Tank having multipe screw-type transfer augers

a transfer auger and multi-pe technology, applied in the field of tanks, can solve the problems of affecting the efficiency of the transfer auger, the single auger is relatively inefficient at moving materials within the tank, and the load is relatively heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While those having ordinary skill in the relevant art field will recognize that changes may be made to the preferred embodiments disclosed in this application, without deviating from the spirit of the invention, with reference to the drawings some of the presently preferred embodiments will be described.

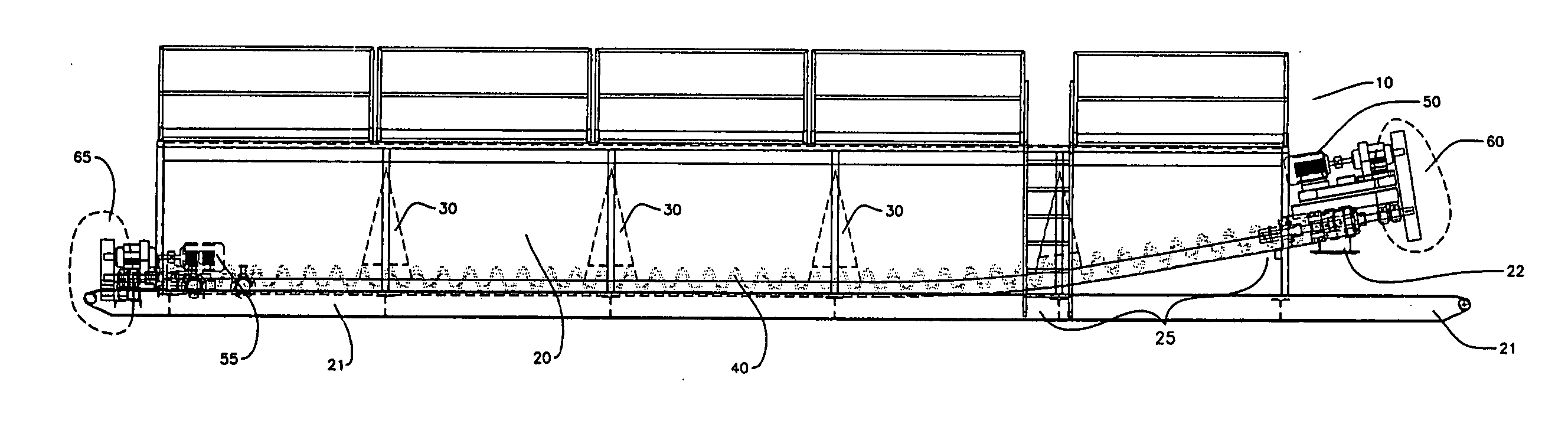

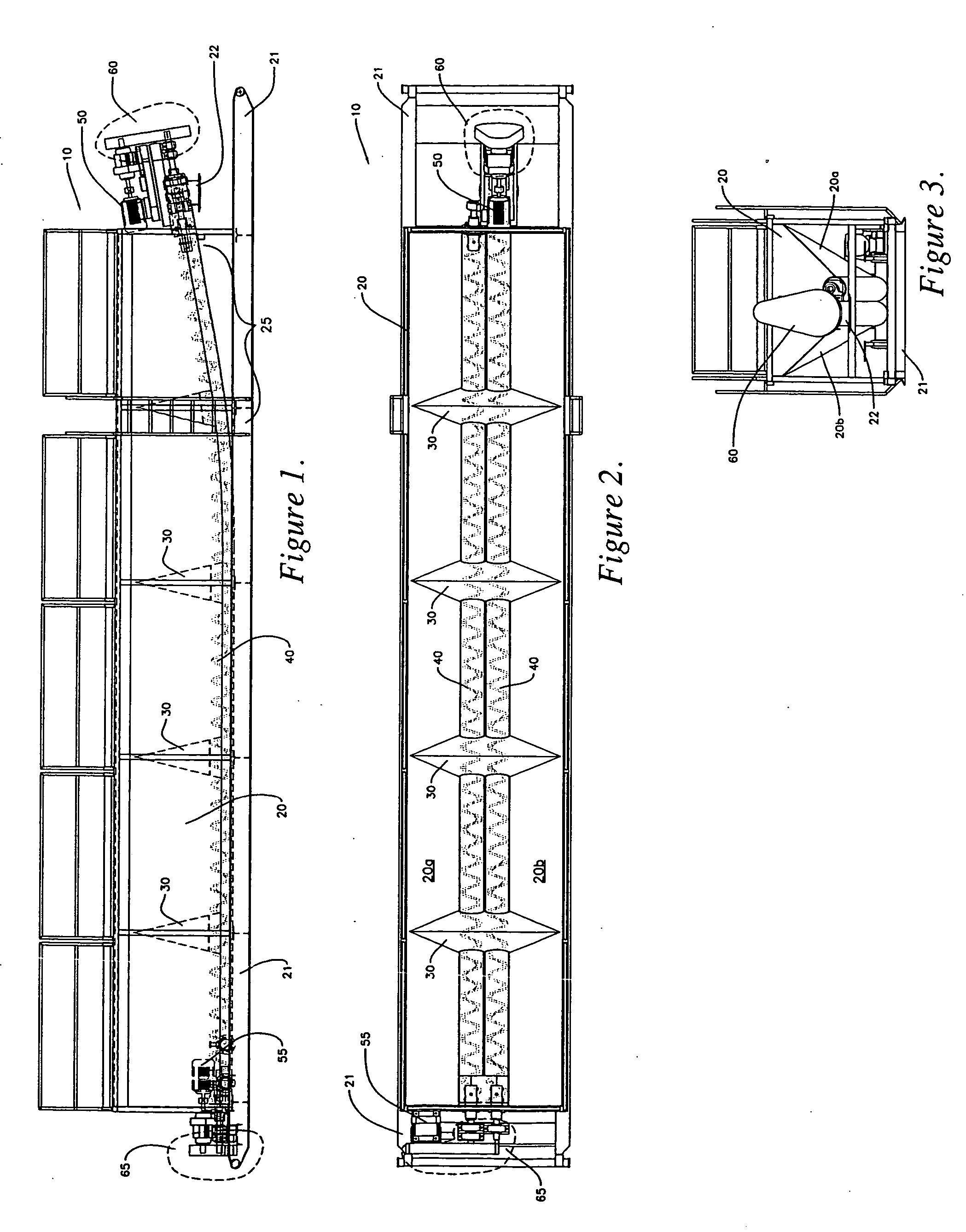

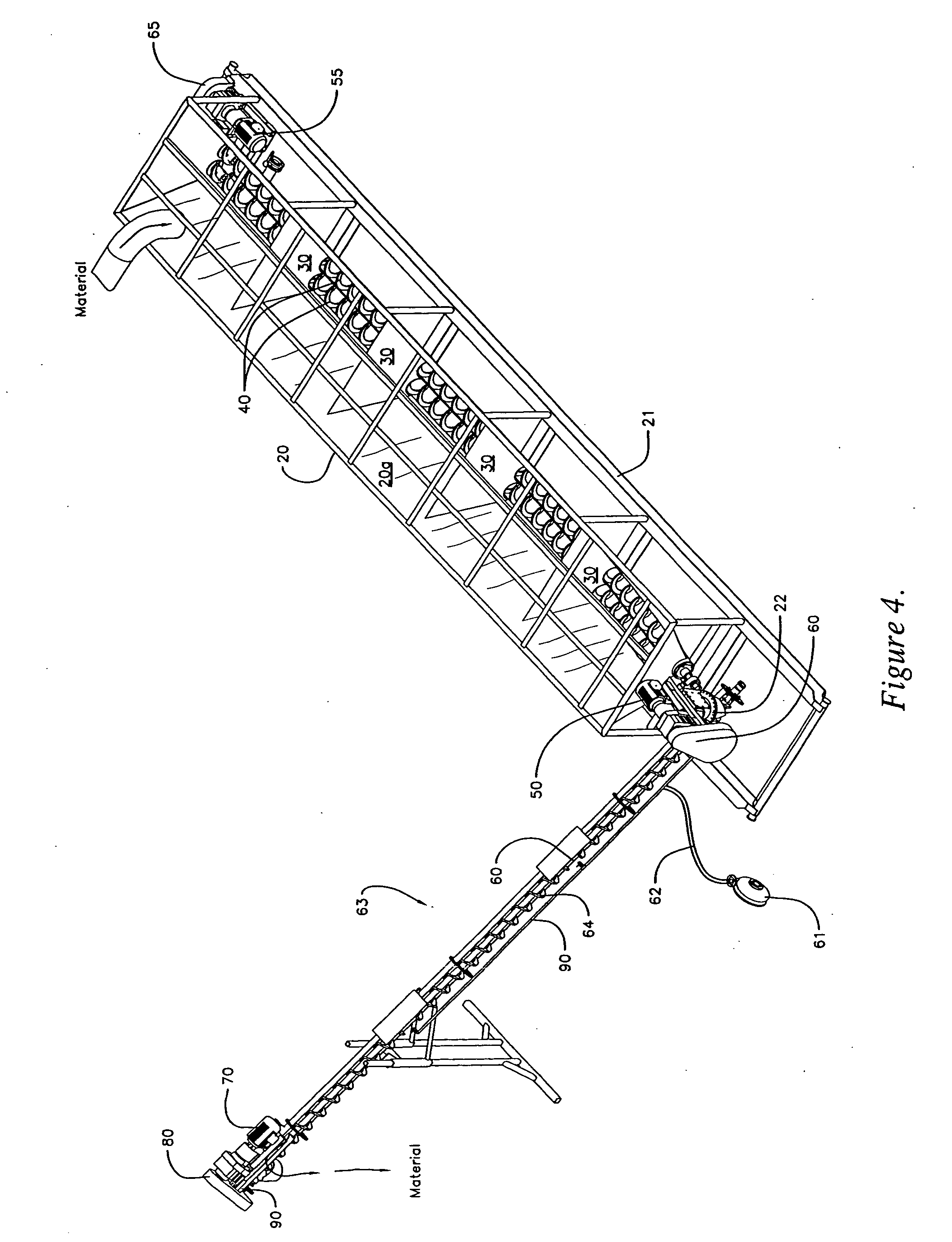

[0021] As shown in FIG. 1, the multiple screw auger tank 10 comprises a generally horizontally elongated tank 20 having opposing sides 20a and 20b, sloping inwardly toward one another from top to bottom. Tank 20, in the presently preferred embodiments, forms generally a V-shape in transverse cross section, with the bottom apex of the "V" somewhat truncated.

[0022] As can be seen particularly in FIGS. 1-3, tank 20 comprises at least one, and preferably two or more, transverse baffles 30, spanning from one side of tank 20 to the other side. In one presently preferred embodiment, baffles 30 extend substantially to the bottom of tank 20, with openings in baffles 30 through which tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com