Beverage bottle cooling method and apparatus with assembly for holding ice and water

a technology for ice and water bottles and cooling methods, which is applied in the field of beverage coolers, can solve the problems of cumbersome use, two liter and other large-scale sizes are susceptible to the same, and the beverage becomes hot quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Several embodiments of the invention are described and shown.

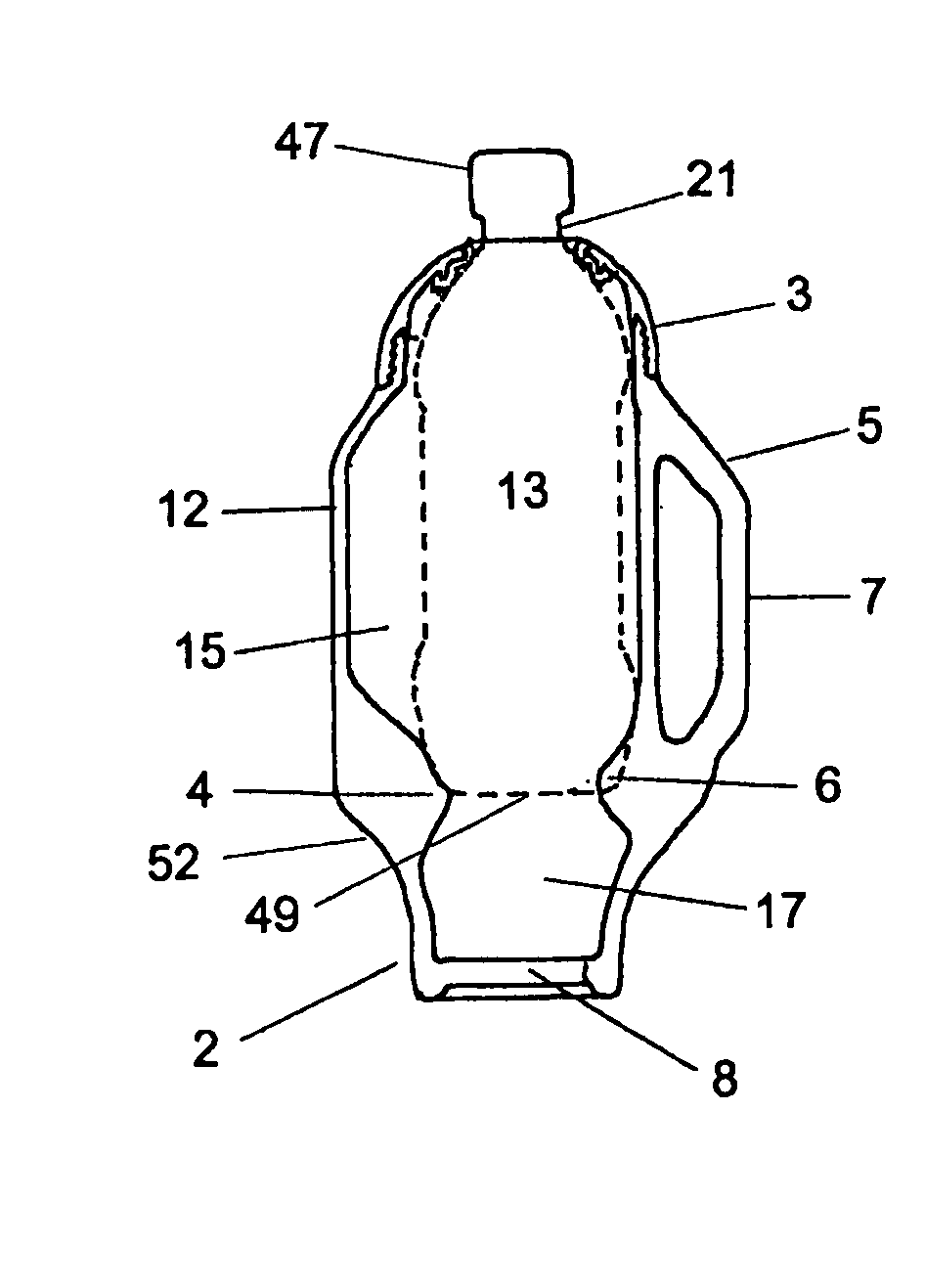

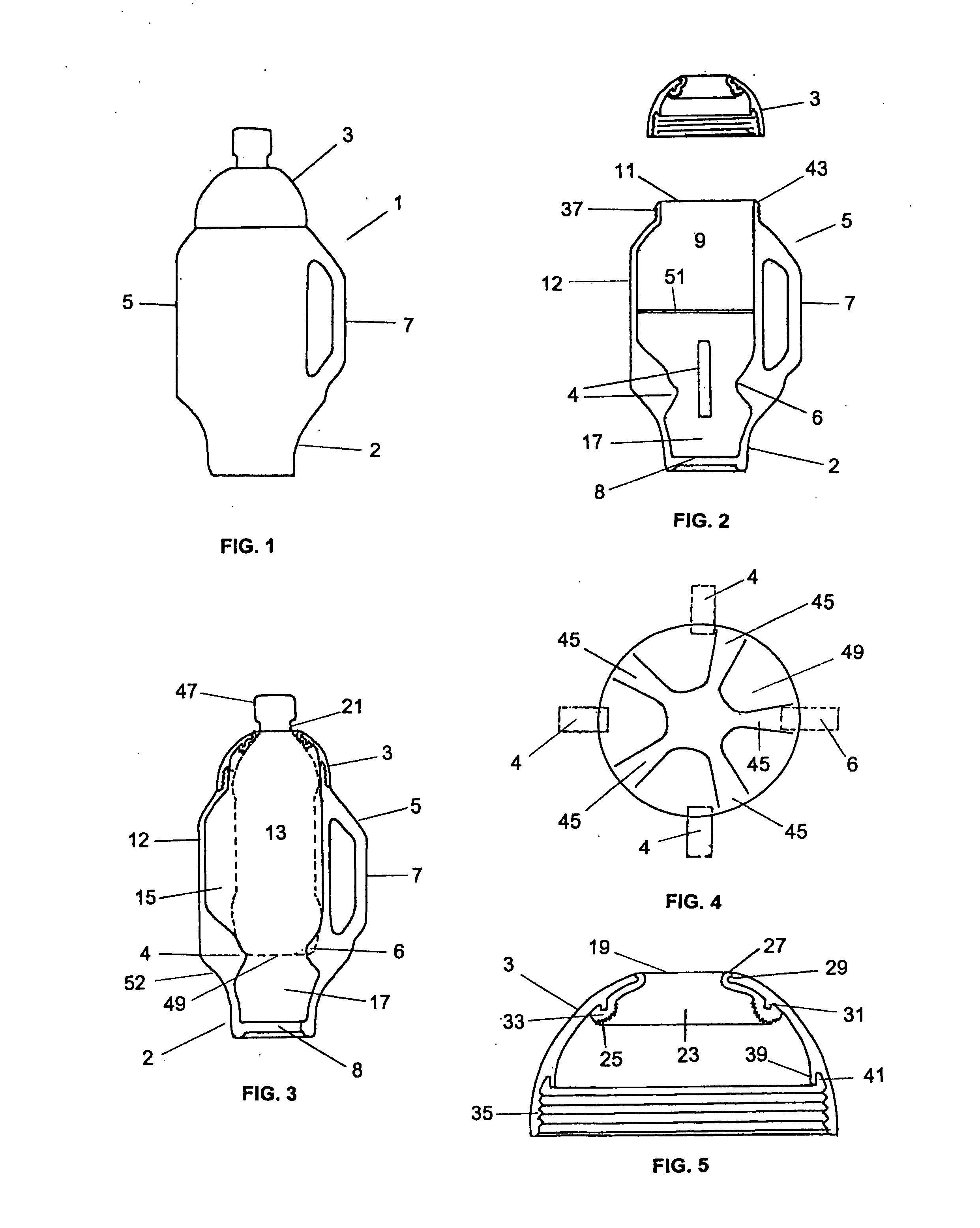

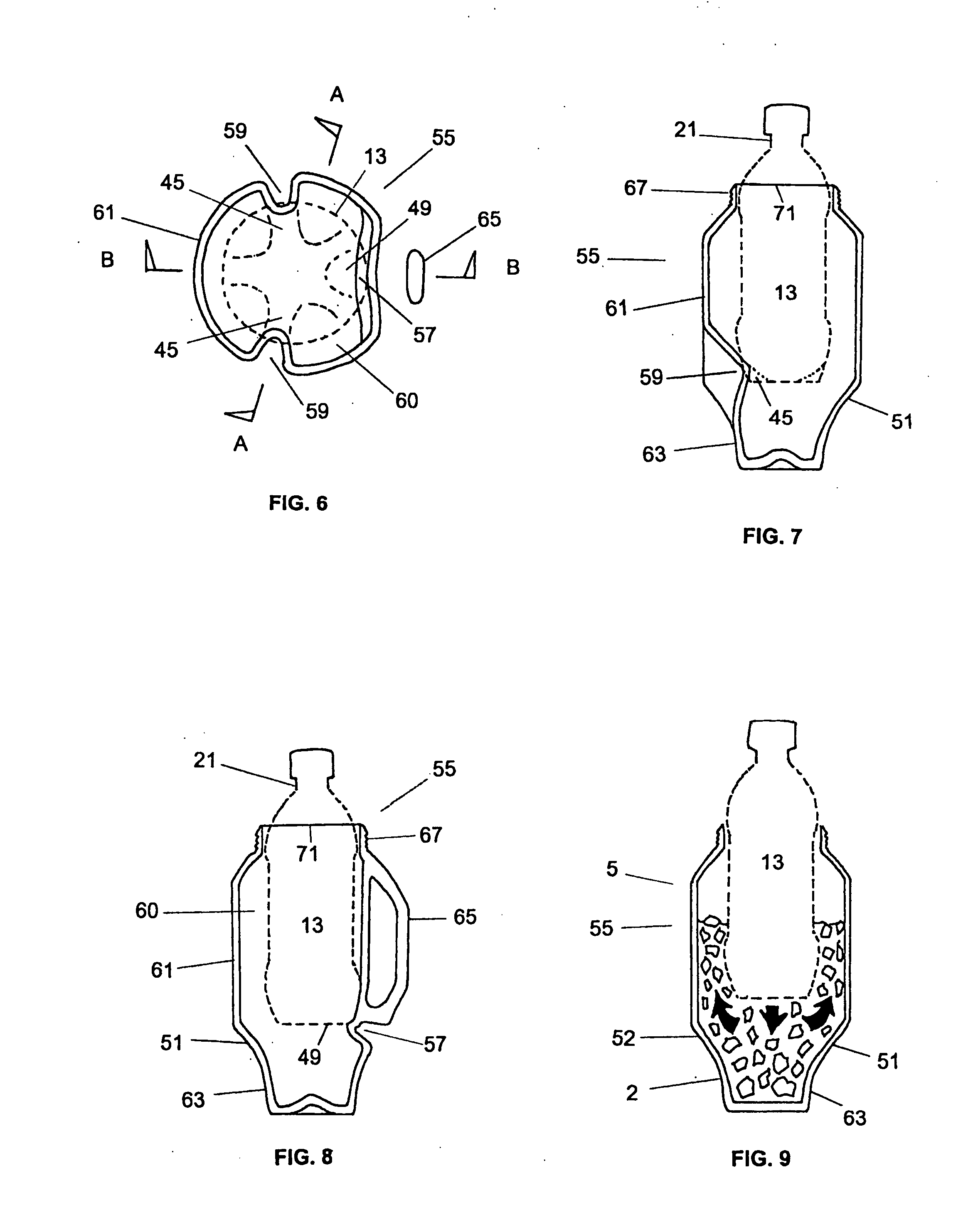

[0041]FIGS. 1-3 show a first embodiment of the present invention 1 having a container 5 and cap 3 designed to be connected and sealed together. As seen in FIGS. 2-3, container 5 is preferably an open-top container having a handle 7 and an internal space 9 formed by a wall 12, much like a large mug, wherein an opening on the top 11 enables a bottle 13, such as a commercial PET bottle, to be inserted therein. Container 5 preferably has extended on the inside thereof a plurality of supports 4, 6, such as extending inward from wall 12, which are adapted to provide lateral and vertical support to bottle 13. This way, bottle 13 can be inserted into container 5, and supported by supports 4, 6, in a substantially fixed location, wherein spaces 15, 17, shown in FIG. 3, can be formed between bottle 13 and wall 12 of container 5 for storing ice and water therein.

[0042] All or a portion of wall 12 can be cylindrical or any sh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap