Electrically controlled exhaust valve

a technology of electric control and exhaust valve, which is applied in the direction of mechanical equipment, machines/engines, transportation and packaging, etc., can solve problems such as the use of electric actuators, and achieve the effects of reducing the amount of thermal conduction, and reducing the amount of thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

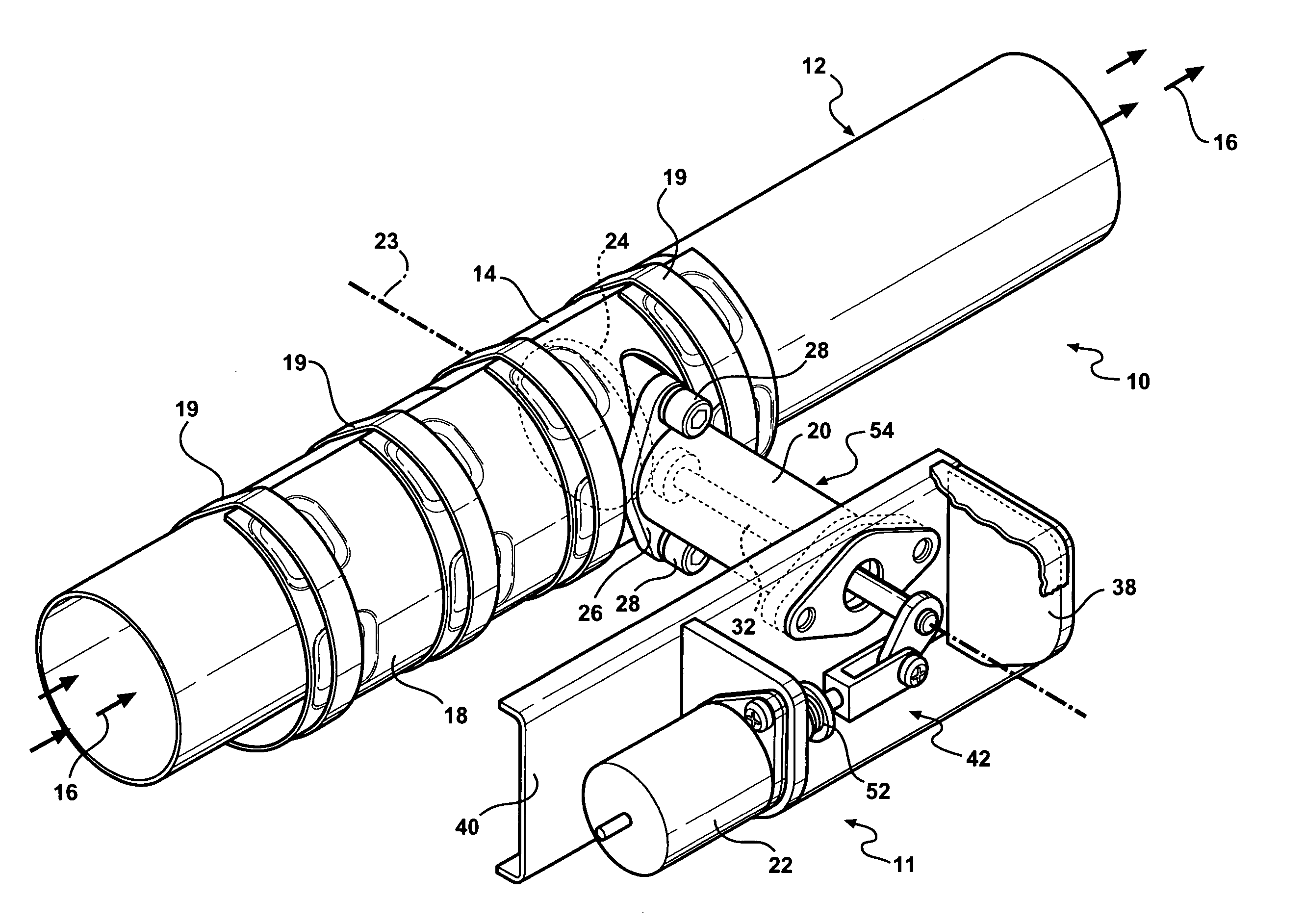

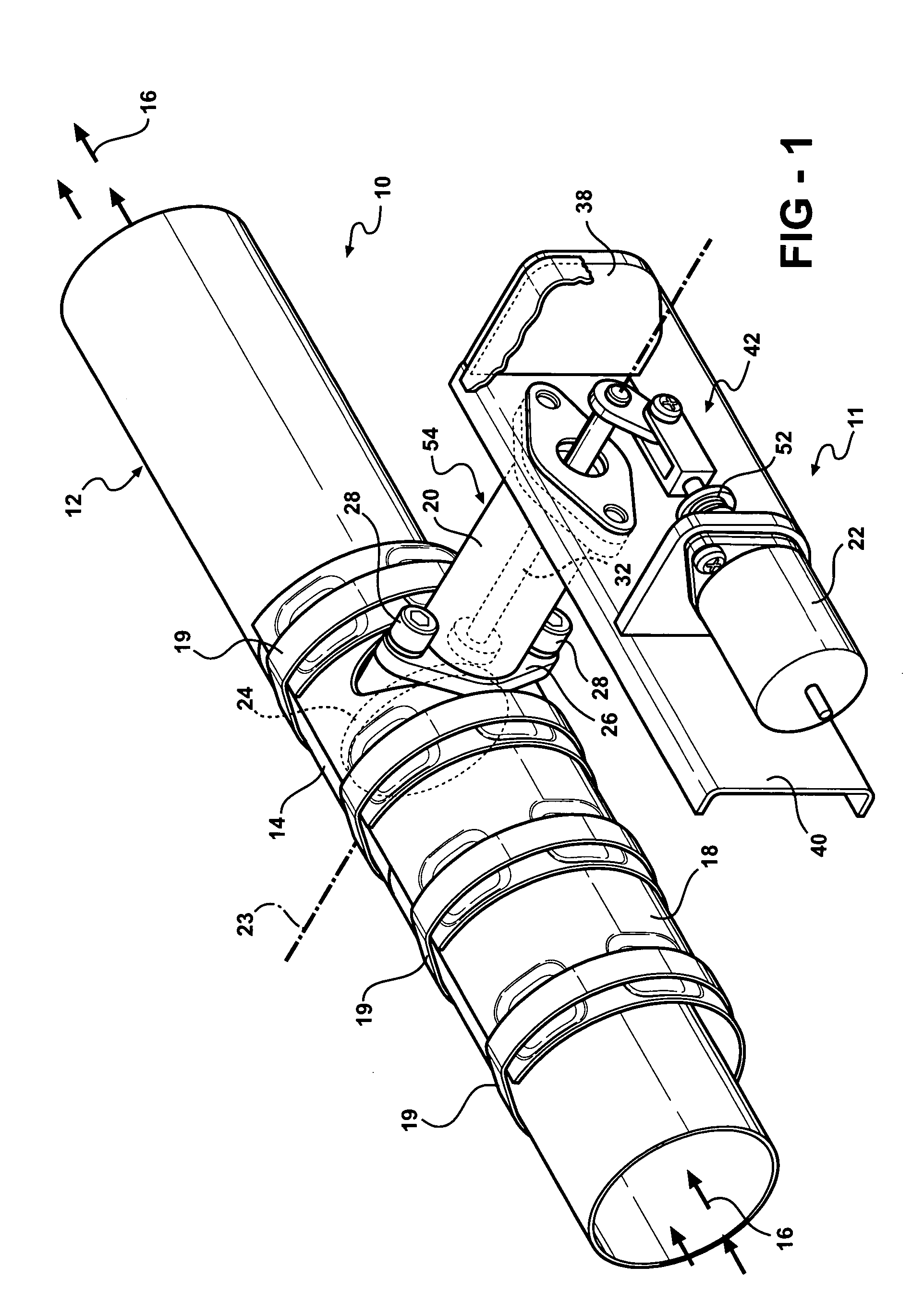

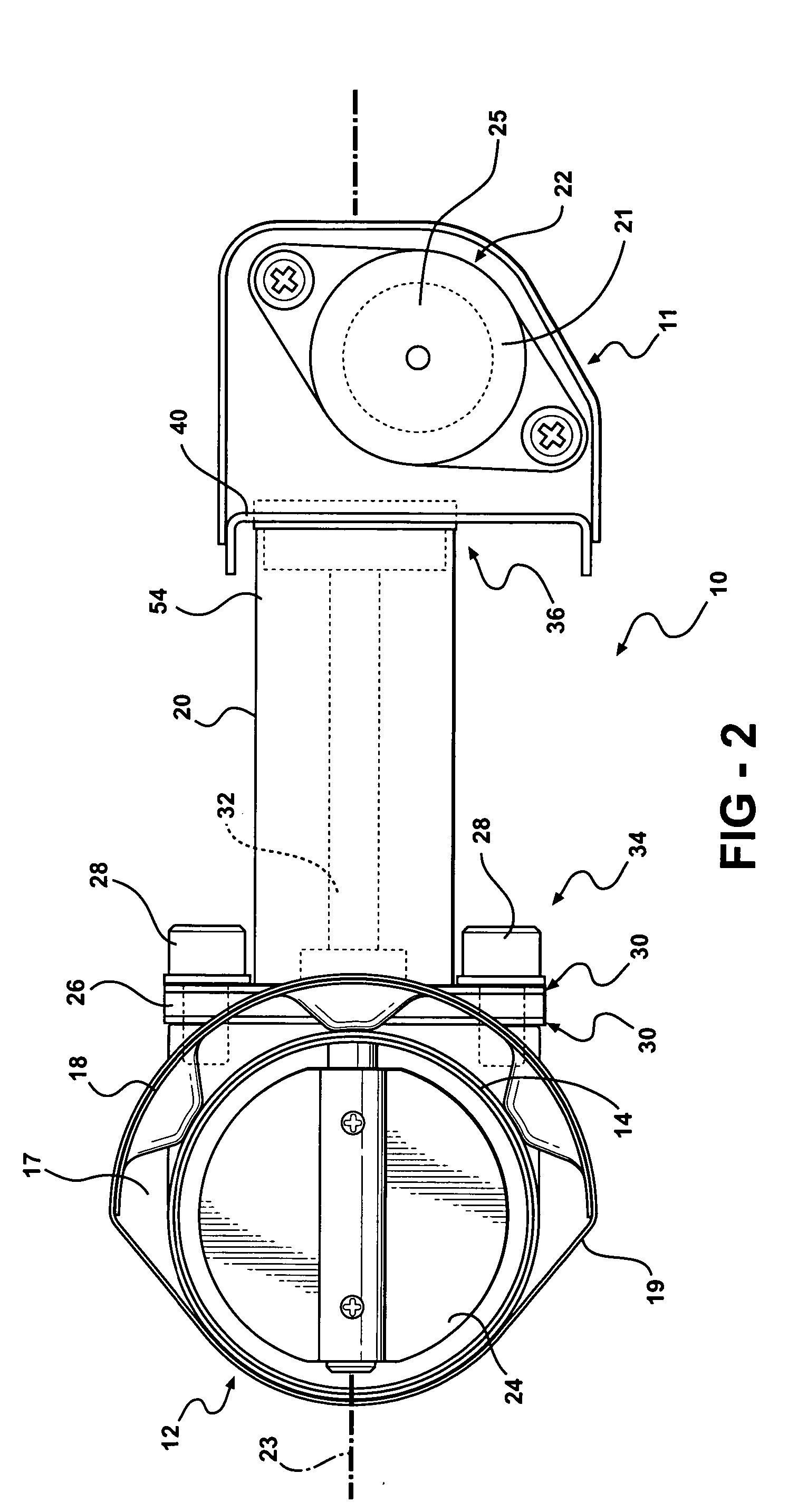

[0017] Referring to FIG. 1, an exhaust system 10 includes an exhaust pipe 12. Exhaust gases 16 flow through the exhaust pipe 12 after being discharged from combustion cylinders of an engine. The exhaust gases 16 resonate through the exhaust pipe 12 to emit a distinctive sound. The sound differs with the displacement of the engine. In applications where the engine provides variable displacement by selectively actuating and de-actuating cylinders depending on the driving conditions, the noise emanating from the exhaust system 10 varies in response to changes in displacement. It is desirable for sounds emanating from the exhaust system 10 to have a consistent sound regardless of the displacement of the engine. To provide this consistent sound, an exhaust valve assembly 11 is actuated to change the function of the exhaust system dependent upon engine displacement.

[0018] An exhaust valve assembly 11 is disposed within the exhaust system 12. The exhaust valve assembly 11 includes a valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com