Fluid dispenser member

a dispenser and fluid technology, applied in the field of fluid dispenser components, can solve the problems of achieve the effect of relatively simple assembly of the dispenser member and relatively complicated assembly of the pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

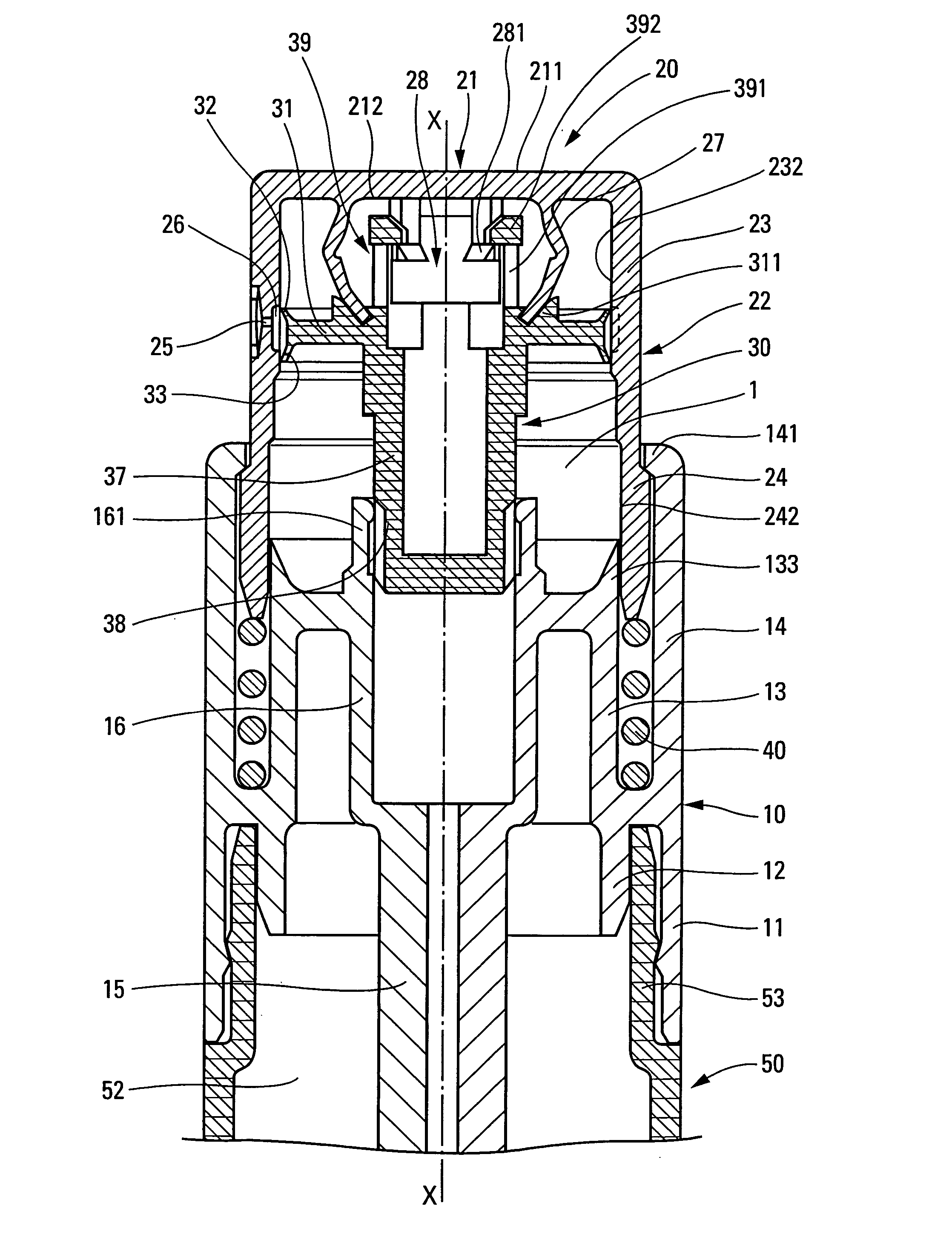

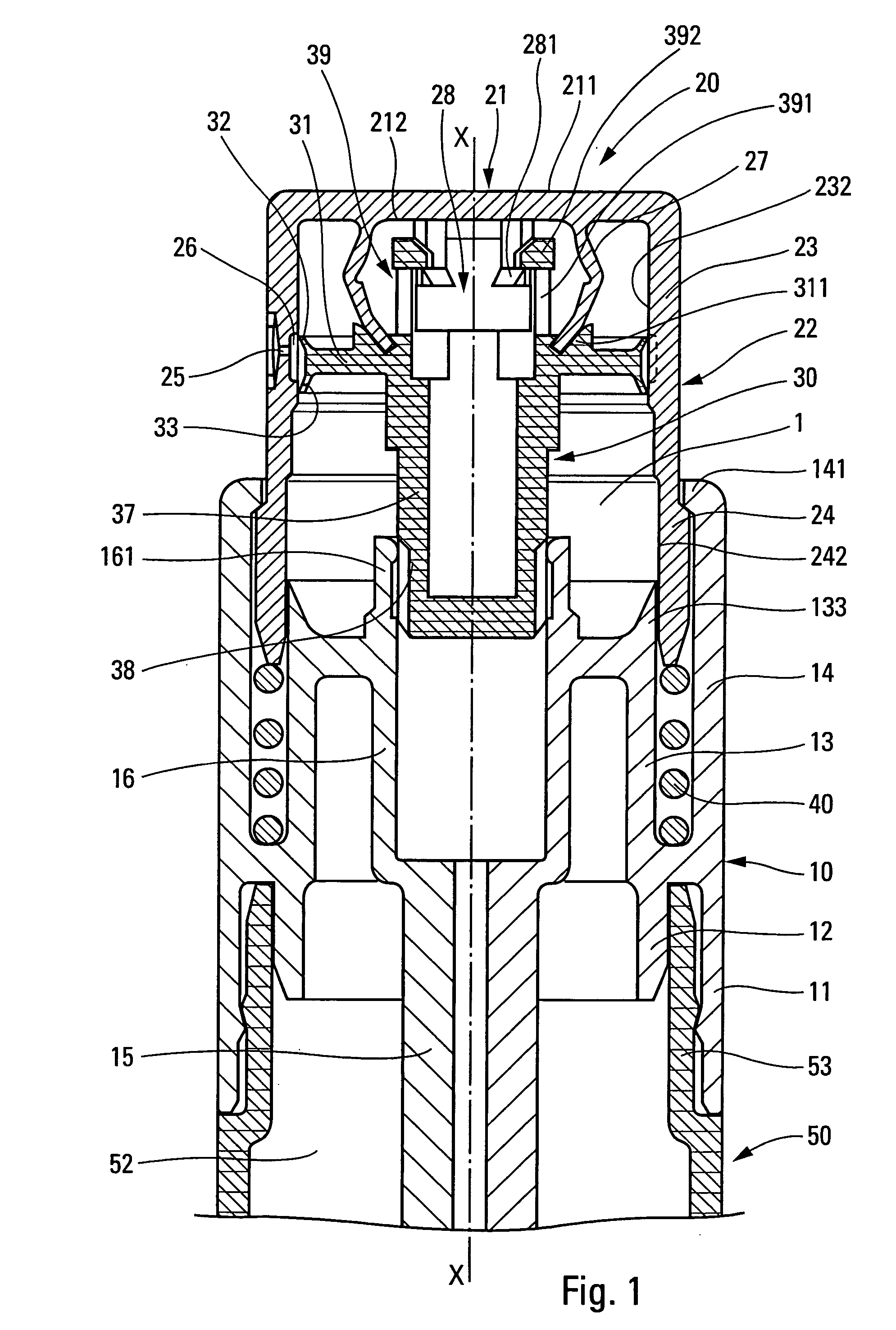

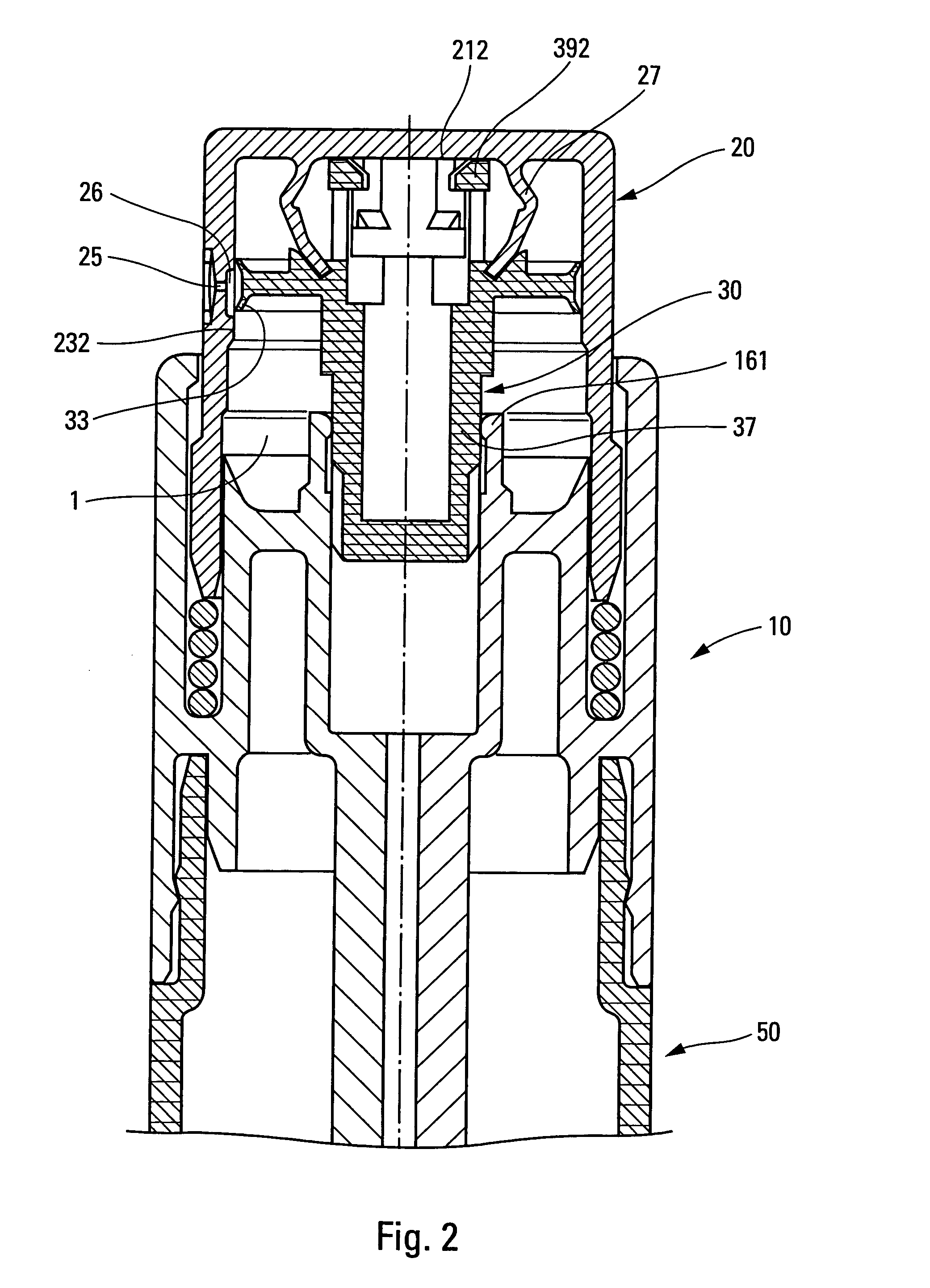

[0025] The embodiment of the dispenser member of the invention shown in FIGS. 1 and 2 is shown in association with a receptacle 50 defining an opening in the form of a neck 53 which advantageously has a fixing profile on its outside surface. The receptacle 50 internally defines a fluid reservoir 5.

[0026] The dispenser member comprises three component elements, namely a body 10, a pusher 20, and a piston member 30. All three parts can be made of a plastics material by injection molding.

[0027] The body 10 has a fixing ring 11 that co-operates with the neck 53 of the receptacle 50. More precisely, the ring 11 comes into engagement around the neck 53. The body 10 can also be provided with a self-sealing lip 12 in sealing contact with the inside wall of the neck 53. A guide band 14 can extend in alignment with the fixing ring 11. At its top end, the ring 14 is provided with an inwardly-extending rim 141 whose function is given below. The body 10 is also provided with a bushing 13 which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com