Radiation tube structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

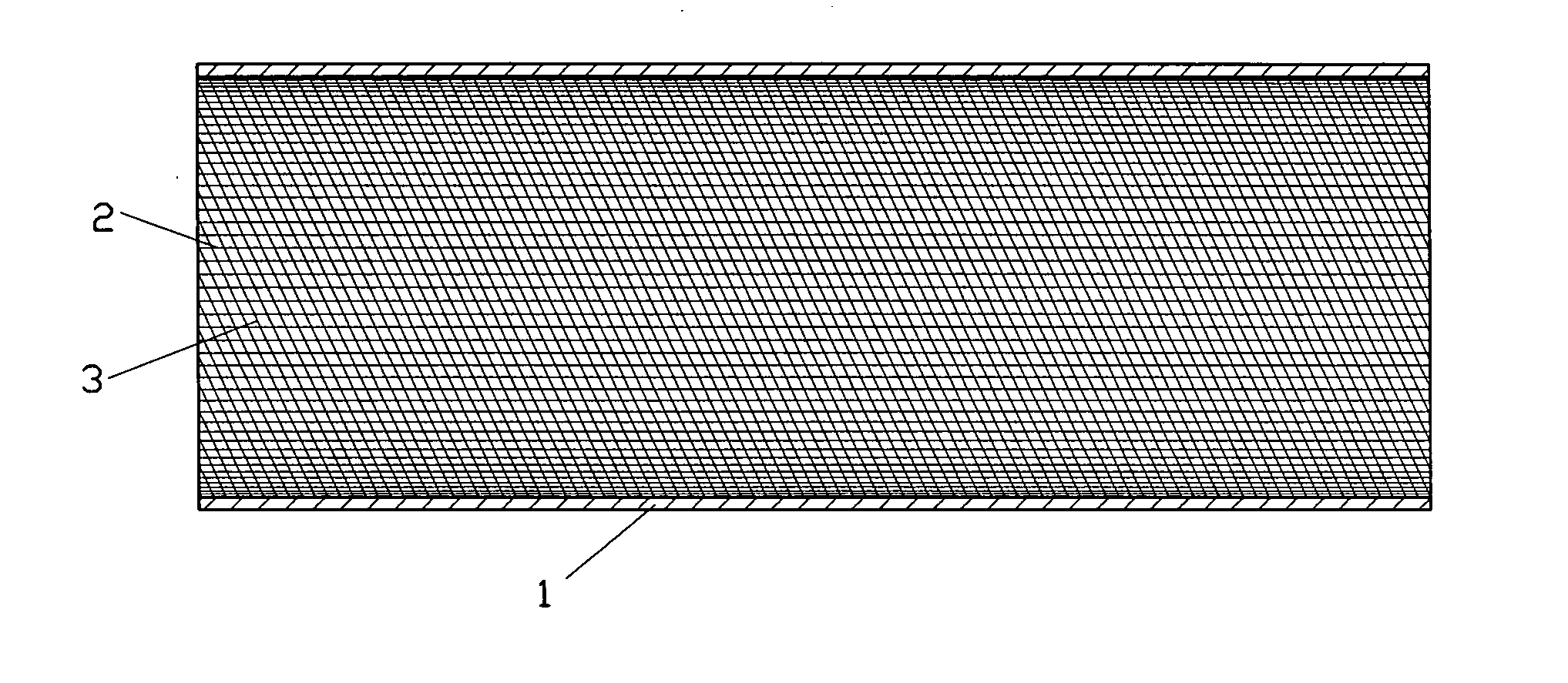

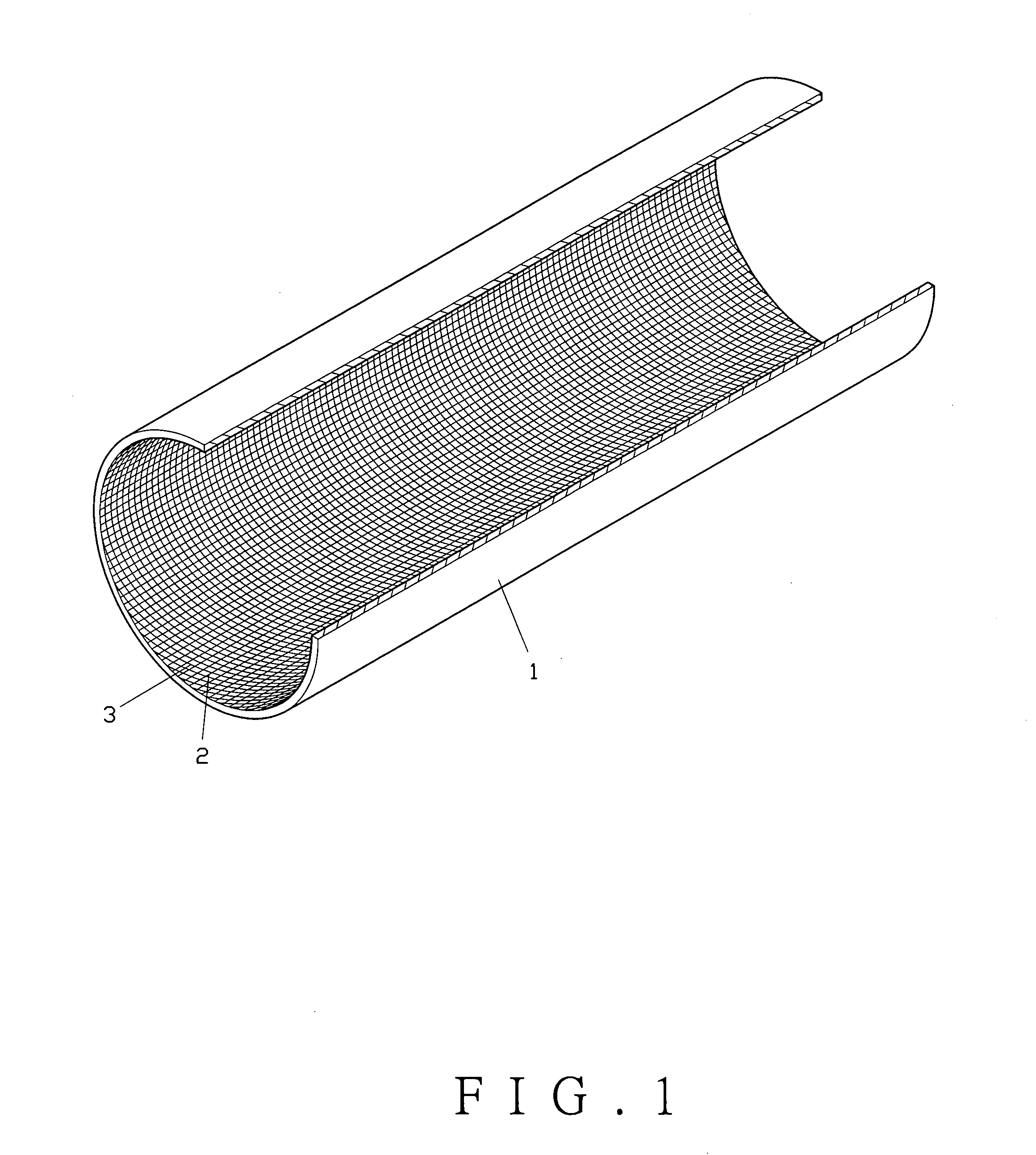

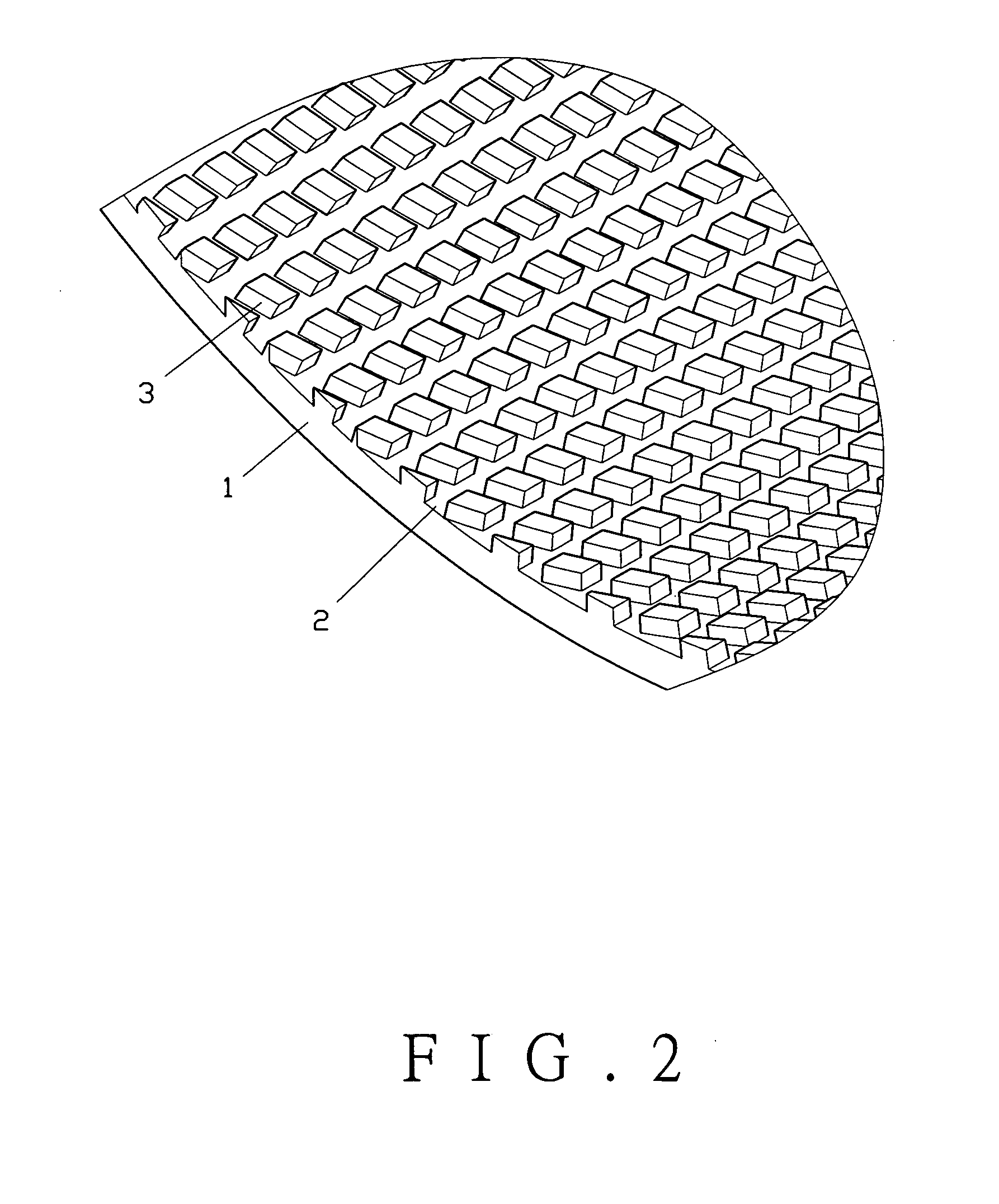

[0018] A radiation tube structure of the present invention, as shown in FIGS. 1 and 2, comprises a mental tube 1 broached with lengthwise grooves 2 and continuous circular grooves 3 on the internal wall. (The circular grooves 3 may be milled in circle formed independently or in a spiral method.) The circular grooves 3 cross the lengthwise grooves 2 to form grids on the internal wall.

[0019] To practice, as shown in FIG. 3, coolant fluid flows through the interior of the tube 1. The grids formed by the lengthwise grooves 2 and the circular grooves 3 increase the surface. Thus, the coolant fluid will be in contact with larger surface. This helps the coolant fluid to spread more evenly on the surface of the internal wall of the tube 1. The capillary effect will reach to the best effect in dissipating heat within the tube 1.

[0020]FIG. 4 shows a second embodiment of the present invention. The internal wall of a tube 4 is milled with circular grooves 5 in one direction. After this proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com