Method for improving the ductility of high-strength nanophase alloys

a nano-phase alloy and nano-phase technology, applied in metal-working apparatuses, transportation and packaging, cryogenics, etc., can solve the problems of large scattering in the tensile test, material with anisotropic tensile properties, and reduce the strength and ductility of billets, and achieve the effect of condensing powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any expressed or implied theory presented in the preceding technical field, background, brief summary or the following detailed description.

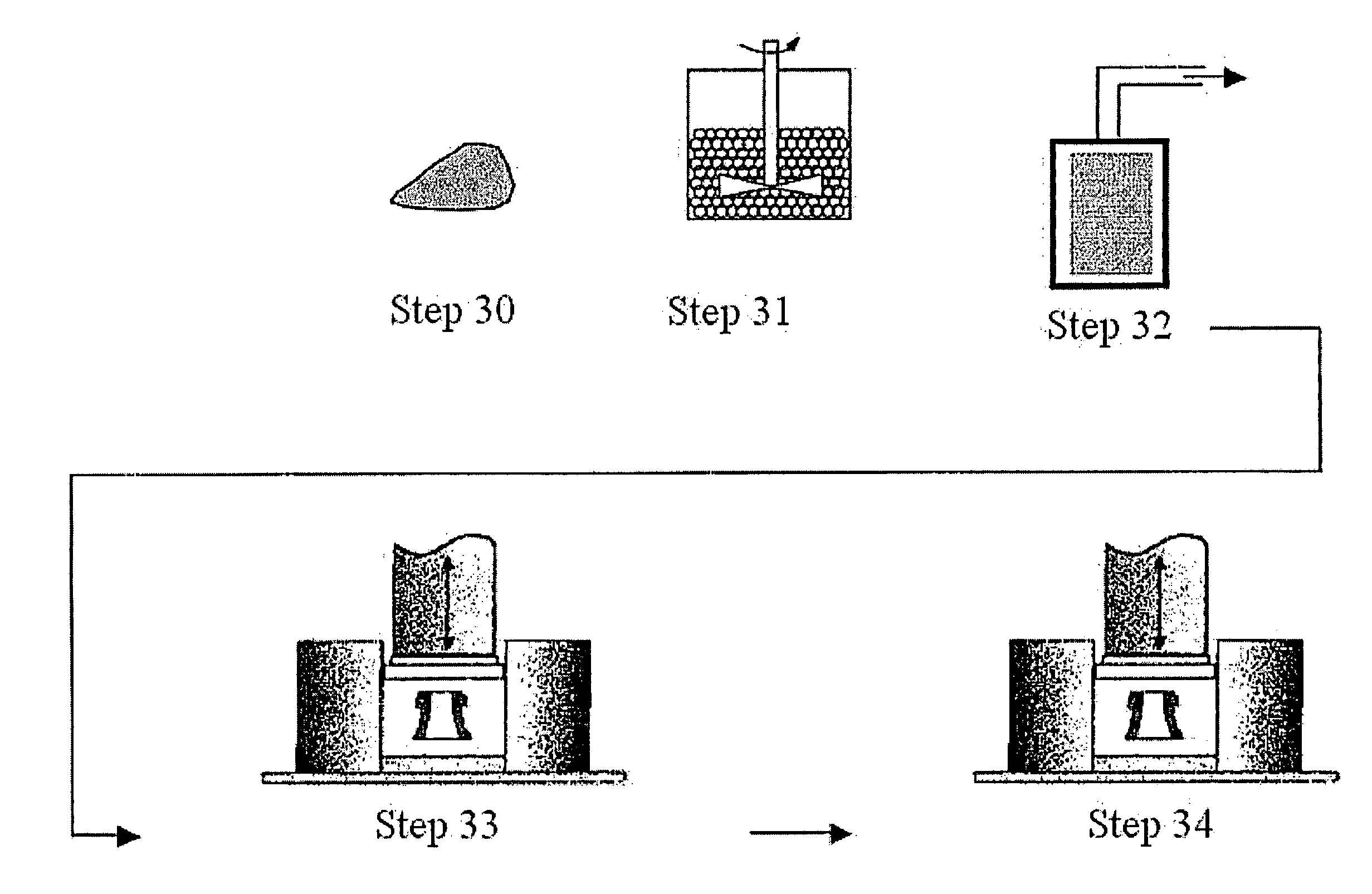

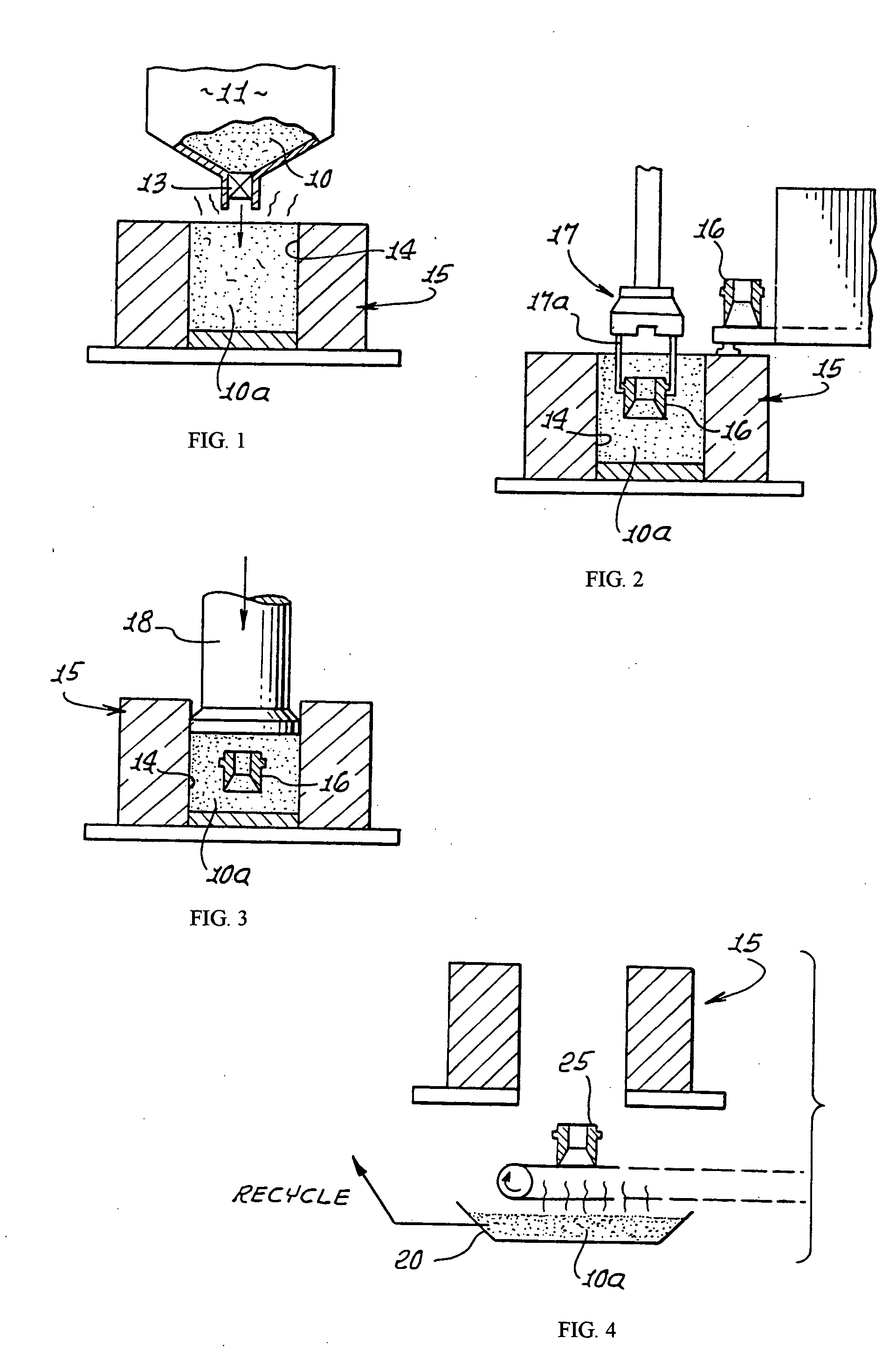

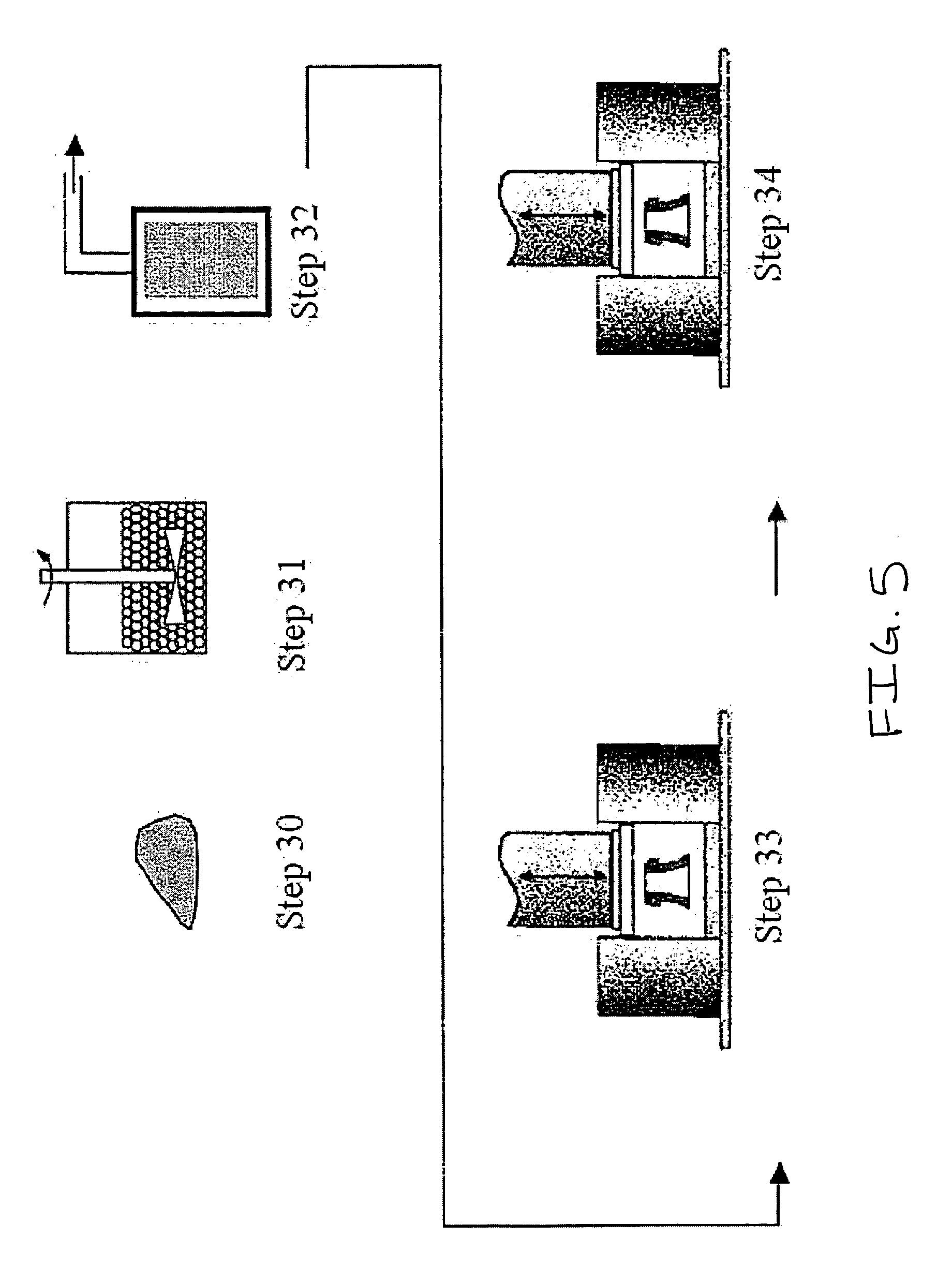

[0016] The terms “nanoscale,”“nanophase,” and the like as used herein refer to particles whose linear dimensions are substantially less than 1 micrometer. Achieving particles within these size ranges is accomplished by methods known in the art, and aluminum particles within these size ranges can be obtained commercially. However, manufacturing nanophase aluminum can be accomplished by using ribbons, particles larger than nanometer scale such as micron-sized particles, or any other aluminum form or shape as a starting material. A preferred method of reducing the materials to the nanometer size range includes subjecting the materials, most...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com