Flexible panel

a technology of flexible panels and panels, applied in the field of flexible panels, can solve problems such as the path to separation, and achieve the effects of reducing the shear stress on the cord, easy assembly, and convenient manufactur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] While this invention is susceptible of embodiment in many different forms, there are shown in the drawings and will be described in details herein three specific embodiments, with the understanding that the present disclosure is to be considered as an example of the principles of the invention and is not intended to limit the invention to the embodiments illustrated and described.

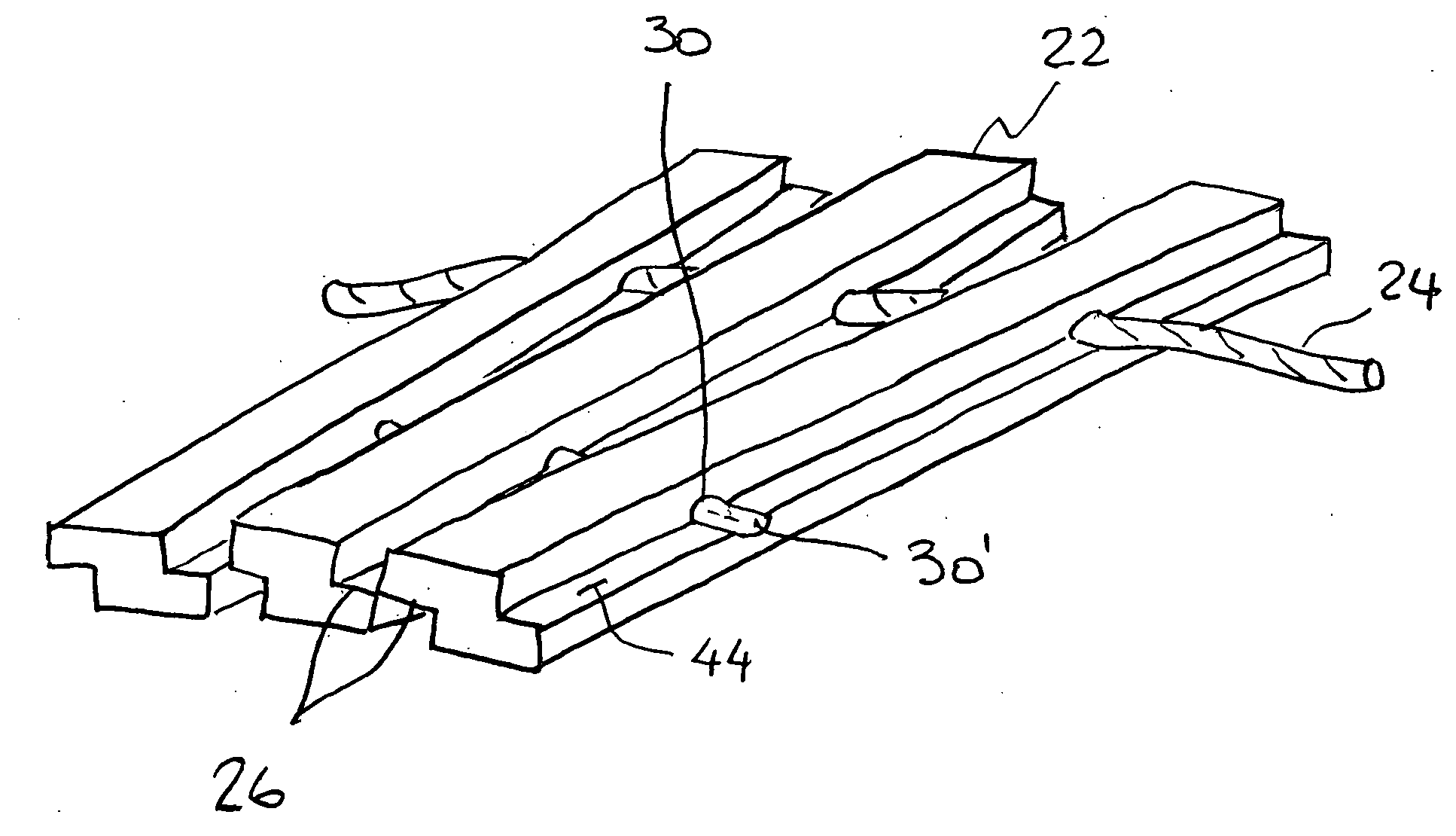

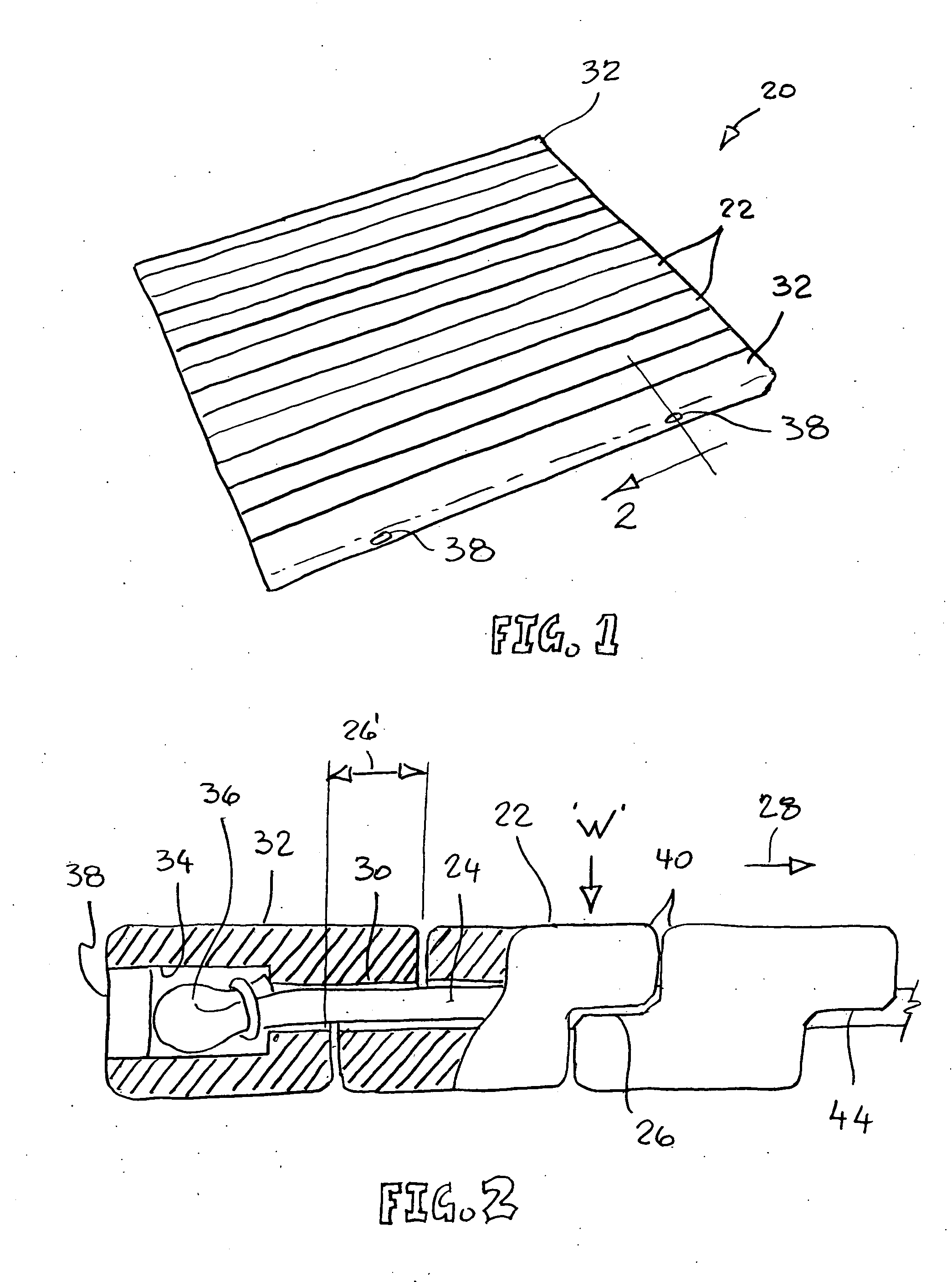

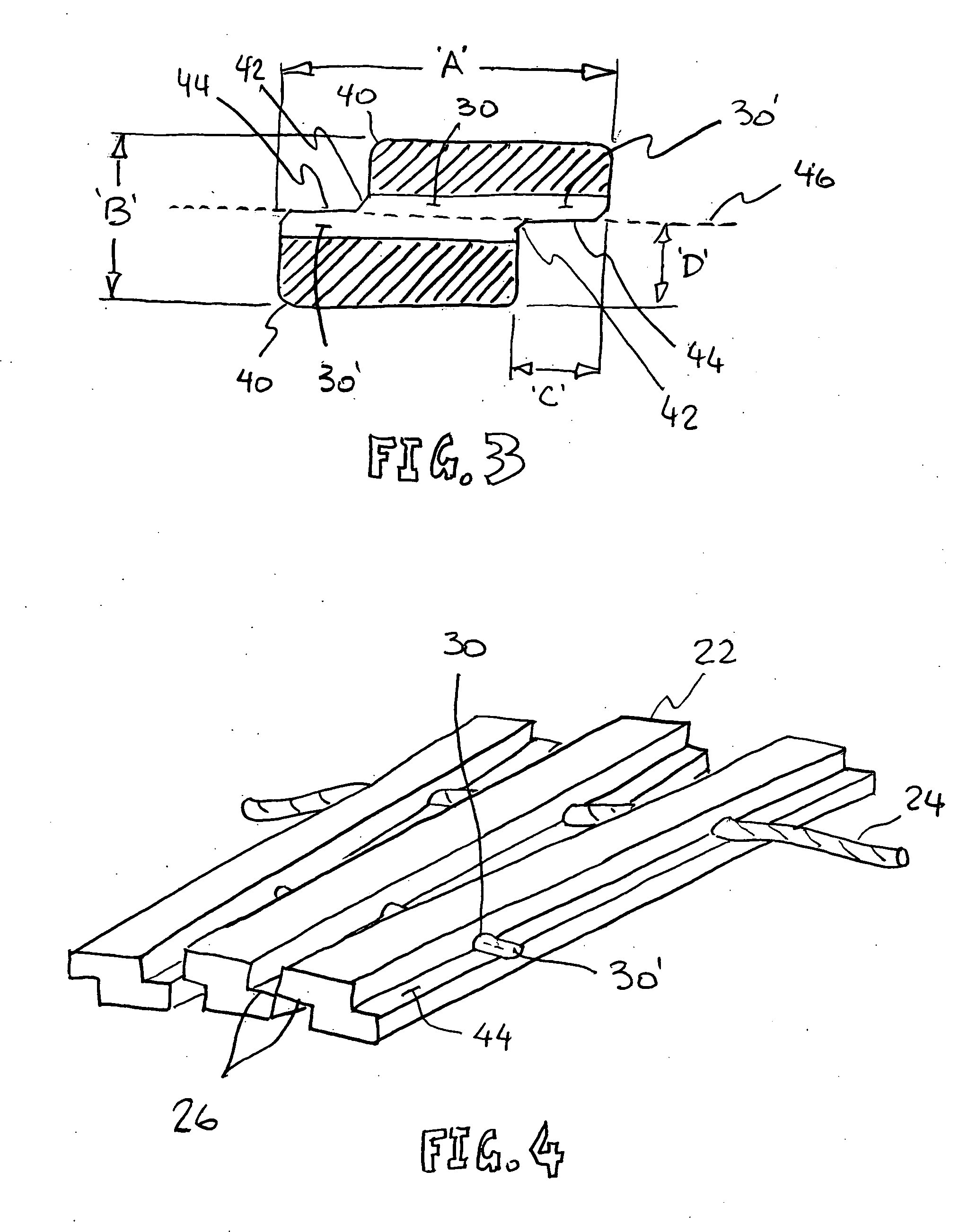

[0040] In a first preferred embodiment of the present invention, there is provided a panel 20 made of juxtaposed rigid bars 22, as illustrated in FIG. 1, through which are threaded two elastic cords. These elastic cords 24 are better illustrated in FIGS. 2 and 4. Each panel 20 is rigid along the bars 22 and is flexible across the bars. The bars 22 have shiplap edges 26 as shown in FIGS. 2 and 4 such that the edge of one bar overlaps the edge of an adjacent bar to distribute a concentrated load to a number of bars. The bars 22 in the panel 20 are held together by the tension set in the elastic cords ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexible | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com