Use of detergent additives in high-ethanol fuels for deposit control

a technology of detergent additives and high-ethanol fuel, which is applied in the direction of fuel additives, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of harmful and undesirable deposits on the fuel intake valves of the engine, and unacceptable combustion chamber deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

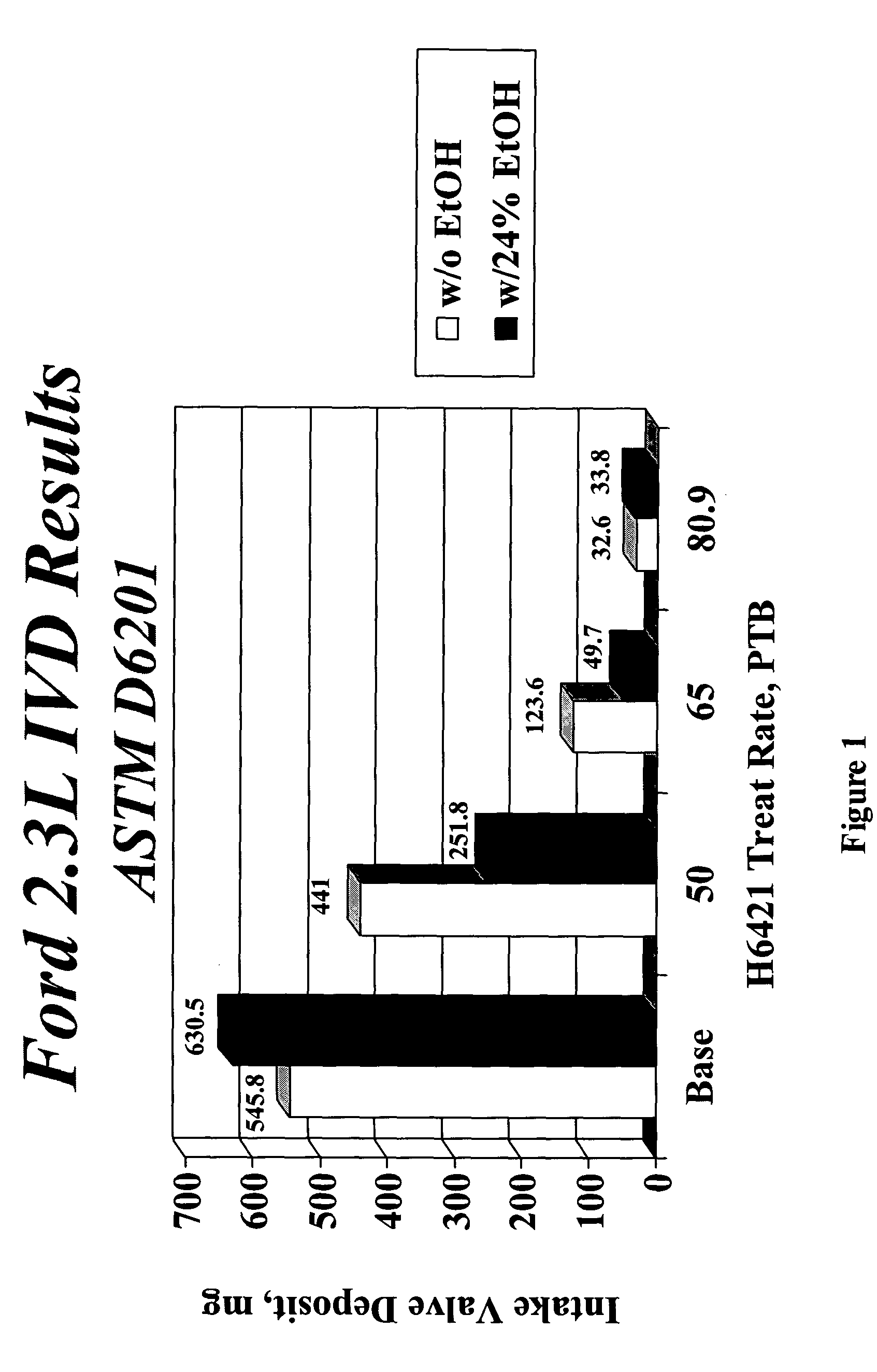

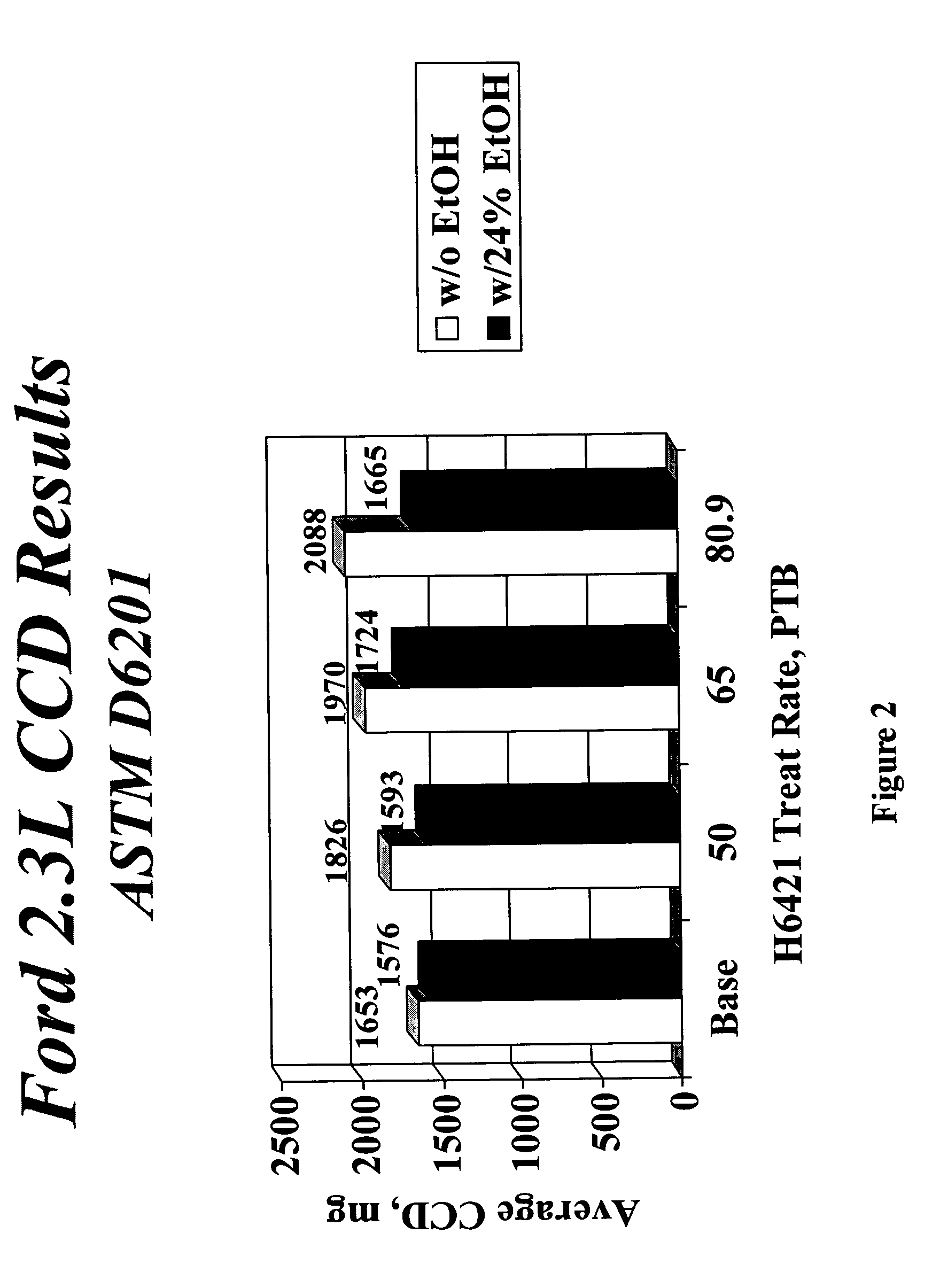

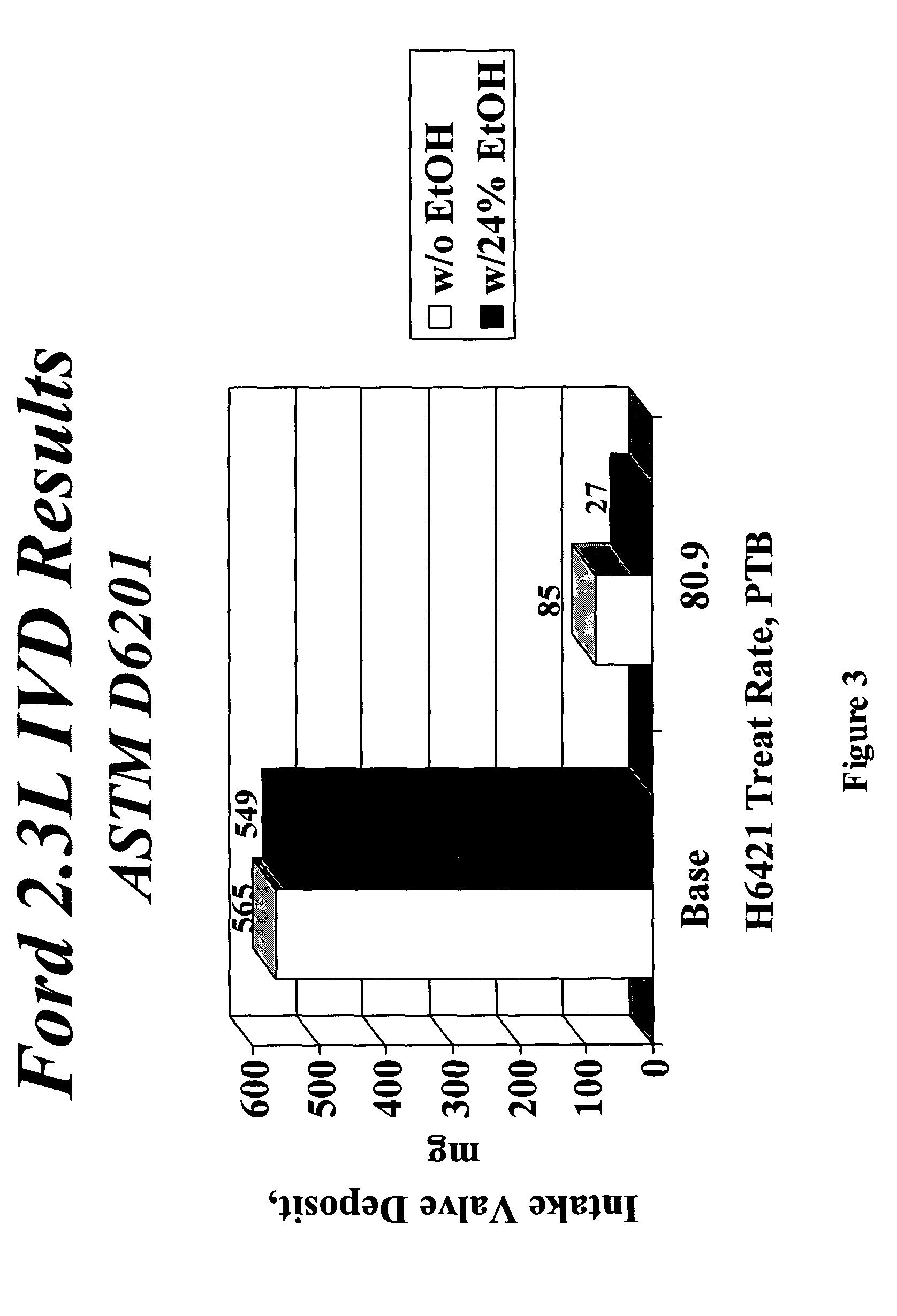

[0005] The present invention is directed to the reduction of engine deposits formed as a result of the combustion of fuels in the engine. Engine deposits include intake valve deposits (IVD) and combustion chamber deposits (CCD). Historically, a reduction of IVD meant an increase in CCD. The present invention includes a method for reducing all engine deposits (especially IVD) by combusting a fuel having a high concentration of an oxygenate and a detergent-containing fuel additive. In one embodiment, the oxygenate in the fuel is ethanol, and the detergent is Mannich-based. It has also been discovered that increasing the amount of oxygenate increases the conductivity of the fuel. It is postulated, without limitation to this theory, that the increase in conductivity, in combination with the addition of a detergent, more effectively reduces engine deposits. Good results are obtained in one embodiment when the conductivity of the fuel is in excess of about 1×103 nS / m.

[0006] By “fuel” or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

| volume percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com