Antenna device

a technology of antenna support and antenna body, which is applied in the structural form of antennas, antenna supports/mountings, radiating elements, etc., can solve the problems of handling thin flexible items in the manufacturing process, and achieve the effect of facilitating the manufacturing of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

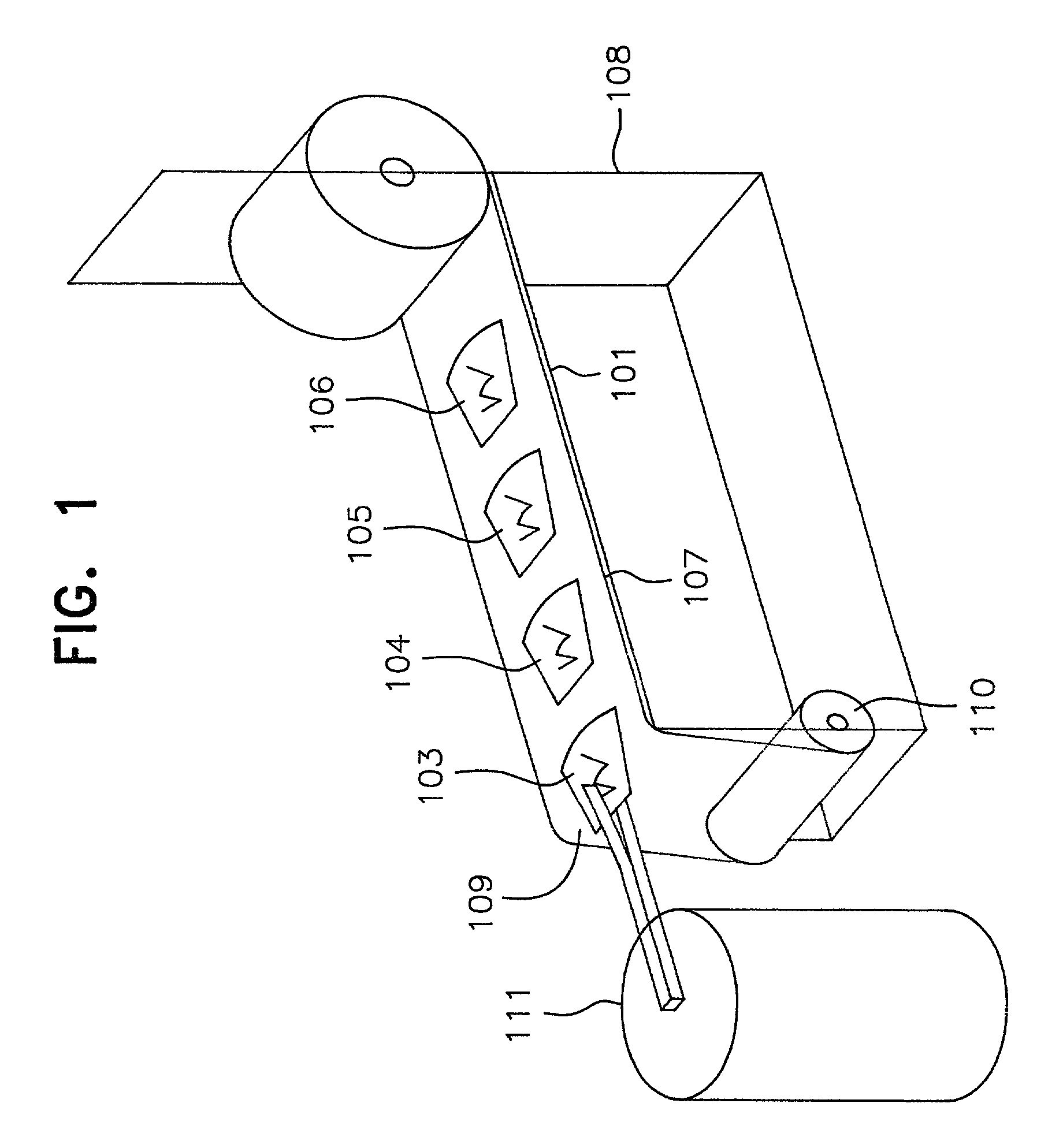

[0021] FIG. 1 shows a long flexible film 101 arranged in a roll 102. The film 101 comprises antenna elements, whereof four 103, 104, 105 and 106 are visible, and a protective carrier layer 107. The antenna elements consist of etched printed circuits, having specific radio frequency characteristics, applied on a flexible substrate. Between the antenna elements and the protective layer 107 is an adhesive agent present (not shown). The roll 102 is mounted on a stand 108 according to known methods and the film 101 is fed over an edge 109 to a dispose roll 110 which collects the protective layer 107. When the film 101 is fed over the edge 109 the antenna element 103 detach from the protective layer 107. The film 101 is fed so that a convenient part of the antenna element 103 protrudes out from the edge 109. This enables a mounting machine 111 to easy grab the antenna element 103 for mounting on a antenna support structure (not shown). The mounting machine 111 is depicted in a schematic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

| adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap