Premixed air-fuel mixture supply device

a technology of air-fuel mixture and supply device, which is applied in the direction of lighting and heating apparatus, combustion types, and combustion using lumps and pulverizing fuel, etc., can solve the problems of satisfactorily vaporizing, and achieve the effect of improving fuel atomizing characteristic, high injecting rate and high injecting velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

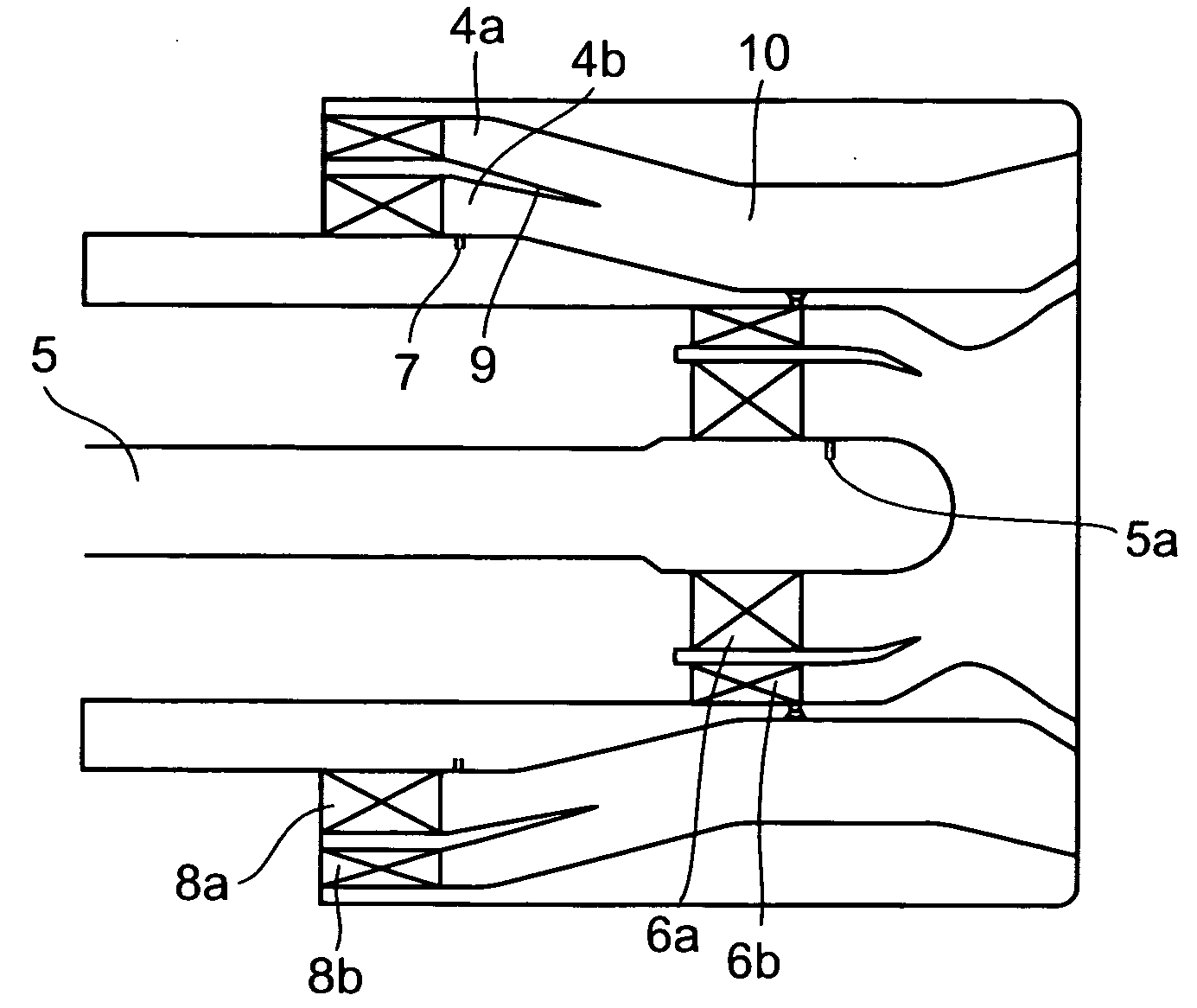

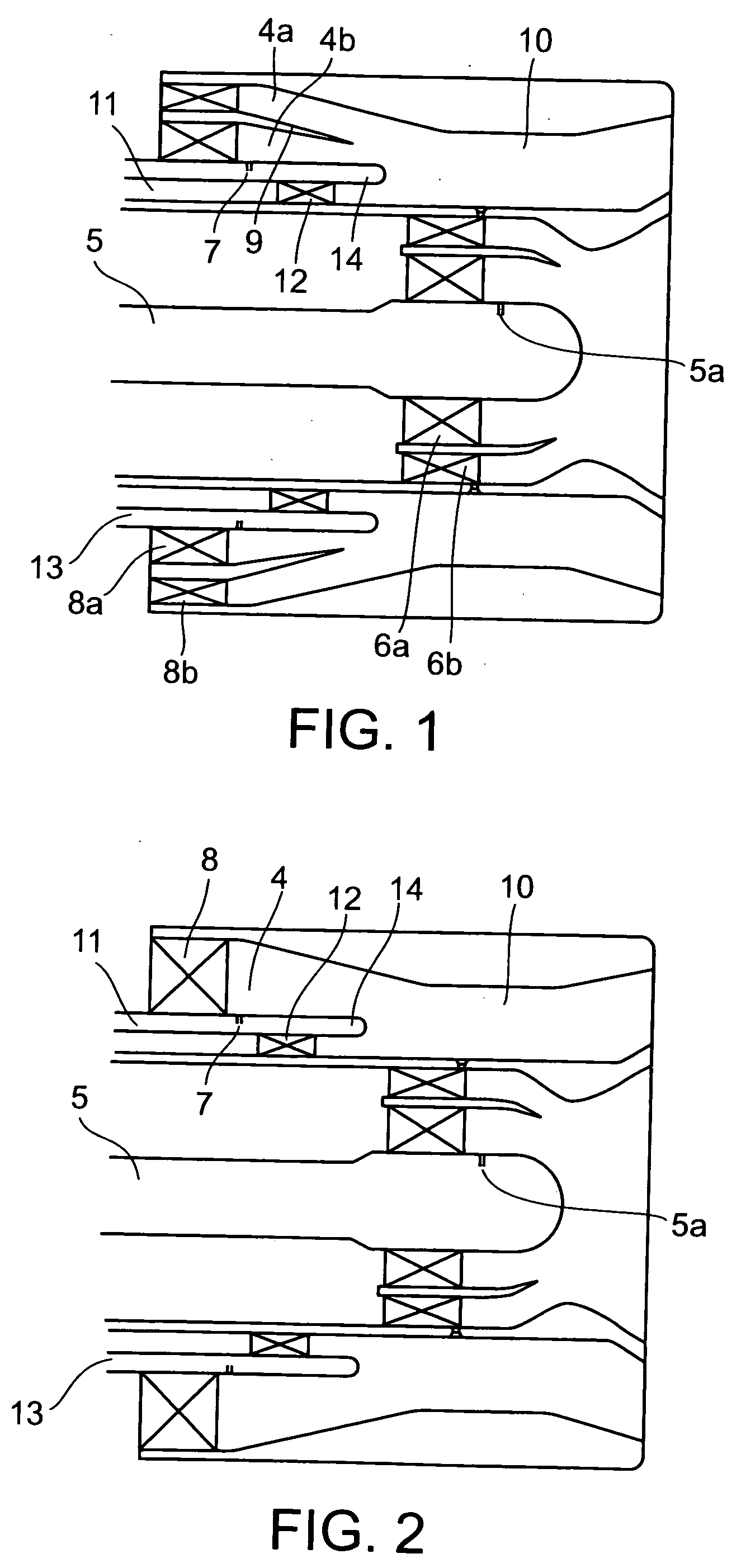

[0035] Referring to FIG. 1 showing a premixed air-fuel mixture supply device in a first embodiment according to the present invention that injects fuel radially outward, an inner wall is joined to the head of a combustor liner (combustor liner 2 shown in FIG. 5) and an outer wall is joined to the head of the combustor liner so as to surround the inner wall. A pilot fuel injection unit is formed inside the inner wall, and a main fuel injection unit is formed in a space defined by the inner and the outer wall. The main fuel injection unit has a prevaporizing, premixing chamber 10 and is provided with swirling devices and an atomization lip dividing an upstream part of the prevaporizing, premixing chamber 10 into an outer combustion air passage 4a and an inner combustion air passage 4b. An intermediate wall 13 is inserted in the inner combustion air passage 4b to define a secondary combustion air passage 11 around the inner wall. The intermediate wall 13 has a tail part shaped in an at...

third embodiment

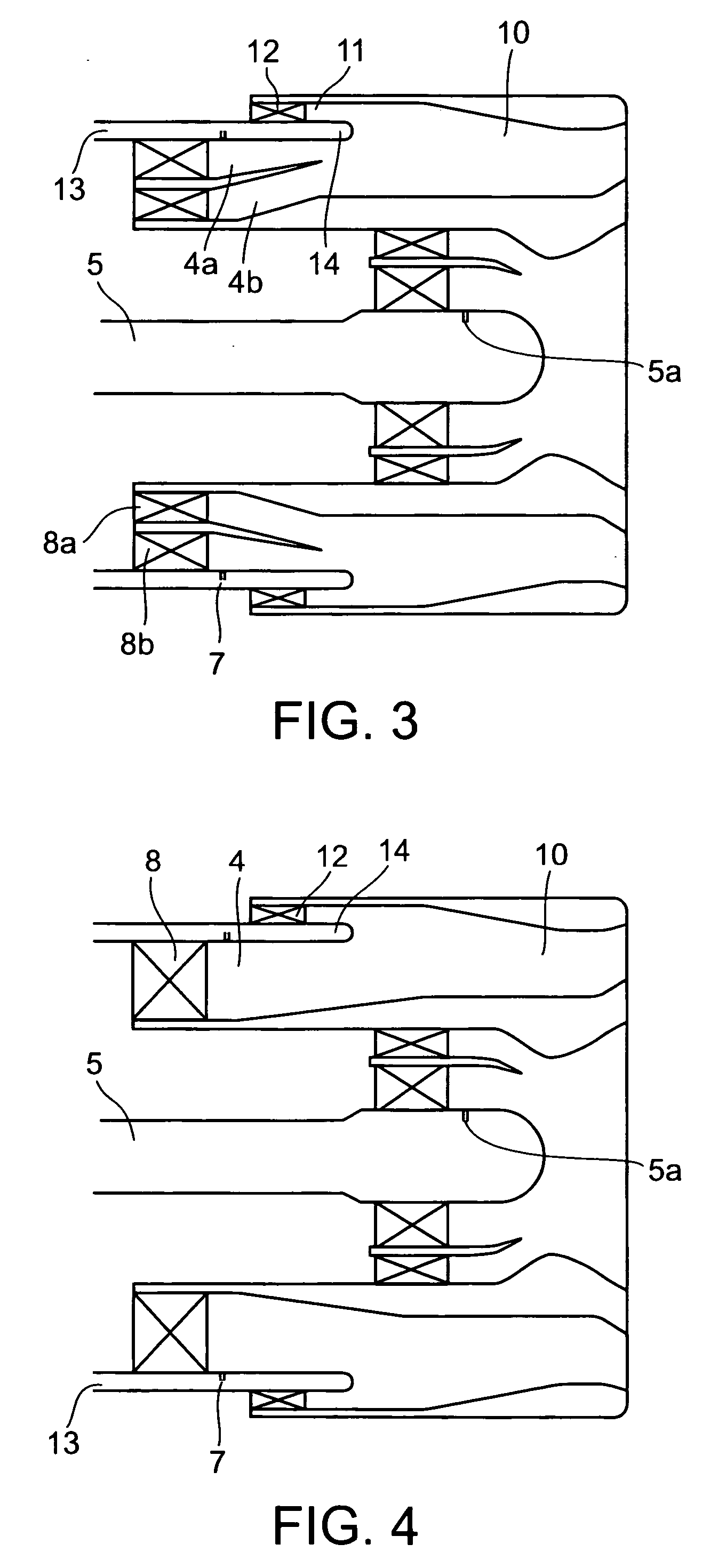

[0037]FIG. 3 shows a premixed air-fuel mixture supply device in a third embodiment according to the present invention that injects fuel radially inward. Referring to FIG. 3, an inner wall is joined to the head of a combustor liner (combustor liner 2 shown in FIG. 5) and an outer wall is joined to the head of the combustor liner so as to surround the inner wall. A pilot fuel injection unit is formed inside the inner wall, and a main fuel injection unit is formed in a space defined by the inner and the outer wall. The main fuel injection unit has a prevaporizing, premixing chamber 10 and is provided with swirling devices and an atomization lip dividing an upstream part of the prevaporizing, premixing chamber 10 into an outer combustion air passage 4a and an inner combustion air passage 4b. An intermediate wall 13 is inserted in the outer combustion air passage 4a to define a secondary combustion air passage 11 around the inner wall. The intermediate wall 13 has a tail part shaped in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com