Solar energy collector for hot water

a solar energy and collector technology, applied in the direction of collector casings, sustainable buildings, light and heating equipment, etc., can solve the problems of failure to anticipate the use of extended side panels, the inability to provide positioning and retention means for the supports, and the cost of higher system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

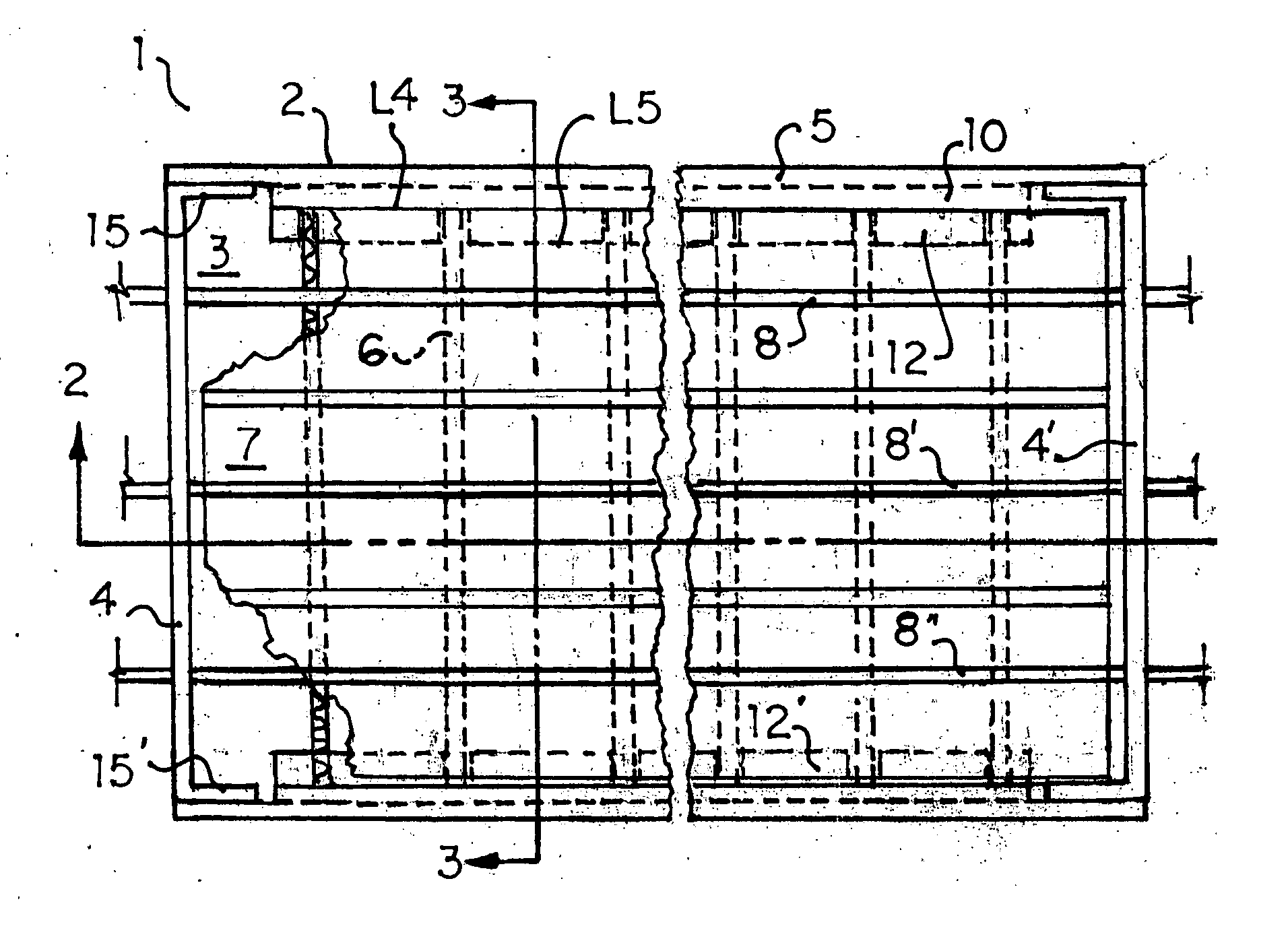

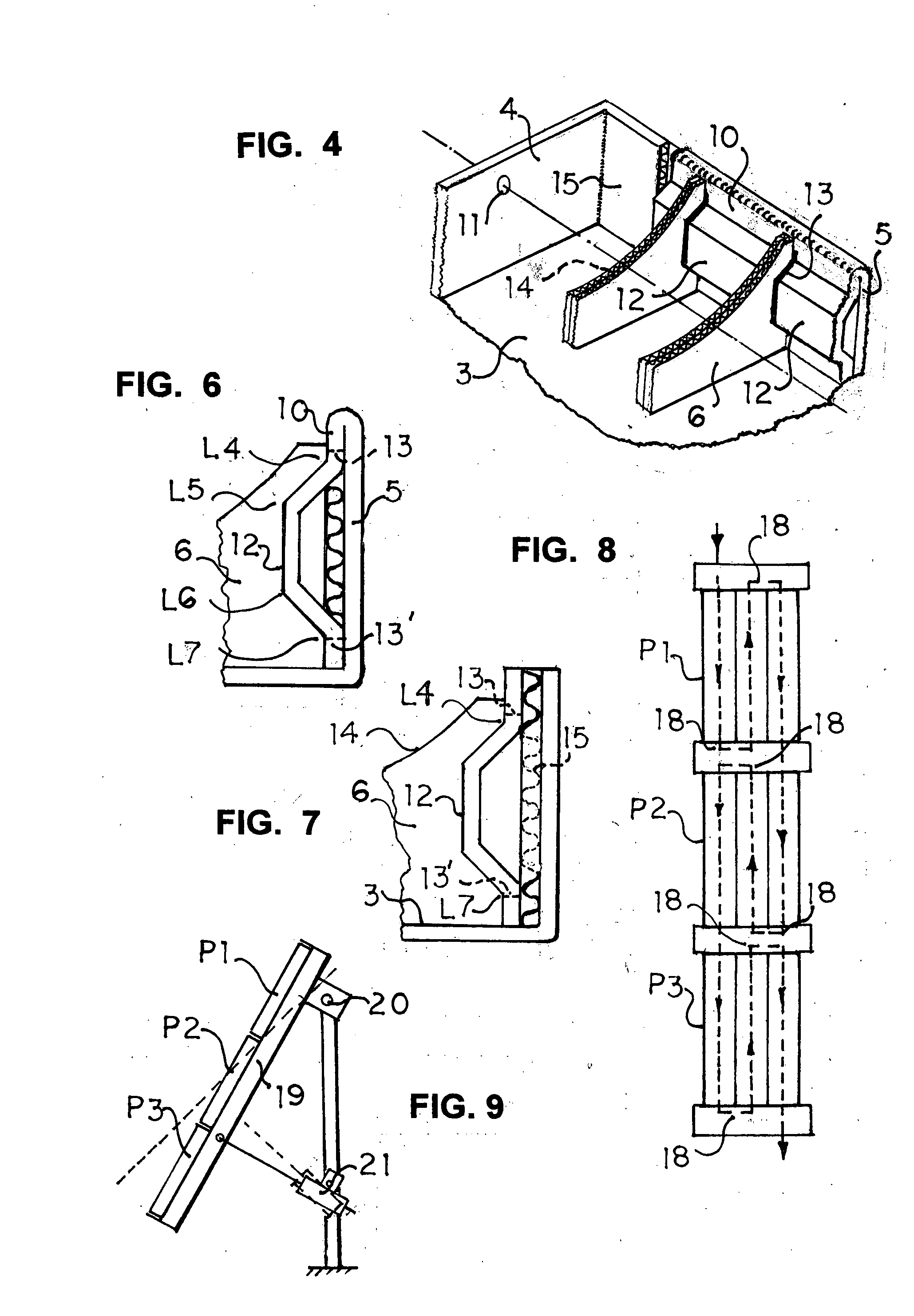

[0020] In FIG. 1, solar collector panel 1 consists of a frame having a bottom surface 3, end panels 4, 4′, side panels 5, 5′ and in the preferred embodiment, inwardly folded side panel extensions (10,10′ (see FIG. 6).

[0021] In FIG. 1, parabolic supports 6 (see FIGS. 3, 5) support reflector surface 7 (shown cutaway on the left side) and are held in slot cutouts 13 in the inside folded side panels 10,10′. Reflector surface 7 is bonded to an insulating substrate 17 (see FIG. 3) and focuses solar rays to absorbing collector conduit 8.

[0022] In FIG. 1, surface 7 extends between the inside folded panels 10,10′ and substantially between end panels 4, 4′.

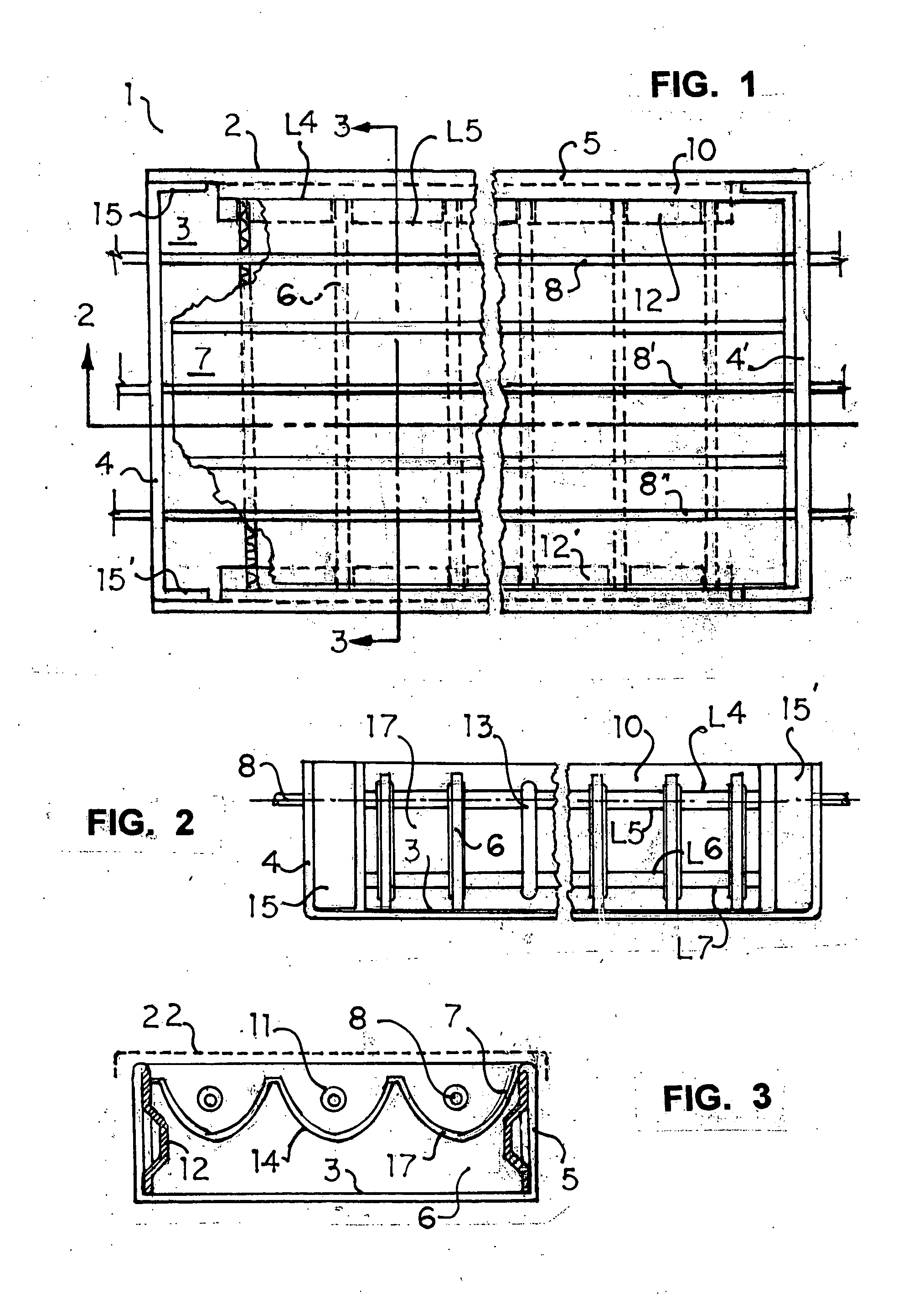

[0023] In FIG. 2, the third slot 13 is shown without the support 6 to define its shape and length, noting that the upper slot end is above score / fold line L 4 and the bottom end is below score / fold line L7 to insure that ends of support 6 butt against surfaces of panels 10,10′.

[0024] In FIG. 3, absorber conduits 8 passes thru apertures ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com