Gemstone cut

a technology of gemstones and cut stones, applied in the field of gemstone cutting, can solve the problems of reducing the yield of diamonds, so as to achieve the effect of improving yield and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

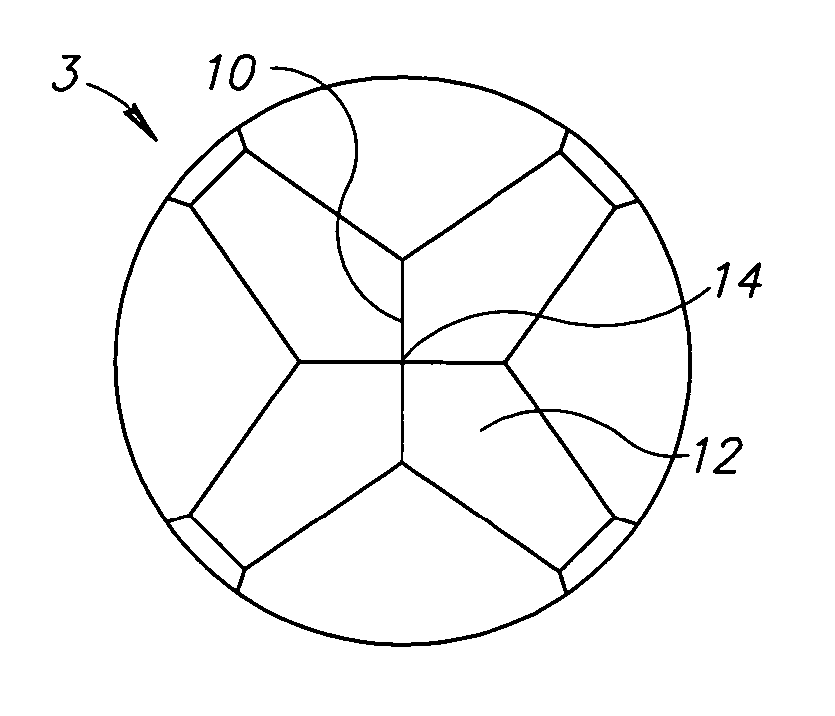

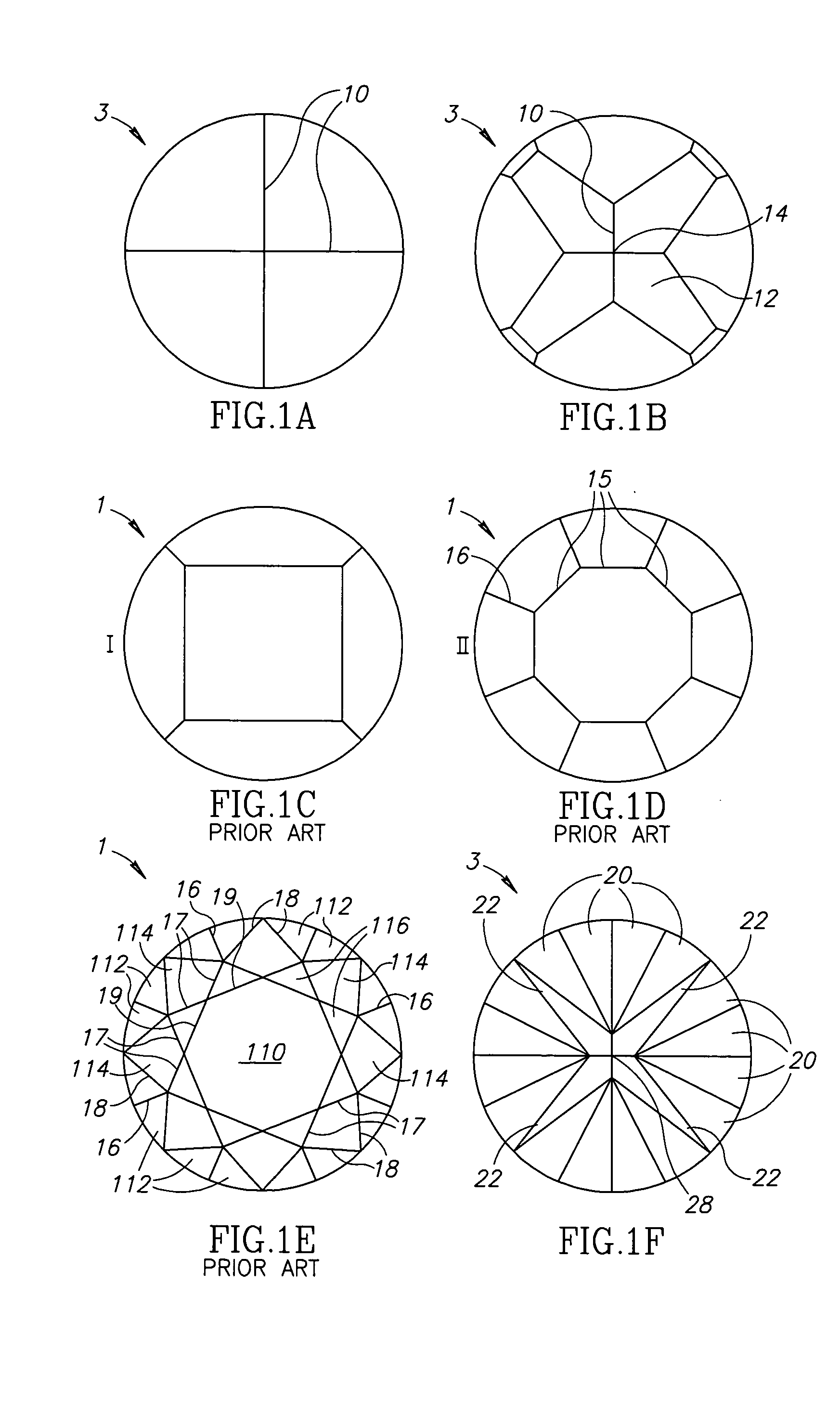

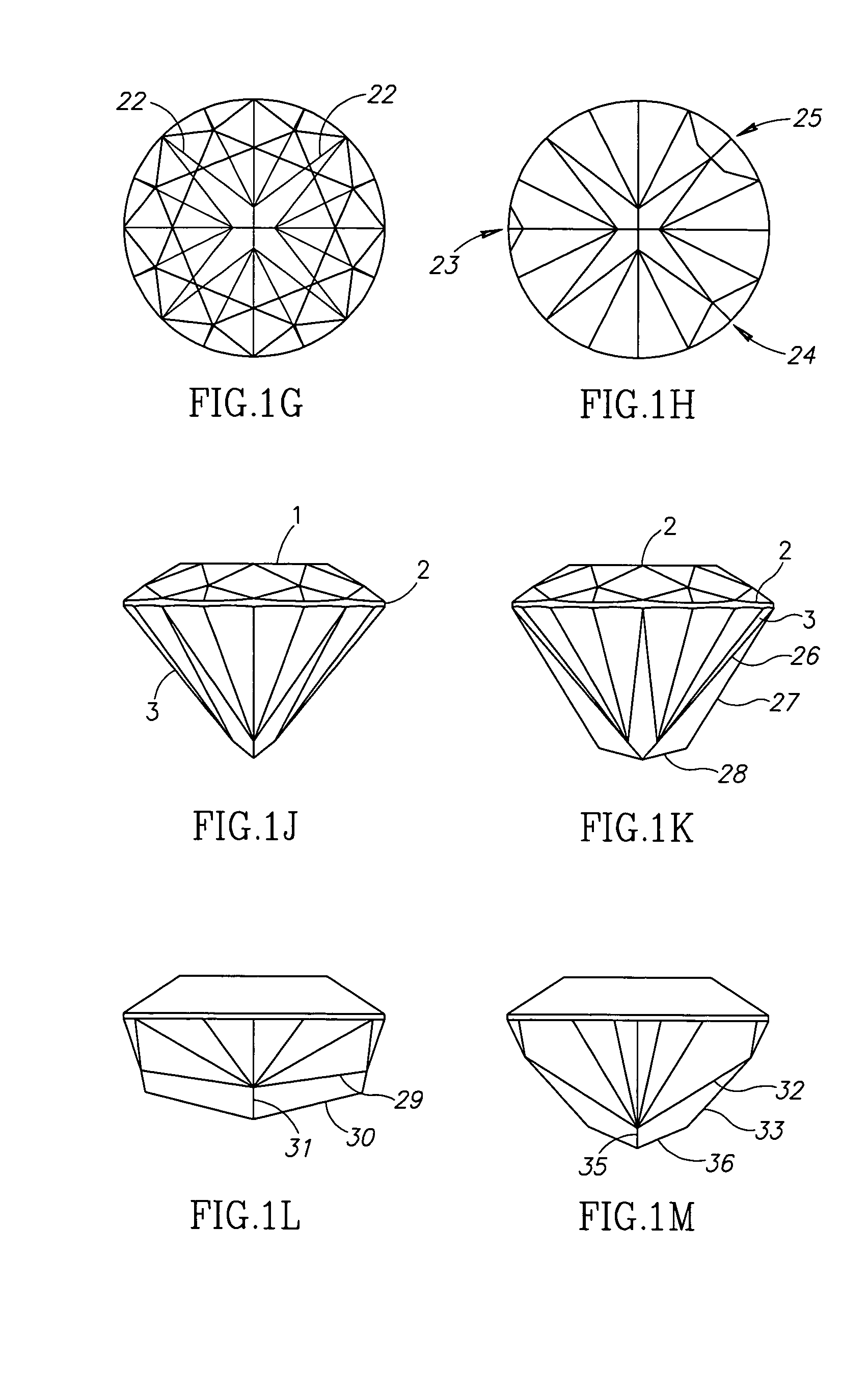

Image

Examples

Embodiment Construction

[0054] The present invention is directed to a new method of cutting a gemstone which increases the yield while achieving a achieving a brilliance and having light dispersion.

[0055] The accepted theory in the gem industry that the optimal angle of the base facets is roughly 41 degrees and that even small deviations from this figure will affect the brilliance of the stone has unduly limited the development of other methods of cutting stones. The inventor has realized that, contrary to standard practice, by cutting the base with fewer pavilions there will be a substantially increase in the yield. Thus, for example, a one carat brilliant cut stone may be produced from a rough stone weighing approximately 1.3-1.4 carat, compared with standard cuts which use a rough stone weighing approximately 1.7 to 2 carats to achieve a one carat stone. As will be appreciated such an improvement in yield (of approximately 30%) is especially significant in the diamond industry, where stones are relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com