Elastomeric glove coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

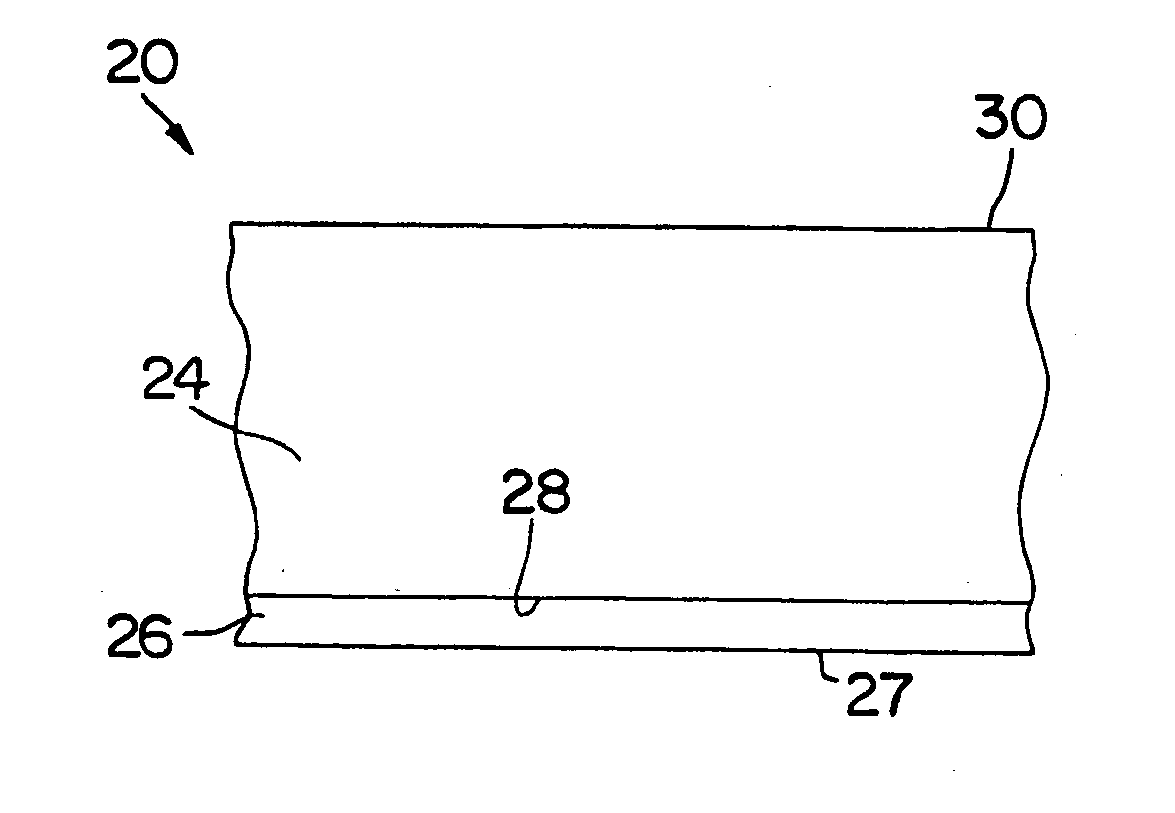

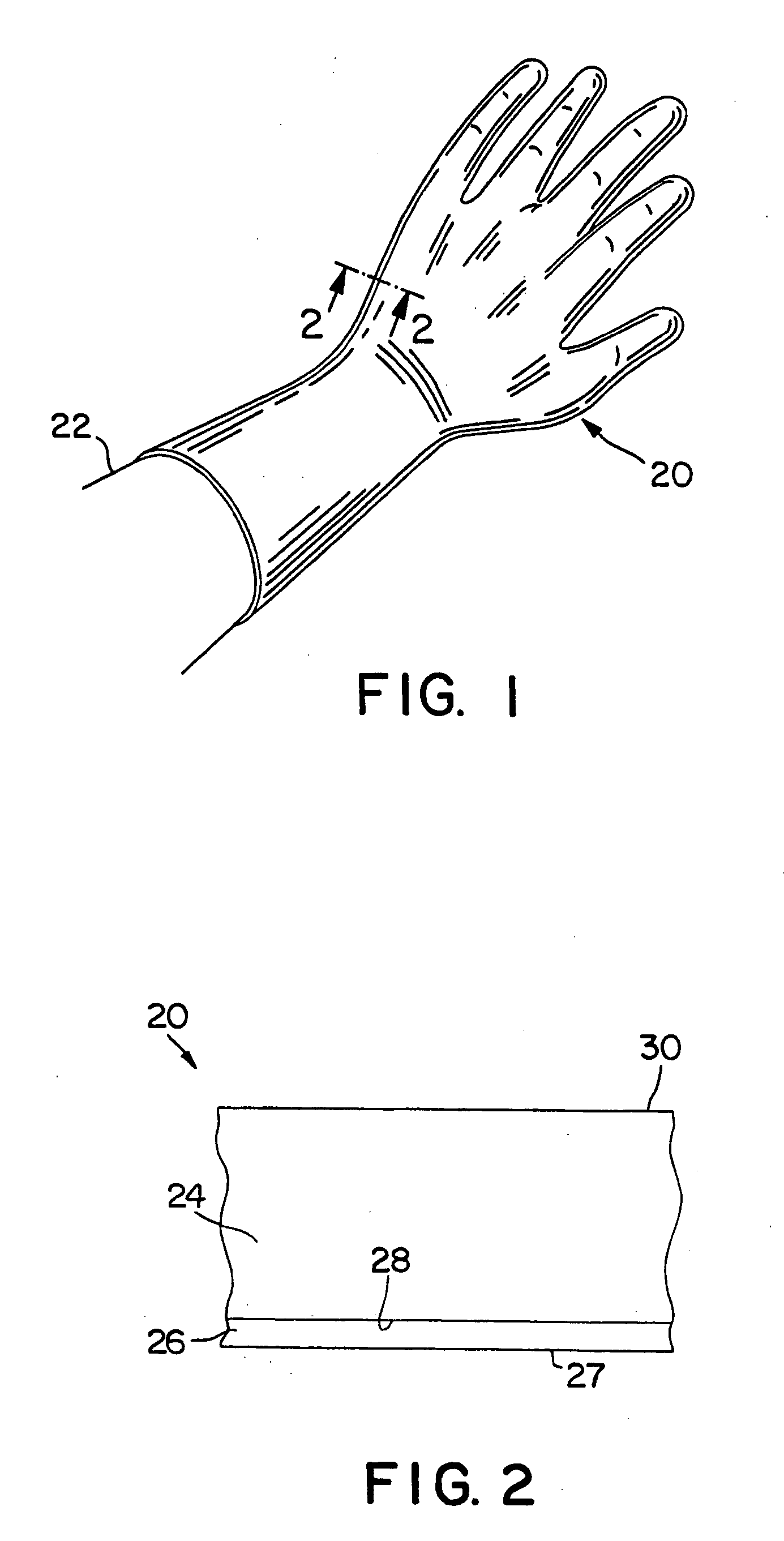

Image

Examples

example

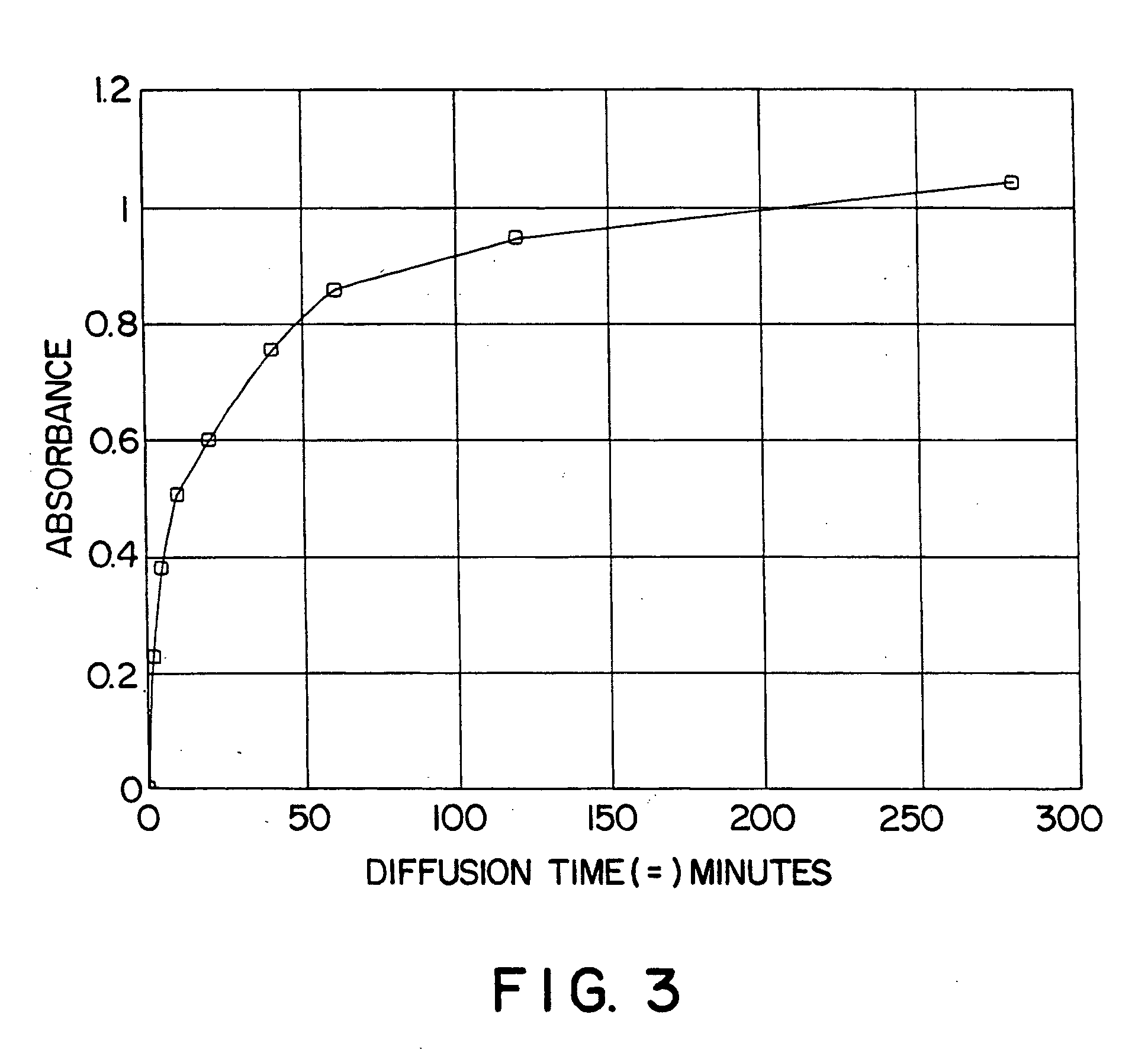

[0044] The ability to form an elastomeric glove in accordance with the present invention was demonstrated. Initially, a pre-heated, glove-shaped former was dipped into a coagulant solution that contained calcium nitrate, calcium carbonate, a surfactant, and water. The coated former was then dipped into a dip tank containing compounded, pre-vulcanized natural rubber latex. After dipping, the former was removed from the natural rubber latex dip tank and leached with water. Thereafter, the latex-coated former was cured in an oven at a temperature of 115° C. for about 20 minutes. The glove was manually removed from the former by turning the glove inside out as it was stripped from its corresponding former. After being removed from the former, the glove was also rinsed in deionized water. The thickness of the resulting glove was 0.24 millimeters. After the drying process, the glove was turned inside out and placed into a chlorinator. Chlorine gas mixed with a water stream was injected in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com