Hard drive test fixture

a test fixture and hard drive technology, applied in the field of hard drive test fixtures, can solve the problems of relative cost of fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

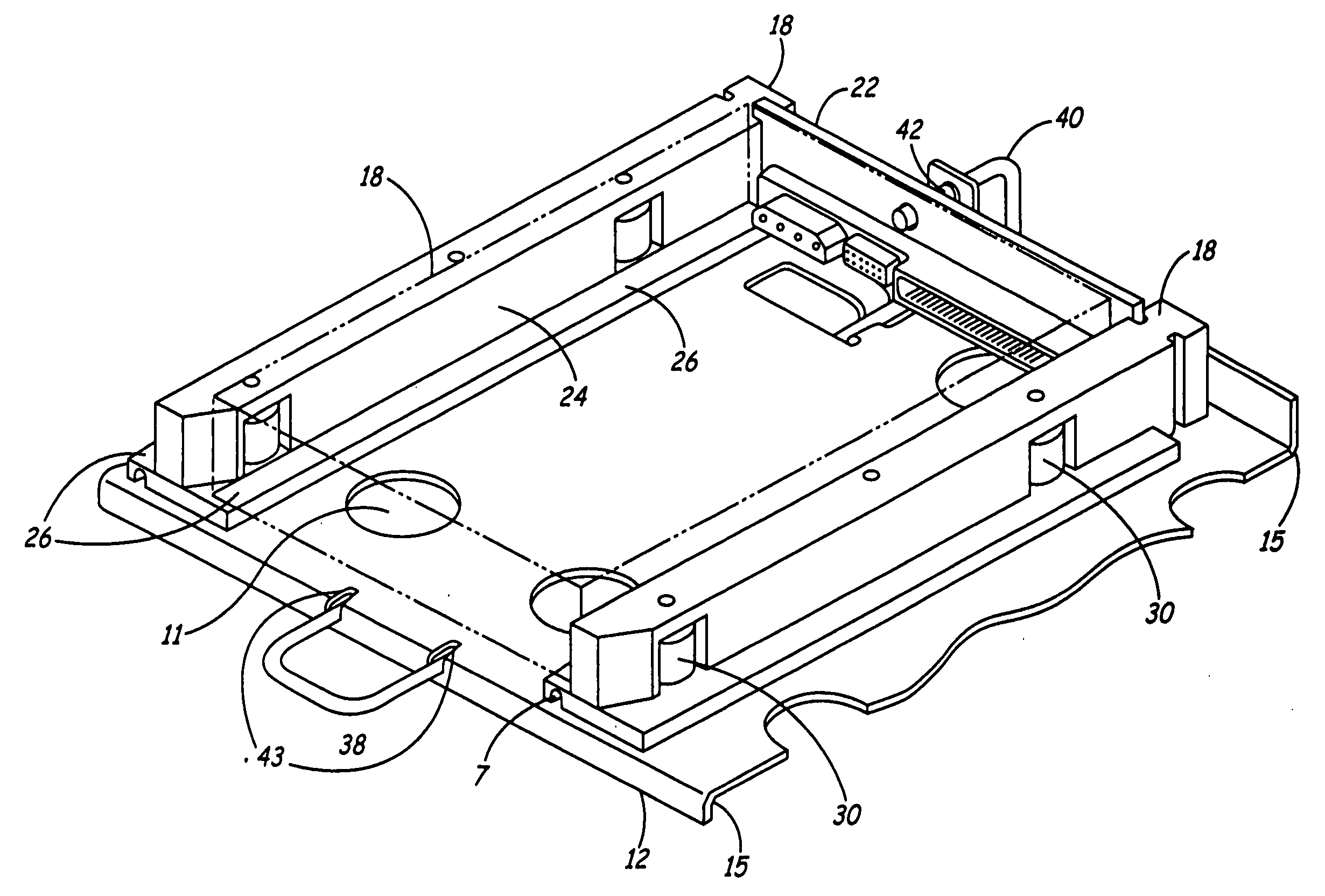

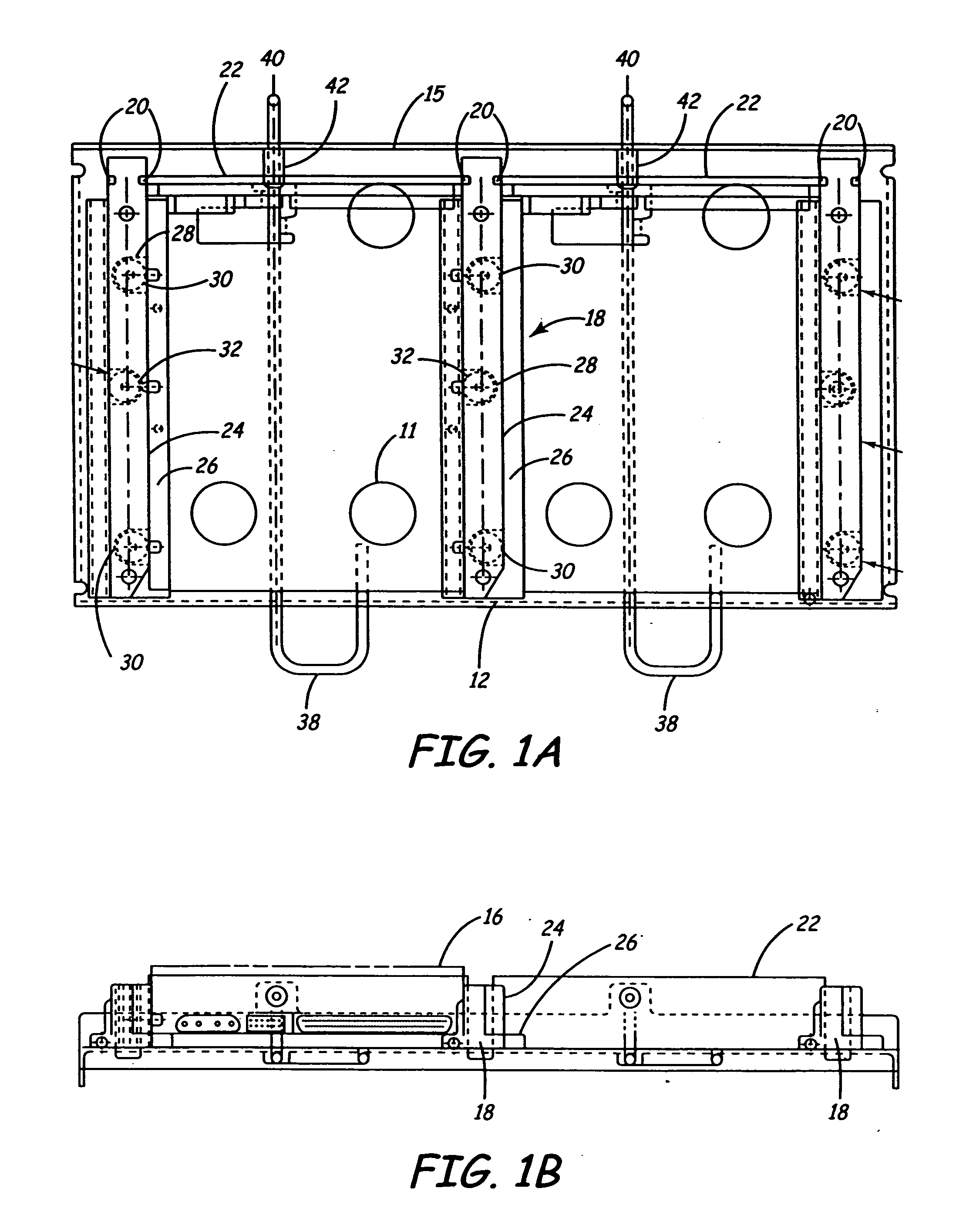

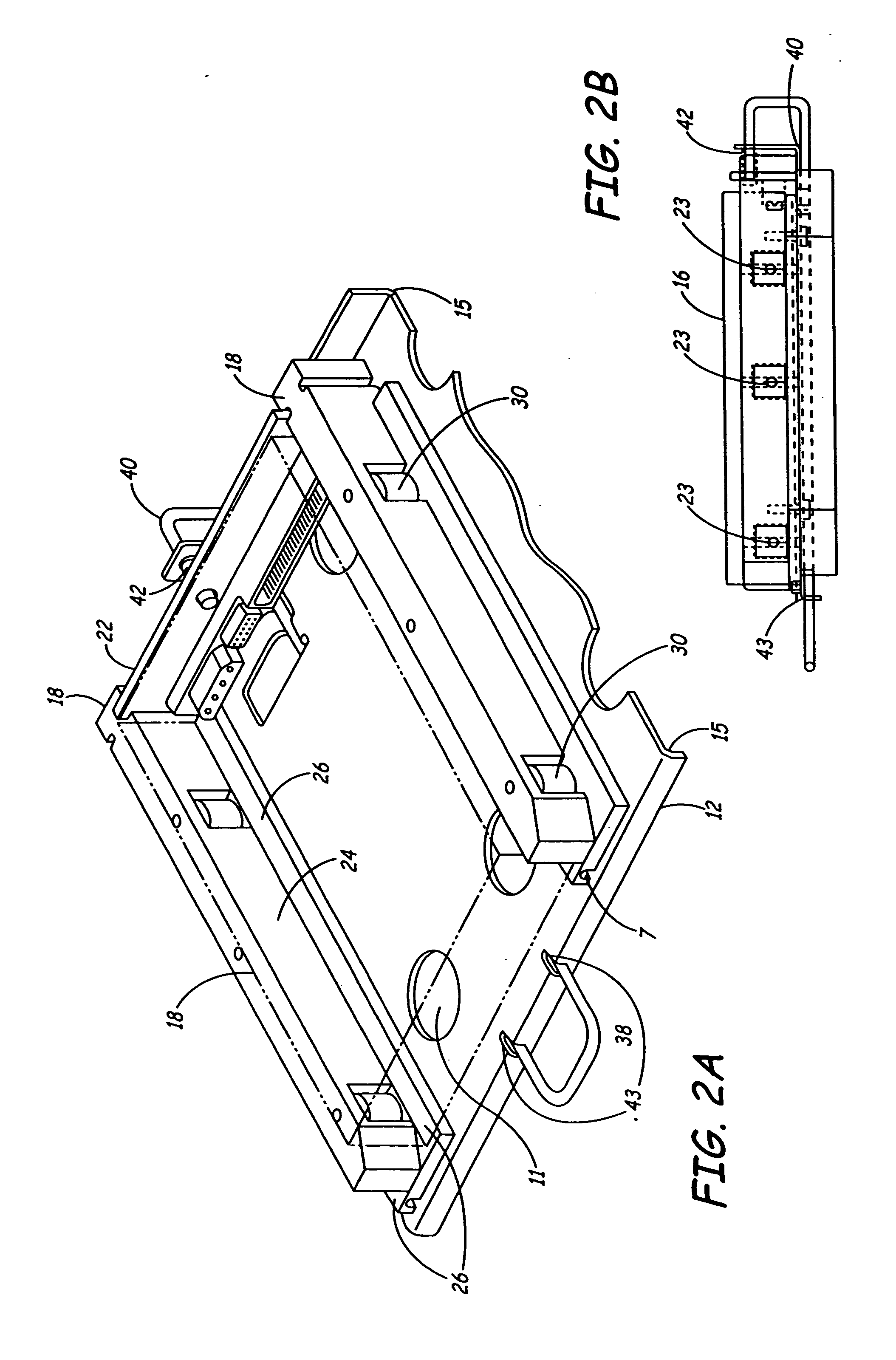

[0022] As shown in FIG. 1A, the present invention is a test fixture 10 specially adapted to support a hard drive during testing and to interface thereto. The subject invention is especially suited for use within an environmental chamber, but is easily adapted to cooperate with racks or storage cabinets that are generally known in the art.

[0023] As shown in FIGS. 1A and 1B, in one embodiment, a pan 12 forms the “backbone” of the fixture 10. Preferably, the pan 12 is fabricated from nonmagnetic stainless steel. Two bends 15 extend longitudinally along the pan stiffening the pan 12. Airflow holes 11 are punched in the pan 12 in a pattern generated to maximize the flow of air through and around the inserted hard disk drive 16 (shown by dashed lines in FIGS. 2A and 2B), while maintaining adequate stiffness to provide rigidity.

[0024] Connected to the pan 12 is a bearing surface which serves to guide a hard drive 16 during insertion into the fixture 10, and to locate the hard drive 16 du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com