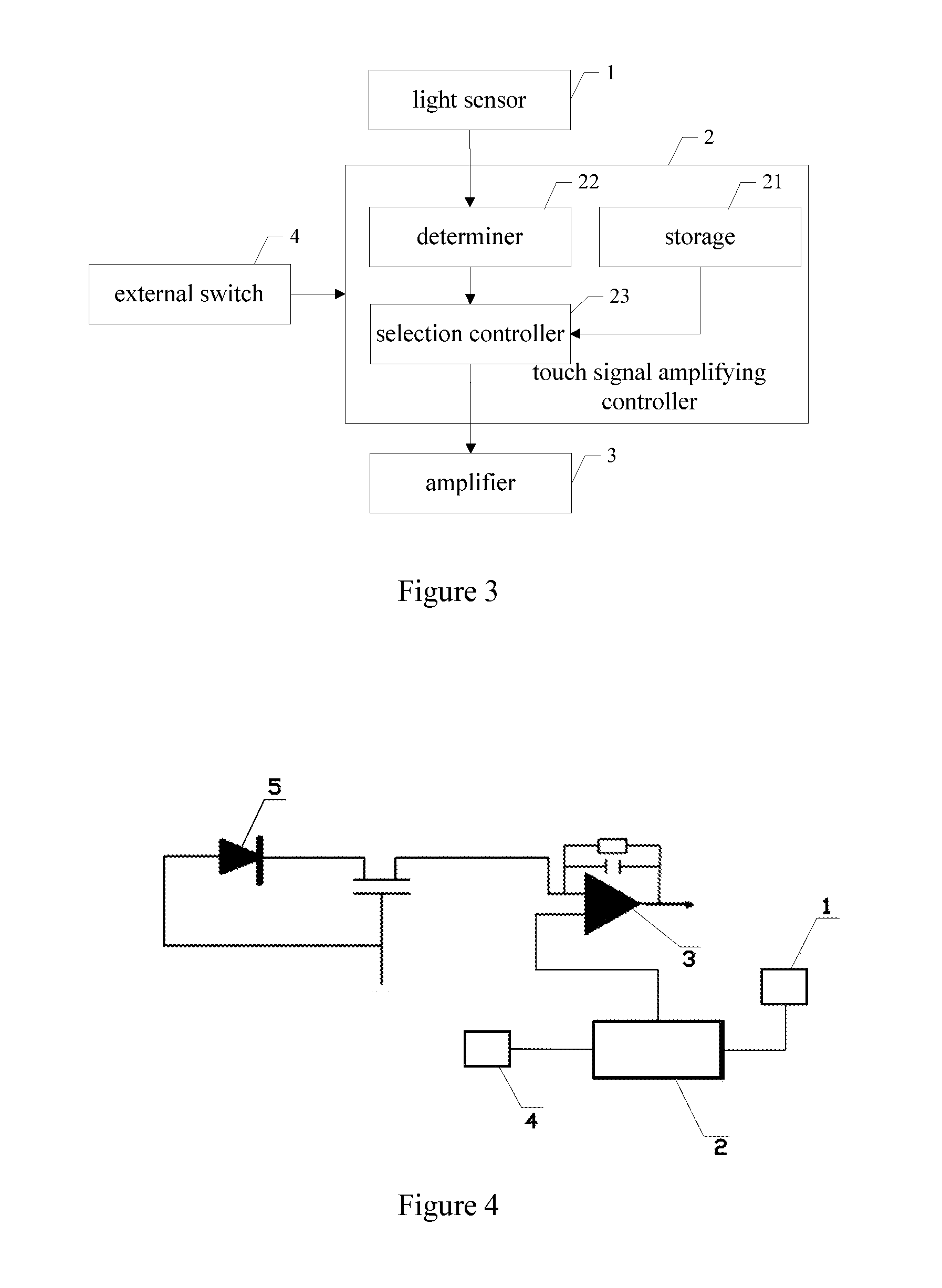

Light Sensing Touch Panel and Low-Power Driving Control Method Thereof

ActiveUS20150187245A1Reduce power consumptionWithout affecting touch sensitivityStatic indicating devicesDigital data processing detailsLight sensingTouch panel

The present invention discloses a low-power driving control method of light sensing touch panel, which comprises the following steps: measuring the ambient light field intensity of the light sensing touch panel, and outputting a light field signal; outputting an amplification signal adapting to a touch signal according to the intensity of the light field signal; amplifying the touch signal according to the amplification signal, and driving the light sensing touch panel. The present invention further discloses a light sensing touch panel. The light sensing touch panel and the low-power driving control method thereof according to the present invention can reduce the power consumption of the touch panel without affecting the touch sensitivity.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

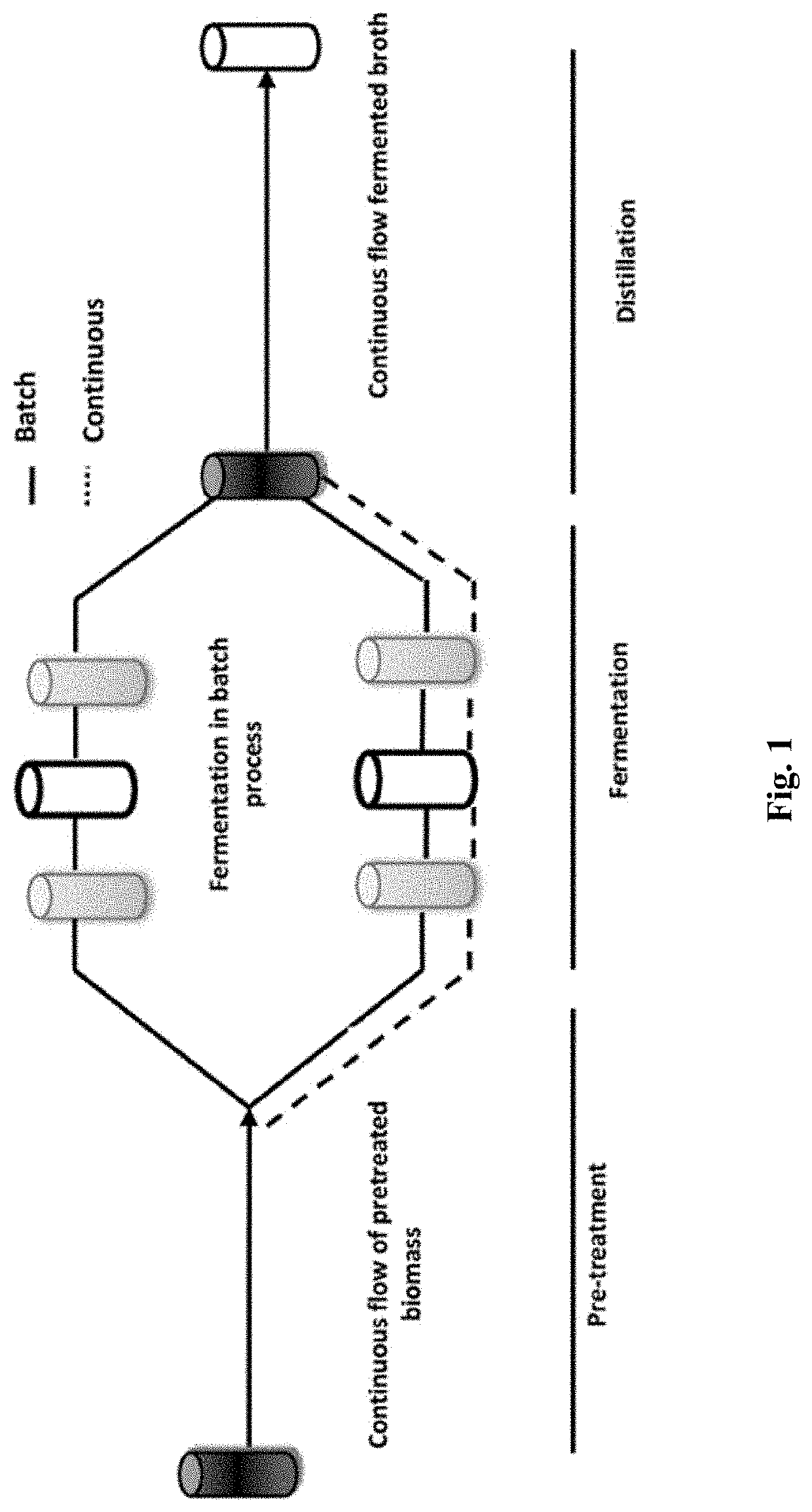

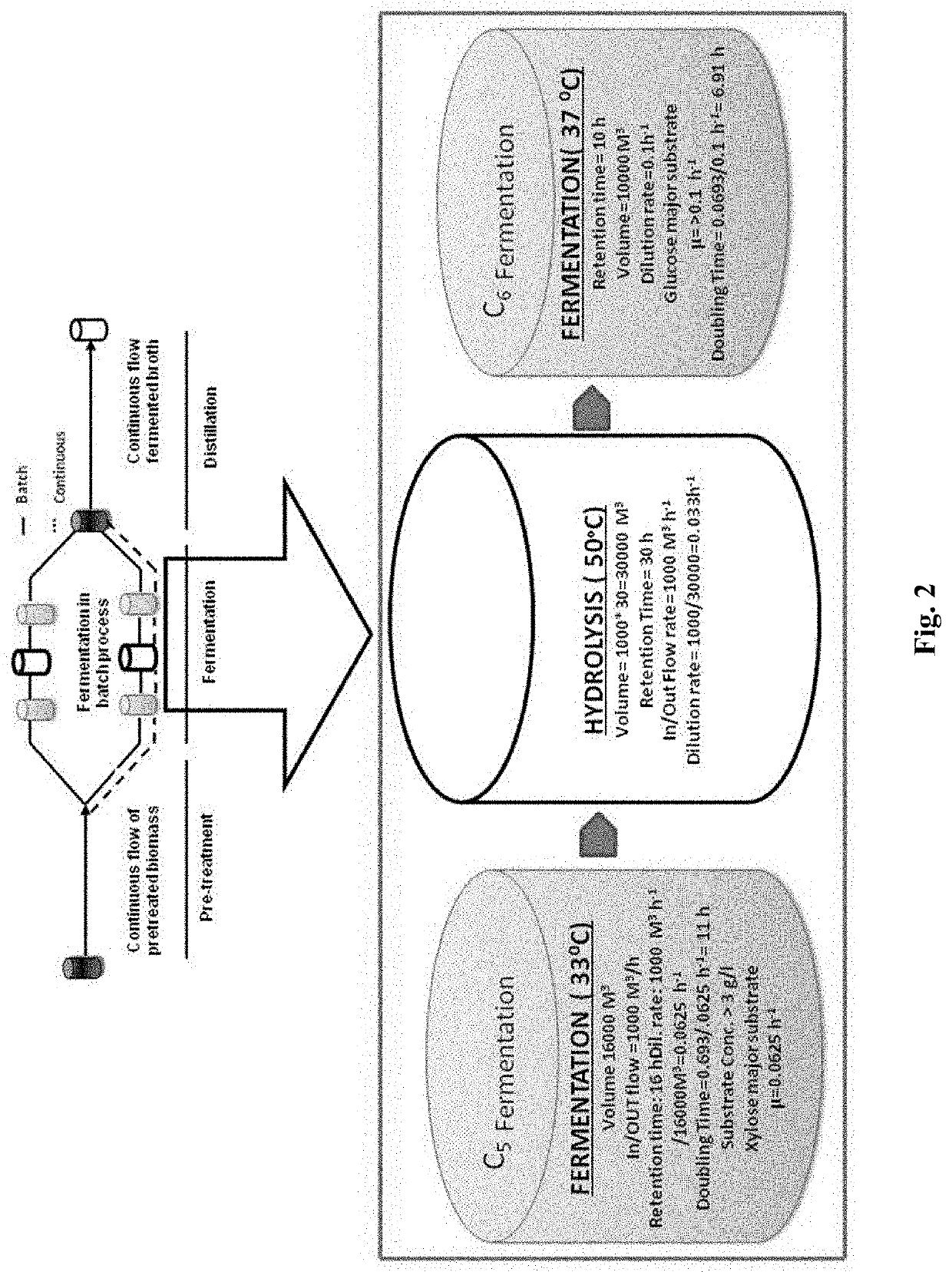

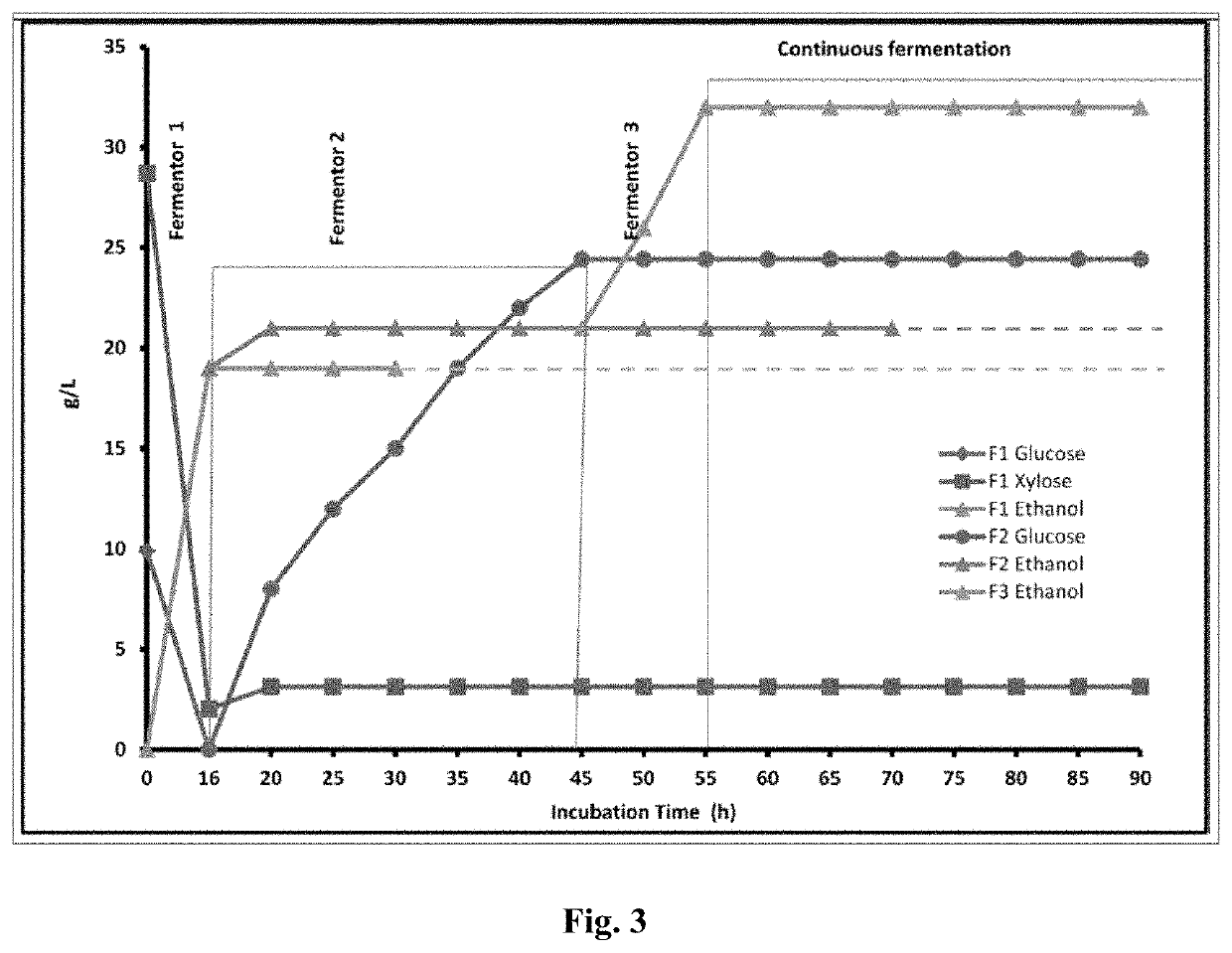

Method for continuous second-generation ethanol production in simultaneous saccharification and co-fermentation process

PendingUS20210246474A1High ethanol titerSave overall energy inputBiofuelsFermentationCelluloseHydrolysate

The present invention relates to a process for continuous production of second-generation ethanol from lignocellulosic biomass via continuous simultaneous saccharification and co-fermentation (SSCF) process, wherein the process includes a first fermentor vessel for selectively fermenting C5 sugars and then Continuous transferring the fermented biomass to a second fermentor vessel for hydrolyzing the fermented biomass and then Continuous transferring the hydrolysate to a third fermentor vessel for selectively fermenting C6 sugars to obtain ethanol. Overall, the ethanol yield achieved was up to 70% for both C5 and C6 sugars from pretreated biomass; and C5 utilization exceeded 95% after SSCF.

Owner:INDIAN OIL CORPORATION +1

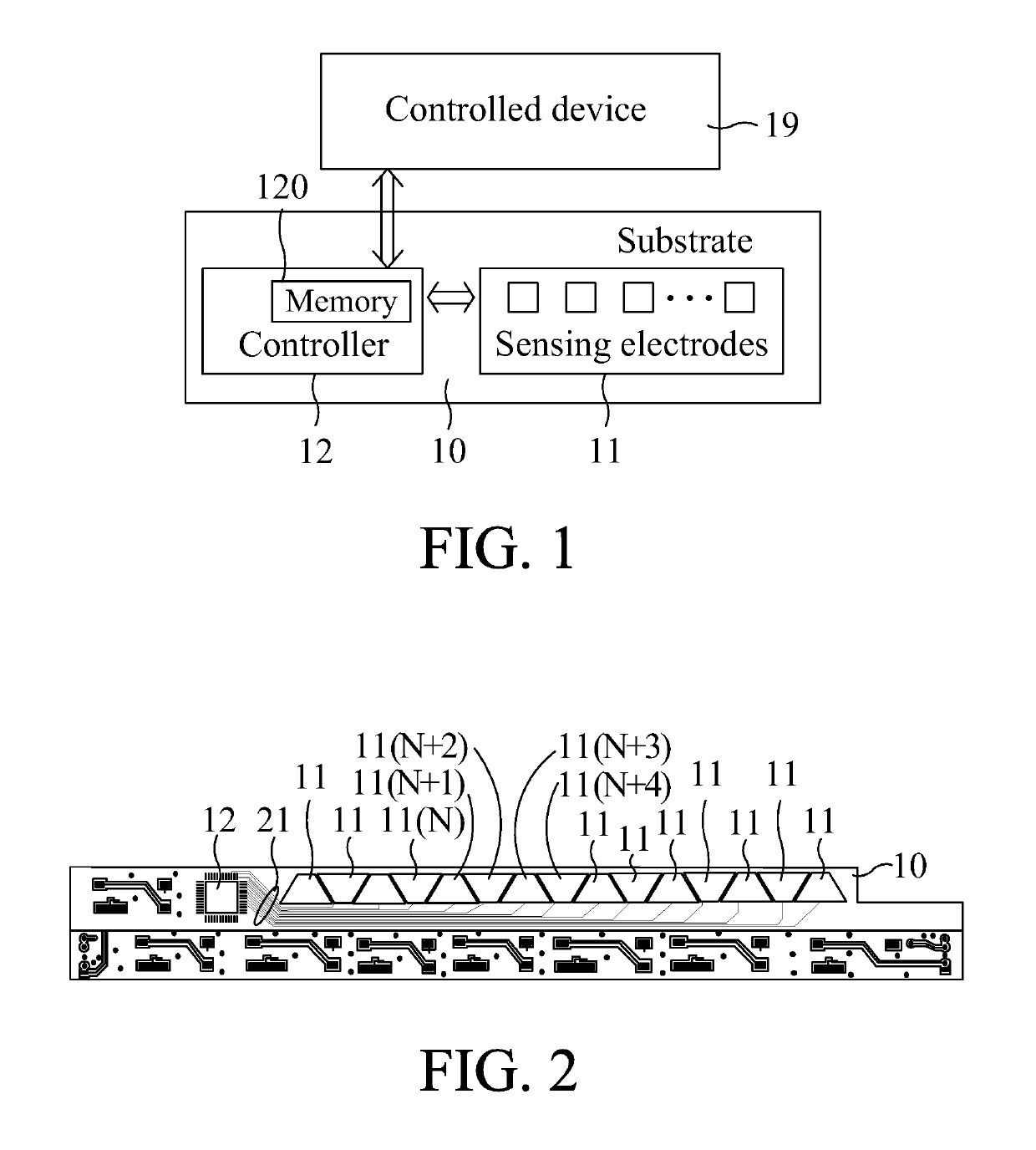

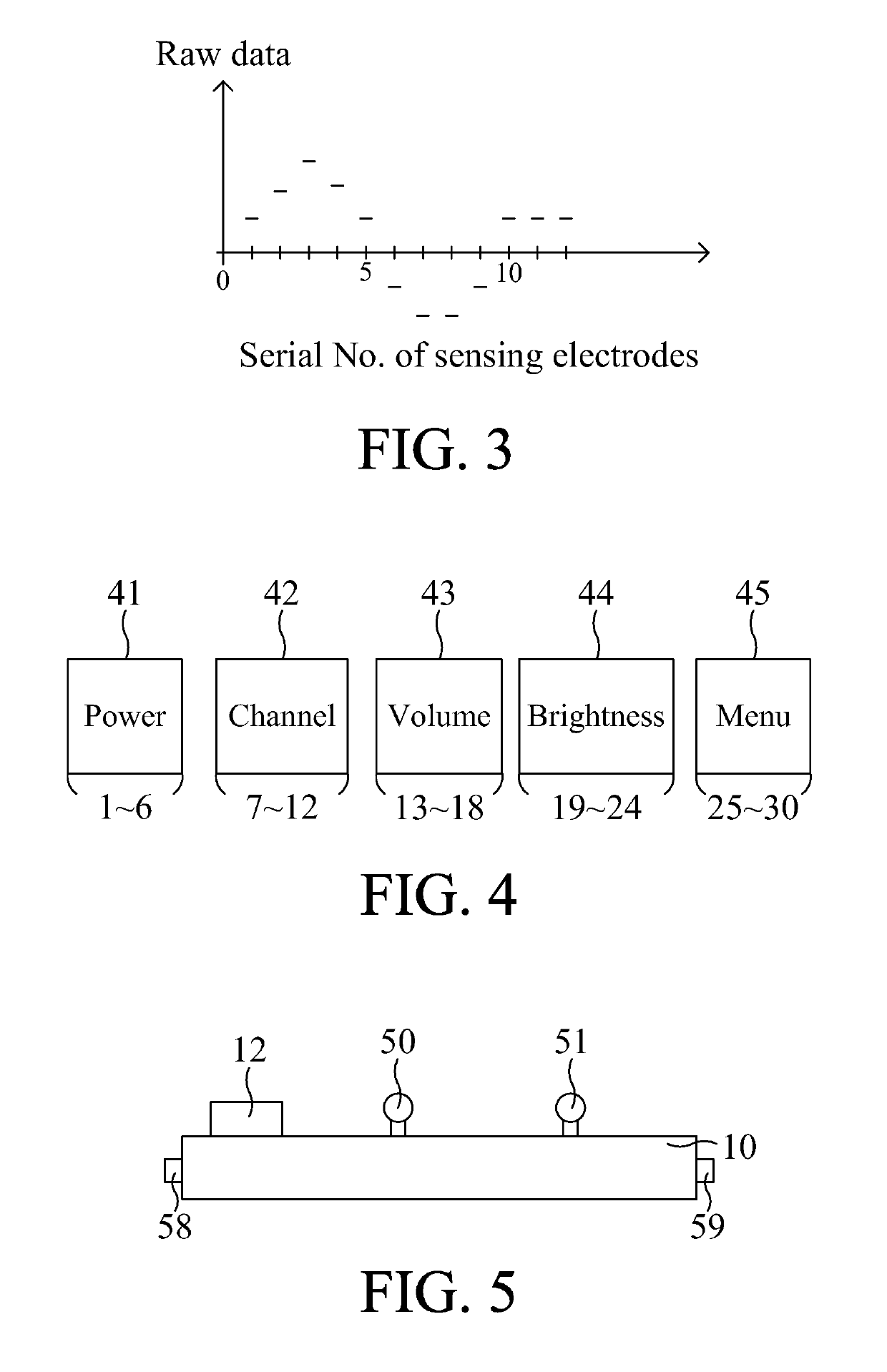

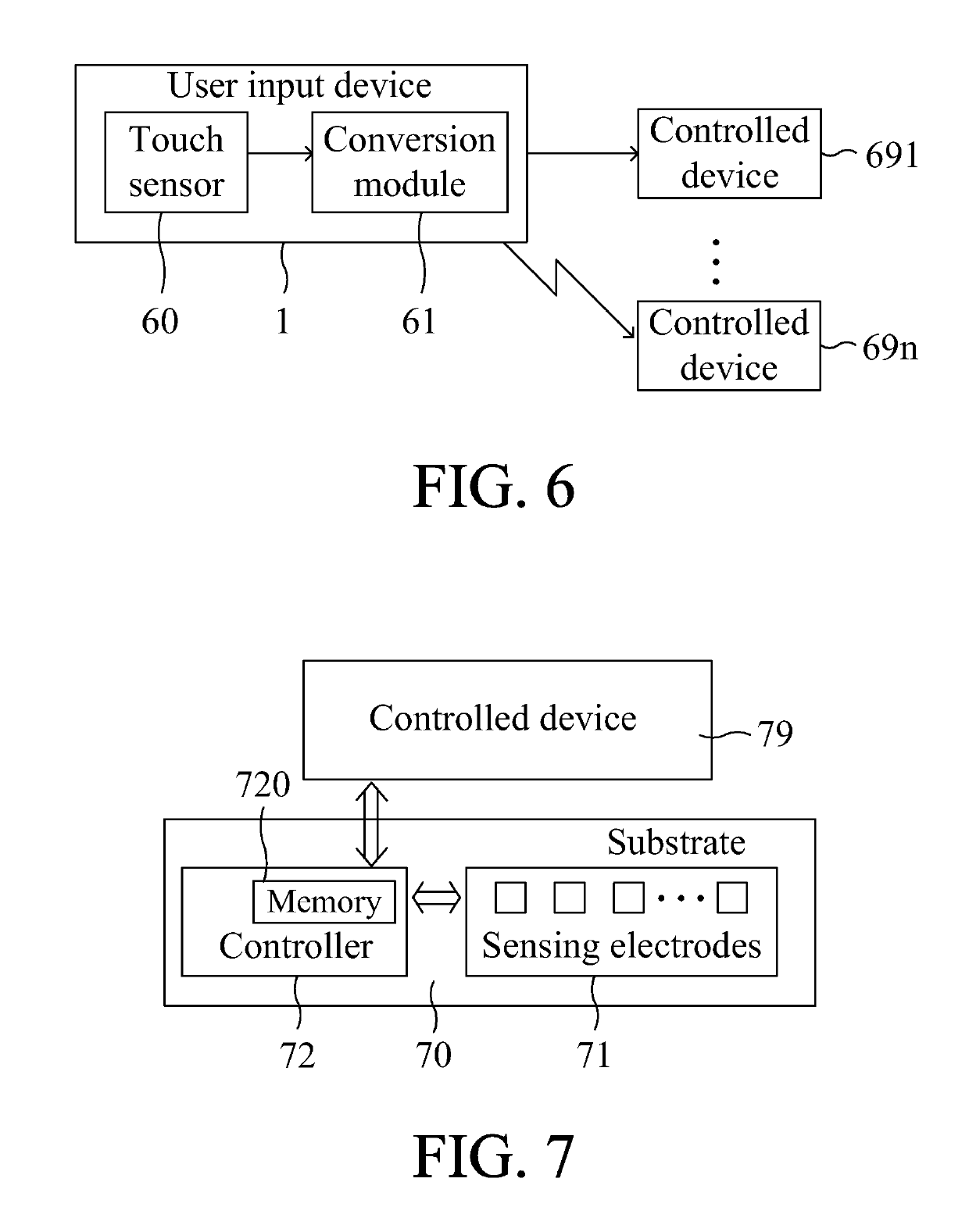

Adaptive user input device

ActiveUS10409485B2Highly problematicNon-electrical signal transmission systemsElectronic switchingElectricityCapacitance

A user input device for use with a controlled device. The user input device includes a substrate; a plurality of sensing electrodes disposed separately on or in the substrate for sensing an object; and a controller electrically coupled to the sensing electrodes and stored therein at least one virtual key allocation table, wherein the controller executes a converting operation to generate a sensed object information according to a capacitance data realized from the sensing electrodes, and generates an input command associated with a specified key in the virtual key allocation table, which corresponds to the sensed object information, for controlling the controlled device. The same sensed object information can be designed to correspond to keys of different definition under different virtual key allocation tables, and / or derive different input commands in different operational.

Owner:DECENTRALIZED MOTION INTELLIGENCE CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com