Tank lining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

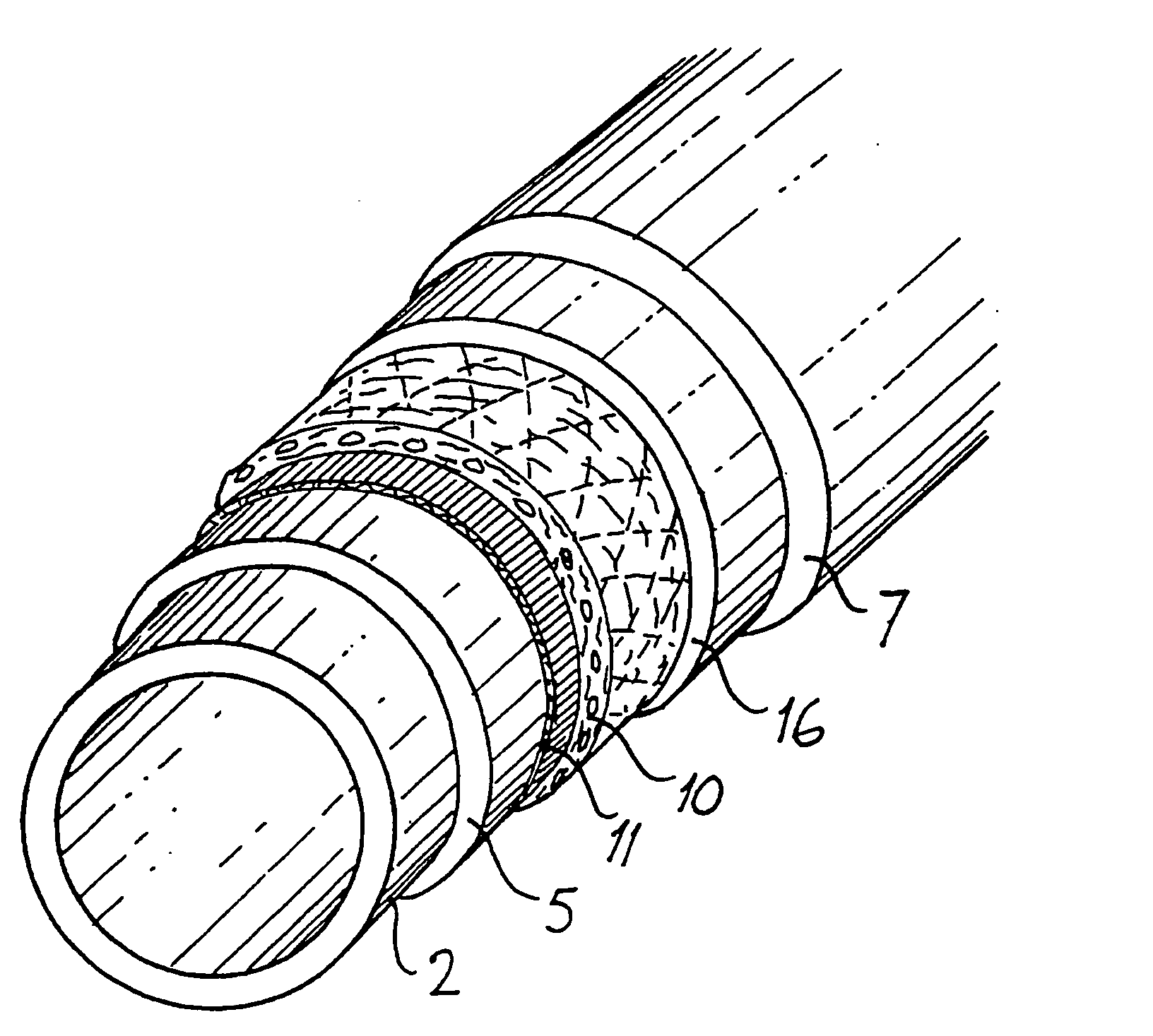

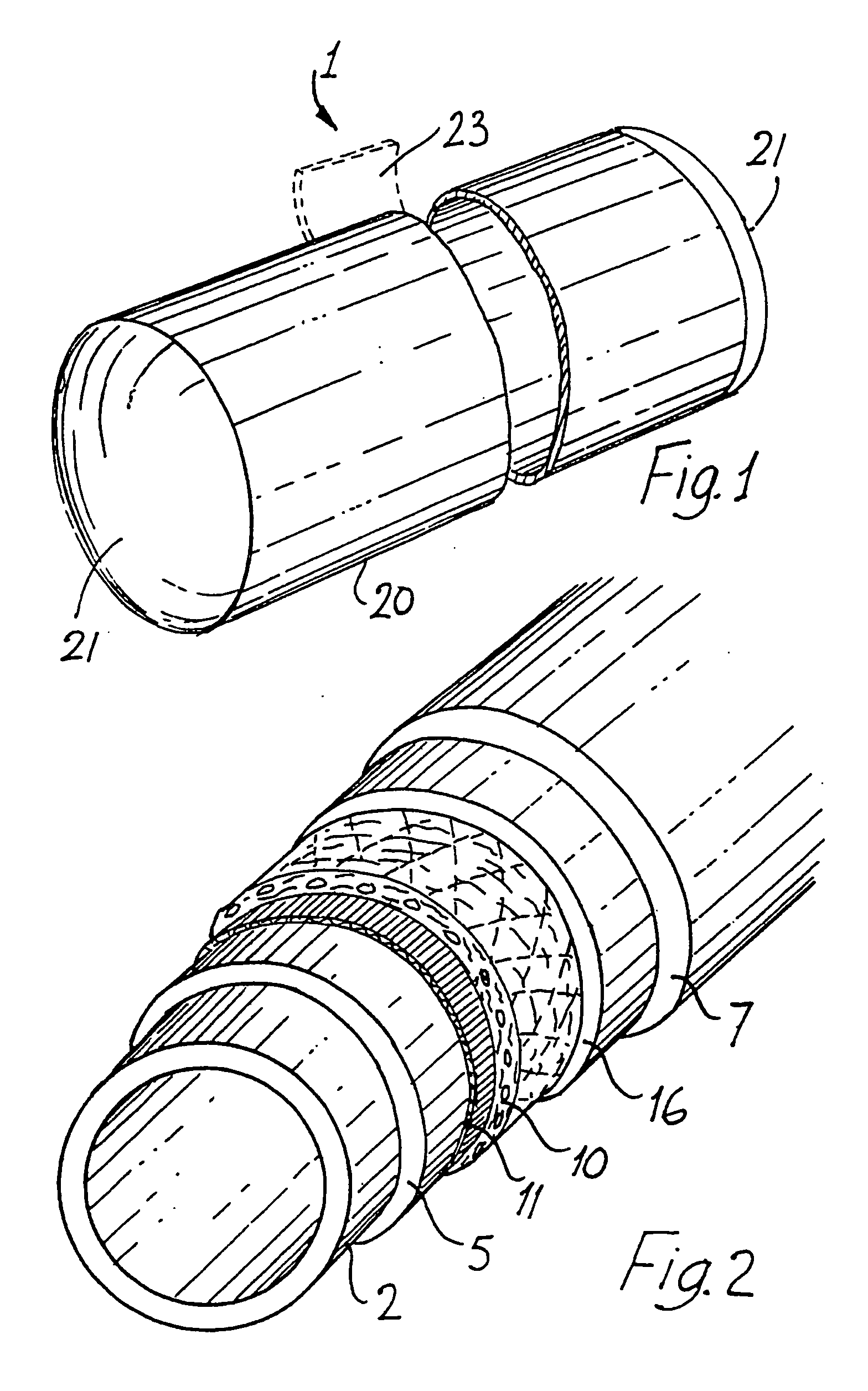

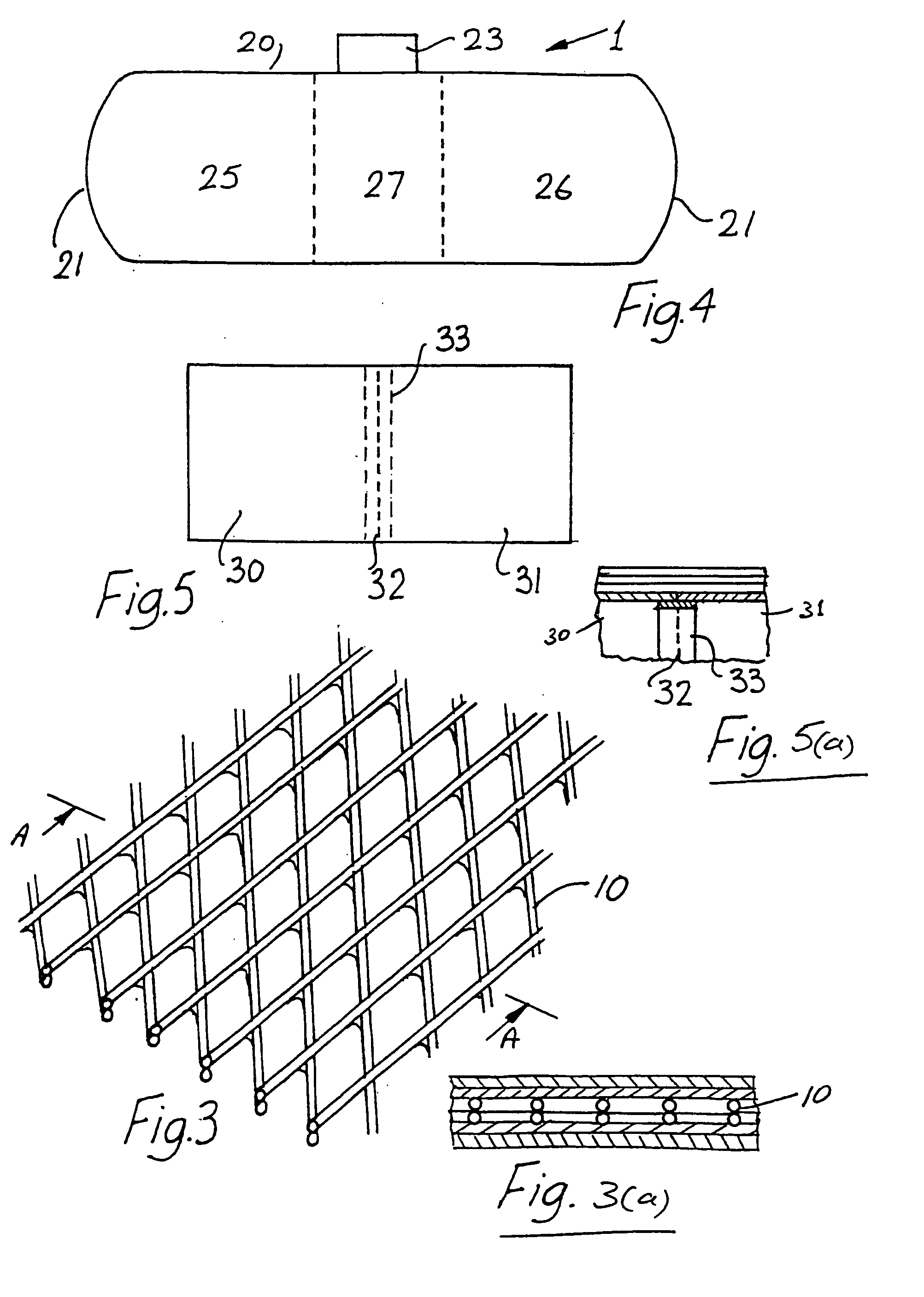

[0049] Referring to the drawings there is illustrated in FIG. 1 a typical underground tank 1 for storage of petroleum products and chemicals generally. The tank 1 may, for example, be an underground petroleum products storage tank located at a service or filling station and comprises a main cylindrical body 20 with domed ends 21. The tank 1 typically has a generally centrally disposed manway 23.

[0050] The storage tank 1 is lined in situ by accessing the tank 1 through the manway 23. The inner surface 7 of the tank wall is first cleaned using water jetting to remove scale, rust and surface contaminants. The tank internal wall is then inspected to ascertain any leak areas or perforations. A full inspection of the tank is carried out using an ultrasonic wall thickness gauge to establish any internal / external corrosion patterns. Any resultant defects are repaired using an epoxy filler. Where necessary the striker plate, which is a steel plate below the manway 23, is removed. Weld spatt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com