Universal spacer for tire building drum

a technology for building drums and spacers, which is applied in the field of universal spacers for tire building drums, can solve the problems of collmann spacers that cannot be fitted into the bot drum application without major modification of the drum, and the spacer in the collmann patent has the potential to change with vibration loosening,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

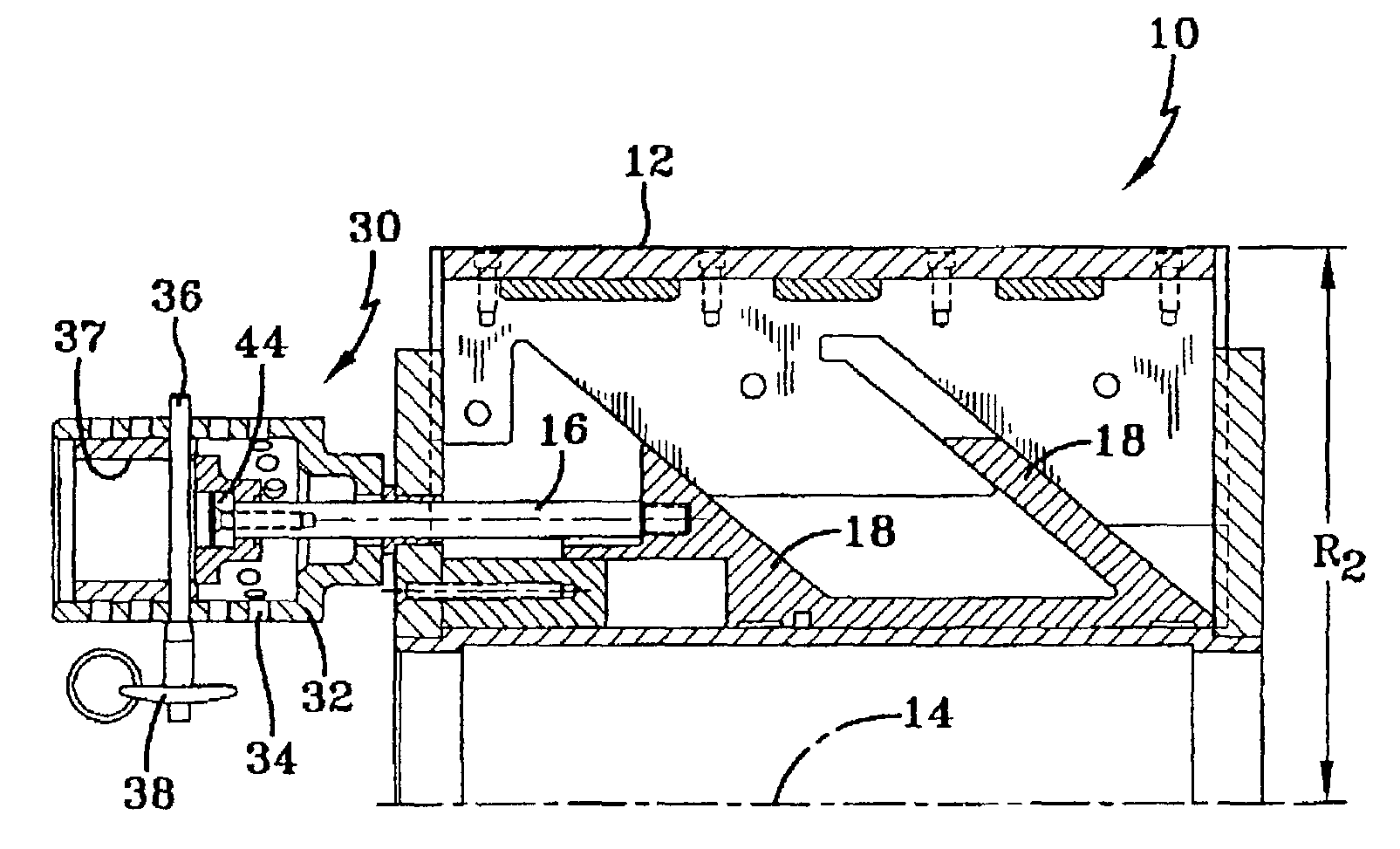

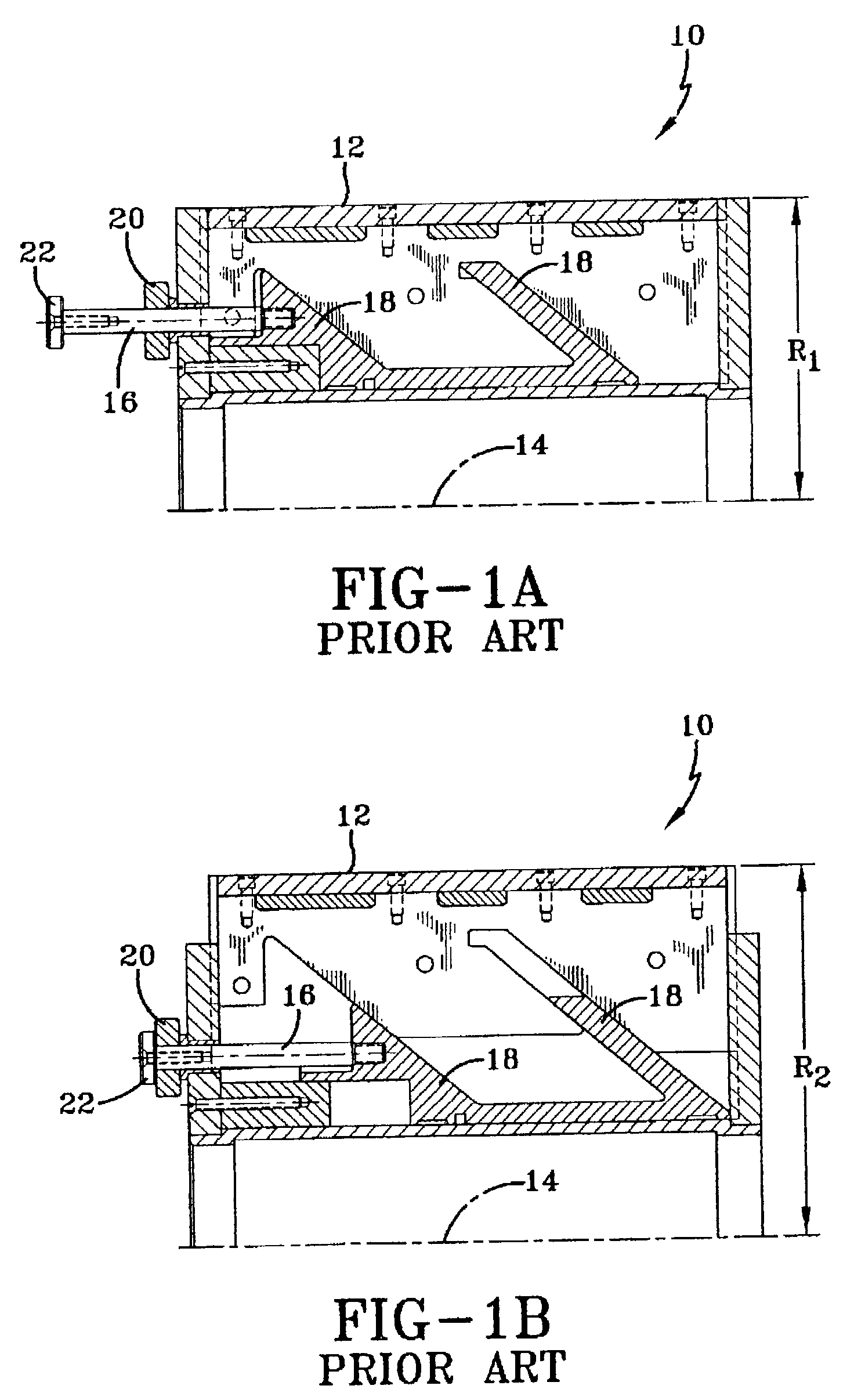

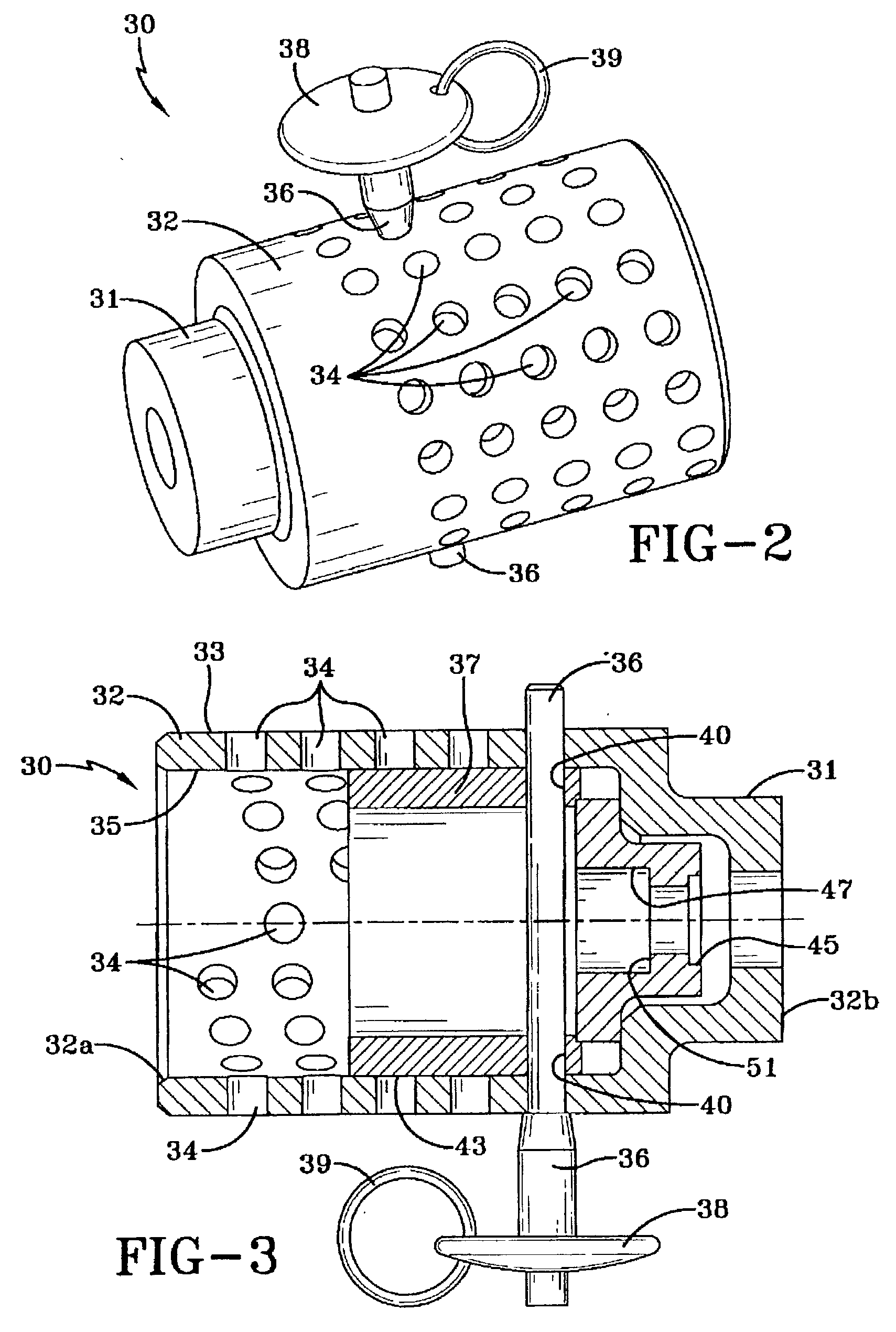

[0029] The operation of the prior art spacer block method of limiting or controlling the diameter of a tire tread breaker package building drum 10 (which includes but is not limited to a BOT (belt overlay tread) drum) is evident upon examination of FIGS. 1A and 1B. In FIG. 1A, the outer cylindrical surface 12 of the drum 10 is shown in its maximal radially inward position, corresponding to a radius of R.sub.1 with respect to center axis 14. A traveling shaft 16 is contiguous with a cam assembly 18 which moves axially to the right to force the outer cylindrical surface 12 radially outward, as shown in FIG. 1B where the radius of the cylindrical surface 12, with respect to the centerline 14, is R.sub.2. Pneumatic force is used to move the cam 18 axially to the right from the position shown in FIG. 1A to the position shown in FIG. 1B. Typically, there is a spring component that will return the cam to its initial position once the pneumatic force is withdrawn. A prior art spacer block 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| circumference | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com