Apparatus and process for making a tape useful as a tire cap ply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

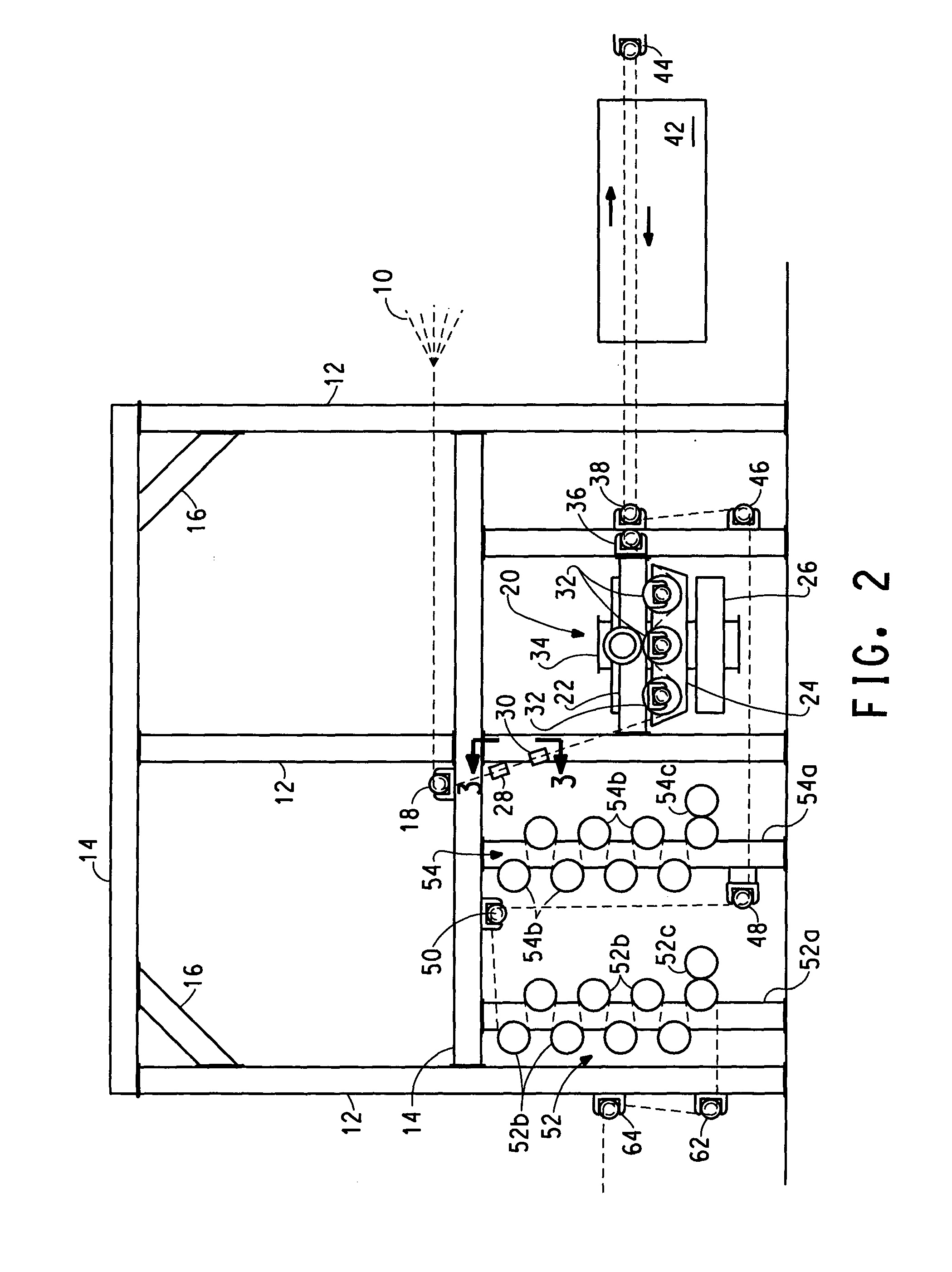

[0036] A tape may be made using the apparatus of FIG. 2 from a plurality of single end cords, such as T-728, commercially available from DUSA, International. The cords may then be sent to a dip pan, where an rfl dip, may be applied. This dip may be made by adding water, sodium hydroxide (NaOH), or caustic pellets, resourcinol flake and formaldehyde to a tank, to form a sollution with a solids content of about 6%. The solution should be mixed for approximately 30 minutes. This solution may then aged for a minimum of about 3 hours (minimum of 2 hours, maximum of 4 hours). In another tank, a latex may be added. Then water may be mixed with ammonium hydroxide, NH4OH, and added to the latex slowly.

[0037] Then an anti-foaming agent may be added to form a solution, which should be mixed slowly. This solution may have a solids content of about 35%. This solution may then combined with the solution from the first tank. The combined solutions should be mixed together for about 30 minutes pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com