Method and product of enhanced durability wrinkle resistant and/or pucker free garments

a technology of enhanced durability and garments, applied in the field of methods and garments, can solve the problems of adverse effects on garment wear, wrinkle resistant finishing, and garment seams that are created by wrinkling or puckering, and achieve the effect of enhancing the wear life of garments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

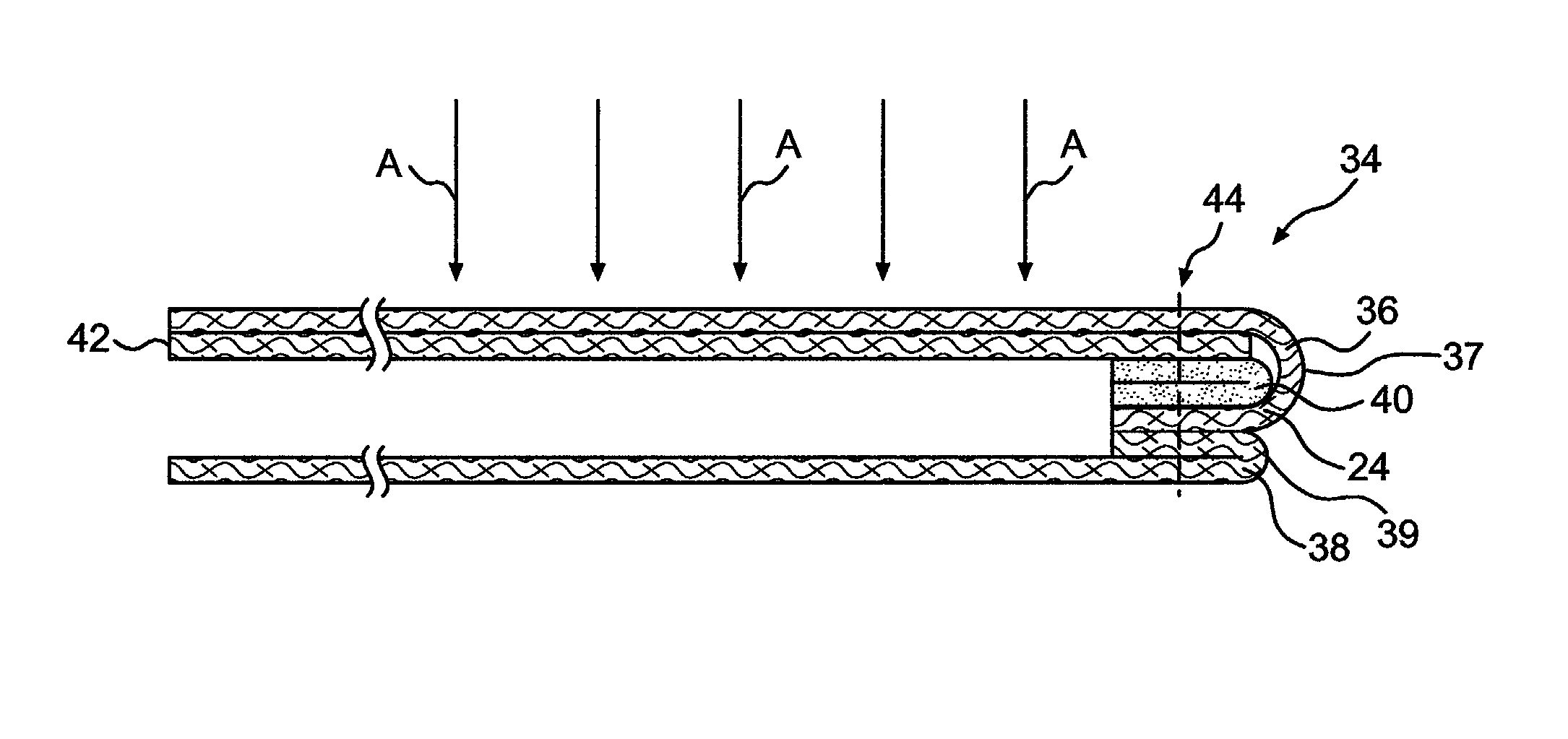

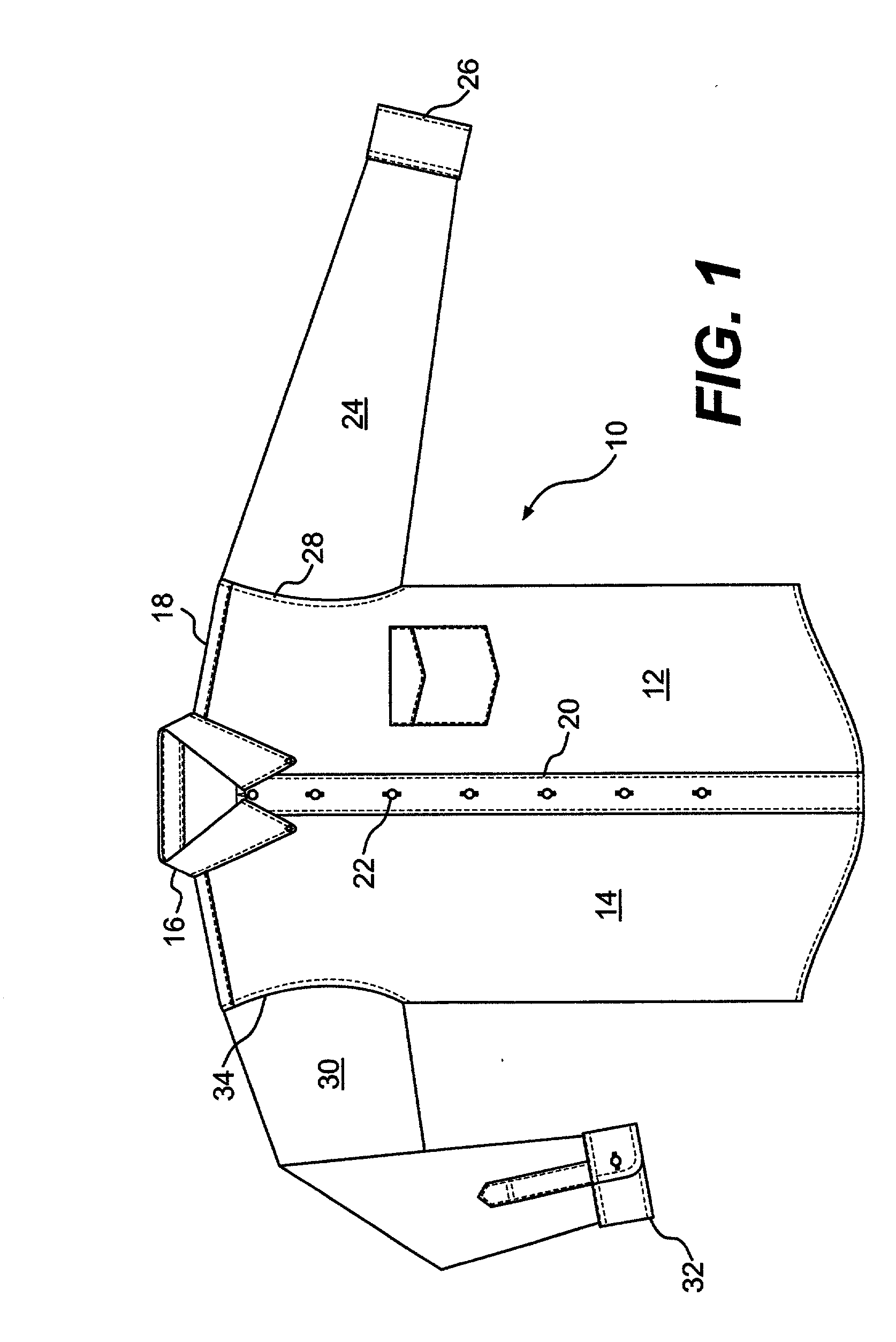

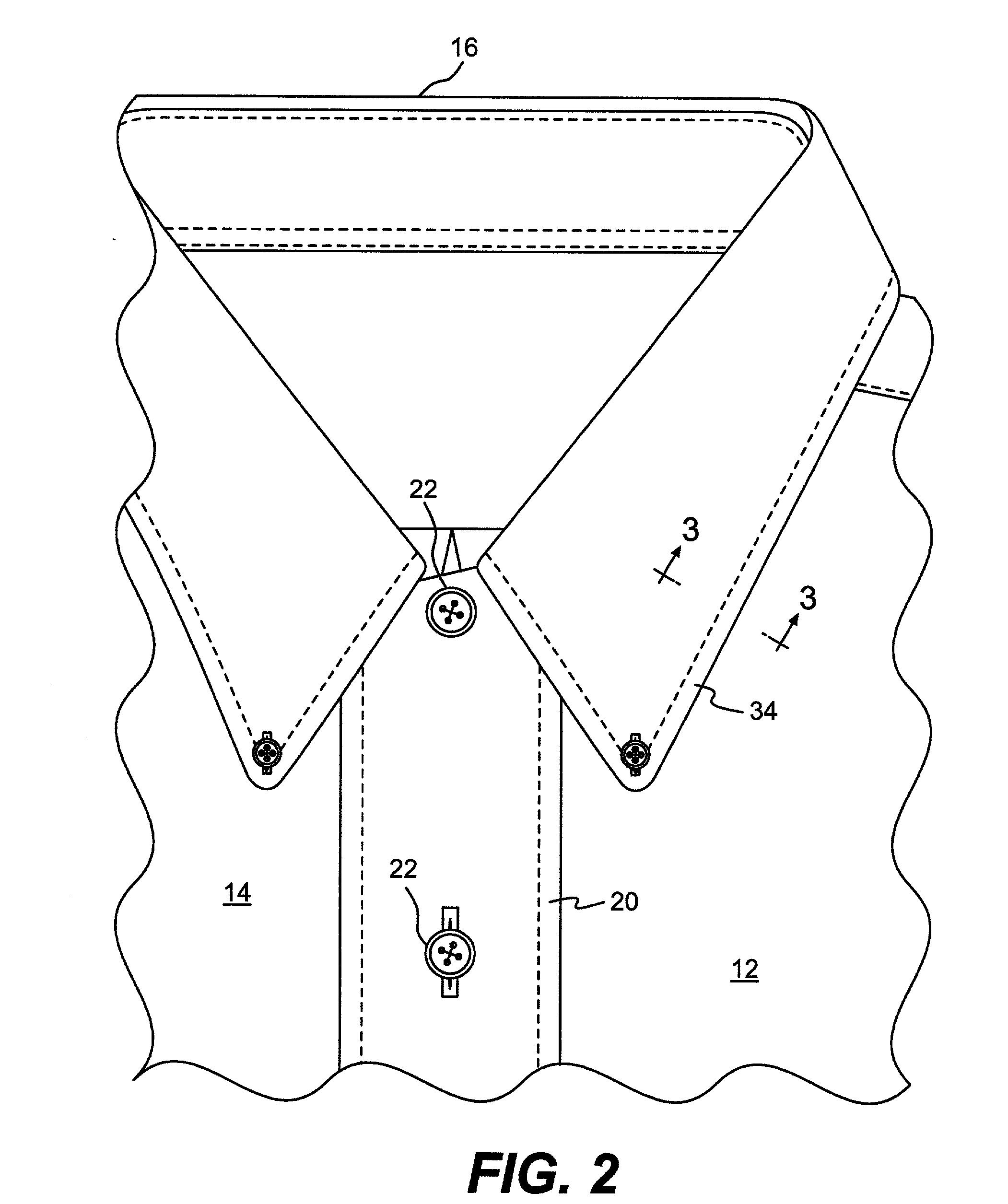

[0058] The following examples demonstrate a specific application of the invention to shirts and pants. The shirts are first dipped or sprayed with the wrinkle resistant finish solution, extracted and partially dried. Next, a sodium tetraborate solution is applied to any part of the shirt requiring treatment, such as outer edges of collar, cuff or center placket. The amount of solution needed is the minimum amount to wet the parts to a desired depth. The treated shirts are then pressed and cured just as one would do in normal garment production.

[0059] Pants are dipped or sprayed with a wrinkle finish solution, extracted and dried. After normal pressing, but prior to curing, any part of the pants that are subject to excessive wear are treated with the cross-linking inhibitor, e.g. the crease edges of the front and back of the bottom hem. As with the shirt application, sufficient solution is used to wet the parts. The pants are then cured in the normal manner. The inhibitor can also be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com