Moisture-resistant floor tile covering system for concrete floors

a floor tile and concrete technology, applied in the field of floor tile covering systems for concrete floors, to achieve the effect of avoiding or substantially reducing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

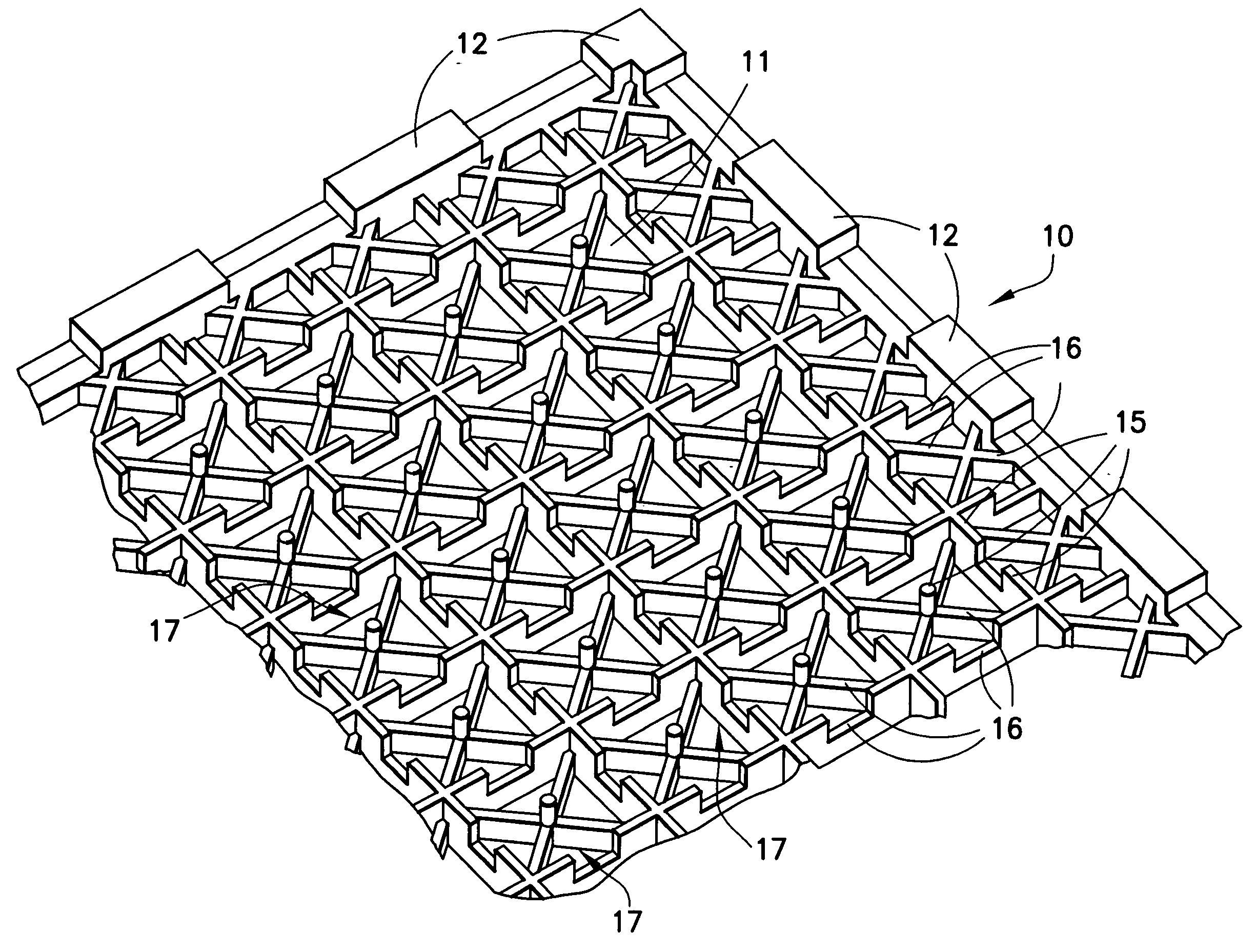

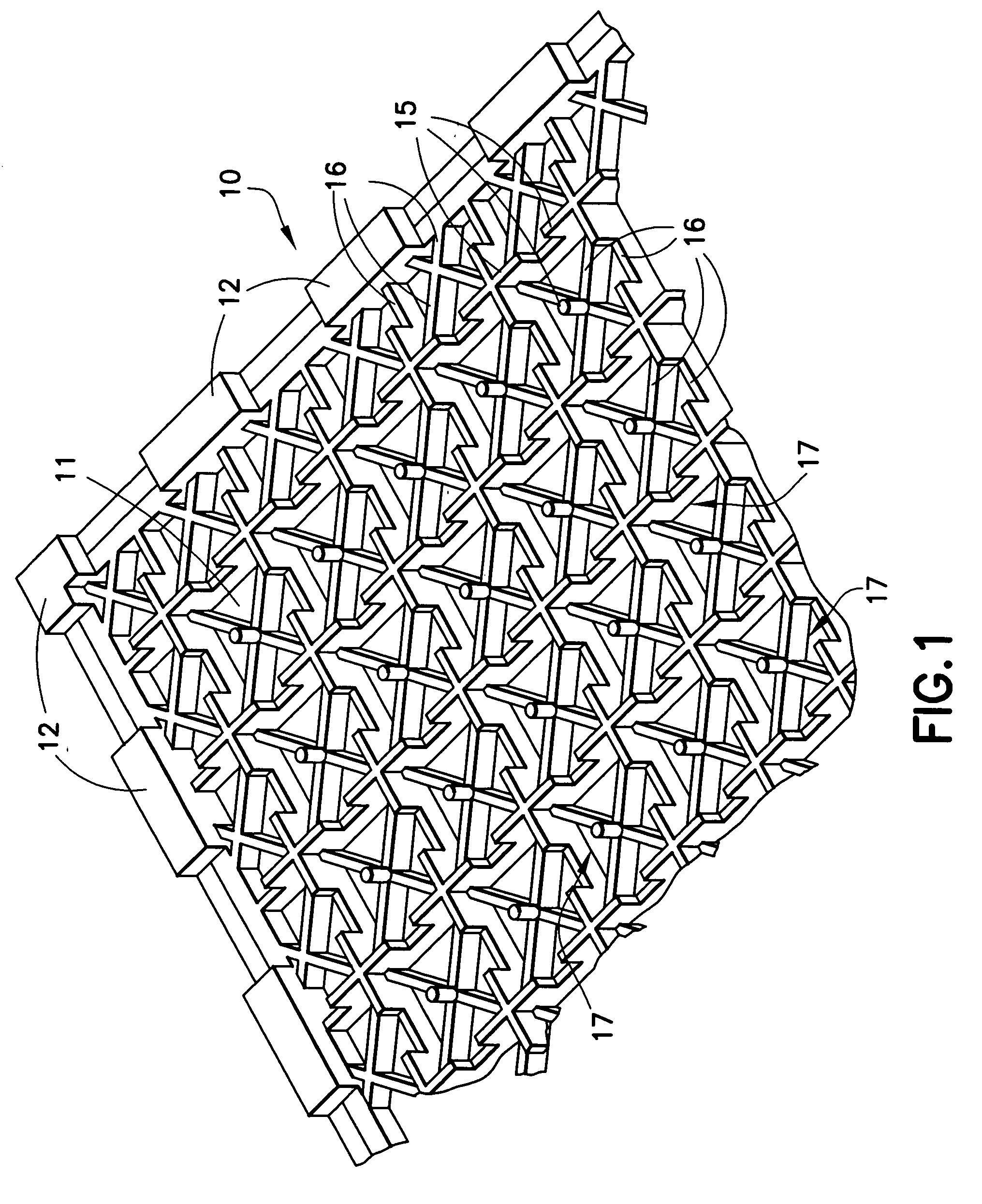

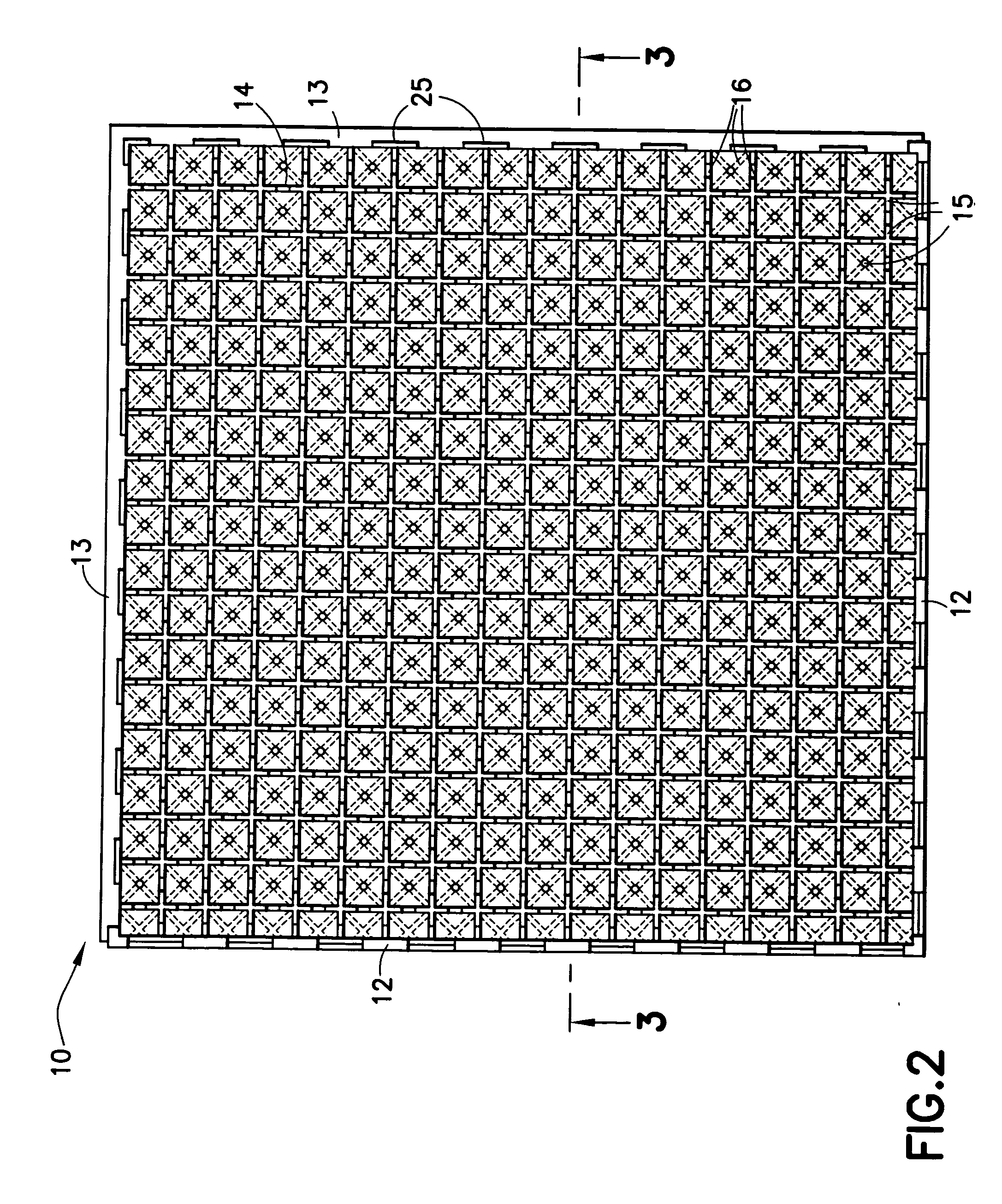

[0017] Referring to FIG. 1, the underside 11 of a corner section of a solid water-resistant plastic floor tile 10 is illustrated, the tile 10 having groove or slot means 12 along two edges thereof and tongue means 13 along the other two edges, as shown in FIGS. 2 and 3, for mating with corresponding complementary means on adjacent tiles to lock the tiles to each other and produce a substantially-continuous, smooth plastic floor surface which is water impervious.

[0018] The plastic tile 10 of FIGS. 1 to 3 is molded to have integral spaced plastic support studs or legs or wall sections 15 projecting a maximum distance from the underside 11 thereof, and intermediate plastic network sections 16 of intermediate height. The legs or wall sections 15 project down a uniform distance to contact the concrete floor 11, a distance of about {fraction (5 / 16)}″, to form an interconnected insulation airspace image network 17 between the upper surface of the concrete floor and the underside of the ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal break | aaaaa | aaaaa |

| heat conduction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com