Creel for textile machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

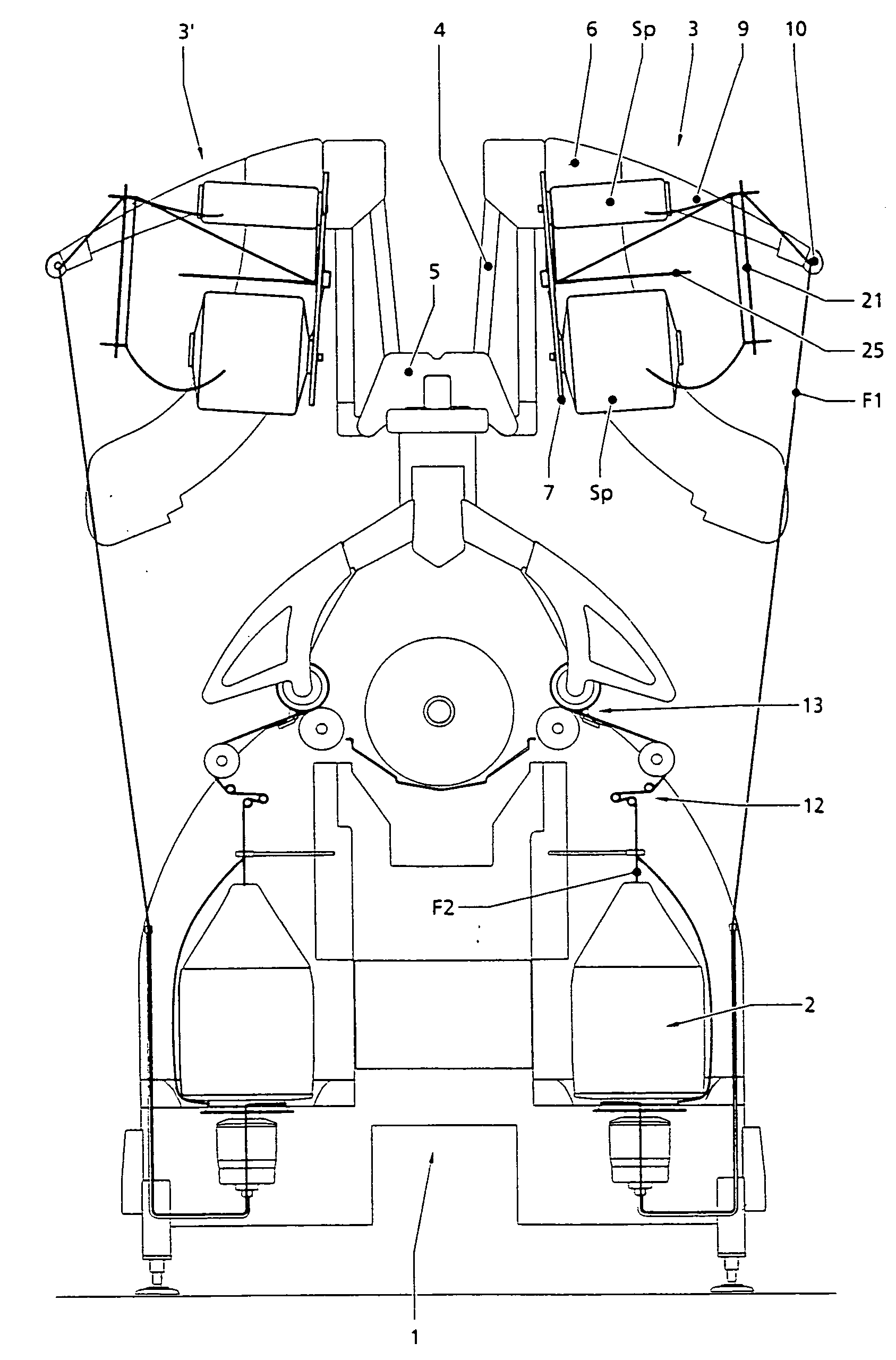

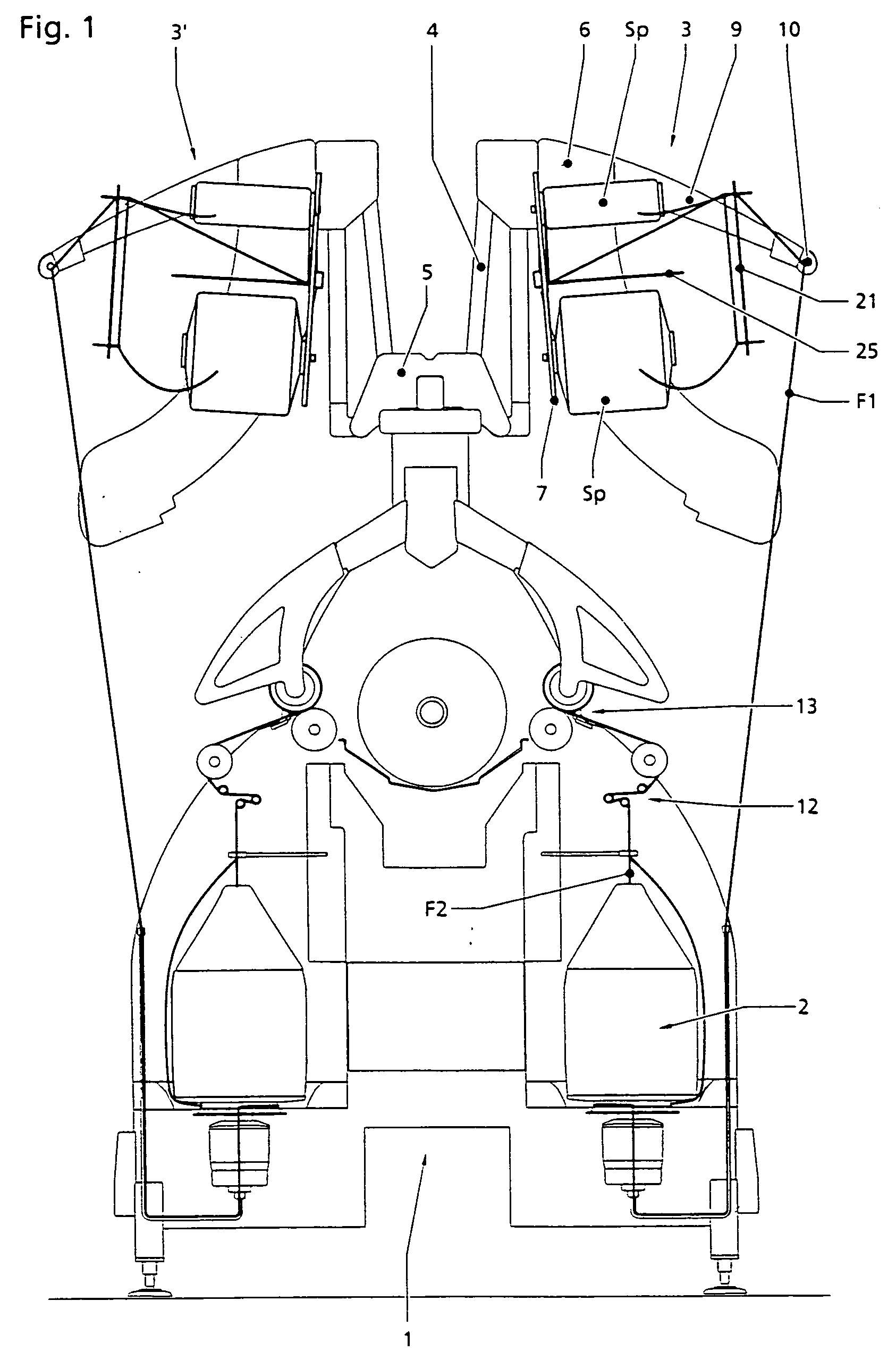

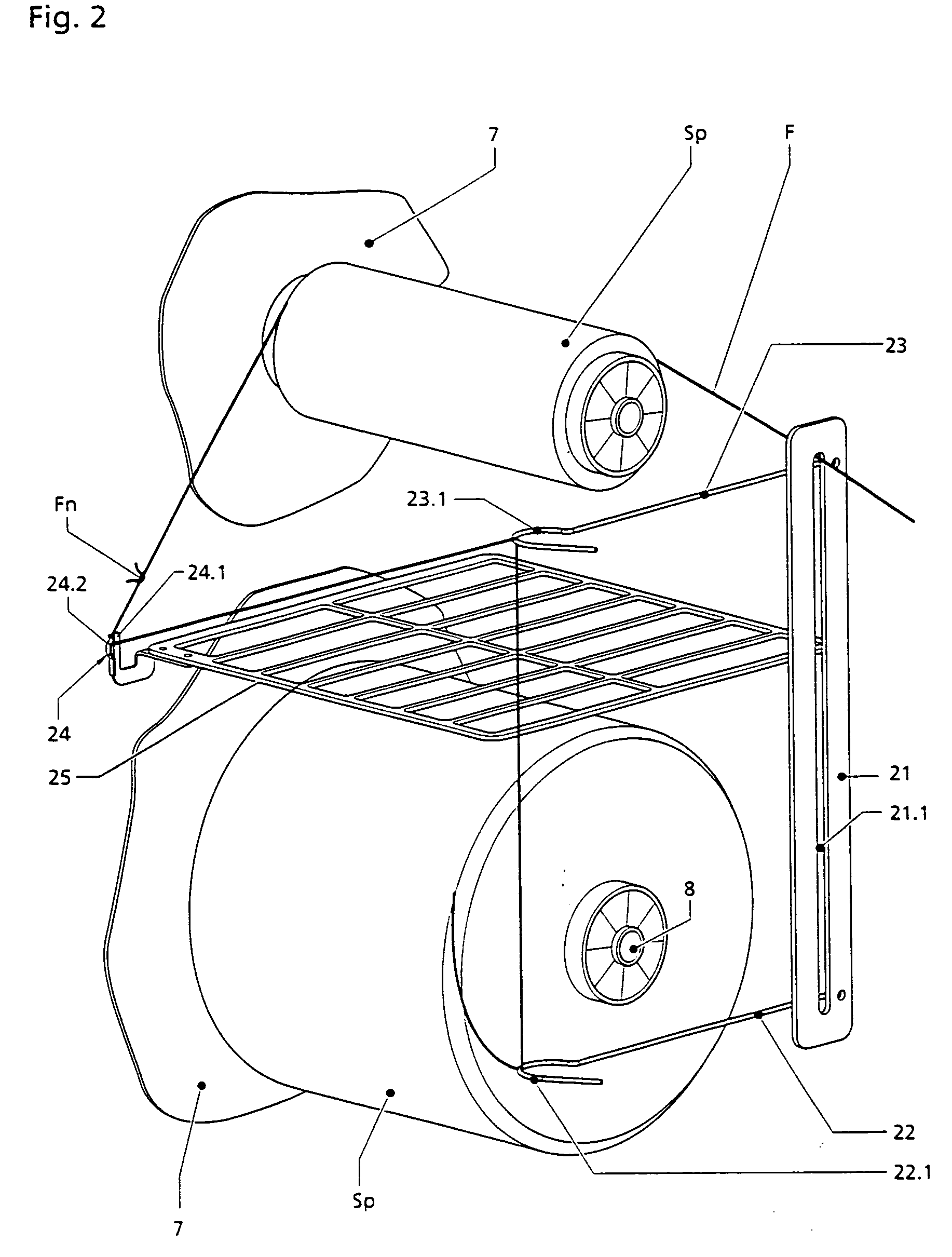

[0022] In connection with the textile machine 1 that is only schematically illustrated in FIG. 1, the textile machine is, for example, a cabling machine having cable spindles extending on both sides thereof along the machine longitudinal direction. The one creel 3 associated with an individual cable spindle 2 is pivotally mounted on the upper side of the machine frame 5 by means, for example, of a four piece linkage 4. The individual creel 3 can also be configured in a conventional manner as a double creel such that each creel is provided with four feed packages Sp or, respectively, can be loaded with such feed packages, so that each respective pair of neighboring cable spindles of the cabling machine can be served by an individual package creel. In connection with the feed package Sp, such packages are the so-called simple-feed packages for the outer yarn of the cabling process.

[0023] The creel 3 comprises a support plate 6 on which, on each side thereof, there is respectively mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com