Plastic building material components

a technology of building materials and components, applied in the direction of fencing, other domestic objects, buildings, etc., can solve the problems of plastic material streaking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

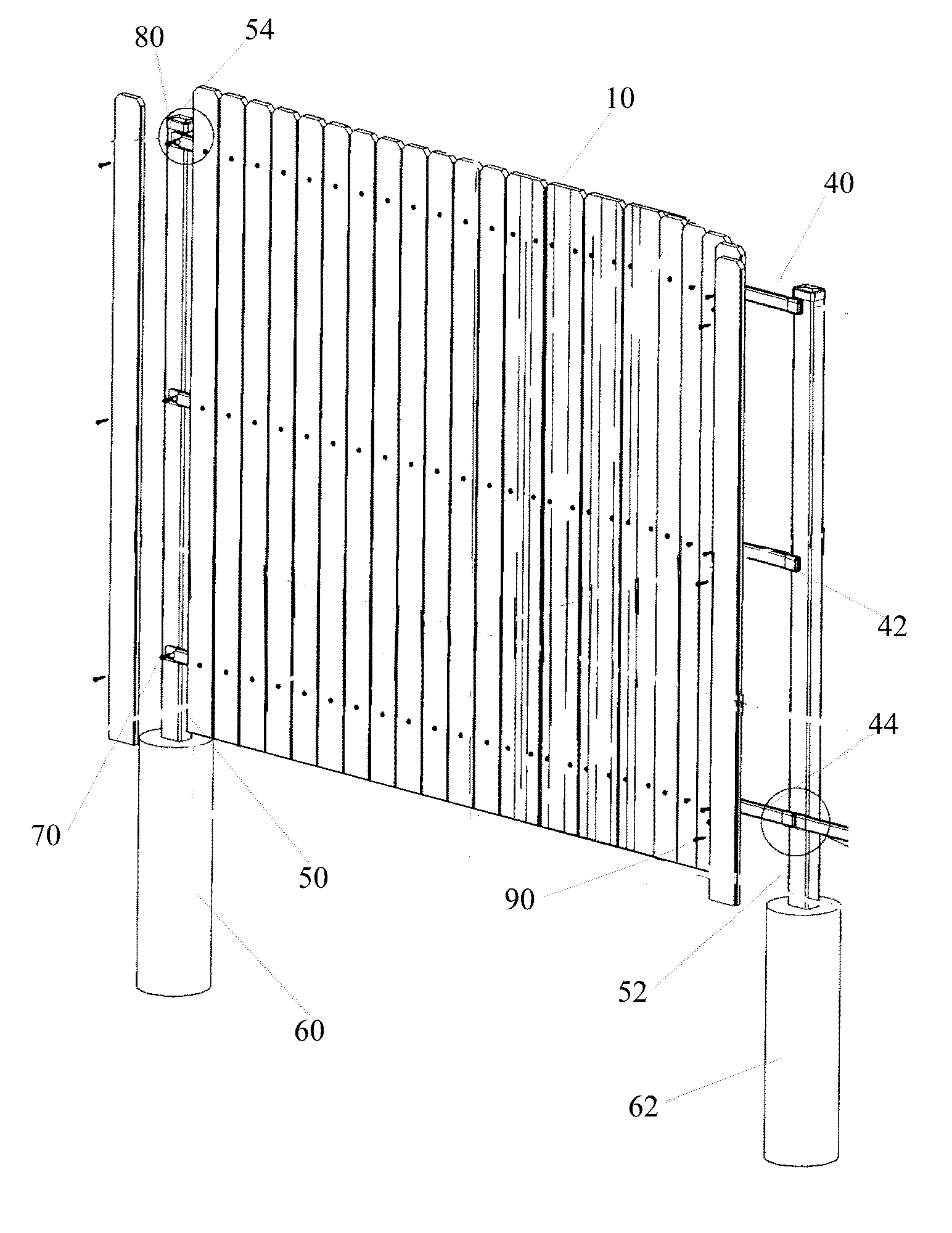

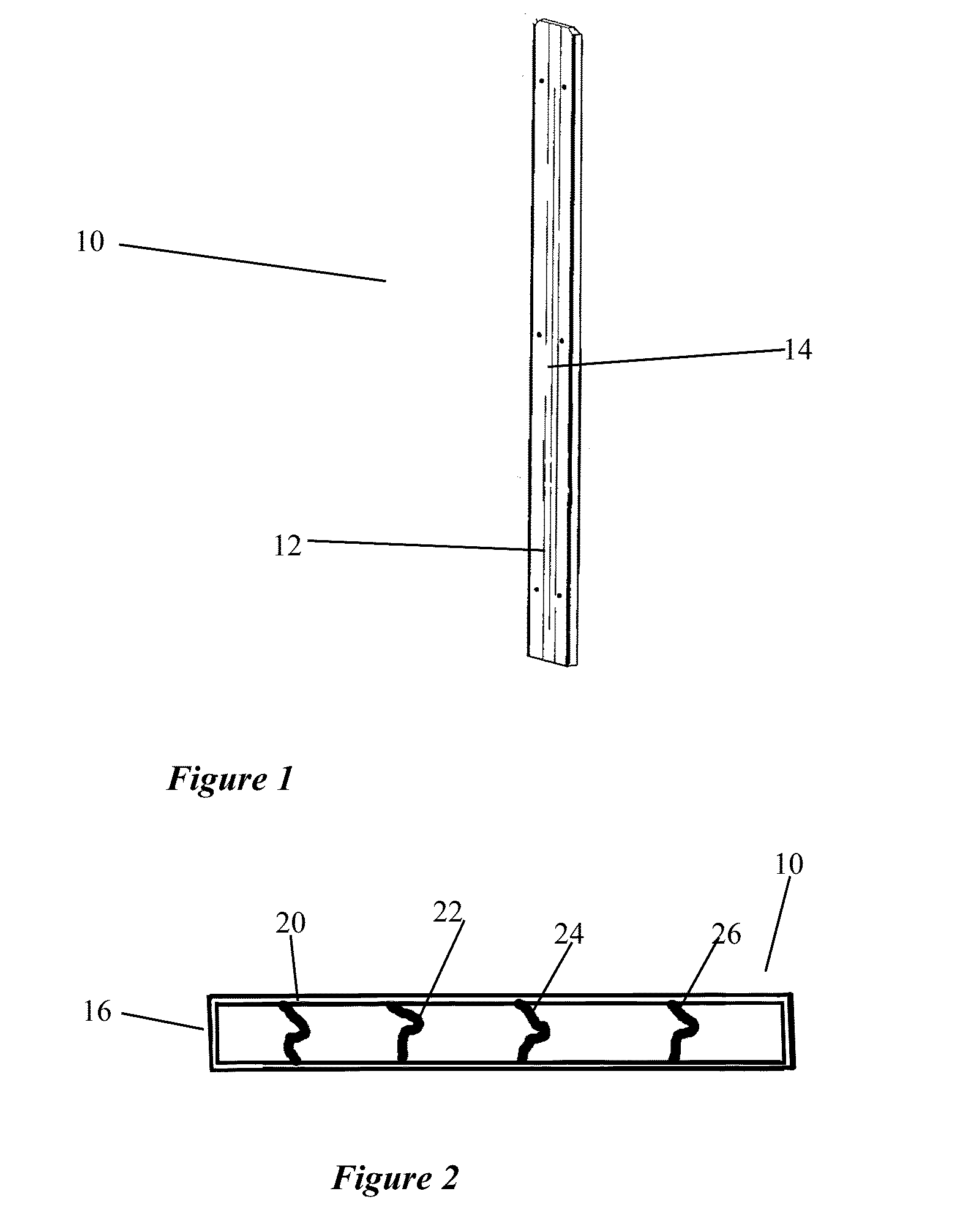

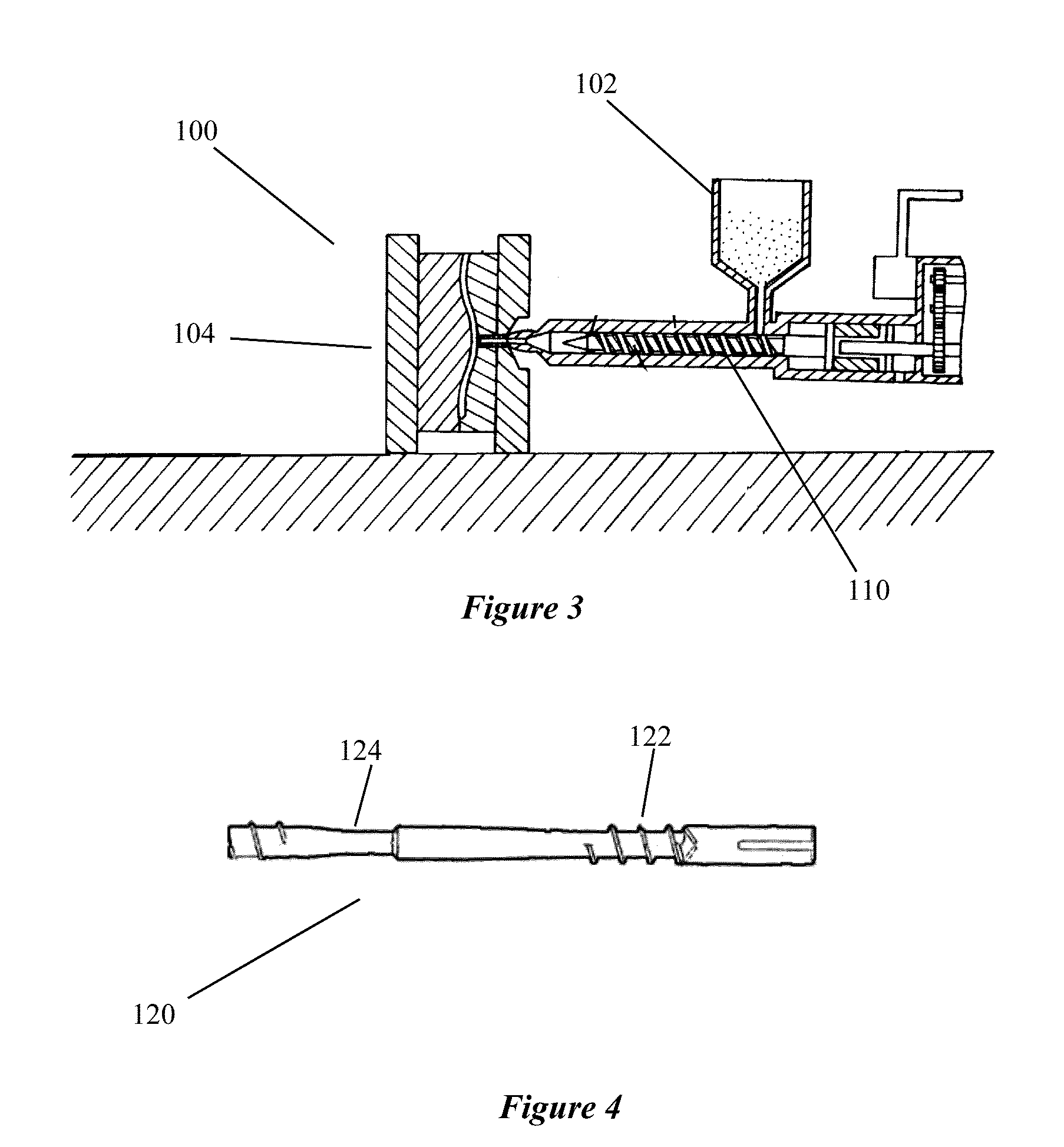

[0022] The present invention, in a preferred embodiment, provides a plastic component system for use in fencing, skirting, barricading and other applications. The present invention also provides a fencing system as well. A preferred embodiment of the present invention is described below. It is to be expressly understood that this descriptive embodiment is provided for explanatory purposes only, and is not meant to unduly limit the scope of the present invention as set forth in the claims. Other embodiments of the present invention are considered to be within the scope of the claimed inventions, including not only those embodiments that would be within the scope of one skilled in the art, but also as encompassed in technology developed in the future.

[0023] The descriptive embodiments provided herein describe a component system for use with fencing as well as other decorative applications. It is to be expressly understood that the components have application in many other uses beyond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Color | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com