Control system for hydrostatic pump

a control system and hydrostatic pump technology, applied in the direction of pump control, pump parameter, positive displacement liquid engine, etc., can solve the problems of swashplate incorrect positioning, pump and servo system usually not matching the resolution and accuracy of input signal,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

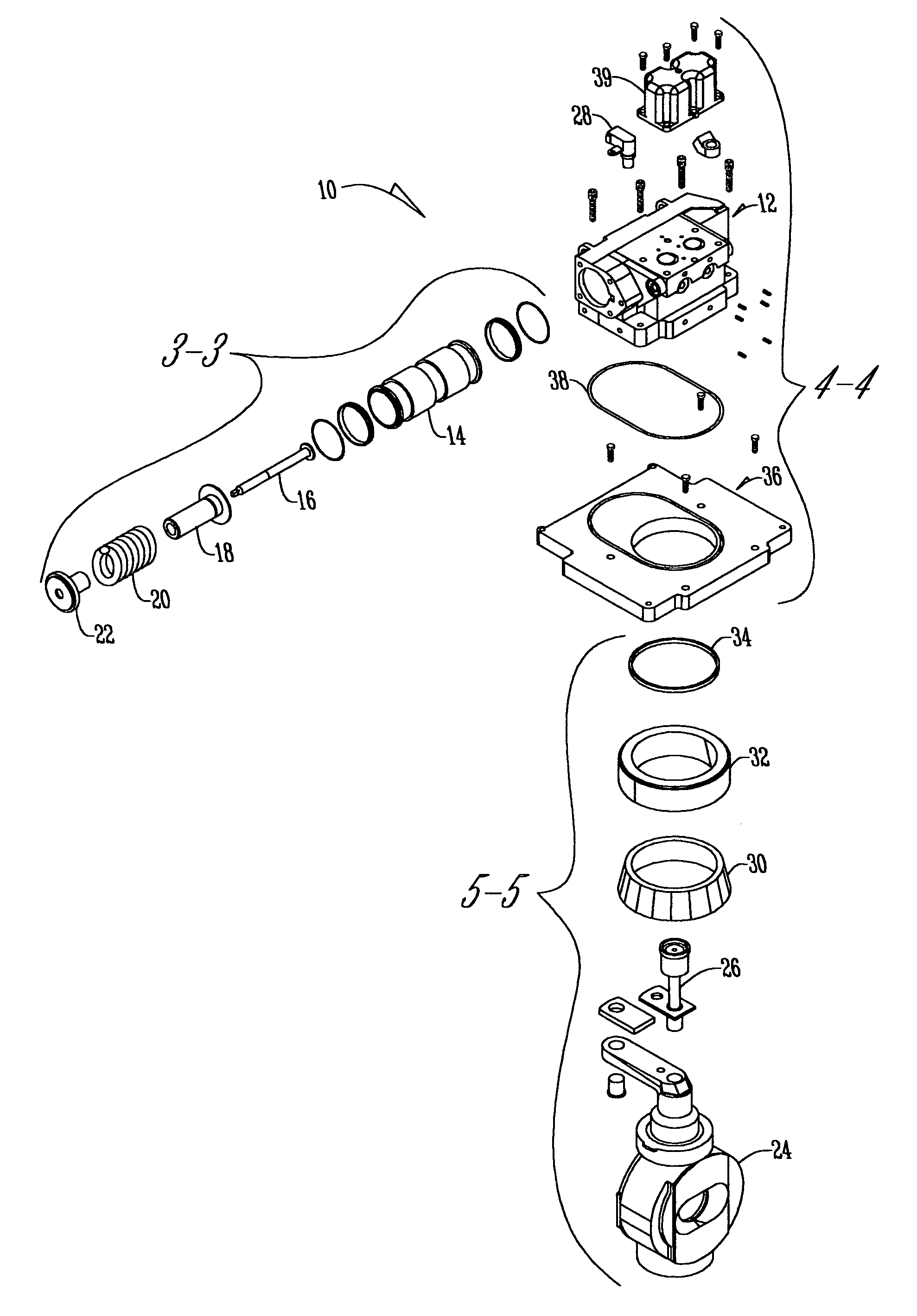

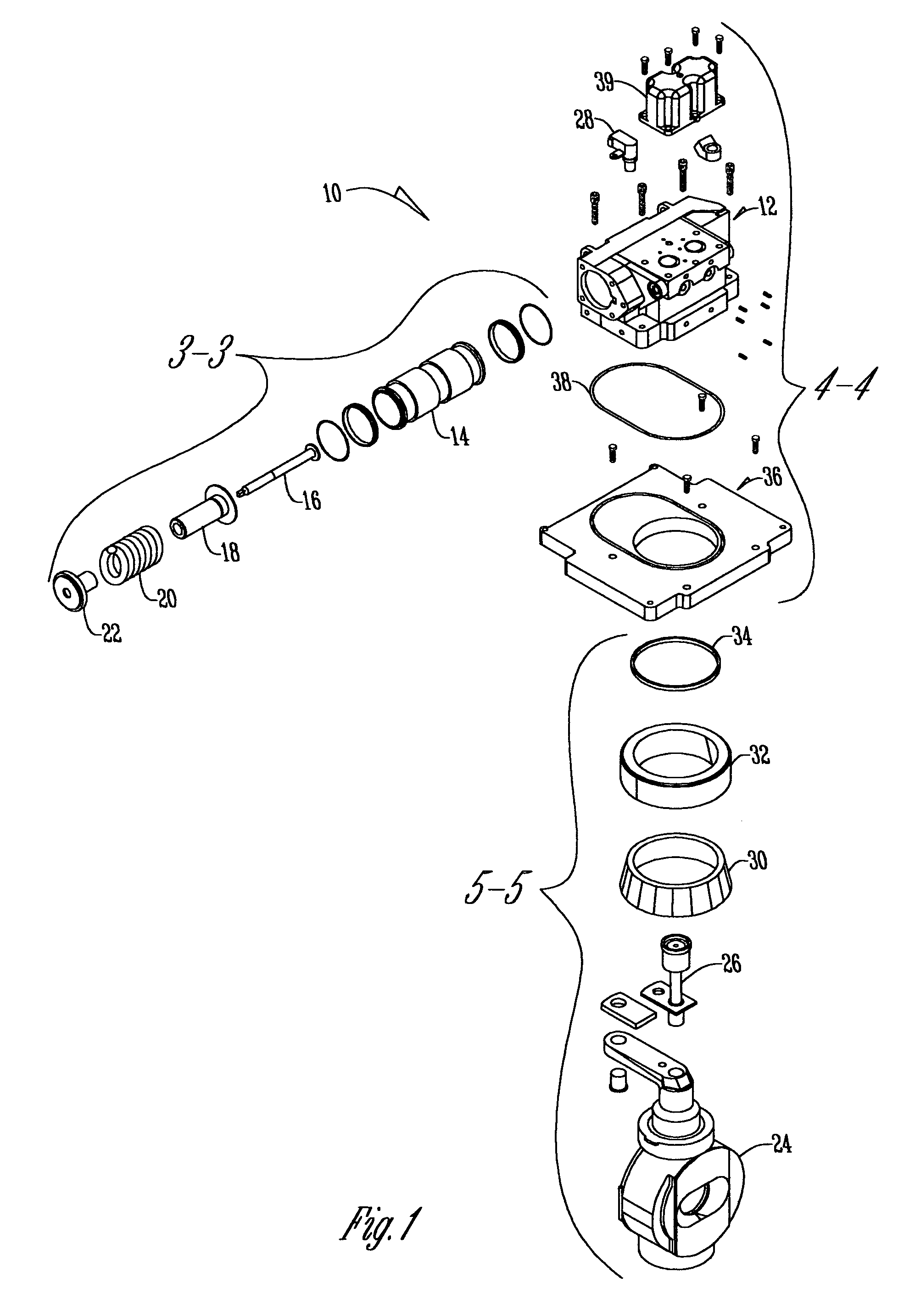

[0014] The control system of the present invention can be connected to the hydrostatic pump seen in FIG. 1. The hydrostatic pump 10 has a central housing 12 of a standard servo hydrostatic pump. A servo piston 14 is disposed through the central housing 12. The servo piston 14 incorporates a servo screw 16, spring guide 18, servo spring 20, and spring seat 22.

[0015] The hydrostatic pump 10 also has a swashplate 24. Swashplate 24 is connected to a shaft feedback assembly 26 that works with the angle sensor assembly 28 to determine the angle of the swashplate 24. The swashplate 24 connects to the central housing 12 by use of a cone bearing 30 that is connected to cup bearing 32 which is then connected to a first O-ring 34. The first O-ring 34 rests against the bottom of plate adapter 36. A second O-ring 38 meshes between the plate adapter 36 and the bottom of the central housing 12. On the top of the housing is a bi-directional pressure control PCP assembly 39 having two coils. As one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com