Diode cutoff and safe packaging method for textile detonating cord

a technology of detonating cord and cutoff point, which is applied in the direction of transportation and packaging, packaging goods type, containers, etc., can solve the problems of high labor intensity in the packaging of detonating cord using this method, the material and labor costs of the resultant product are high, and the regulations governing the air shipment of explosives are quite stringen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

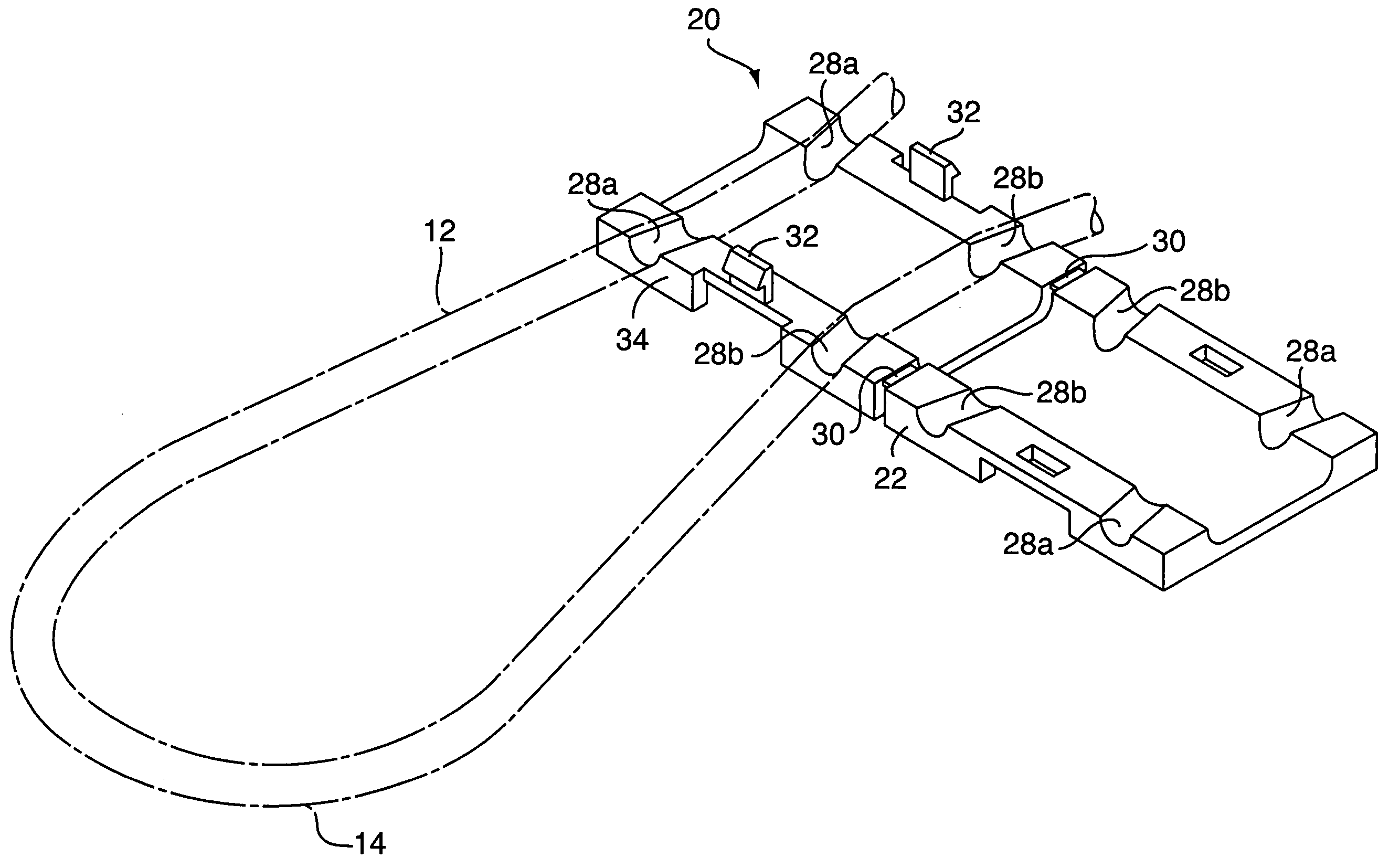

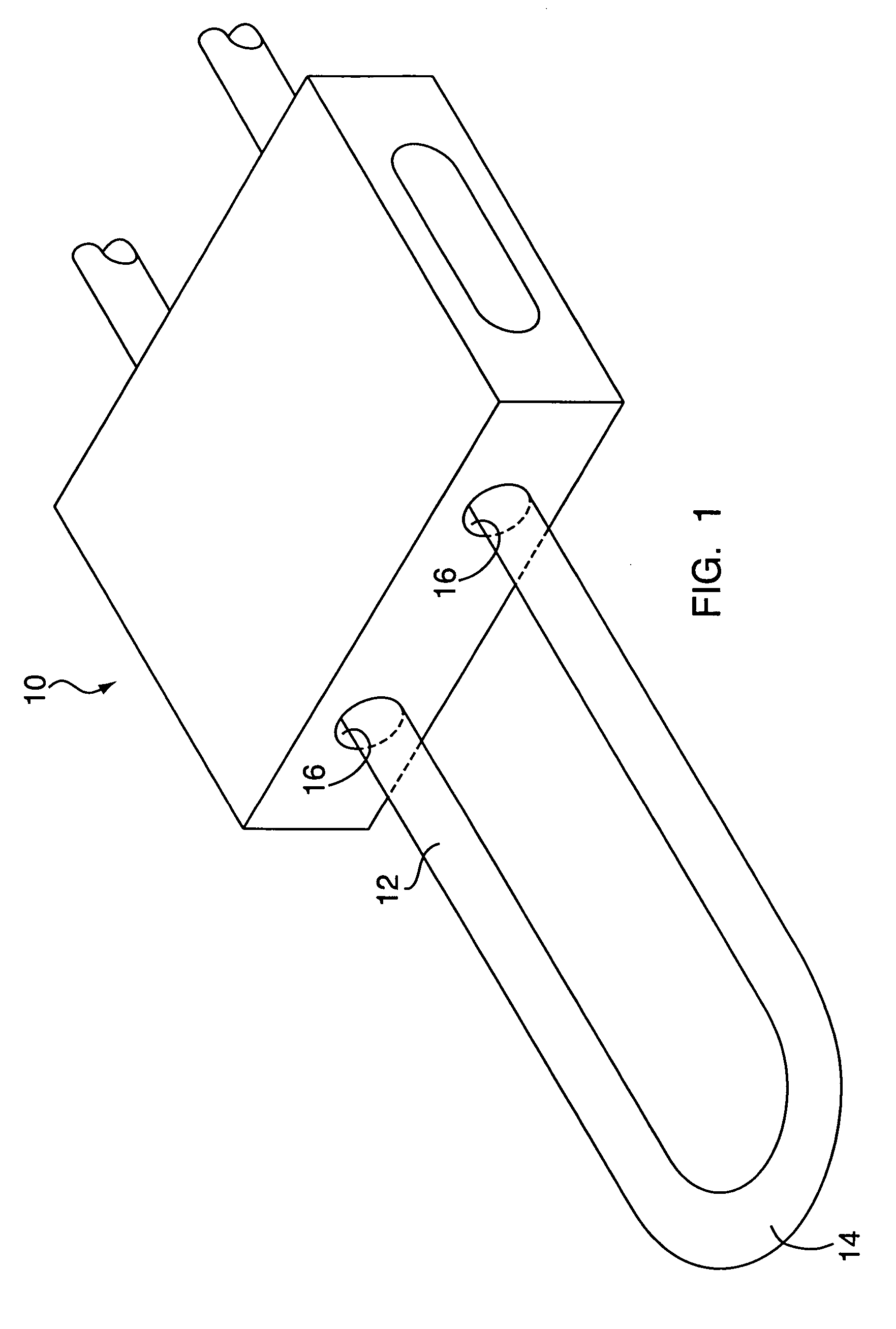

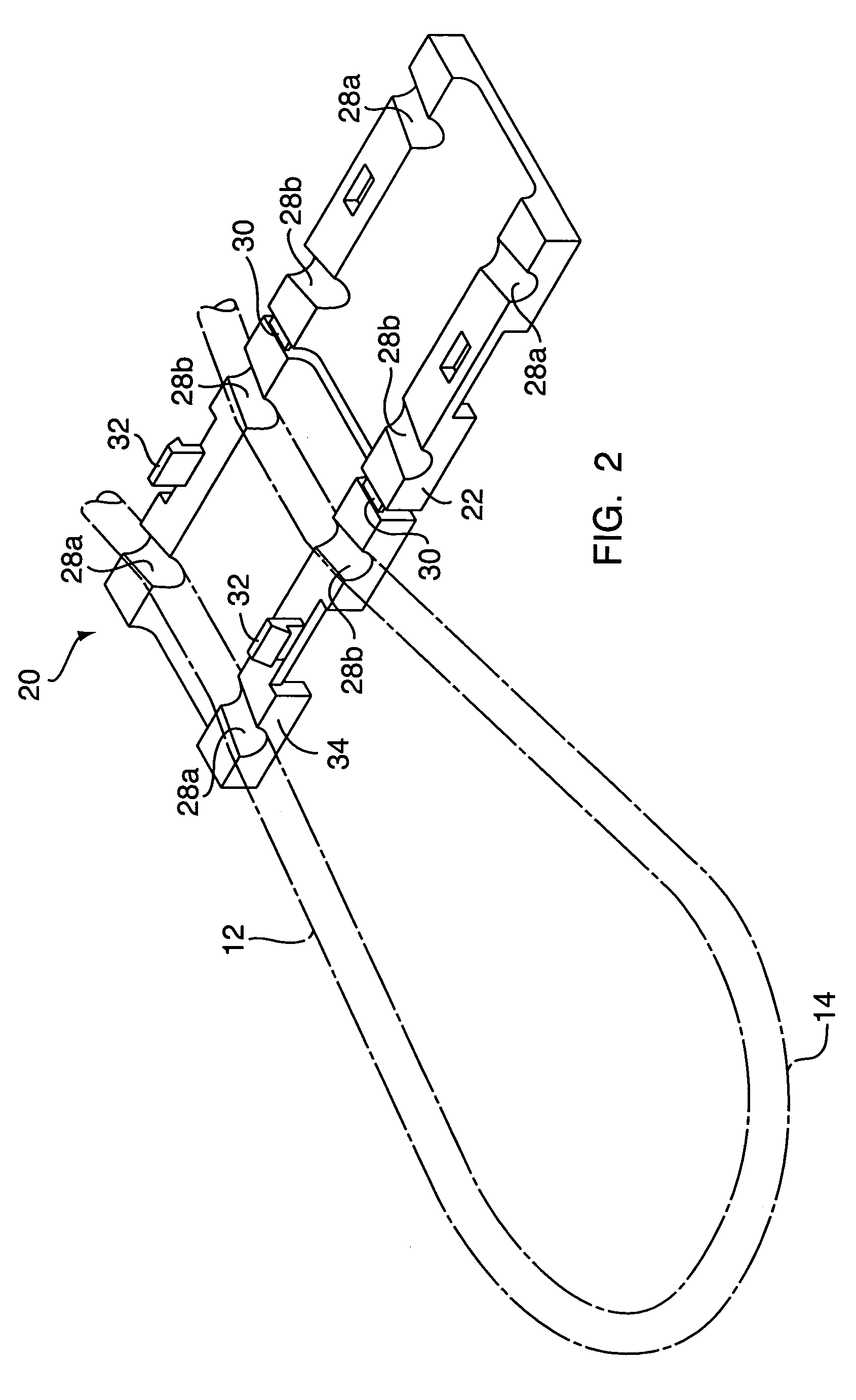

[0017] A diode cutoff block is shown in FIG. 1. In this drawing, the diode cutoff block (10) is shown. The block has two through holes 16, 16 for detonating cord and a channel through the block for focusing the air blast of the detonating cord. Detonating cord (12) passes through the diode block (10) and then forms a loop (14) before the cord passes through the diode block in the opposite direction. The diode block functions by focusing the air blast of the detonating cord through the block and severing the adjacent detonating cord section. The length of the loop (14) must be selected to allow the air blast to sever the adjacent detonating cord before the detonation wave can travel around the loop and pass through the block again.

[0018] The block can be made out of a variety of materials such as metal, wood, or plastic. From a cost and weight standpoint, the preferred material is usually plastic. The dimensions of the block are determined by the quantity of explosive loading in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com