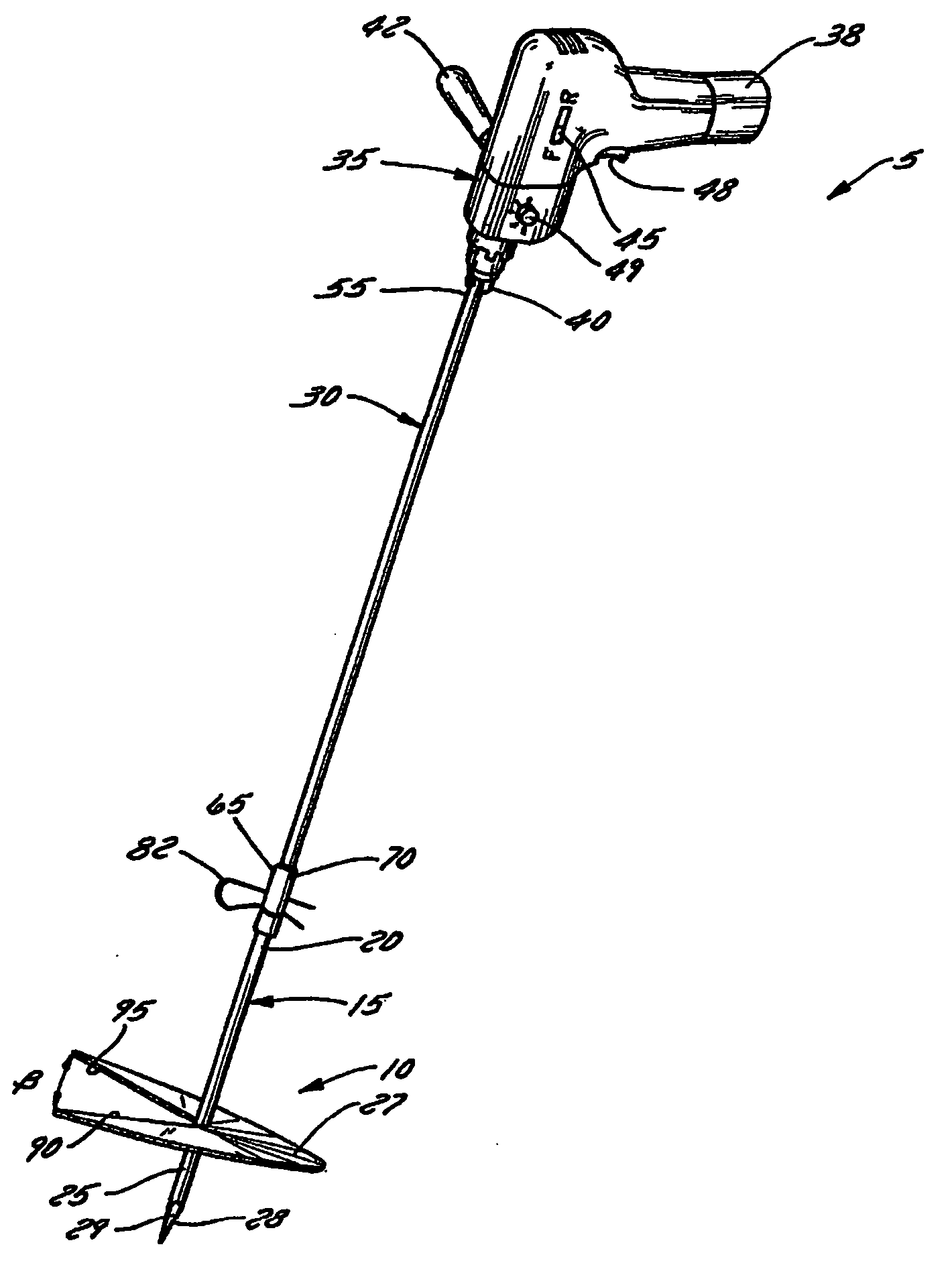

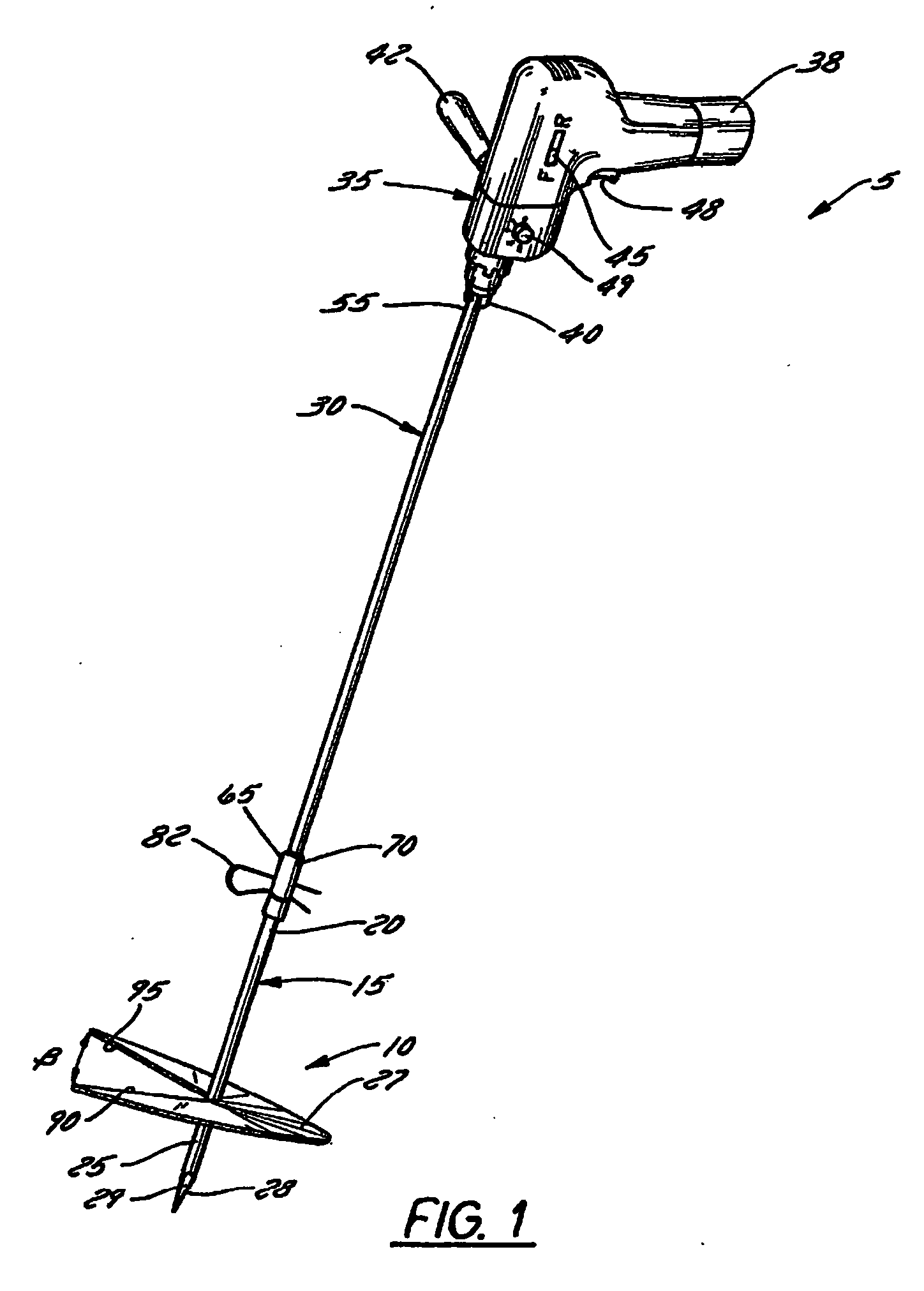

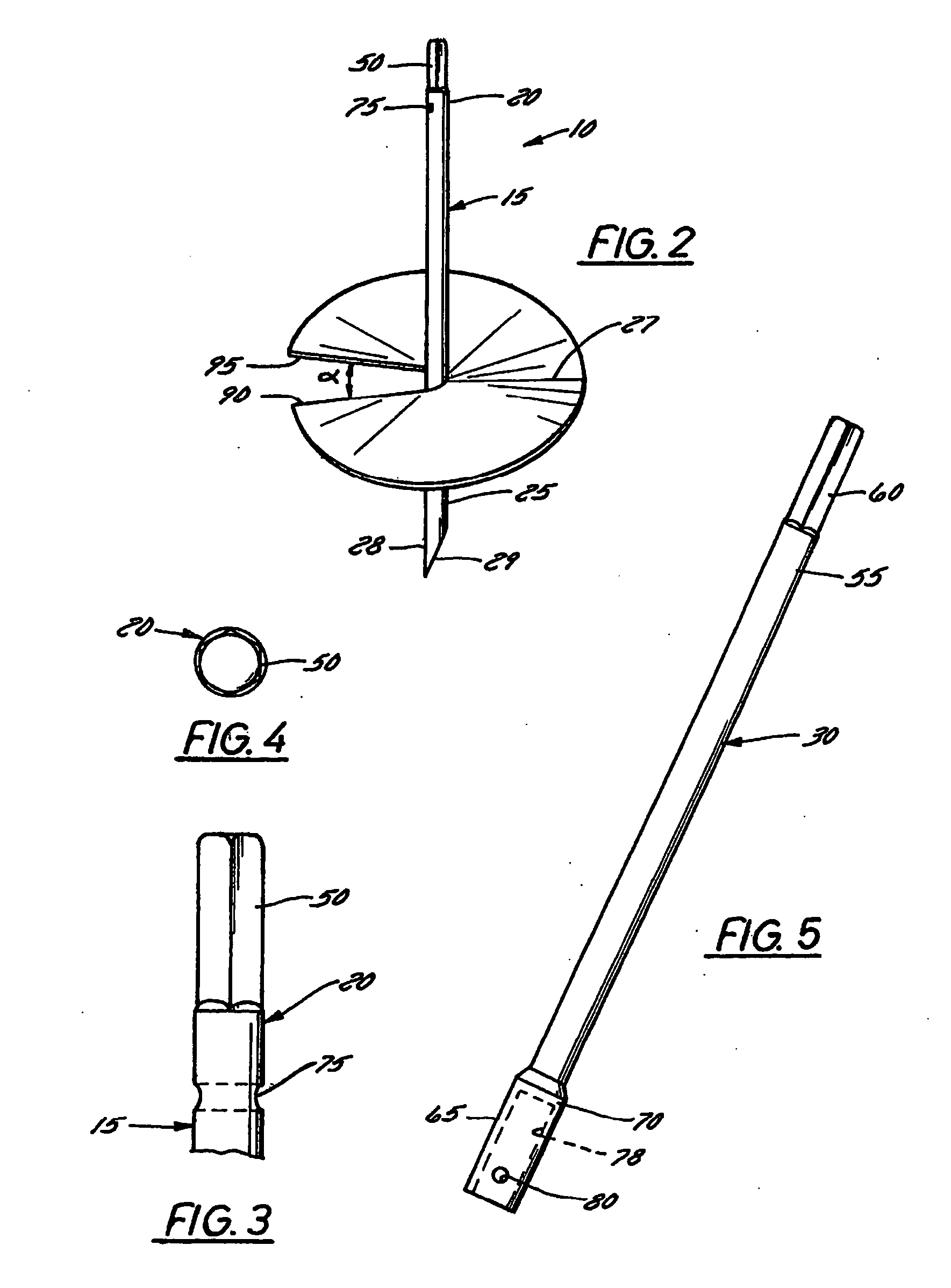

Auger for boring and weeding

a technology for boring and weeding, applied in the field of augers, can solve the problems of unsatisfactory requirements, relatively high cost of recognized solutions, and achieve the effect of simple manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention and the various features and advantageous details thereof are explained more fully with reference to the non-limiting embodiments described in detail in the following description.

1. System Overview

[0042] In its most basic form, the invention is an attachment to a device that provides power, such as a hand-held drill or a weed trimmer. The auger portion contains 1 to 4 discs which are rotated. They are connected to a shaft with a hex head which prevents it from slipping when power is applied. The attachment can be extended to about 26 inches long so the user can stand up while using it, and does not have to stoop over. A pin mechanism holds the first shaft to a second or extension shaft. The device is preferably zinc-coated steel so it is somewhat rust free. However, it may also be made of stainless steel. The power source can be a typical 12 volt or better electric drill, either portable, battery-operated type, or electrical or can be an electric or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com