Fabric laundering using a select rinse fluid and wash fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Modifications of the machine shown in U.S. patent application Ser. No. 10 / 699,262, “Non-Aqueous Washing Apparatus”, filed Oct. 31, 2003, has been used to test the efficacy of the washing and recovery operations depicted in the drawings and the specification should be incorporated herein for reference.

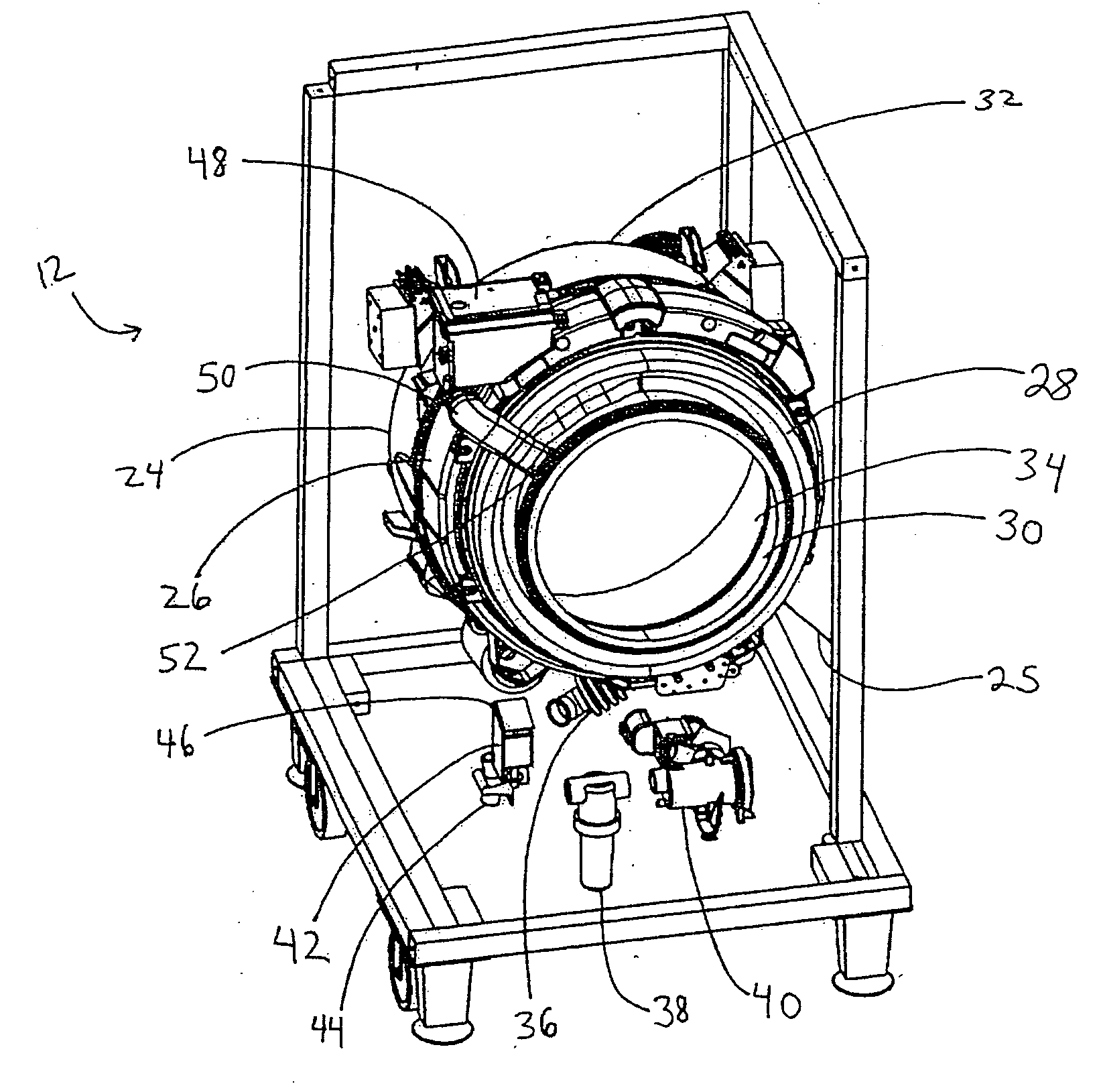

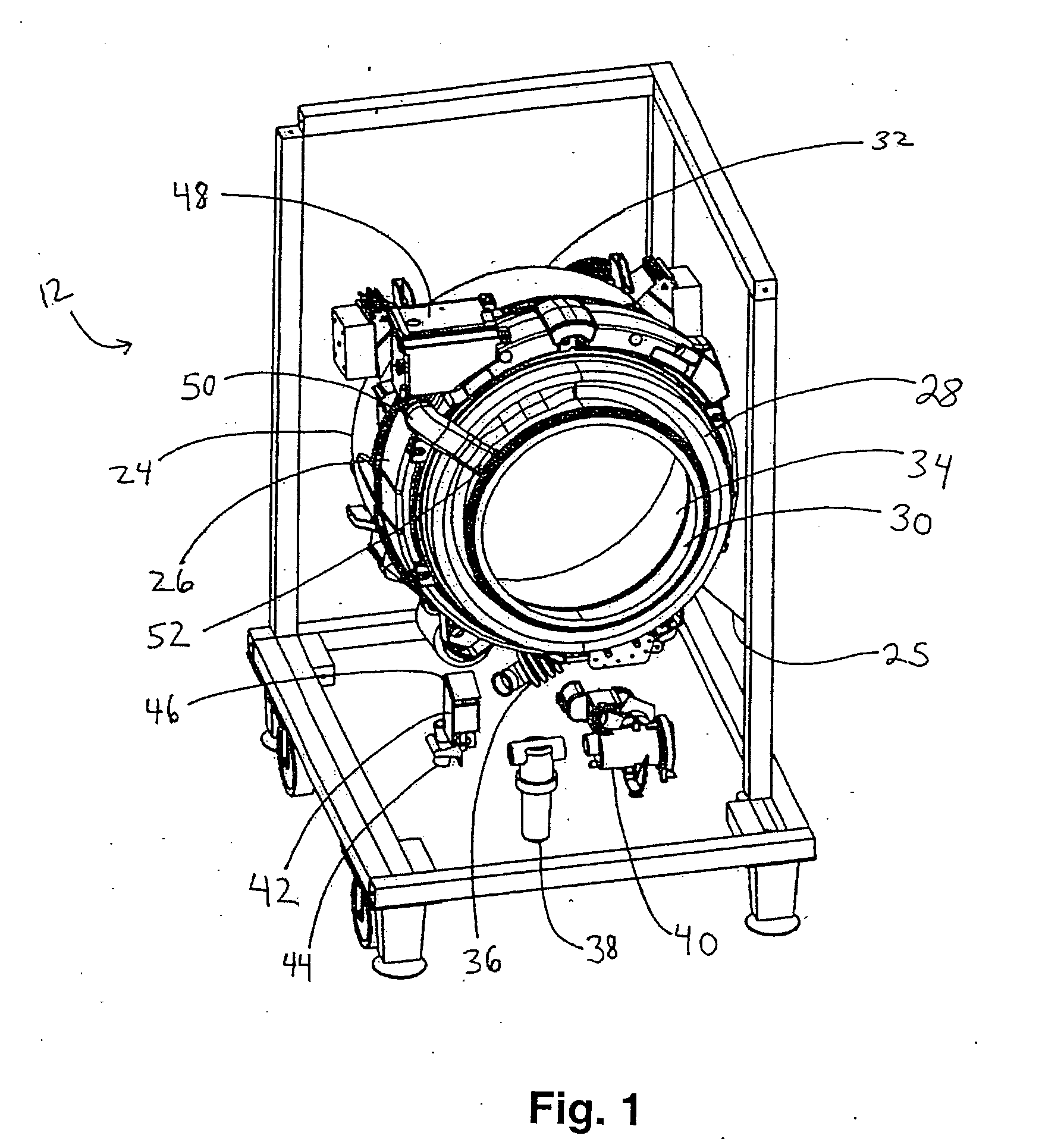

[0043]FIG. 1 depicts an embodiment of the wash unit 12, without the outer housing. Shown is a tub assembly 24, which includes a wash chamber 26 that is adapted to receive the contents to be washed, such as a fabric load (not shown). The tub assembly is connected to an outer structure via various suspension arms 25. The wash chamber 26 also includes a flexible boot 28 that circumferentially surrounds the opening 30 of the wash chamber 26. The boot 28 is adapted to provide a seal around the wash chamber 26 opening and also provide a conduit to the access door. The wash chamber 26 also includes a rear section 32. Inside the wash chamber 26 is a basket 34 that includes one or more p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com