Mast and trolley arrangement for mobile multi-function rig

a multi-functional rig and mast technology, applied in the field of improved, can solve the problem that the system cannot readily accommodate a top drive mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

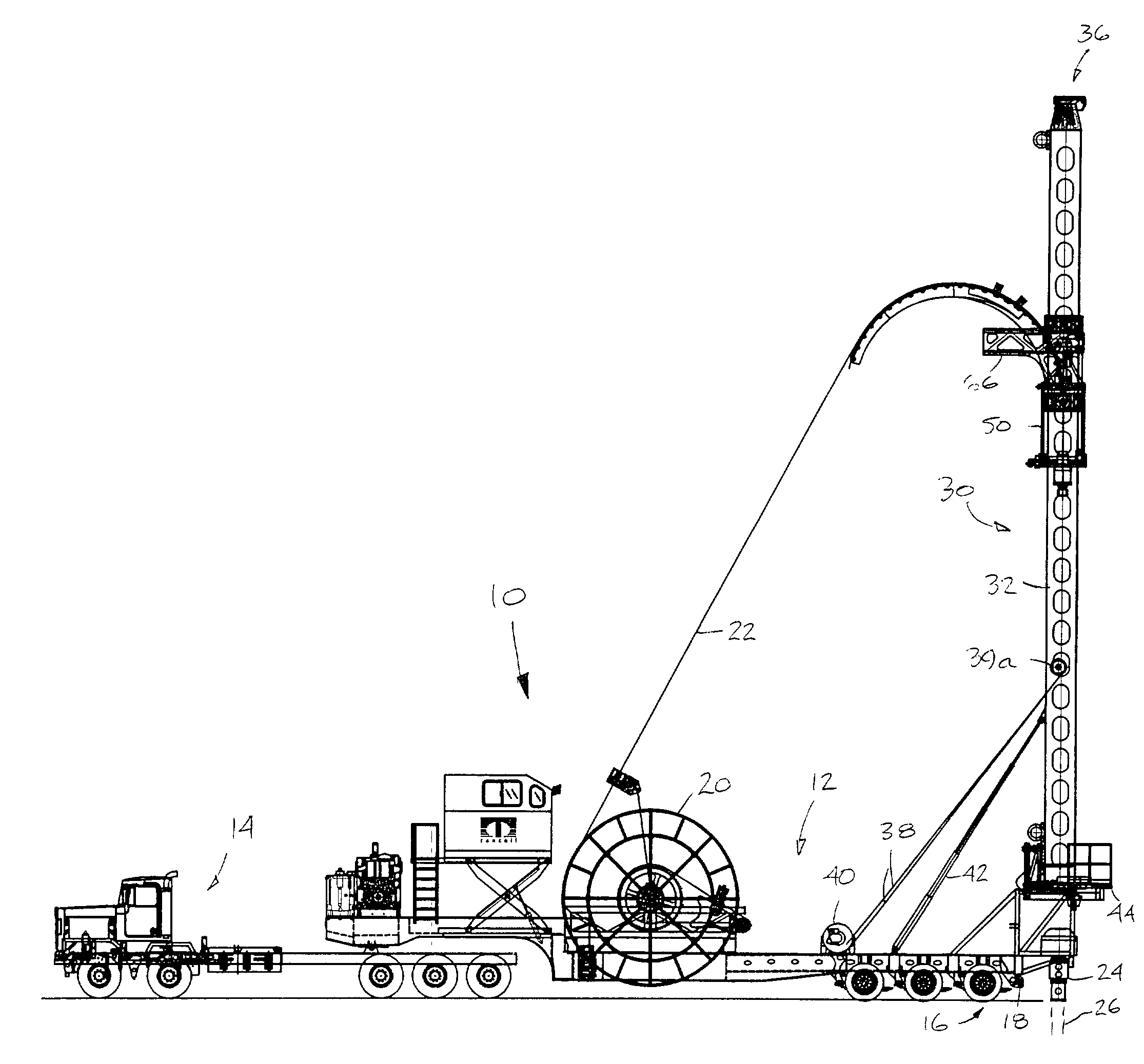

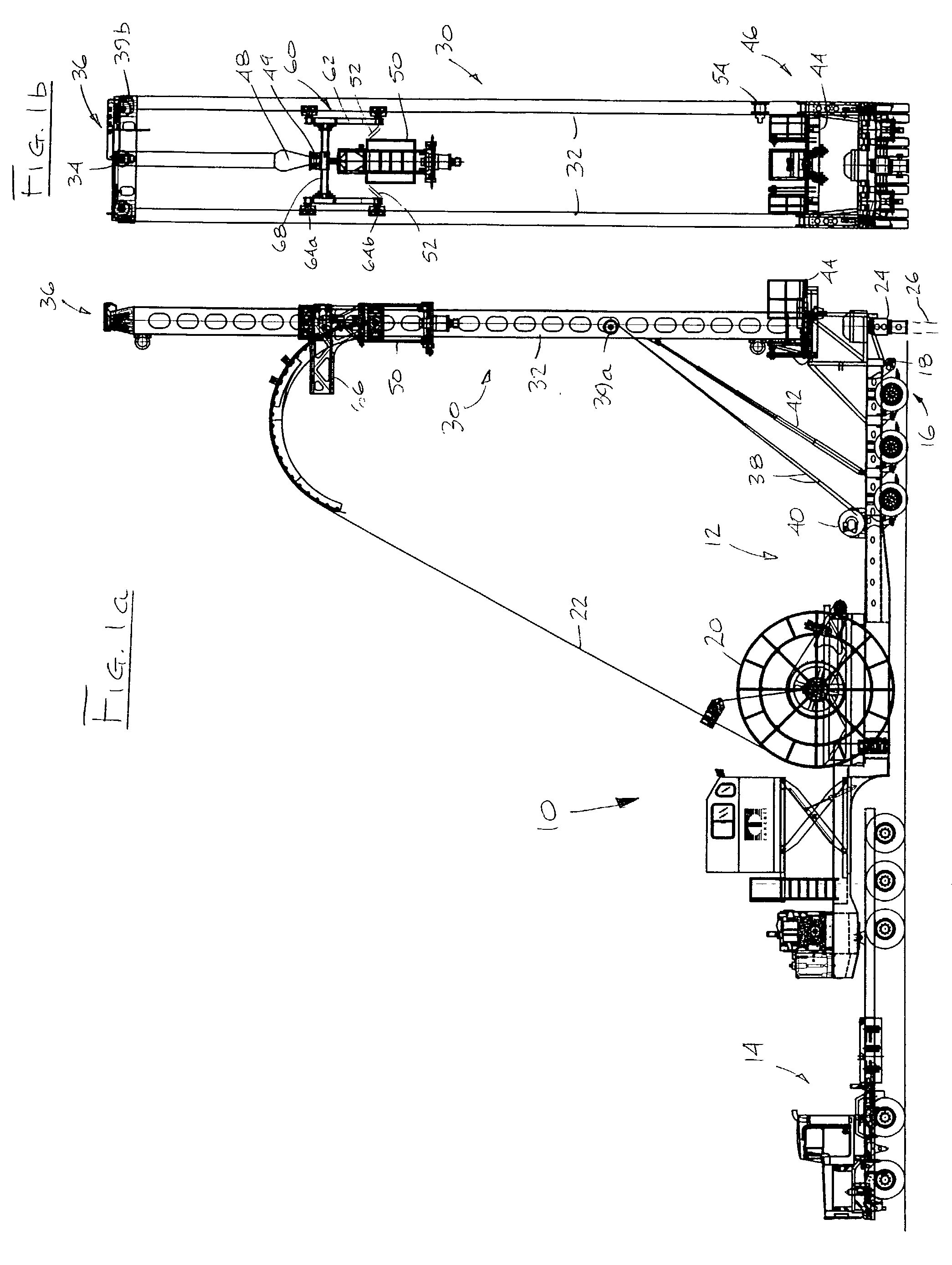

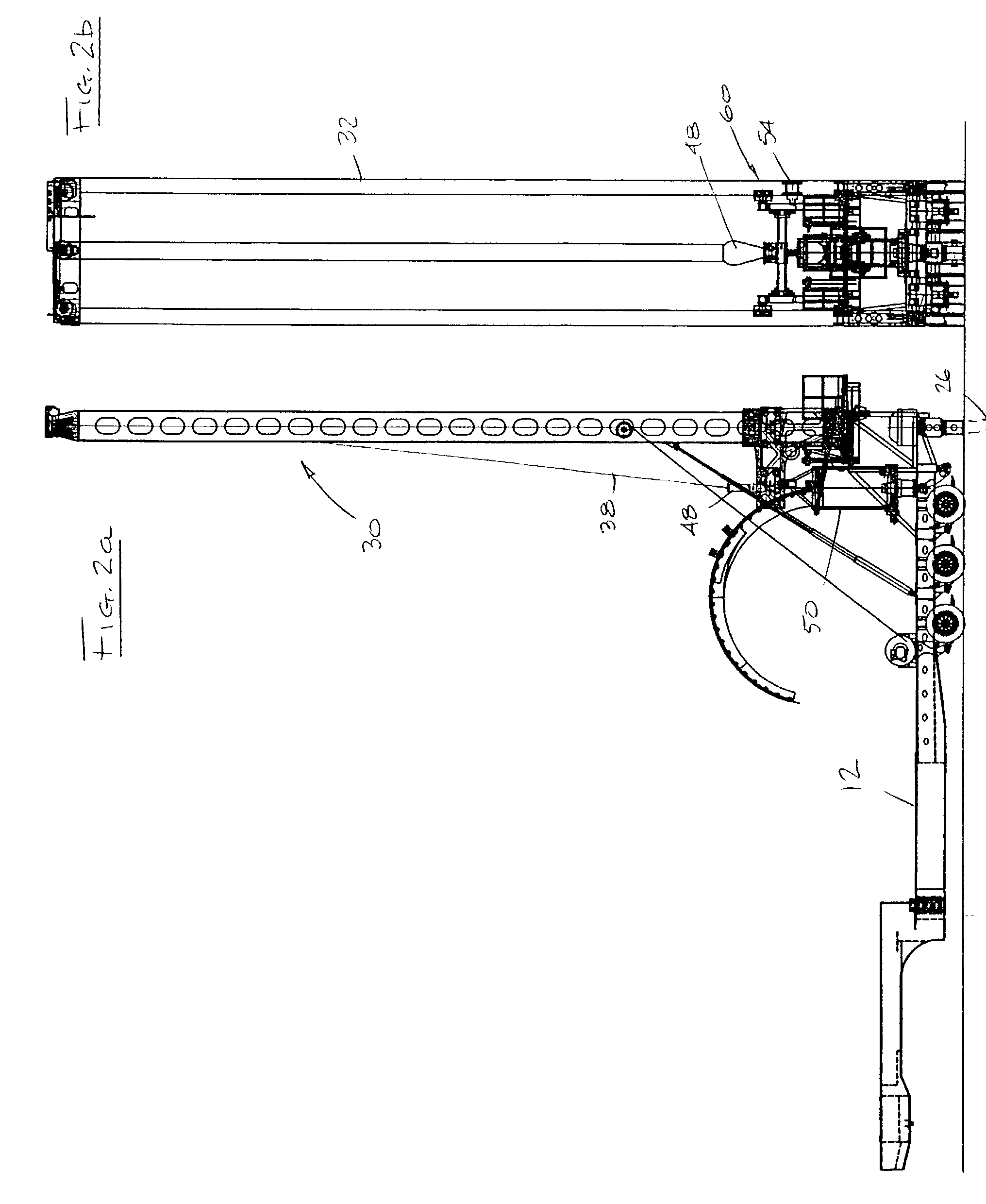

[0059] FIG. 1a shows a mobile rig (generally indicated by reference numeral 10) for transporting drilling and servicing equipment to an oil or gas well site. The equipment, such as a cartridge assembly 20 capable of holding various sizes of continuous or coiled tubing ("CT") 22, is located aboard a trailer portion 12 of the rig which is adapted to be towed by a self-propelled tractor portion 14. A triple axle rear end 16 of the trailer 12 includes a number of hydraulically operated stabilizers 18 for enhancing the trailer's lateral stability once its rear end is located over a wellhead 26 and during well operations. The term "well" is understood herein to mean either an oil or gas well to be drilled, or an existing well or wellhead which is to be tested or serviced. The rig's design is generally symmetrical about its longitudinal axis.

[0060] The rig 10 incorporates a number of drilling and servicing features aboard the trailer 12, including a mast 30 (also referred to as a "derrick"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com