Method to improve charge pump reliability, efficiency and size

a technology of capacitor dielectric and reliability, applied in the direction of electric variable regulation, process and machine control, instruments, etc., can solve the problems of capacitor dielectric used in "high-stress" circuits, oxide reliability concerns becoming more and more severe, and dielectric breakdown of capacitor dielectrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

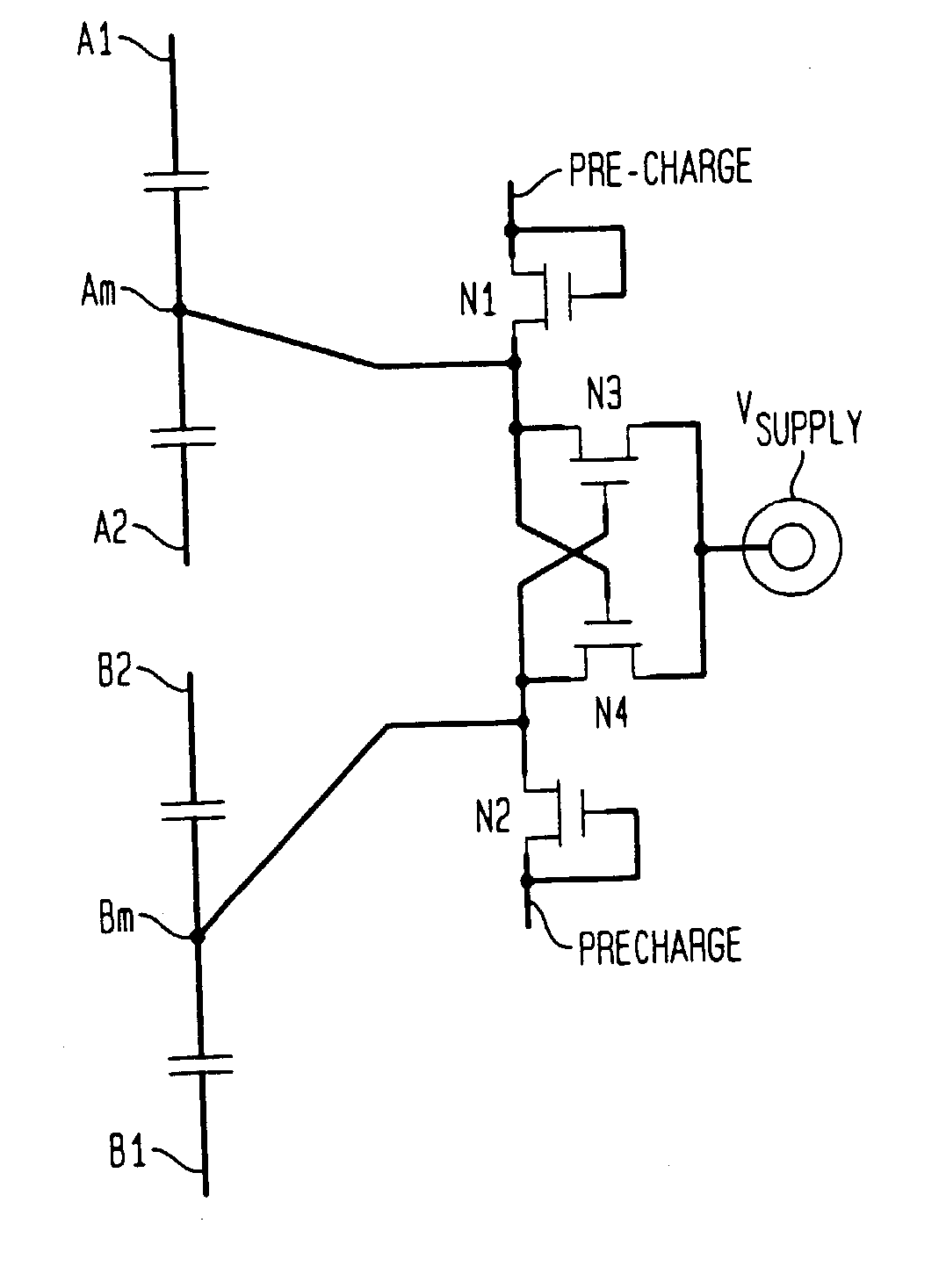

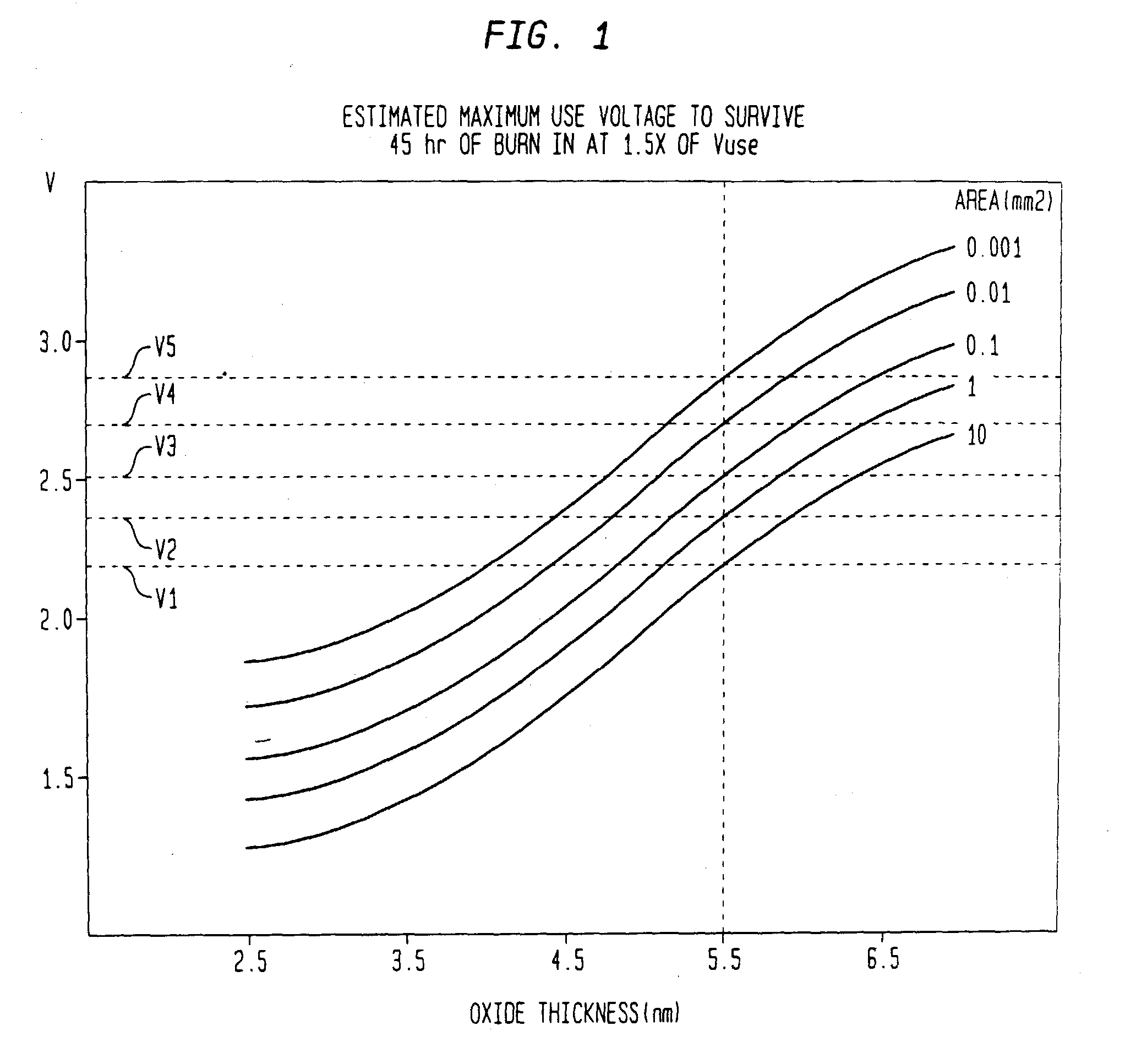

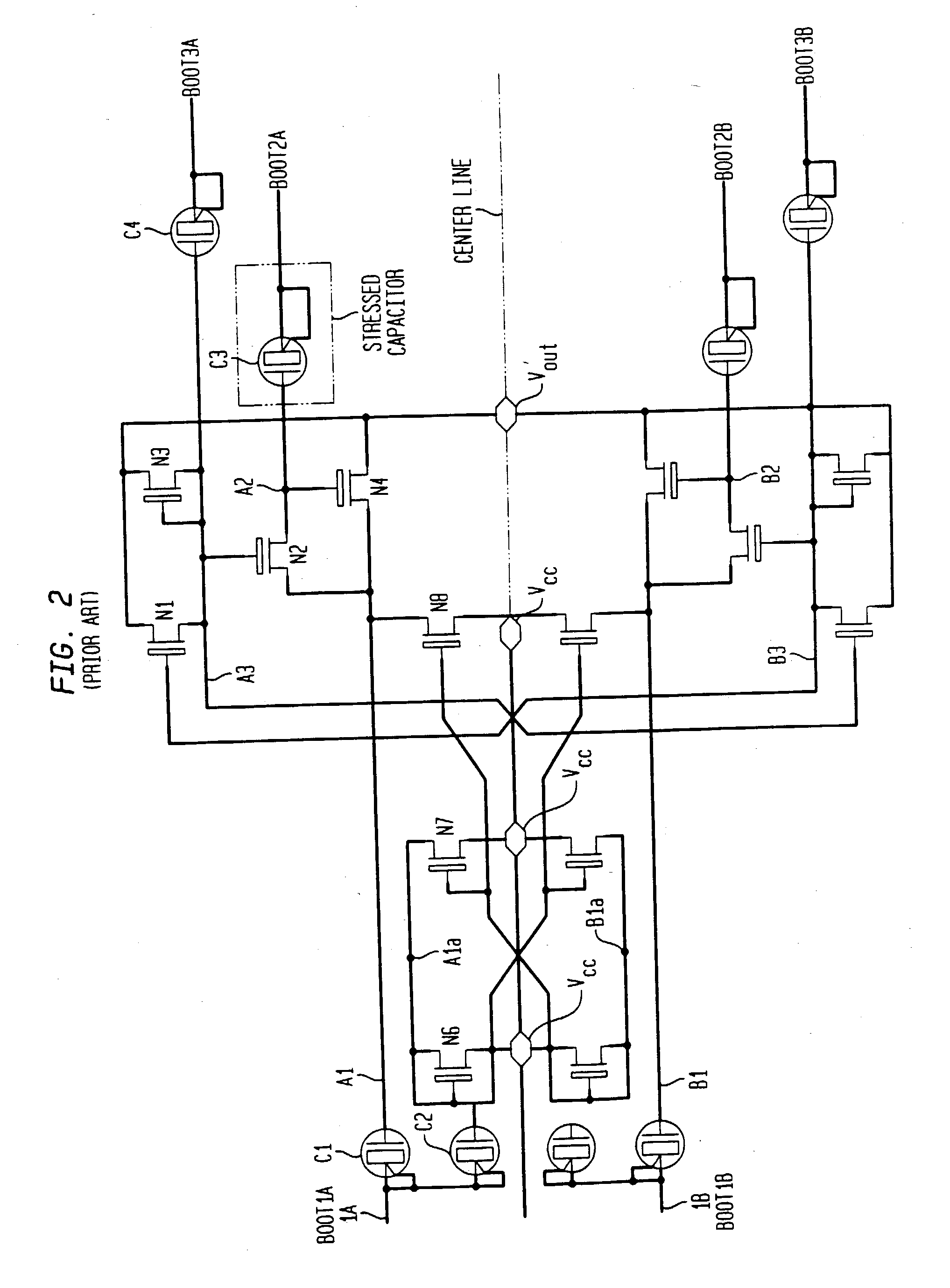

[0023] The invention is a method to prevent dielectric breakdown of semiconductor capacitor structures under excessive voltage stress. More specifically, the method according to the invention prevents dielectric break down of boost capacitors of a charge pump circuit as an example. A modem charge pump is illustrated in FIG. 2. Usually several different sized capacitors, C1, C2, C3, C4, etc., are used to boost the output voltage efficiently. The capacitor size varies from 50 Fm.sup.2 to 4500 Fm.sup.2. Normally, in each DRAM chip, up to forty pumps may be employed. Therefore, the overall stress area can be significant, and the breakdown probability is relatively high.

[0024] The pump has a symmetrical design. The upper portion of the circuit and the lower portion of the circuit are mirrored to the center line. An oscillator and a timing circuit (not shown) are used to generate the clocked boosted signals, BOOTA, BOOTB, etc. During the first half clock period, the upper portion of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com