Blended polymeric draw tapes

a polymer and draw tape technology, applied in the direction of flexible container closures, transportation and packaging, sacks, etc., can solve the problems of unattainable combined sealability and tensile strength by prior art multi-layer or single-layer films, and achieve the effect of low elongation and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

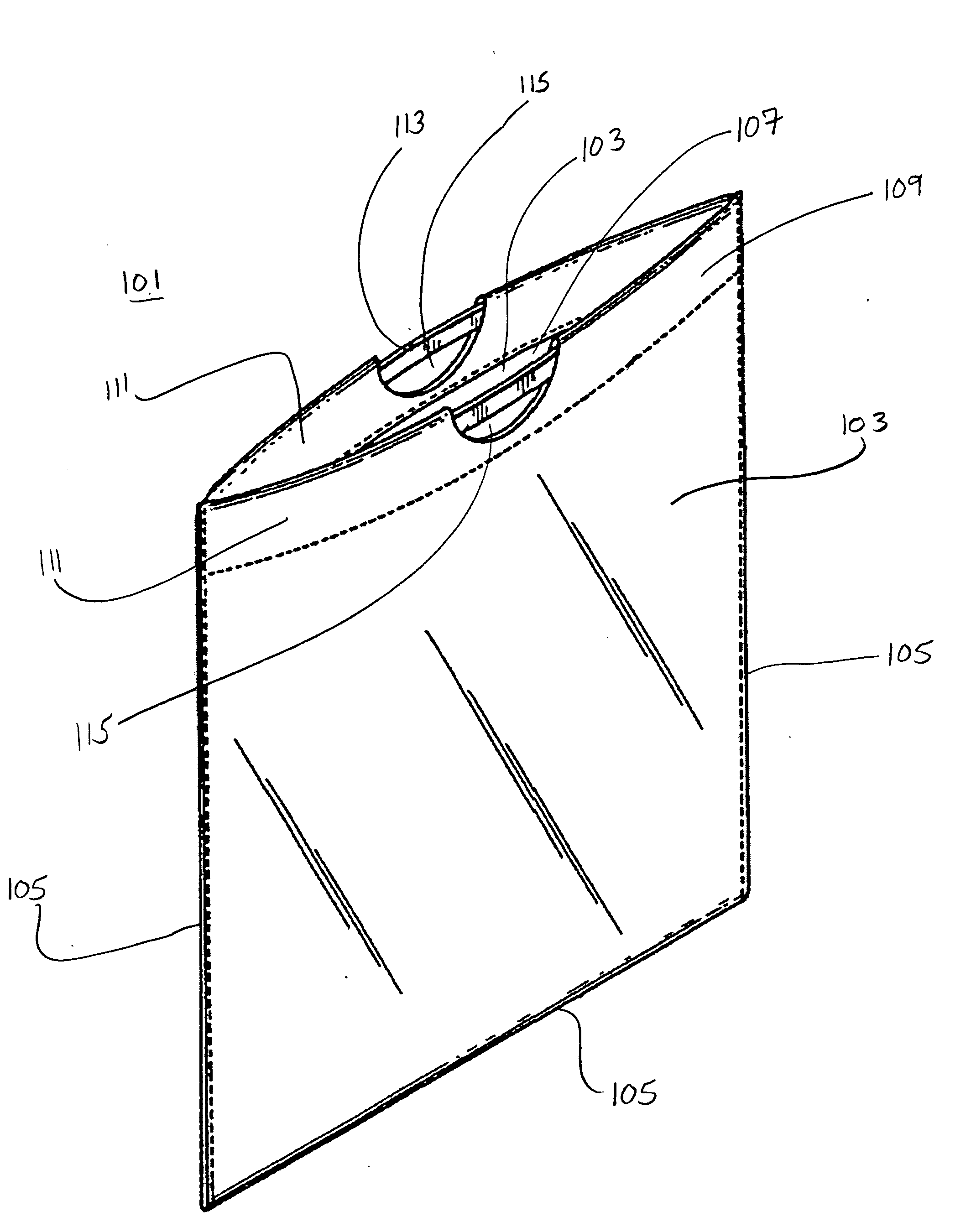

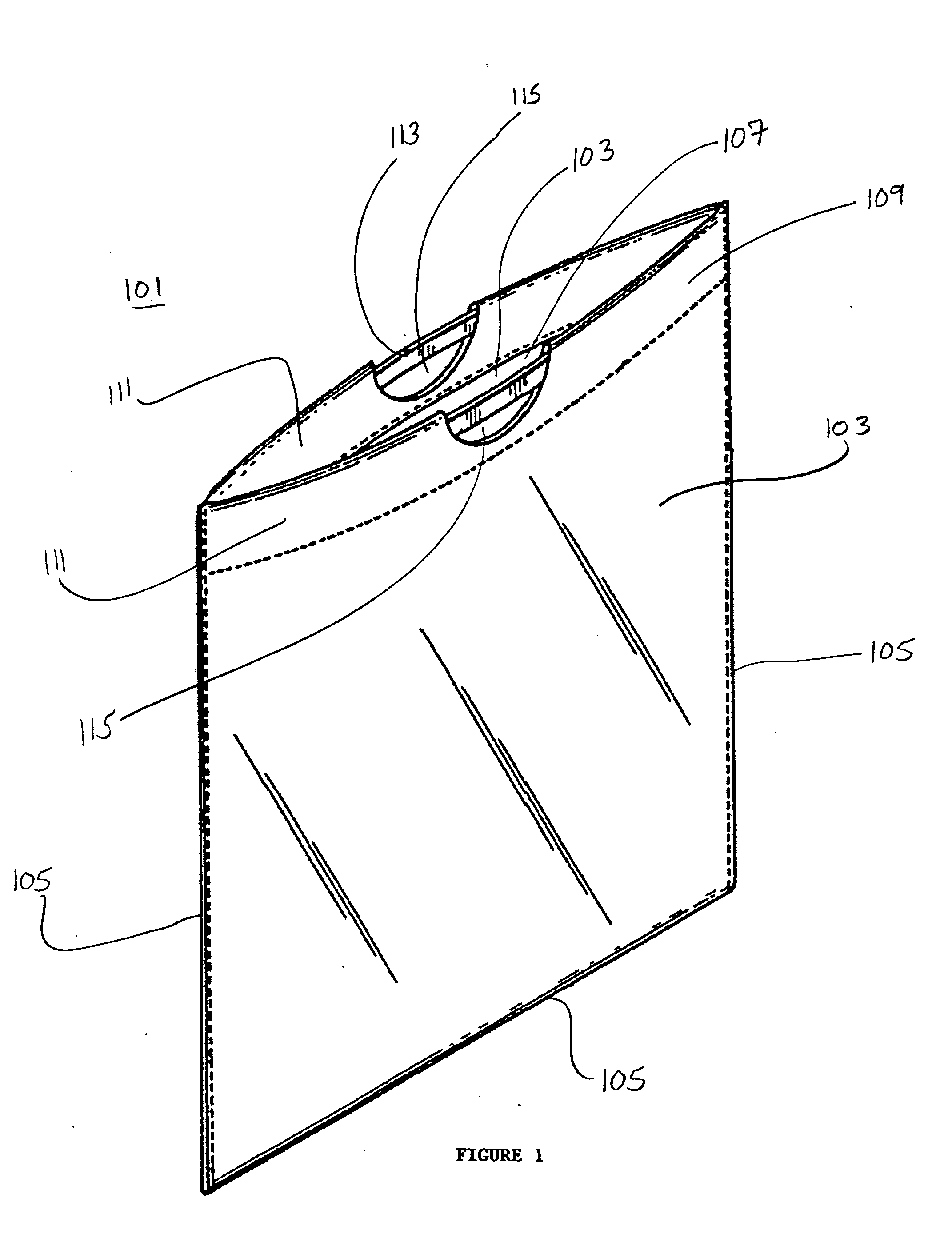

Image

Examples

example 1

[0024] A draw tape was constructed from a polymeric blend consisting of approximately 87.5% high-density polyethylene (HDPE), 10% low-density polyethylene (LDPE) and 2.5% of color concentrate. The HDPE used in this illustrative embodiment was a bimodal distribution high molecular weight material with an at least a density of approximately 0.952 and a melt index of approximately 0.055. The LDPE is a HPLD grade material having a melt index of 2.0 and a density of approximately 0.92. The addition of LDPE acts as a synergistic agent in improving the tensile performance of the draw tape. The color concentrate is pigment dispersed in a 2.0 MI LDPE carrier. The polymeric blend was made into a film by a blown process as known in the art. The blown film was made to approximately 9 mil thick and was then oriented in a machine direction yielding around 1.3 mil thick film. The orientation of the film imparts higher strength and lower elongation. In this particular illustrative embodiment the or...

example 2

[0025] A draw tape was constructed from a polymeric blend consisting of approximately 75% high-density polyethylene (HDPE), 20% metallocene polyethylene (mLDPE) and 5% of color concentrate. The HDPE used in this illustrative embodiment was a bimodal distribution high molecular weight material having a density of approximately 0.952 and a melt index of approximately 0.055. The mLDPE used within the example had a melt index of approximately 1.0 and a density of approximately 0.92. The polymeric blend according to this example was made into a film by a blown process as known in the art. The blown film was made to approximately 6 mil thick and was then oriented in a machine direction to yield around 1.0 mil thick film.

example 3

[0026] A draw tape was constructed from a polymeric blend consisting of approximately 67.5% high-density polyethylene (HDPE), 30% metallocene polyethylene (mLDPE) and 2.5% of color concentrate. The HDPE used in this illustrative embodiment was a bimodal distribution high molecular weight material having a density of approximately 0.952 and a melt index of approximately 0.055. The mLDPE used within this illustrative example had a melt index of approximately 1.0 and a density of approximately 0.92. The polymeric blend according to this illustrative example was made into a film by a blown process as known in the art. The blown film was made to approximately 6 mil thick and was then oriented in a machine direction yielding around 1.0 mil thick film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com