Cyclone furnace for oxygen fired boilers with flue gas recirculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

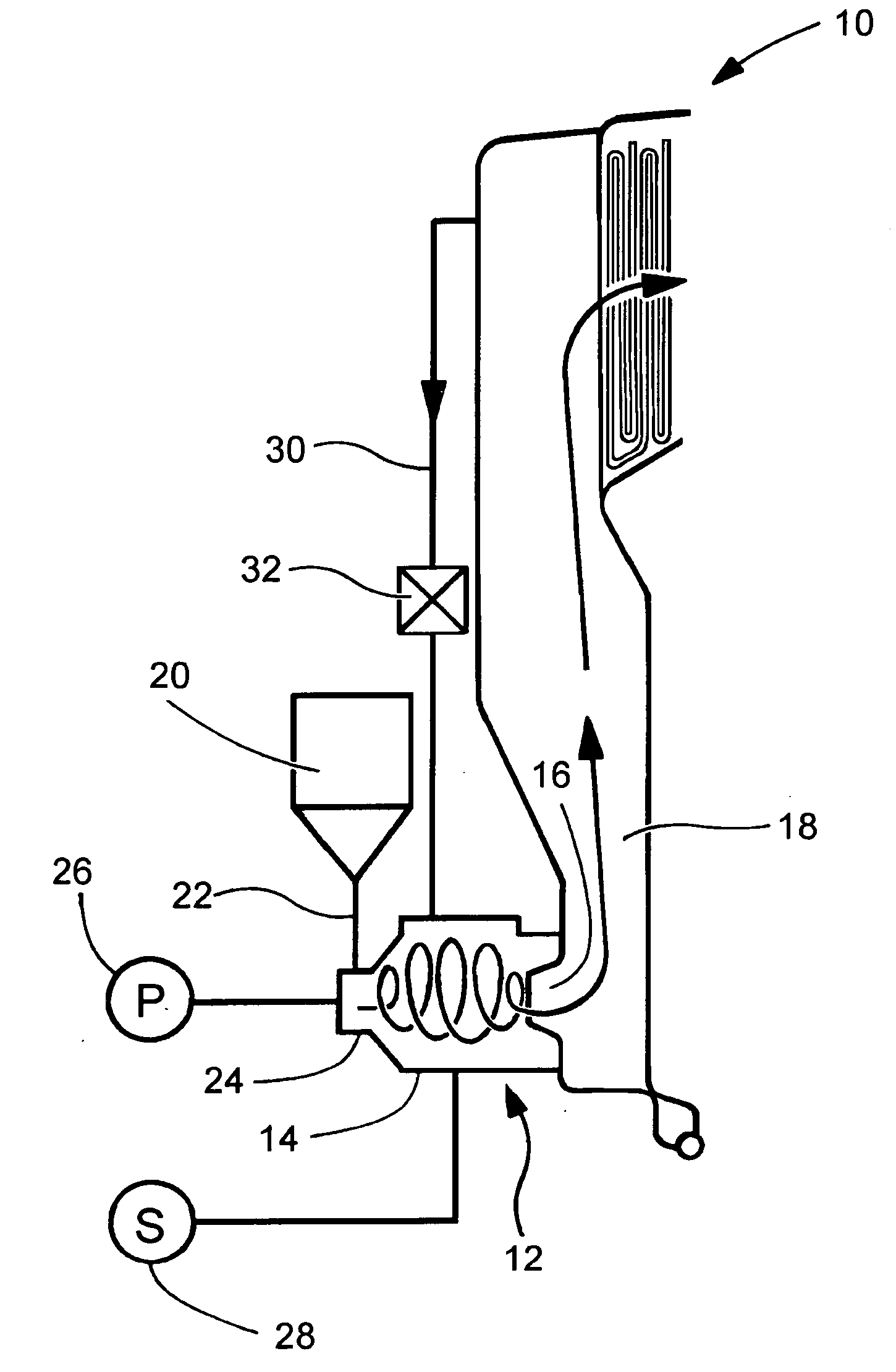

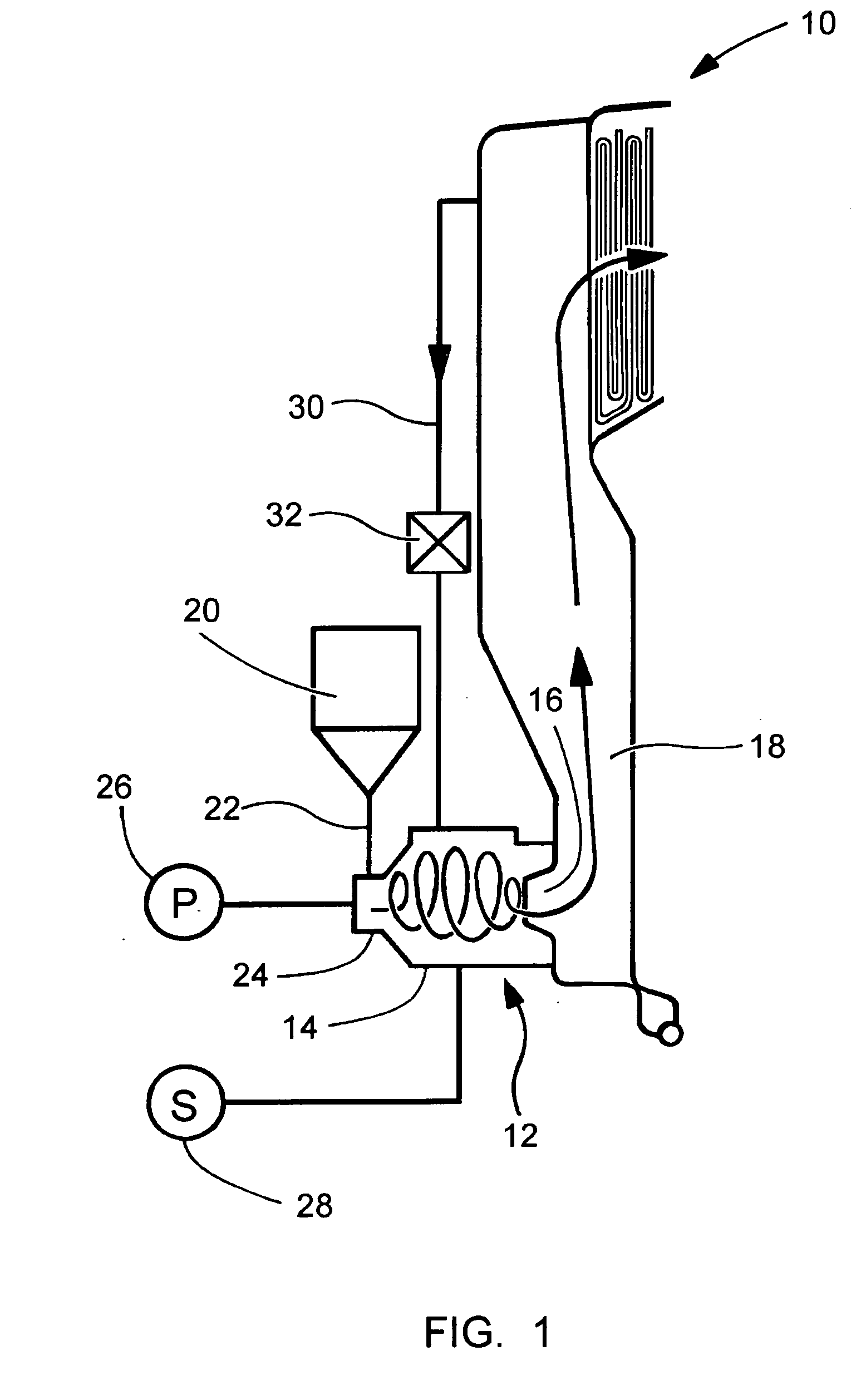

[0012] Referring now to the drawing, FIG. 1 shows a cyclone furnace generally designated 10 having a cyclone burner generally designated 12 with a generally cylindrical cyclone barrel 14 having an outlet or re-entrant throat 16 for discharging combustion products that have been produced in the cyclone furnace as will be explained later in this disclosure. The throat 16 is connected to the lower end of a main furnace 18 with the upwardly directed arrows identify the combustion products which include flue gases that are rich in carbon dioxide.

[0013] Heat from these hot combustion products are taken away preferably by tubes containing water and / or steam in the environment of a boiler where the heat is used for other purposes.

[0014] Crushed rather than pulverized coal is stored in a coal bunker 20 and, using known equipment, is supplied along a fuel supply line 22 to a crushed coal inlet at the top of a radial burner 24. Primary and tertiary flue gas are supplied to burner 24 by suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com