Radiation-curable fiber optic materials having reduced moisture content

a technology of fiber optic materials and fiber optic fibers, applied in the direction of coatings, polyurea/polyurethane coatings, etc., can solve the problems of optical glass fiber delaminate from the inner primary coating layer, optical glass fiber weakened upon exposure to water, and optical glass fiber eventual breakage, etc., to achieve the effect of prolonging the shelf li

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

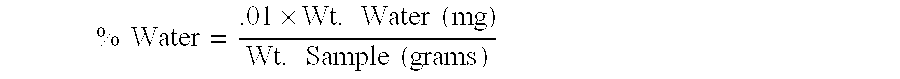

[0106] The amount of water necessary to hydrolyze the functionally-effective glass-binding groups of gamma-mercaptopropyltrimet-hoxysilane was determined. Gamma-mercaptopropyltrimethoxysilane contains in theory at least three alkoxy groups which are capable of binding to glass. However, it has been found that when one of the three alkoxy groups reacts with water via hydrolysis to form a hydroxyl group the other two alkoxy groups are significantly less active or are entirely unable to effect a bonding of the coating composition with the glass fiber surface under typical radiation-curing conditions and subsequent storage of coated glass.

[0107] It has also been found that the gamma-mercaptopropyldimethoxyhydrox-ysilane formed from the hydrolysis of gamma-mercaptopropyltrimethoxysilane will undergo an in situ condensation reaction according to the above formula 2 to produce water under normal shelf storage conditions.

example 2

[0108] The effect of the amount of water present in radiation-curable, inner primary, glass optical fiber compositions on the adhesion of the cured inner primary coating to glass was tested. Two radiation-curable compositions were made using the components shown in Table 1. The amount of water was varied, as shown in Table 2. Variance of water content was the result of determining the amount of water in each of the components prior to making the compositions. For example, Ethoxylatednonylphenolmono-acrylate, available as SR504A (Sartomer), determined to have a relatively low water content, was selected for use in sample 1 and Photomer 4003, determined to have a relatively high water content, was selected for use in sample 2.

[0109] The compositions of sample 1 and sample 2 after aging under normal storage conditions were tested to determine the amount of effective adhesion promoter remaining in the compositions.

[0110] Sample 1, the composition known to have the lower water content in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wt. % | aaaaa | aaaaa |

| storage temperature | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap