Photovoltaic devices fabricated by growth from porous template

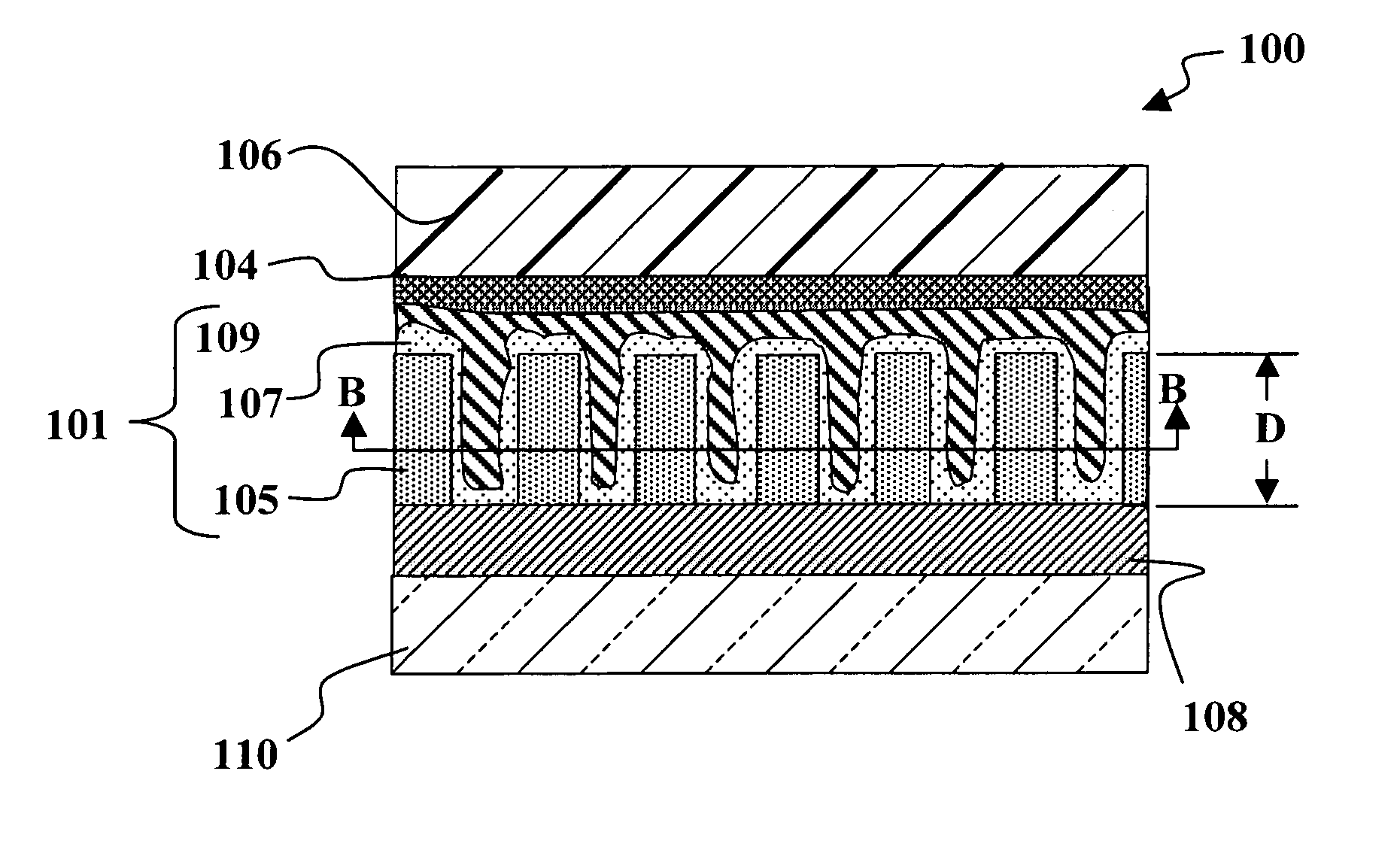

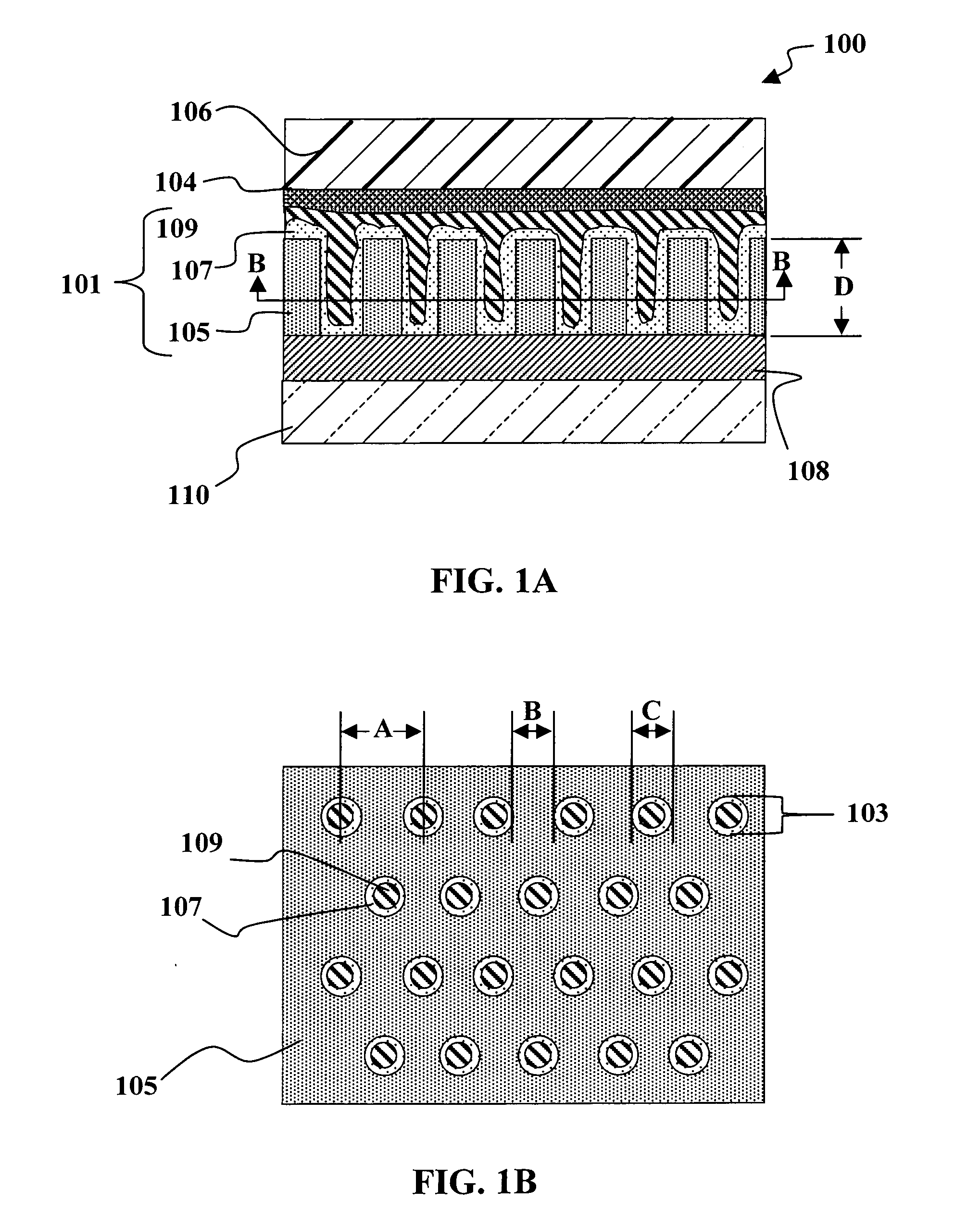

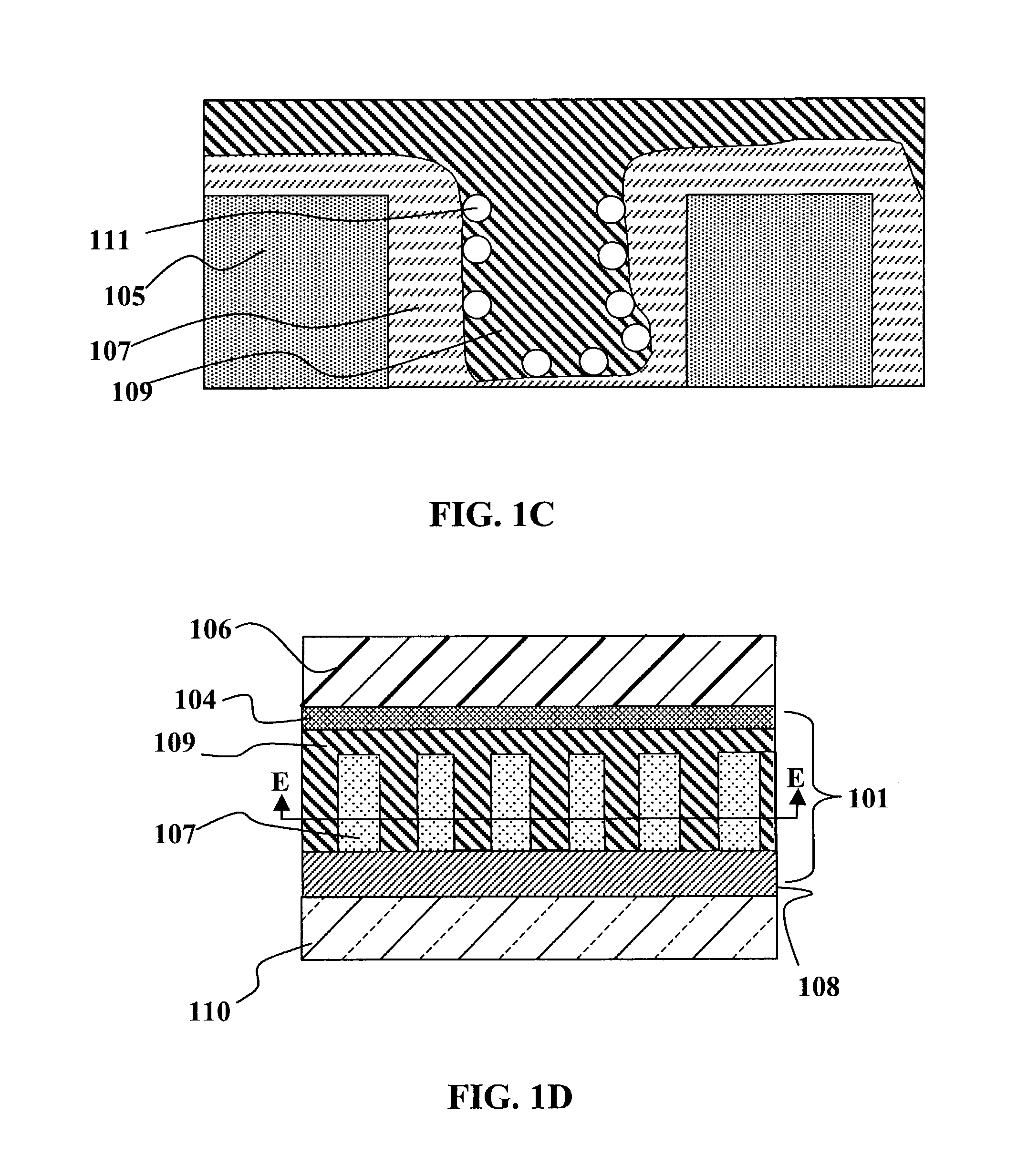

a photovoltaic device and template technology, applied in the field of nanostructured photovoltaic devices, can solve the problems of large aspect ratio, difficult filling of pores, and inability to use hybrid organic-inorganic, organic/organic photovoltaic devices,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Contents

[0024] I. Glossary [0025] II. Introduction [0026] III. General Overview [0027] IV. Photovoltaic Device [0028] V. Photovoltaic Device Fabrication [0029] VI. Alternative Embodiments [0030] VII. Conclusion

I. GLOSSARY

[0031] The following terms are intended to have the following general meanings as they are used herein: [0032] The article “A”, or “An” refers to a quantity of one or more of the item following the article, except where expressly stated otherwise, e.g., “a single” layer. [0033] Active Layer generally refers to the layer within a photovoltaic or solar cell device where conversion of radiant energy to electrical energy takes place. [0034] Anodization refers to the formation of a film, such as an oxide, on a conducting material, such as a metal, by electrolysis. [0035] Array refers to a regular arrangement of objects or structures over a scale of distance greater than some characteristic dimension of a typical structure or object in the array. [0036] Aspect Ratio: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com