Collapsible liquid level measurement device with attachments

a liquid level measurement and collapsible technology, applied in liquid/fluent solid measurement, instruments, machines/engines, etc., can solve the problems of not meeting the current stringent accountability requirements, less than satisfactory accuracy, durability or dependability, and wooden gauge dipsticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

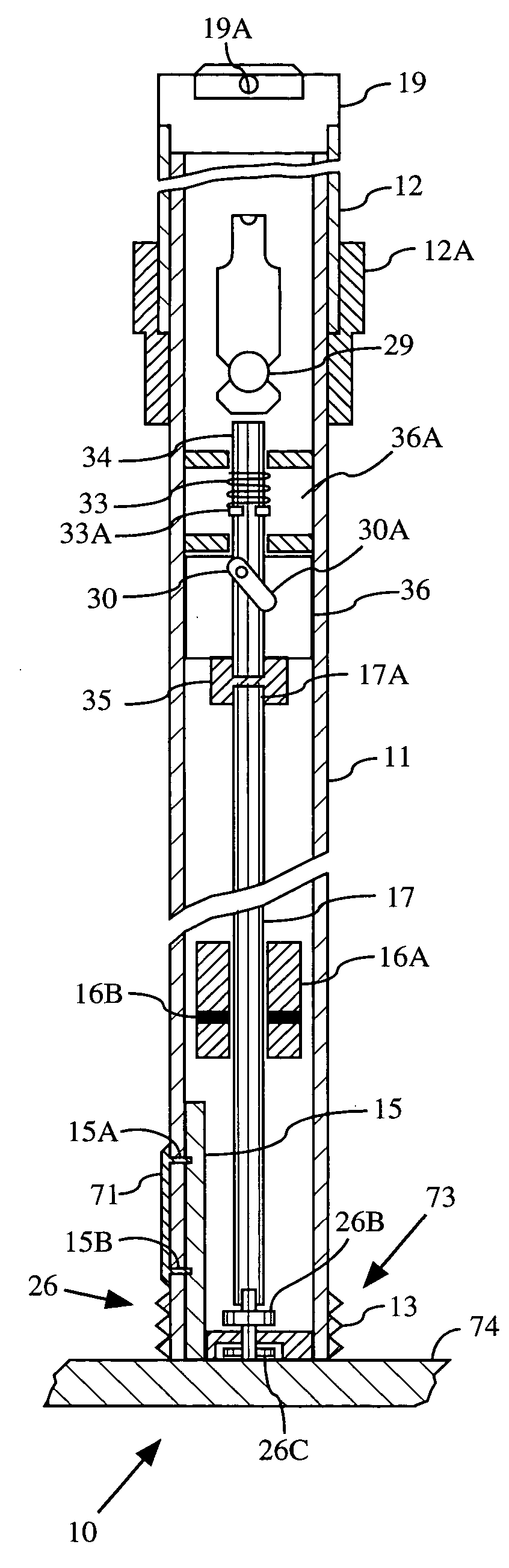

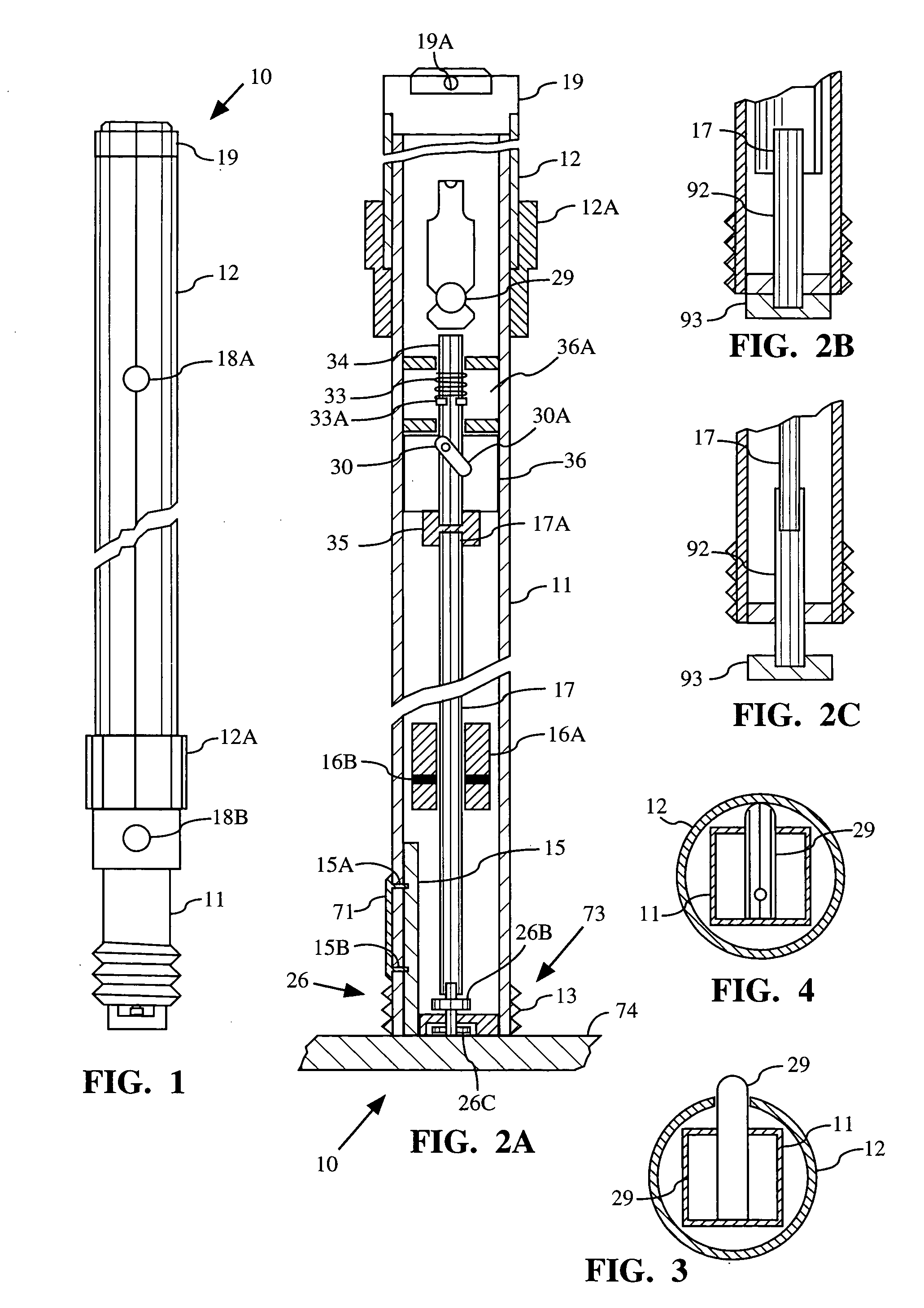

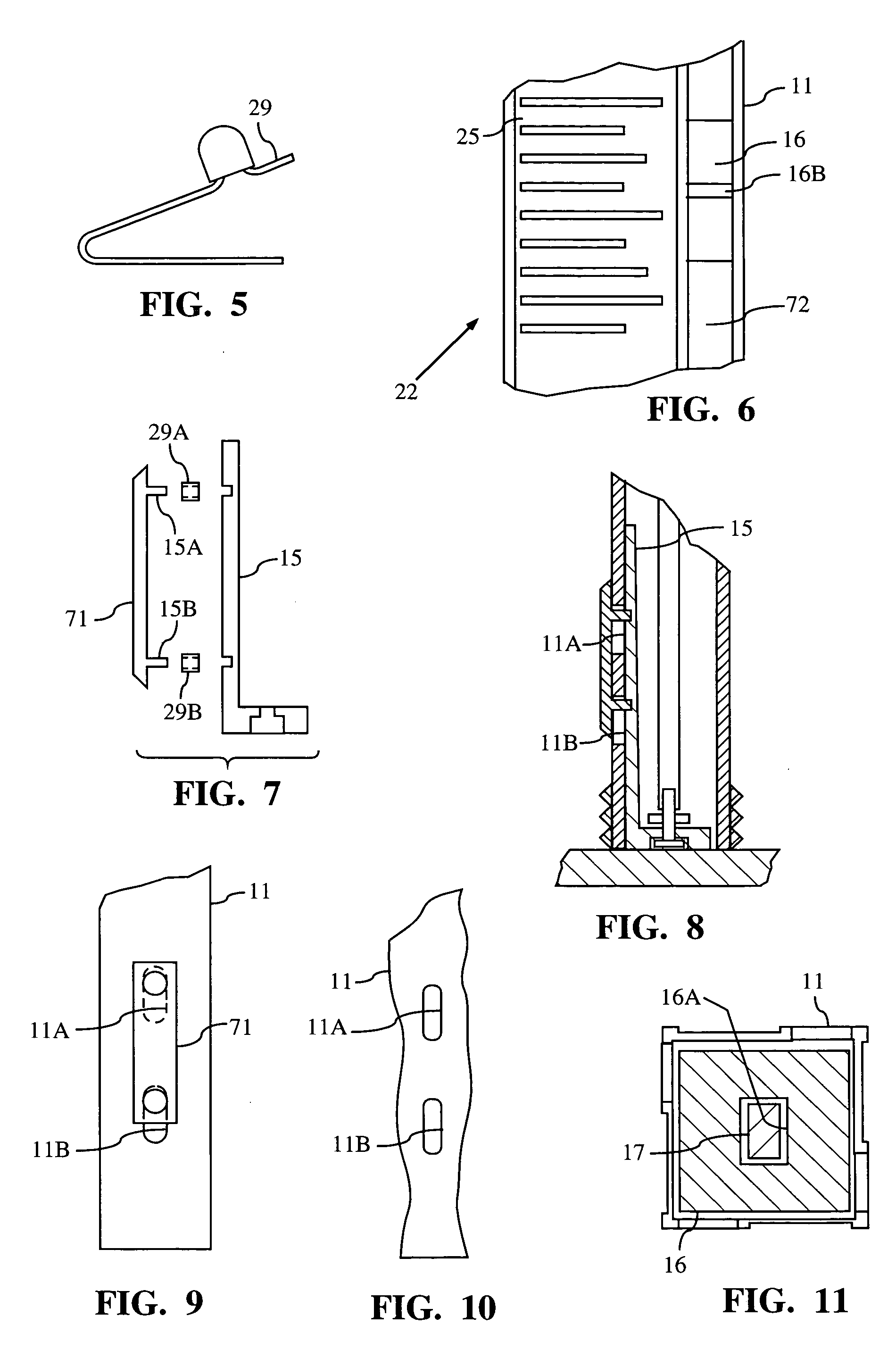

[0033] Turning now to the drawings and particularly to FIGS. 1, 2 and 3, a liquid level measuring device 10 includes an elongated tubular handle 12 and an elongated frame section 11. The handle 12 and the frame section 11 are connected in a telescopic relationship with the frame section 11 extending inside the handle 12 to form a rigid assembly that may be arranged in either an extended configuration for usage or a collapsed configuration for use in measuring liquid levels. It is a primary aim of the device described herein to measure the level of fluids in tanks or containers so that the fluid volume can be determined.

[0034] The liquid level measuring device 10 according to the invention may be advantageously employed for measuring fluids of great variety in containers and tanks such as, for example, containers for domestic heating oil, industrial fluid storage tanks, military storage facilities, gasoline stations, and the like. It is also considered within the spirit of this inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com