Fluid mixing in low aspect ratio chambers

a technology of low aspect ratio and mixing chamber, which is applied in the direction of fluid speed measurement, flow mixer, flat carrier support, etc., can solve the problems of high quality microarray processing, limited sensitivity, and difficult detection of low-expression genes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

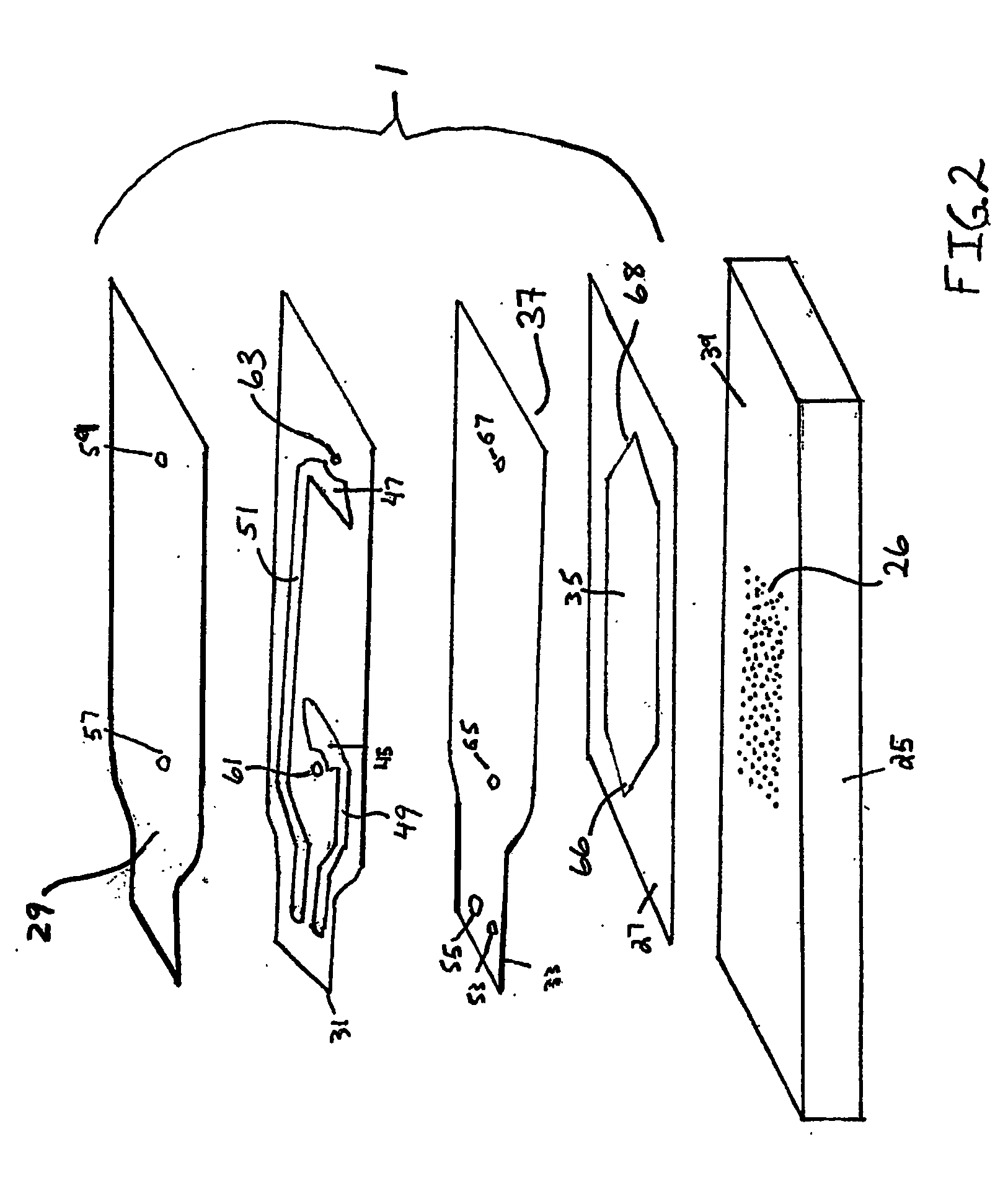

[0033]FIG. 2 depicts a first exemplary embodiment of the invention in the form of an adhesive laminate microarray interface device designed for performing hybridizations on a conventional 1″×3″ microarray slide. The device illustrated in FIG. 2 is described more fully in commonly owned patent application PCT / US02 / ______ (Attorney Docket No. 3153.2.17). The microarray interface device 1 is designed to attach to a glass microarray slide 25 by means of an adhesive gasket 27 to form a hybridization chamber, equivalent to corresponding chamber 3 in FIG. 1, which contains a microarray of arrayed spots 26 of DNA or other material of interest. The device is useful for microarray processing, because providing mixing of labeled target solution during the hybridization process in a low volume hybridization chamber may lead to improved sensitivity and more reproducible microarray processing. The microarray interface device is particularly designed for use with conventional microarray slides, bu...

example 2

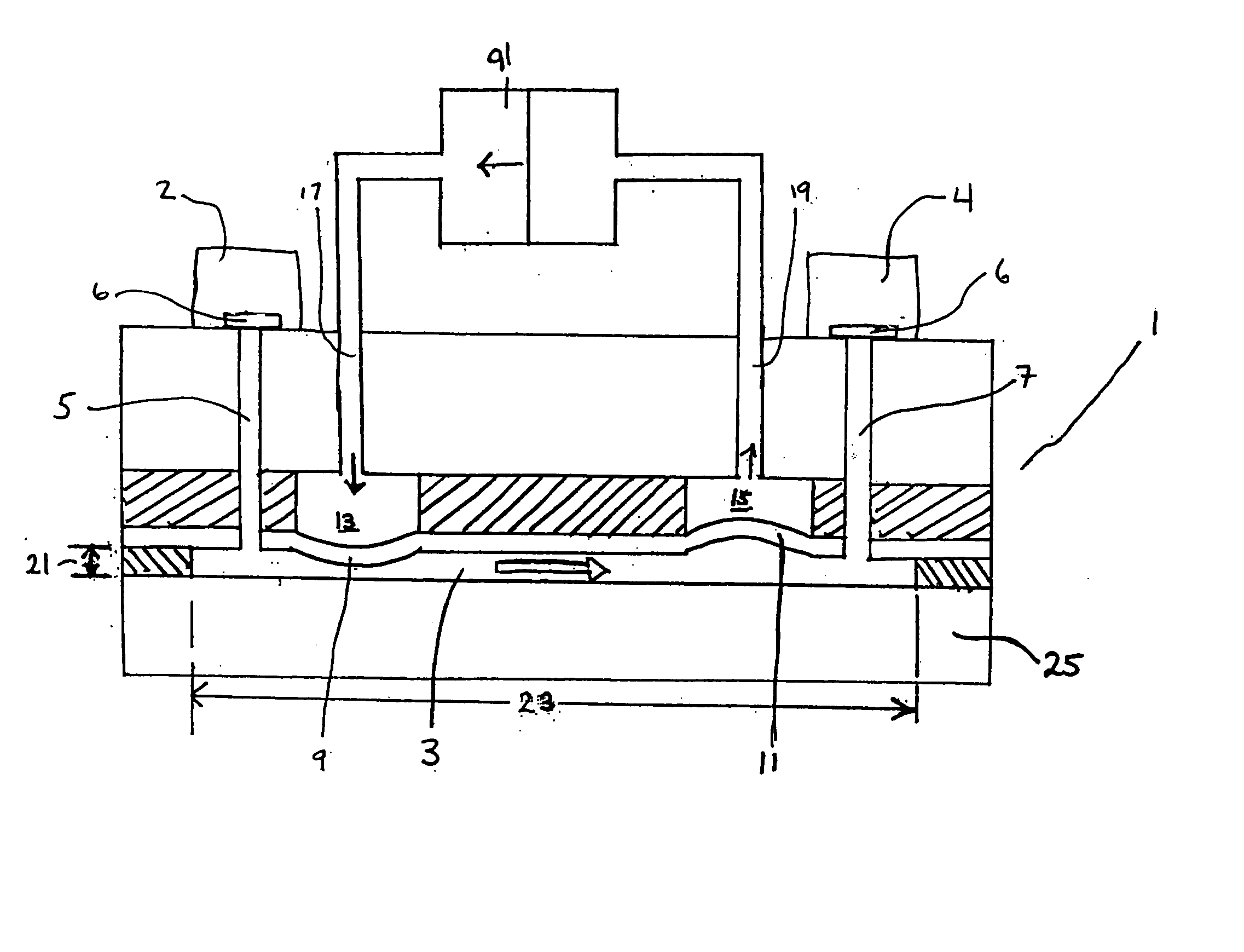

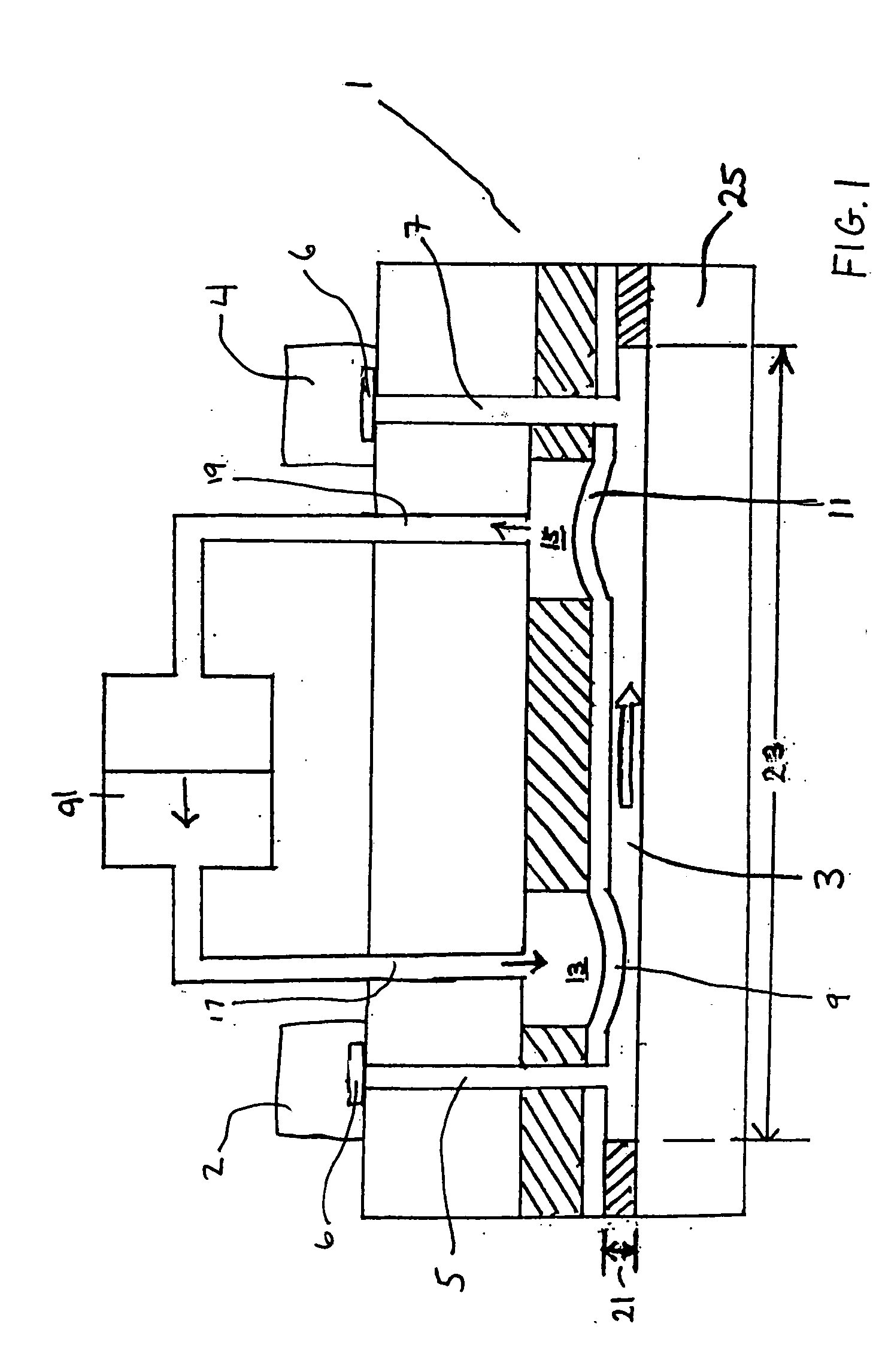

[0037]FIG. 3 depicts an alternative embodiment of the invention in which mixing bladders for generating pneumatic mixing are incorporated into a “hard shell” microarray interface device. This device is functionally similar to the device of FIG. 2, in that it includes a low aspect ratio reaction or hybridization chamber, like reaction chamber 3 in FIG. 1, having a length and width defined by a perimeter wall 70 formed by an opening 69 in a gasket 71. The height of the chamber may be defined by the thickness of gasket 71. However, in other embodiments, not shown in the figures, the chamber height may be modified by setting gasket 71 into a recess in top layer 73, or by recessing the portion of top layer 73 that defines the upper surface of the chamber. Inlet port 5 and outlet port 7 allow fluid to be loaded into and removed from the reaction chamber defined by perimeter wall 70. Note that inlet port 5 and outlet port 7 align with holes 10 and 12 in diaphragm layer 33. Two mixing bladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com