Concrete forming panel having built-in retaining structure for storing loose coupling parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

. 1-8

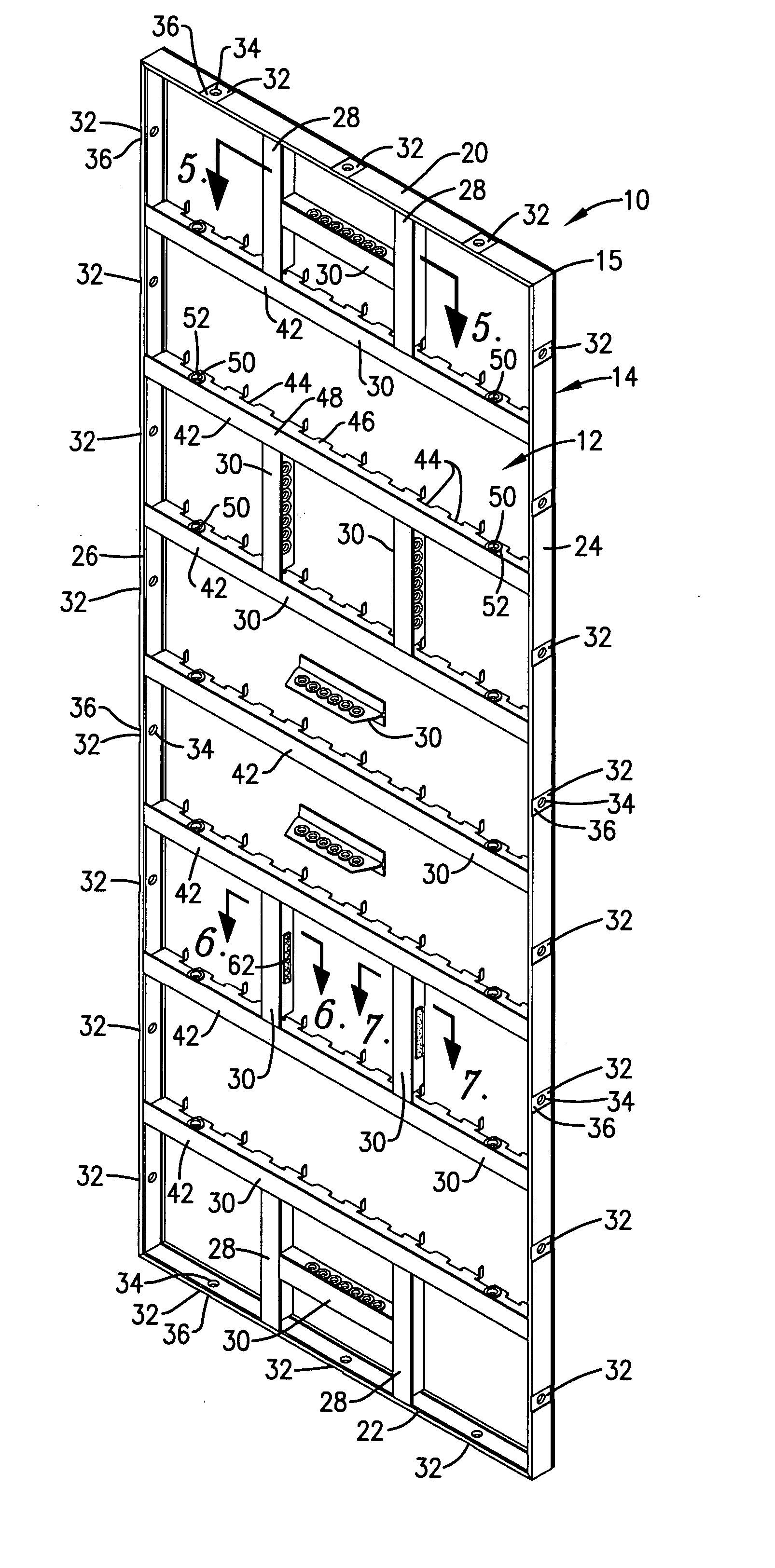

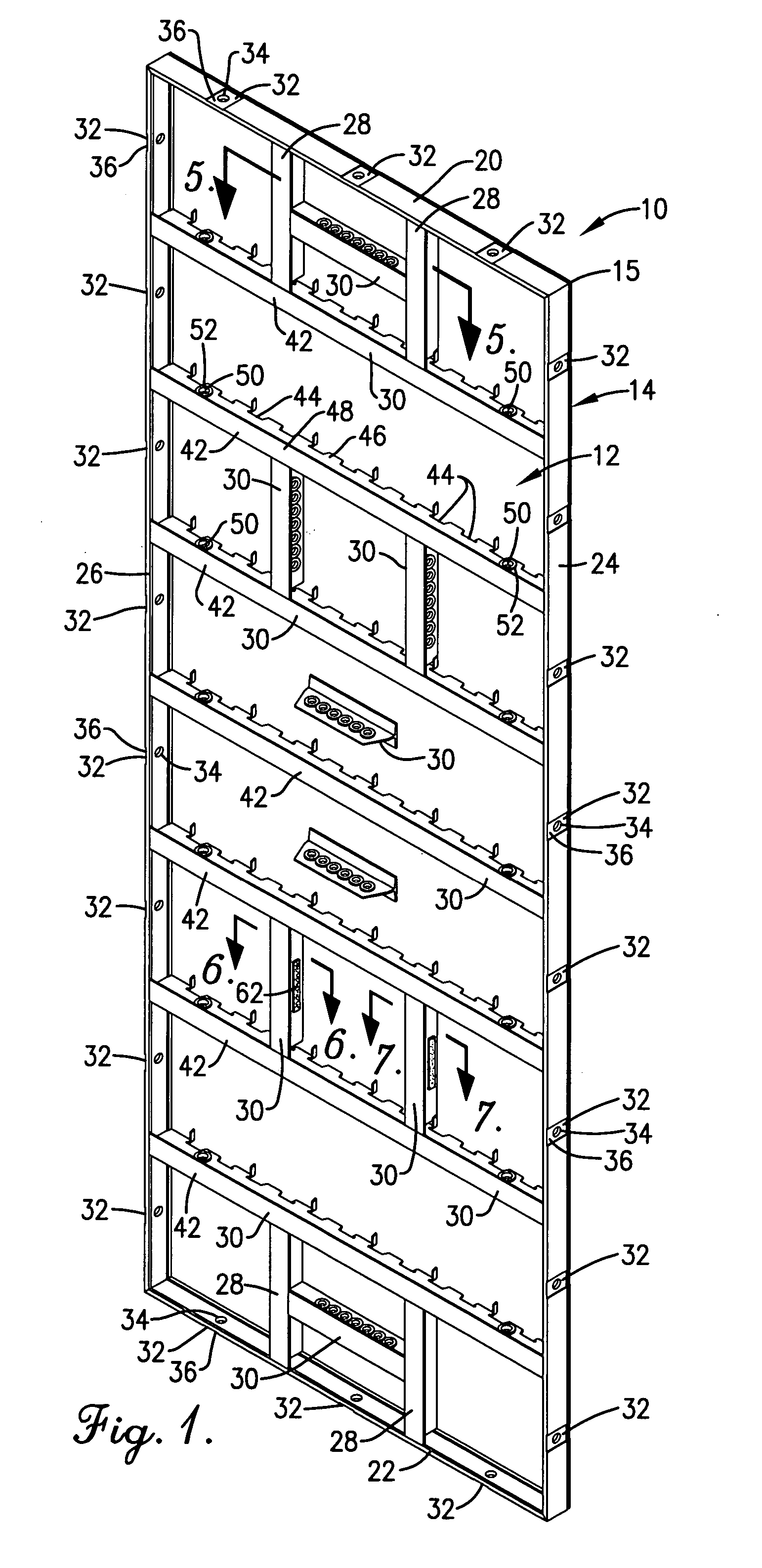

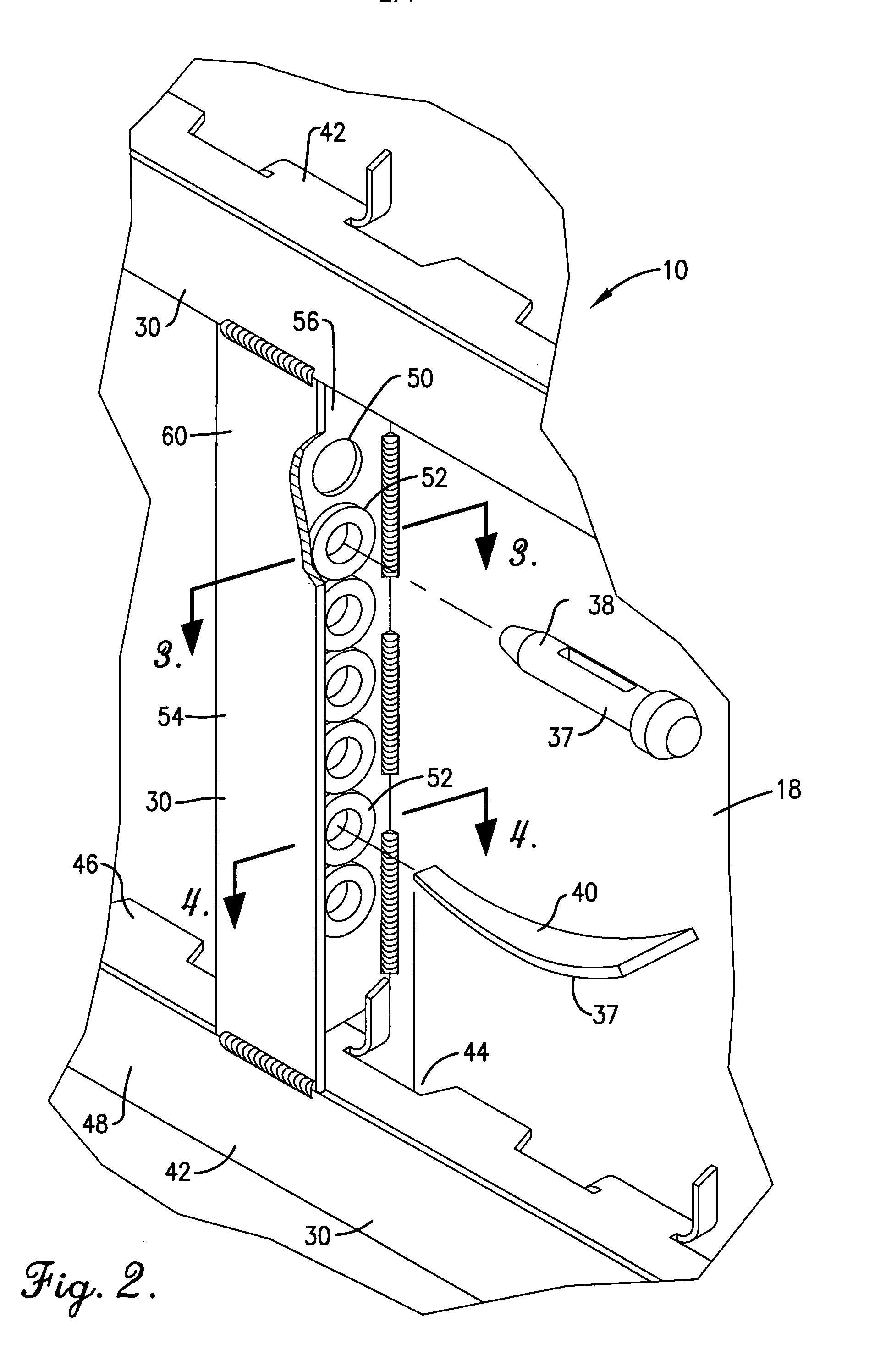

[0024] Referring now to the drawings, a forming panel 10 for receiving flowable concrete there against and providing a form for hardening the concrete to a desired shape is generally shown in FIG. 1 and includes a face sheet 12 and a frame 14. The face sheet and frame are provided preferably primarily of aluminum, to include alloys thereof such as ASTM 6061-T6. The face sheet 12 is relatively thin, for example about 0.090 to 0.125 for lightweight applications but may be made thicker for heavier duty applications, and may be substantially flat or textured to provide a brickface or other texture to the concrete hardening thereagainst. The face sheet 12 includes a perimeter 15, a front side 16 and a back side 18, and is welded to the frame 14.

[0025] The frame 14 has at least one rail of a thickness typically varying between 0.125" and 3 / 8" for lightweight applications, with thicker aluminum stock provided for larger sizes and heavier duty applications if desired. The frame 14 may ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com