Adhesive roller construction

a technology of adhesive rollers and rollers, applied in the direction of film/foil adhesives, cleaning equipments, transportation and packaging, etc., can solve the problems of disadvantageously time-consuming, difficult to remove a single layer of adhesive strips in a single piece without, and disadvantageously messy, so as to facilitate the removal of individual layers and facilitate manual manipulation. , the effect of enhancing the accessibility of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

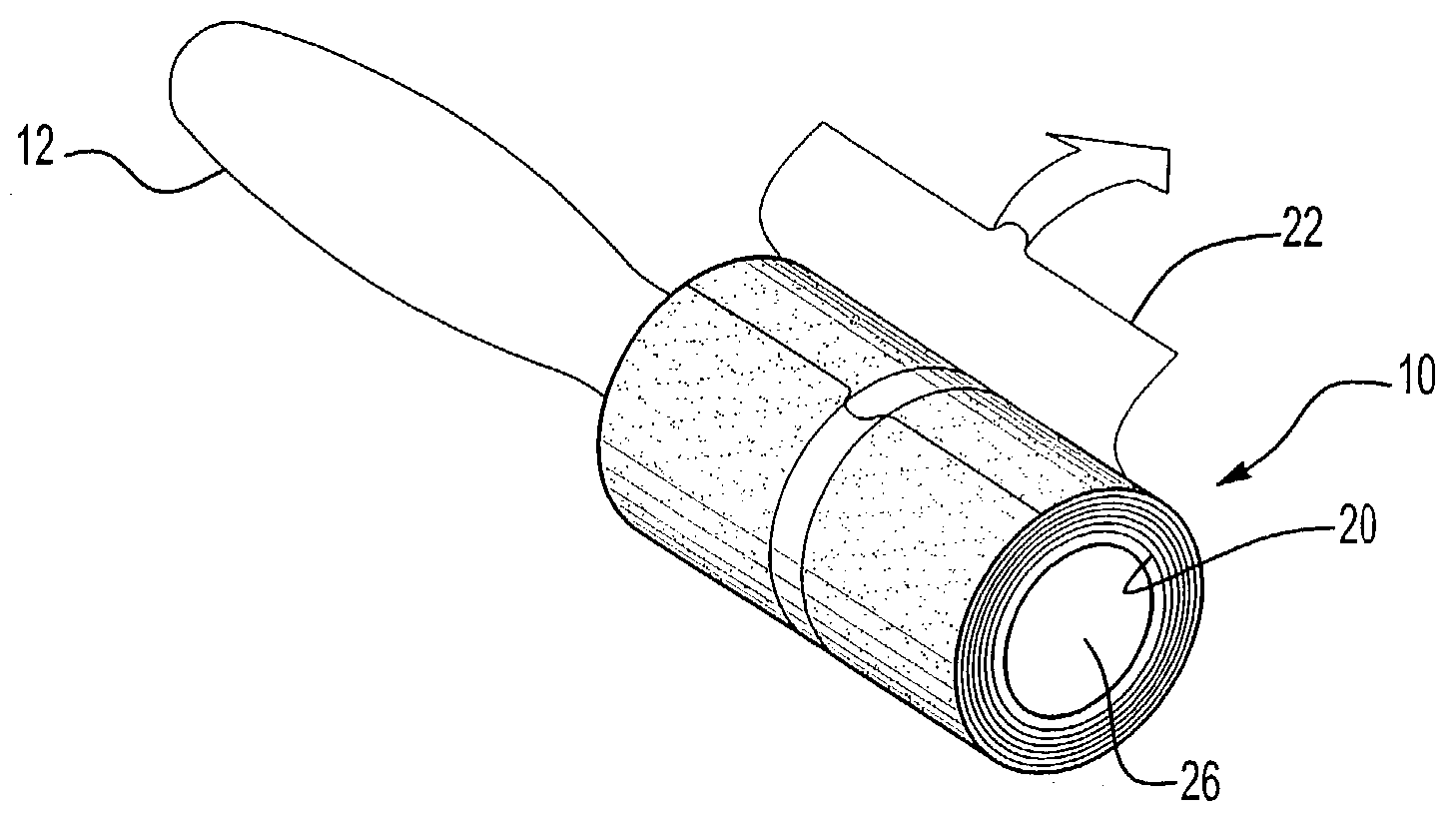

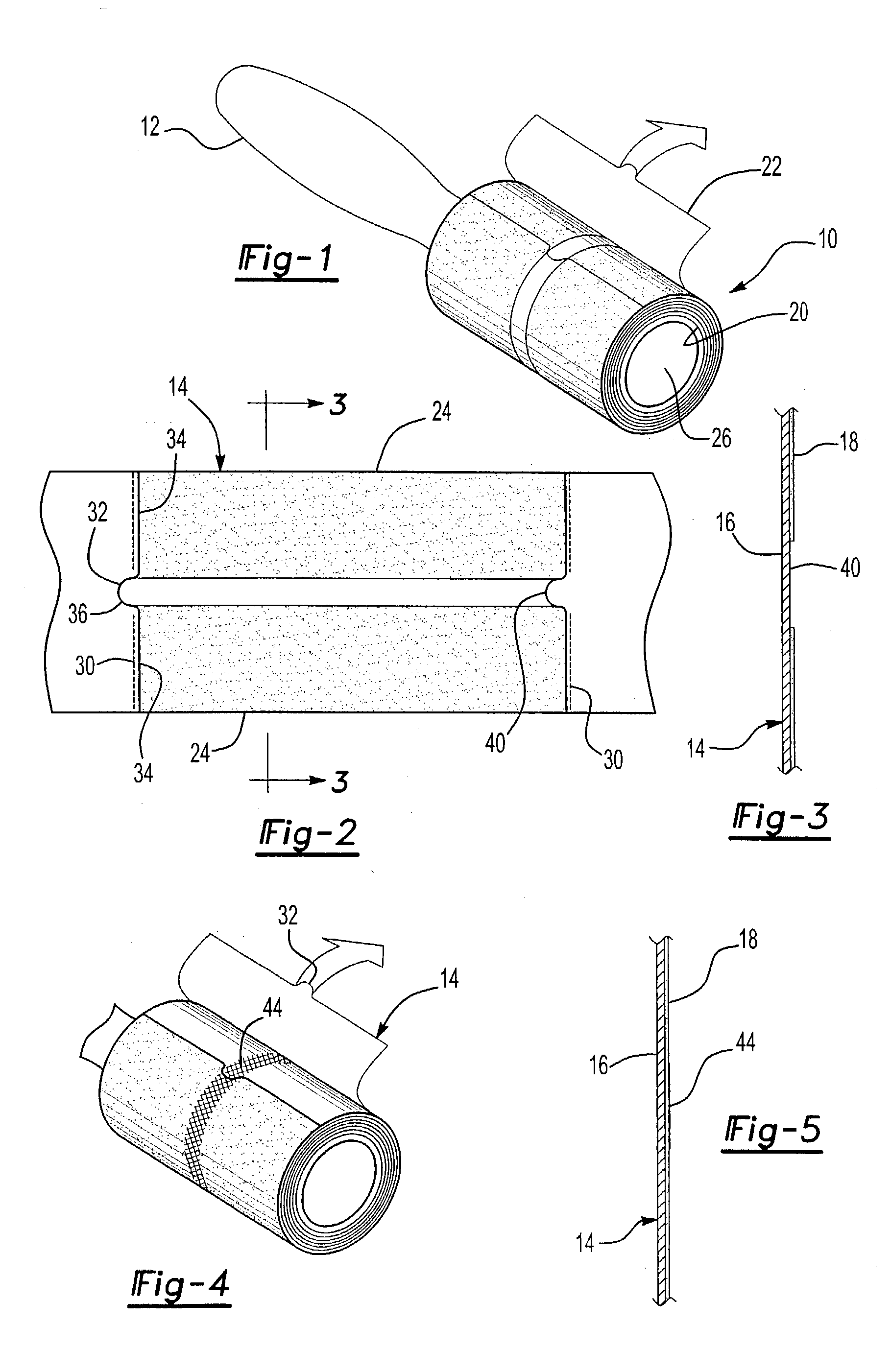

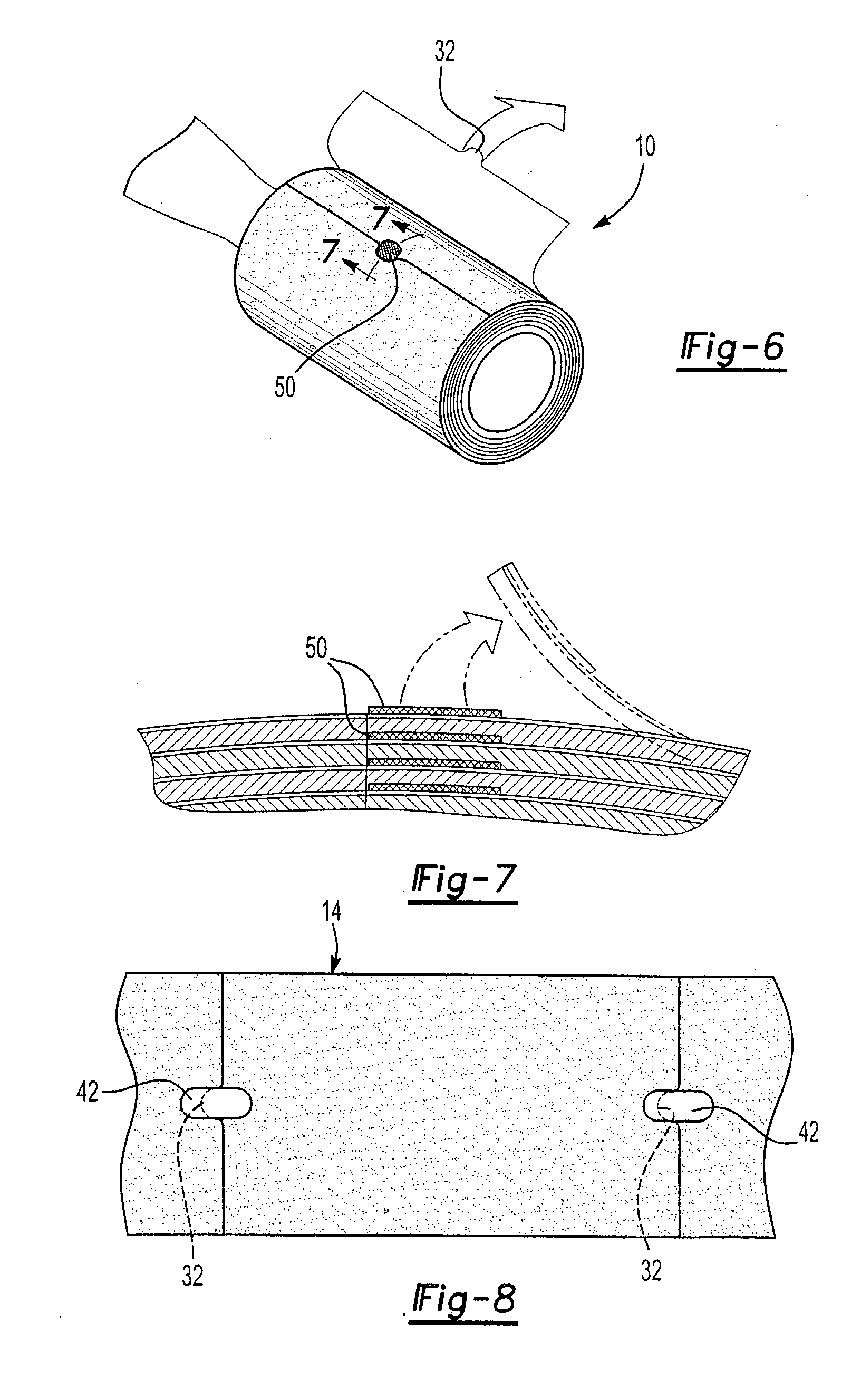

[0027] With reference first to FIGS. 1-3, a preferred embodiment of the adhesive roller construction 10 of the present invention is shown rotatably mounted to a handle 12 in any conventional fashion. The adhesive roller construction 10 includes an elongated strip 14 having a backing layer 16 and an adhesive layer 18 on at least a portion of one side of the backing layer 16. The elongated strip 14 also includes a first end 20 (FIG. 1), a second end 22 and two spaced apart sides 24. The adhesive layer 18 may cover the entire surface of one side of the backing layer 16 or, alternatively, a longitudinally extending dry, non-adhesive, edge may be provided along one, or both, edges 24.

[0028] As best shown in FIG. 1, the strip 14 is wound from its first end 20 and to its second end 22 into a tubular and cylindrical roll so that the adhesive layer 18 faces outwardly. Preferably, the strip 14 is wound about a tubular and cylindrical roller support 26 which is made of any suitable material, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape memory | aaaaa | aaaaa |

| plastic | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com