Rotary blowing type powder feeder

A feeder and screw conveyor technology, applied in the field of powder feeders, can solve the problems of reduced pneumatic conveying efficiency, pipeline corrosion, and damaged conveying pipelines, and achieve the effects of improving feeding efficiency, reducing energy consumption, and prolonging the life of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

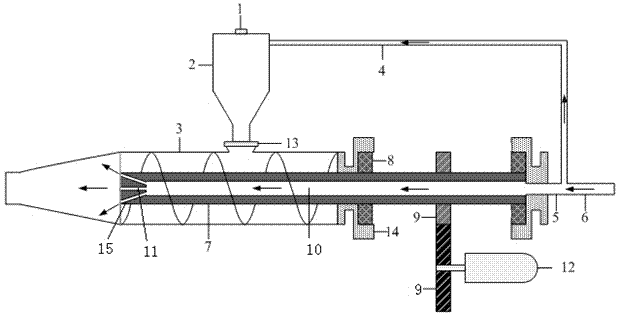

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] see figure 1 , the rotary purge type powder feeder of the present invention comprises a silo 2 with a powder inlet and outlet and a screw conveyor housing 3 placed horizontally, the powder inlet 1 is located at the upper part of the silo 2, and the lower end outlet of the silo 2 is connected to the The inner cavities of the screw conveyor housings 3 communicate with each other and a control valve 13 is provided at the connecting position. The front end of the screw conveyor shell is a conical spray area of 15°~30°. A screw auger 7 is provided in the screw conveyor housing 3, the tail of the screw auger 7 passes through the screw conveyor housing 3, the end of which is passed out is supported by a bearing 8 and a bearing seat 14, and the end of which is passed through a transmission mechanism at the same time It is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com