Boat dock bumper & dockline storage system

a dockline and bumper technology, applied in the direction of waterborne vessels, etc., can solve the problems of difficulty in removing mooring lines, and unsightly mooring lines, so as to prevent damage to cushion boats, easy to store mooring lines, and convenient grabbing of mooring lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

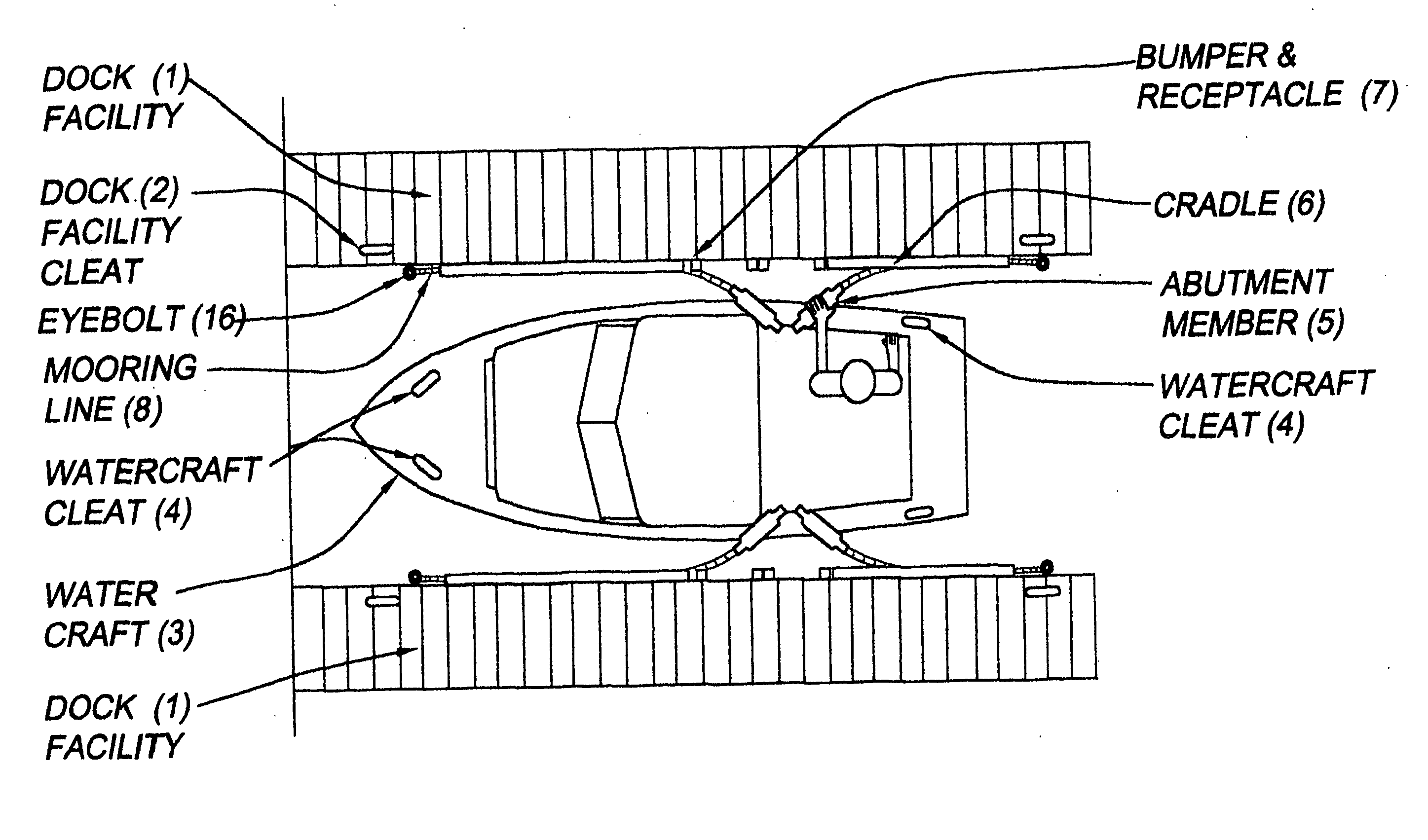

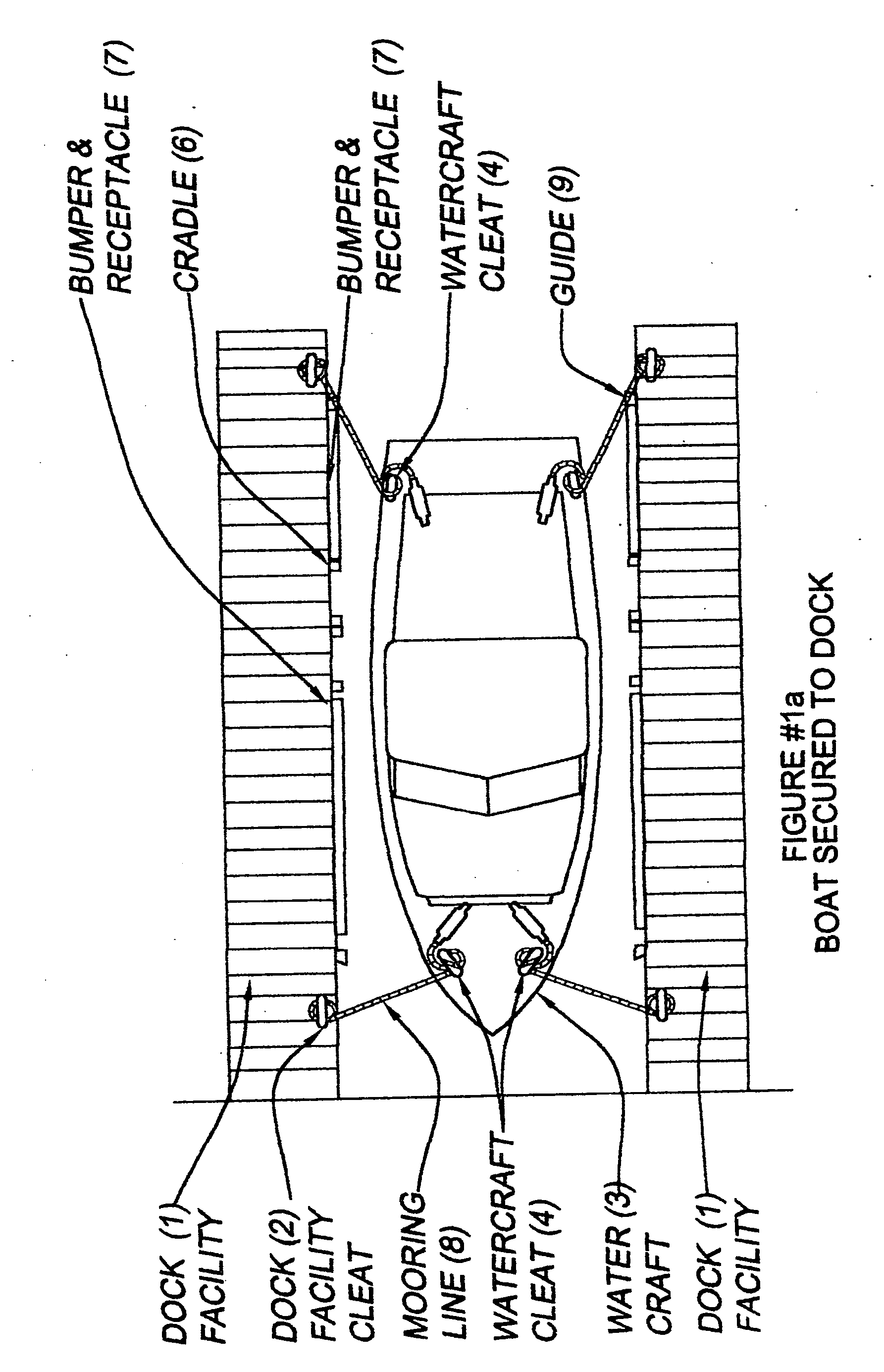

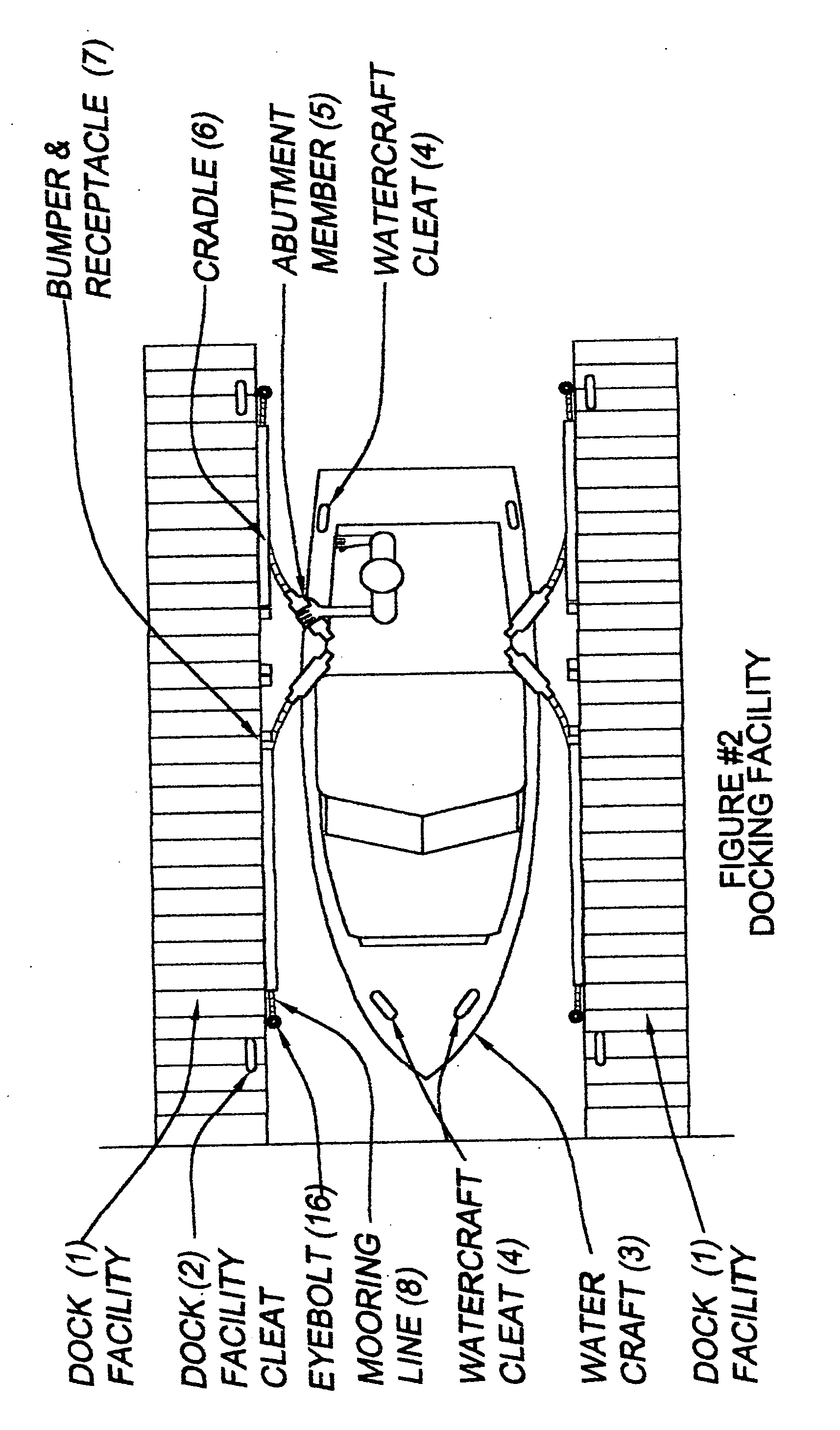

[0028] Referring now to the Drawing. FIG. 1 generally depicts the bumper and mooring line receptacle apparatus according to the present invention in operation with respect to a dock facility 1 and a watercraft 3, wherein a bumper and mooring line receptacle apparatus 7 is depicted by way of example. FIG. 3 depicts the bumper and mooring line receptacle apparatus 7, apparatus according to the present invention.

[0029] As shown by FIGS. 1, 1a, 2, 2a &5 the bumper and mooring line receptacle apparatus 7 for mooring line 8. The bumper and mooring line receptacle 7 is secured to the dock facility 1 thereof, preferably at a location with respect thereto which is adjacent the watercraft bumper 3a.

[0030] Preferably, the abutment member 5 shall be located on dock facility adjacent to the port and starboard sides of the watercraft 3 where the skipper and crew / passengers enter and leave the watercraft, generally aship of the watercraft. Each bumper and mooring line receptacle 7 has an interio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com