Quadrant and anterior dental shells and method of making a multi-tooth crown or bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

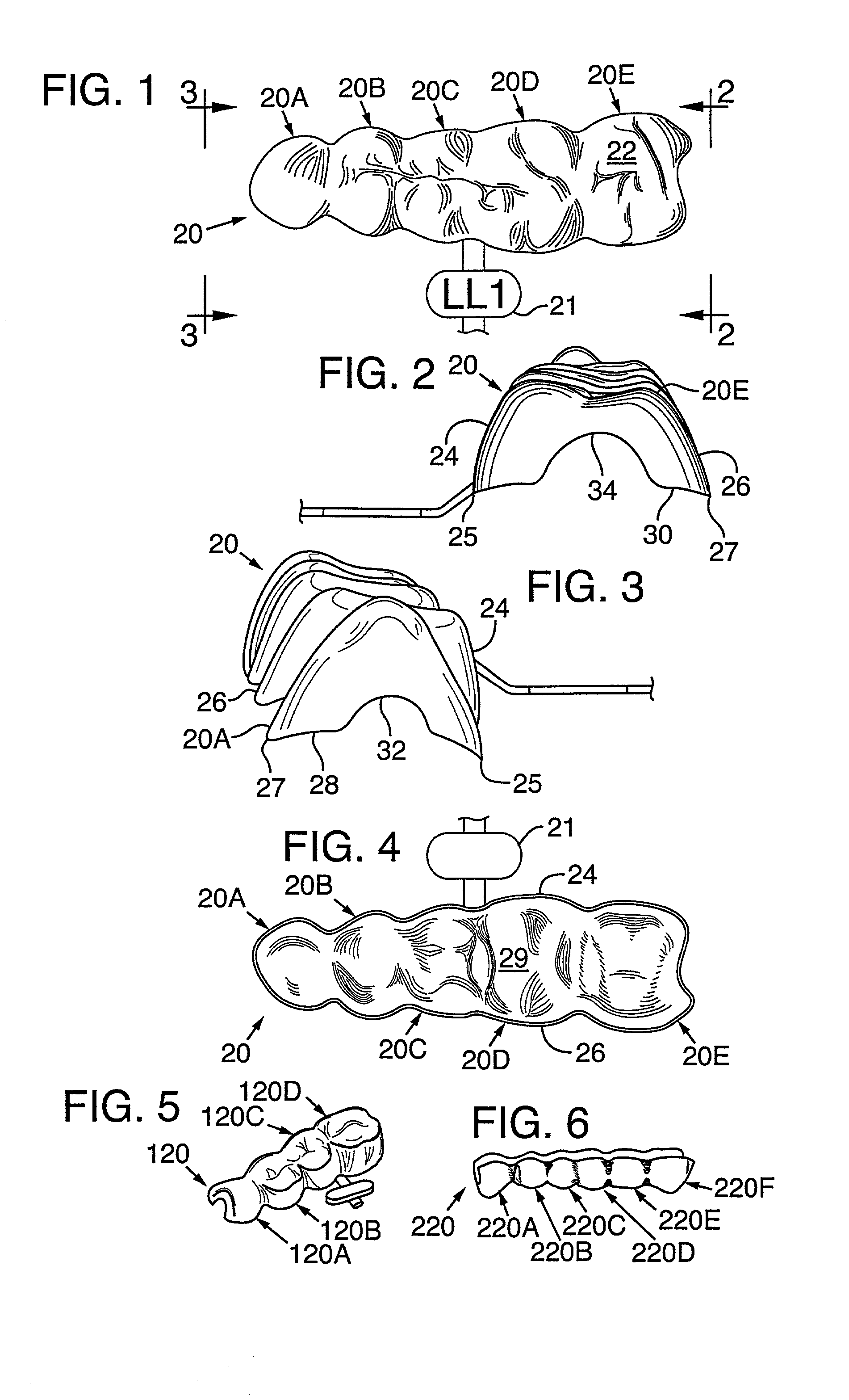

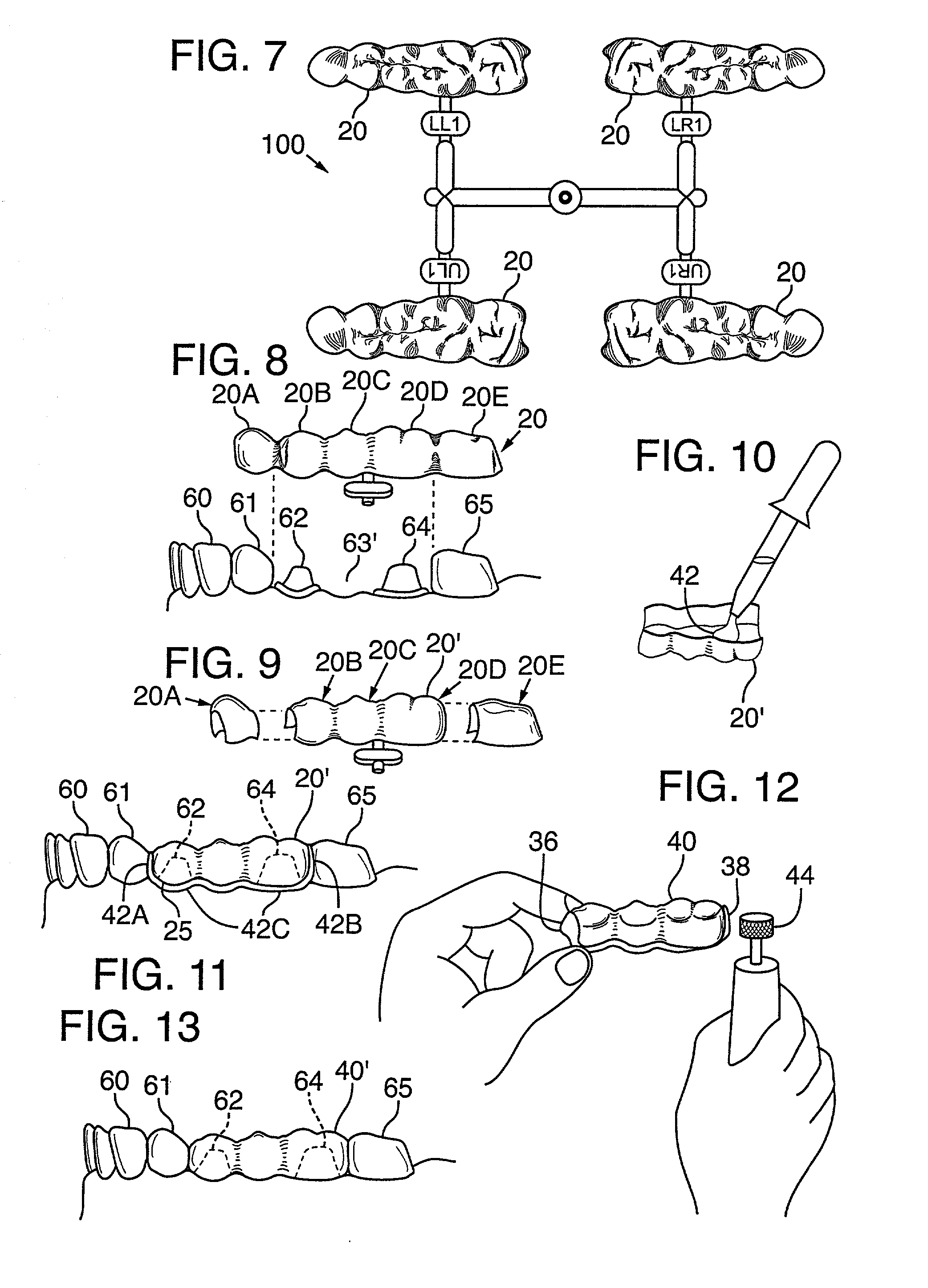

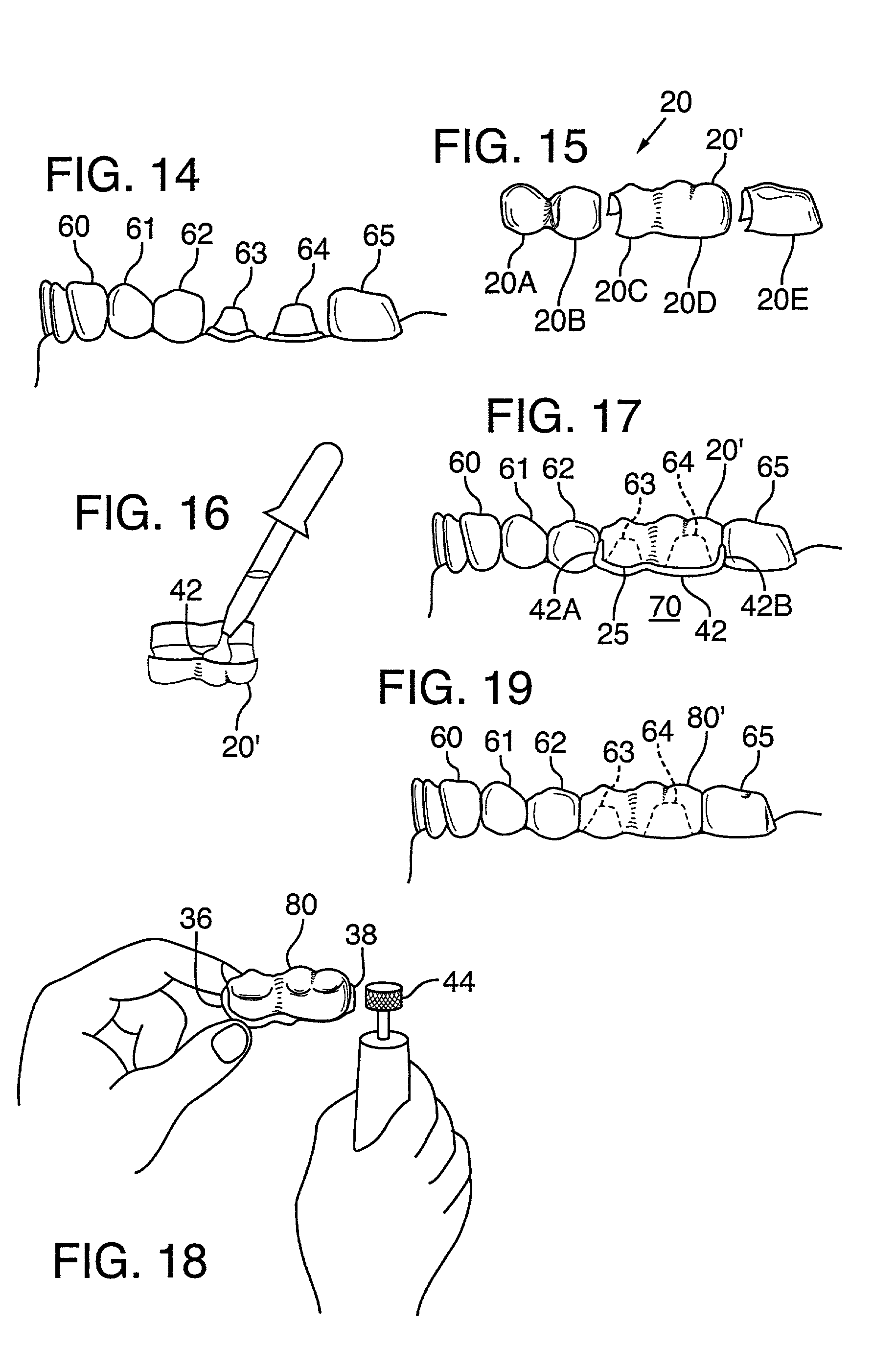

[0052] Generally, a multi-tooth shell according to this invention is an integrally molded unit having multiple single-tooth shell segments, wherein each segment corresponds to a different tooth. Each segment has an external shape approximating the buccal, lingual, and occlusal anatomy of the corresponding natural human tooth. Each segment also has an interior cavity sized to fit over a prepared tooth and to be filled with resin.

[0053] Various different tooth types can be represented by the shell segments in different multi-tooth shells. For a quadrant shell, these tooth types can include cuspids, bicuspids, and molars. For an anterior shell, they can include cuspids, canines, and incisors. For a hybrid quadrant / anterior shell, these shell segments can correspond to any combination of quadrant and anterior teeth in the order normally occurring in a patient's dentition.

[0054] Quadrant shells are preferably formed with segments corresponding to four or five individual teeth within a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com